Novel lead acid accumulator with plastic-lead compound polar plate

A lead-acid battery and electrode plate technology, applied in lead-acid batteries, lead-acid battery electrodes, electrode carriers/current collectors, etc., can solve the problems of lead-acid battery application resistance, bulkiness, and low specific energy, and save lead volume, cost reduction, and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

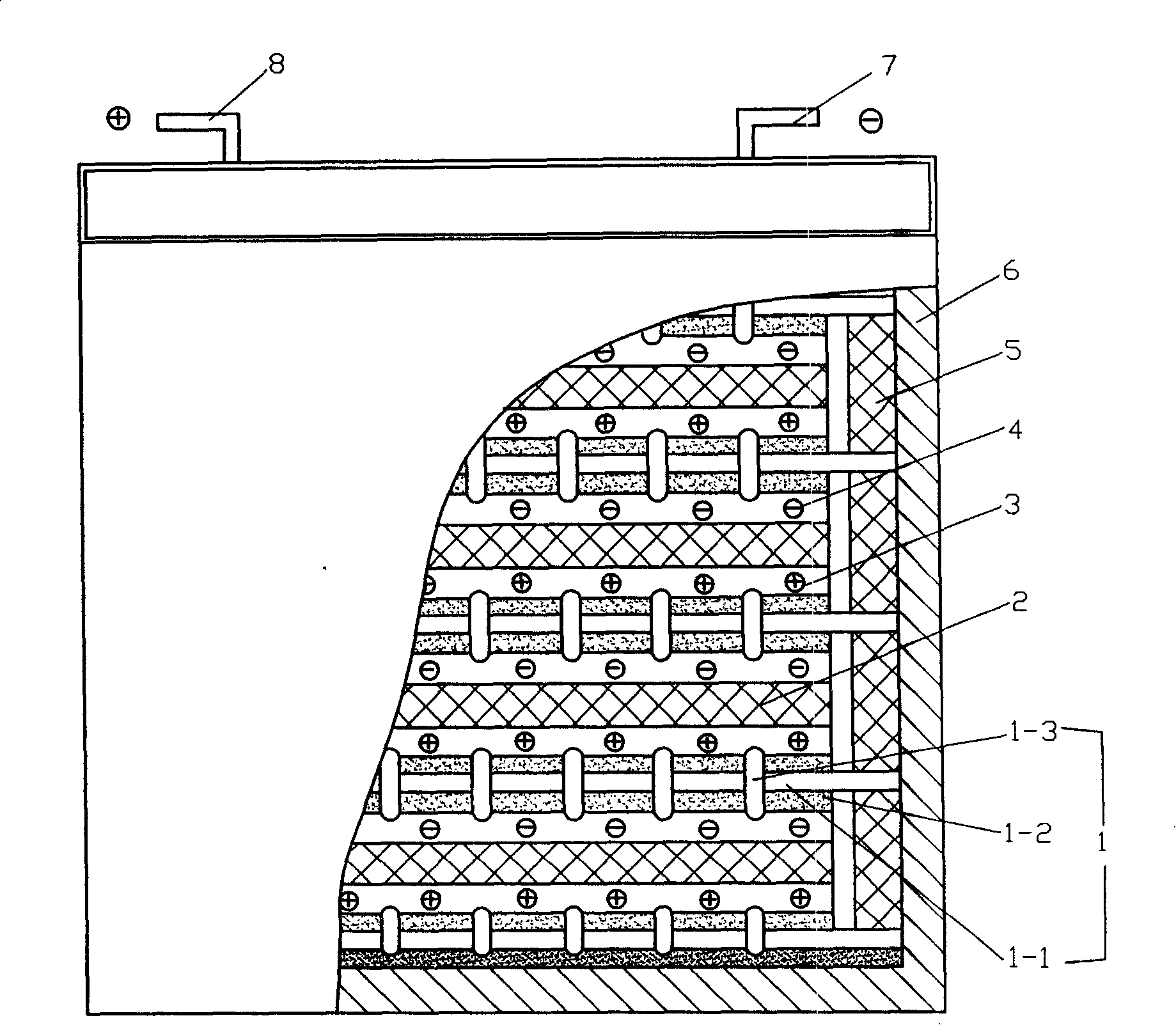

[0022] The present invention includes a casing 6, a sealing frame 5, a negative output terminal 7, a positive output terminal 8, and a positive plate 3 installed in the casing 6, a negative plate 4, a glass fiber separator 2, a plastic-lead composite plate 1, and a plastic-lead composite plate. The pole plate 1 is composed of a composite pole plate 1-1, a thin cotton thread layer 1-2 arranged on the surface of the composite pole plate 1-1, and lead particles 1-3 embedded between the composite pole plates 1-1.

[0023] Composite plate 1-1 is a modified PVC thin plate with a thickness of 0.4mm, a shear size of 170×66mm, a punching diameter of Φ1.2mm, and a uniform distribution of hole density of 10×10mm.

[0024] The thin cotton layer 1-2 is made of 100g polypropylene fiber non-woven fabric, the cut size is 170×66mm, the punching diameter is Φ2mm, the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com