H-shaped cylinder structure for external work output connection of turbo expander

A turbo expander and output connection technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems that plague the industry and lack, and achieve the effects of simple overall structure, high degree of generalization, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

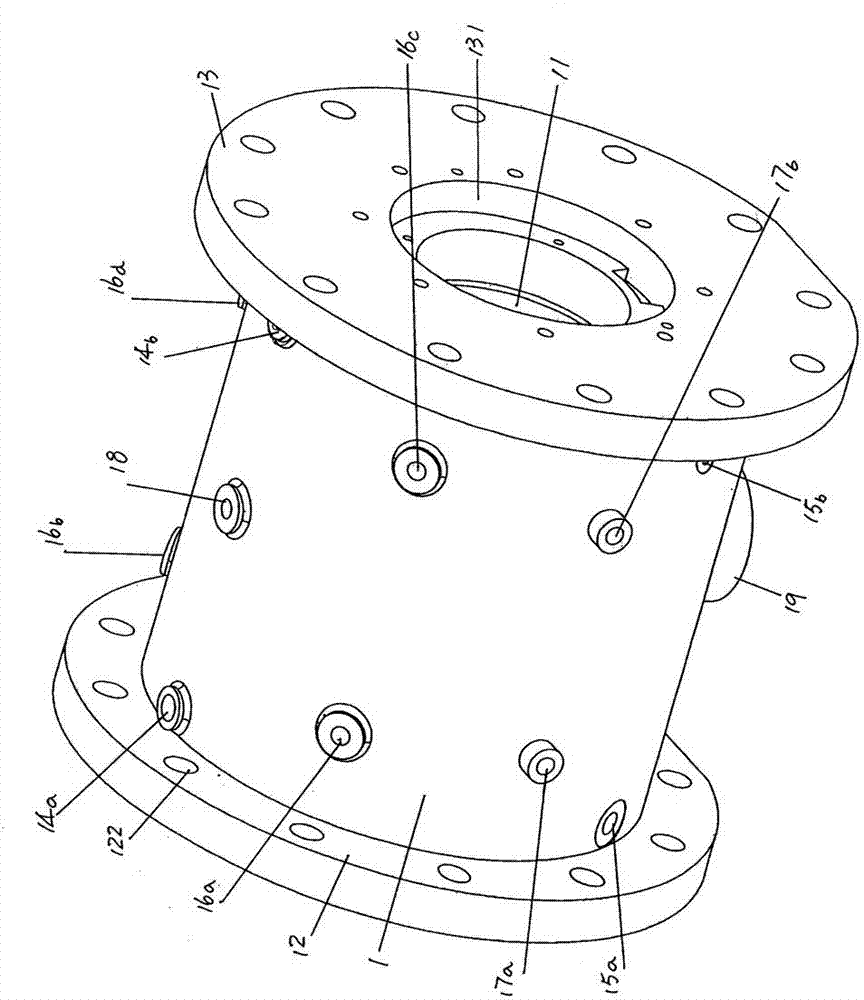

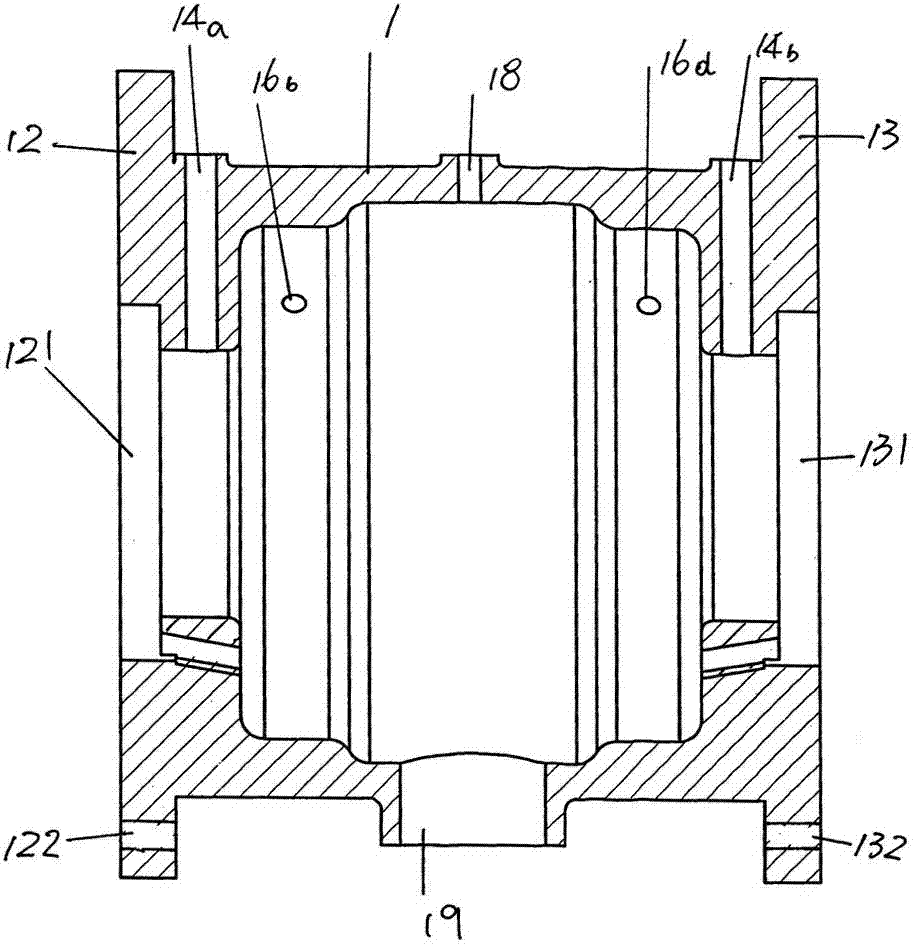

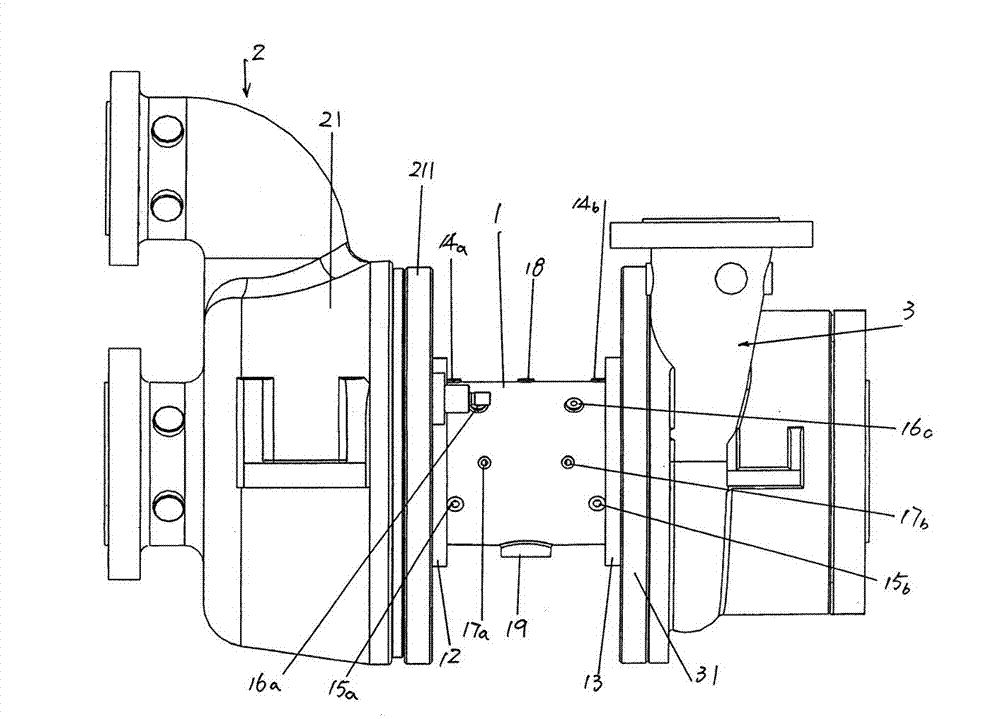

[0016] See figure 1 and figure 2 , shows a cylinder 1 with a cylinder cavity 11. Taking the position shown in the current illustration as an example, a first mating flange with a diameter larger than the diameter of the cylinder 1 is expanded at one end of the cylinder 1, that is, the left end Disc 12, on the first mating flange 12 and around the circumferential direction of mating flange 12, preferably at equal intervals, a set of image 3 The first fixed connection hole 122 connected to the volute flange 211 of the volute 21 of the schematic turbo expander 2, and the first bearing for installing the bearing is formed in the center of the first mating flange 12. Cavity 121. The other end of cylinder body 1, that is, the right end, is expanded with a second matching flange 13 having a diameter identical to that of the first matching flange 12, on the second matching flange 13 and surrounding the second The circumferential direction of the mating flange 13 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com