Lead-coated carbon composite material and application thereof

A carbon composite material, carbon-based material technology, applied in the direction of electrode carrier/current collector, electrical components, battery electrodes, etc., can solve the problems of high cost, heavy weight, immature technology, etc., to reduce quality, reduce weight, improve The effect of volume specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

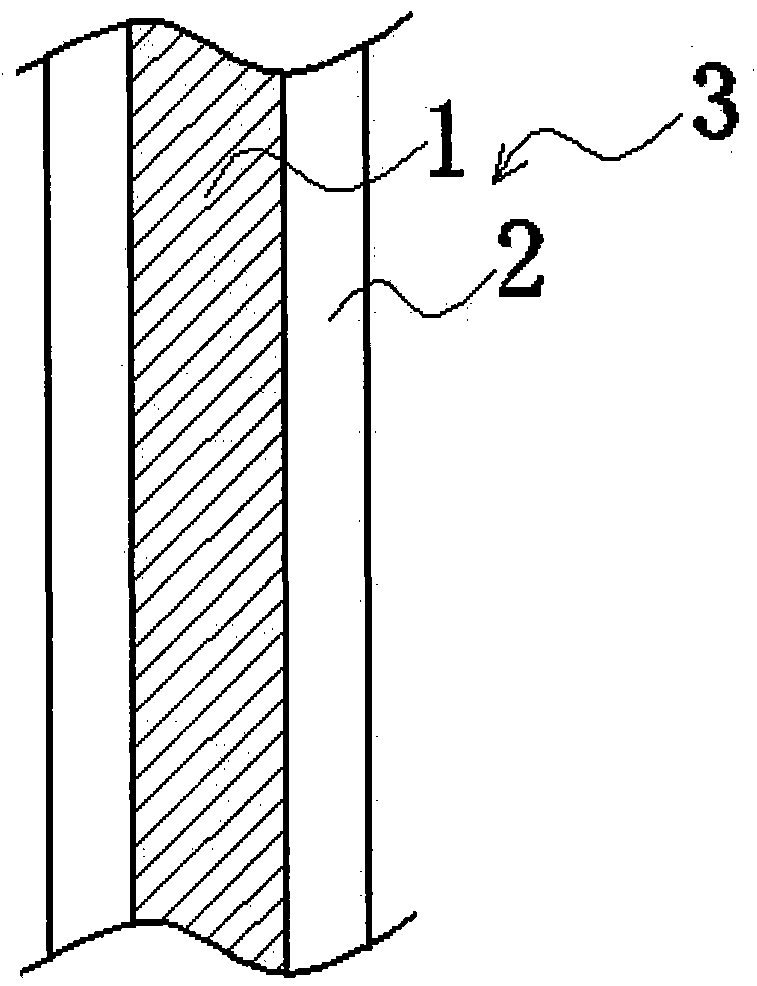

[0016] One embodiment of the present invention can be made of lead 2 wrapped around the carbon-based material 1 and then extruded, such as figure 1 The lead-coated carbon composite shown in 3.

[0017] Among them, the carbon-based material 1 can be powdered or rod-shaped as the matrix, and its main component can be activated carbon or carbon alloy material, and can also add conductive agent and binder, for example, can add copper powder, silver powder, aluminum powder, Graphite, superconducting carbon, graphite milk or conductive carbon black can be used as a conductive agent, and clay or resin can be added as a binder; lead 2 can be pure lead or alloy lead, and alloy lead can be lead-antimony alloy, lead-calcium alloy, lead-antimony alloy Arsenic tin alloy or lead calcium tin aluminum alloy.

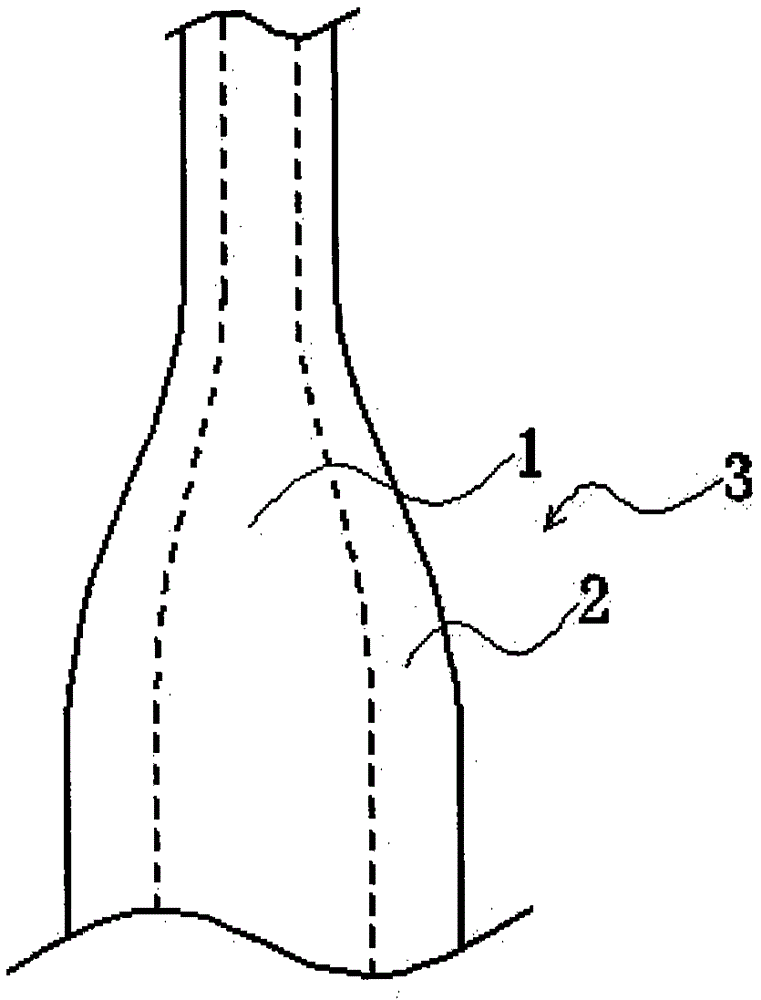

[0018] combine figure 2 As shown, the thin lead skin can also be coated on the carbon powder or the carbon rod, or a certain thickness of lead can be cast on the carbon rod, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com