Lead-acid battery grid, polar plate and manufacturing method of grid

A technology for lead-acid batteries and manufacturing methods, which is applied in the direction of lead-acid battery electrodes, electrode carriers/collectors, etc., can solve the problems of heavy grid weight, difficult application of batteries, and poor corrosion resistance, so as to save lead and improve Charging acceptance and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

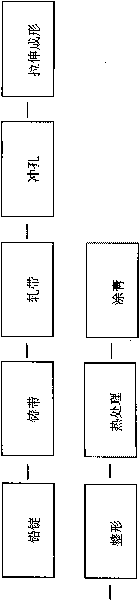

[0040] The following is a further detailed description of the novel plate grid, manufacturing method and effect provided by the present invention according to the manufacturing steps and with reference to the accompanying drawings.

[0041] Step 1). When making the grid, first we melt the lead ingot and cast it into a lead block of a certain shape, that is, a thicker lead strip,

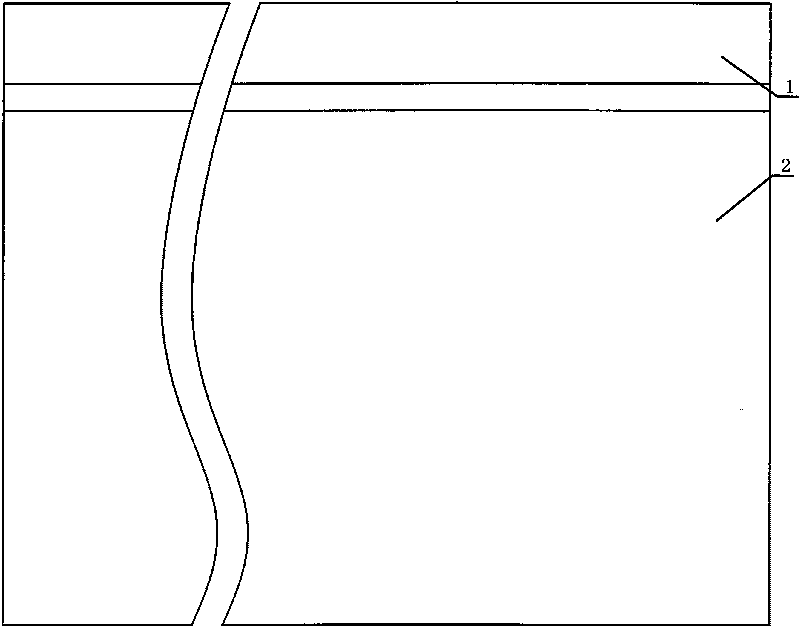

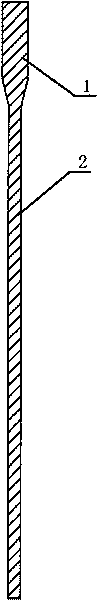

[0042] Step 2). The thicker lead strip that step 1) forms is continuously made the required lead strip by modes such as special-shaped rolling or extruding, namely as figure 2 , 3 In the lead strip shown, the thick side 1 corresponding to the lug and the thin area 2 corresponding to the grid are formed on the lead band. The thickness of the thick side 1 is about 2-3mm, and the thin area corresponding to the grid is coated with active material The thickness of some lead strips should be as thin as possible, generally around 0.5-1mm.

[0043] Step 3). Refer to Figure 4 , then the lead strip is pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com