Fabrication method for negative plate of lead-acid storage battery

The invention relates to a lead-acid battery and a manufacturing method, which are applied in the directions of lead-acid battery electrodes and the like, and can solve the problems of poor bonding between lead alloy ribs and active substances, low charging receiving capacity of active substances, affecting battery weight and environmental protection, and the like. Achieve the effects of being beneficial to environmental protection, weight reduction, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below through the embodiments in conjunction with the accompanying drawings.

[0013] According to the design requirements of the 12V60Ah (L2) starter battery, the negative plate of the lead-acid battery is made, and the operation is as follows:

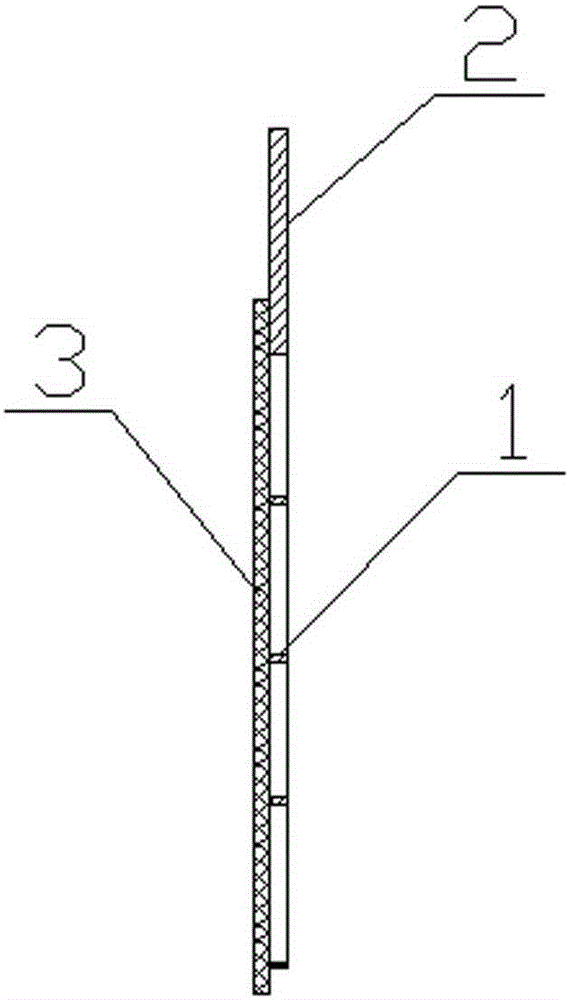

[0014] 1. Use polyacrylonitrile chopped fibers to wind and interweave the polyacrylonitrile organic material mat produced by the non-woven method and carbonize it to make a conductive carbon fiber felt. The weight is 120g / ㎡.mm, and the thickness is 2-4mm. According to size requirements, cut into conductive carbon fiber felt tape.

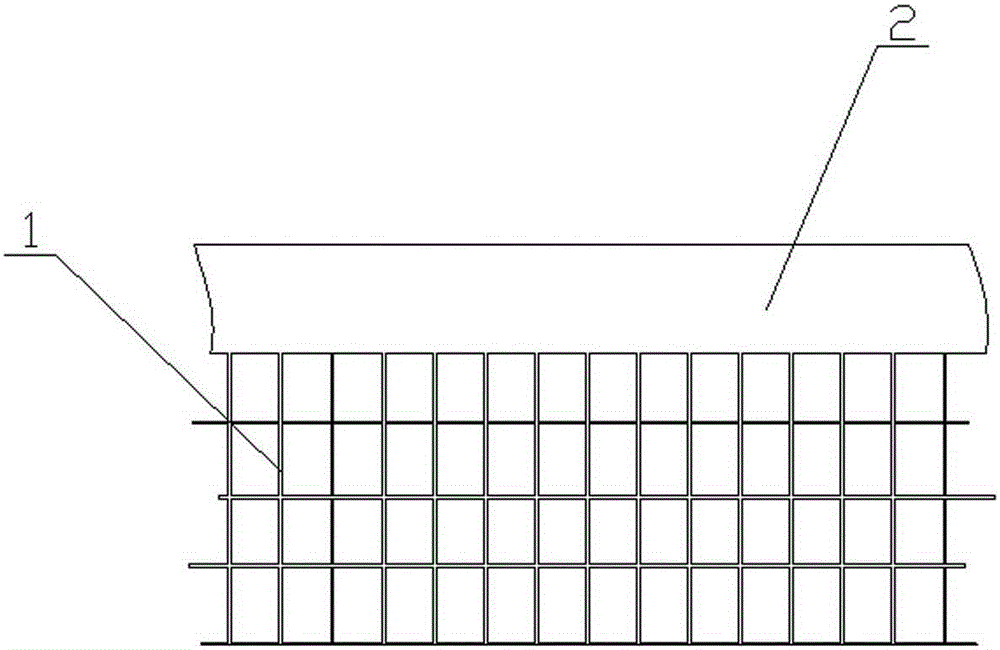

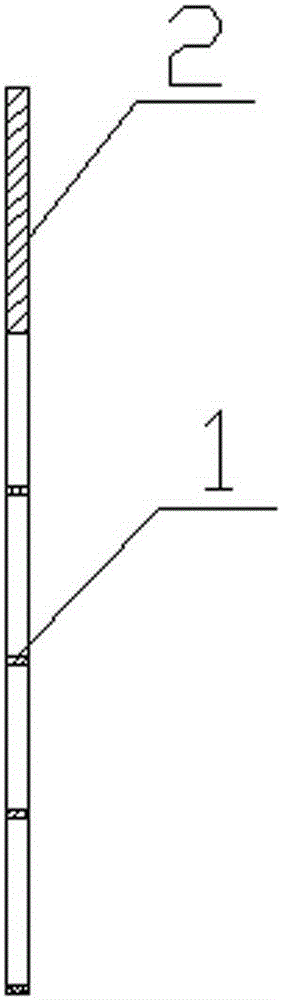

[0015] 2. According to the thickness requirements of the negative plate and the determined thickness of the conductive carbon fiber felt, the lead-calcium-tin-aluminum alloy strip is cold-rolled to make an aluminum alloy with a suitable thickness, the ribs 1 are criss-crossed into a rectangle, and the tab base 2 is provided. belt (such as figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com