Production method for clinker used in alumina sintering method

A production method and alumina technology, applied in the direction of alumina/aluminum hydroxide, energy input, etc., can solve the problems of large influence on the heat balance of the rotary kiln, affect the dissolution rate, and low heat utilization rate of flue gas, so as to reduce the investment of large equipment Use quantity, improve physical and chemical quality, and make full use of the effect of flue gas waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

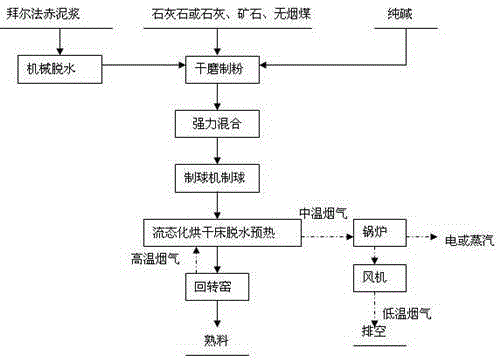

Embodiment 1

[0037] The Bayer process red mud slurry is dehydrated through a drum filter, and the water content of the filter cake slurry is reduced to 35% to 40%; limestone or lime, ore, and anthracite are ground into fine powder by cold air (fineness: 120 # The residue on the sieve is not more than 14%), and the air-swept mill adopts the flue gas from the fluidized bed to dry; the dehydrated filter cake slurry, the fine powder and soda ash produced by dry milling are accurately quantified through the metering facility according to the proportion of the production formula Feed into a strong mixer, fully disperse and mix evenly, and obtain semi-dry raw meal with a moisture content of 20%± that meets the production requirements; the semi-dry raw meal is sent to the ball machine to make raw meal balls with a ball diameter of 5-20mm, and sent to the In the fluidized bed or in the rotary kiln, the high-temperature flue gas (above about 600°C) of the rotary kiln is used to dry and preheat; the r...

Embodiment 2

[0039] Others are the same as in Example 1, except that the prepared raw meal balls are directly sent to the rotary kiln for drying, preheating and firing, and the cold air mill is dried by the flue gas from the rotary kiln.

Embodiment 3

[0041] Others are the same as in Example 1, except that the Bayer process red mud slurry is dehydrated by a plate-and-frame filter press, and the water content of the filter cake slurry is reduced to 30-35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com