Plate grid of negative plate for lead-acid storage battery

A technology of lead-acid batteries and negative plates, applied in the direction of electrode carriers/collectors, etc., can solve the problems of poor charging and receiving capacity of active materials, small bonding surface of grids and active materials, weight reduction and environmental protection, etc., to achieve benefits Environmental protection, negative electrode sulfation overcoming, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

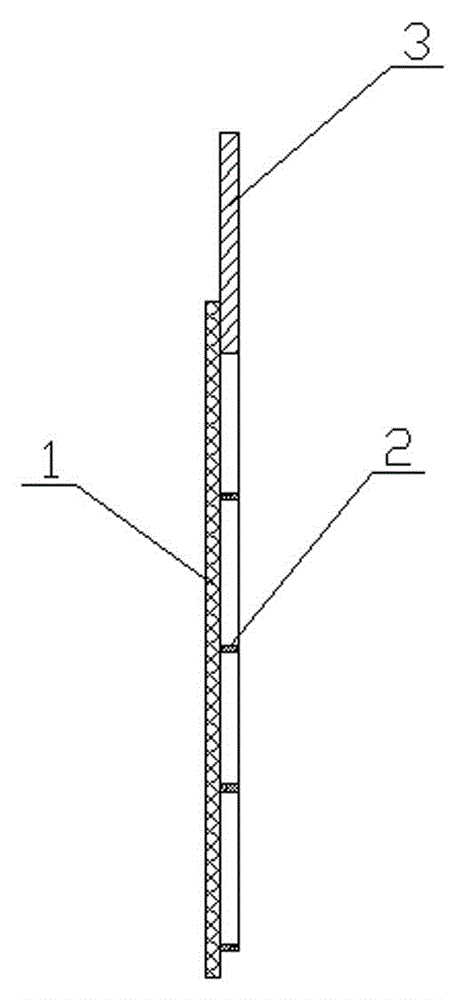

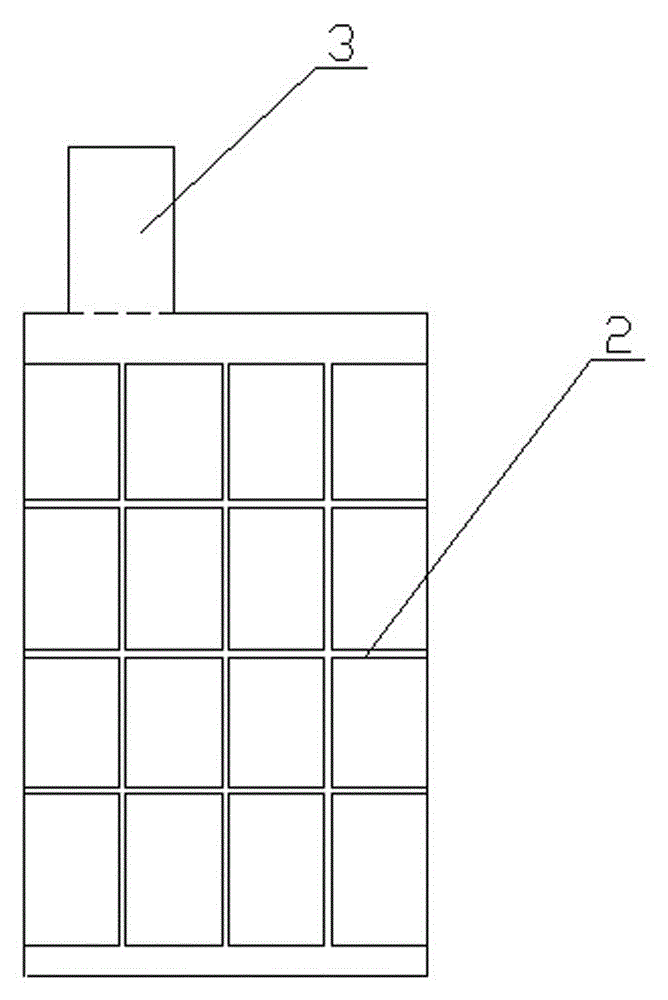

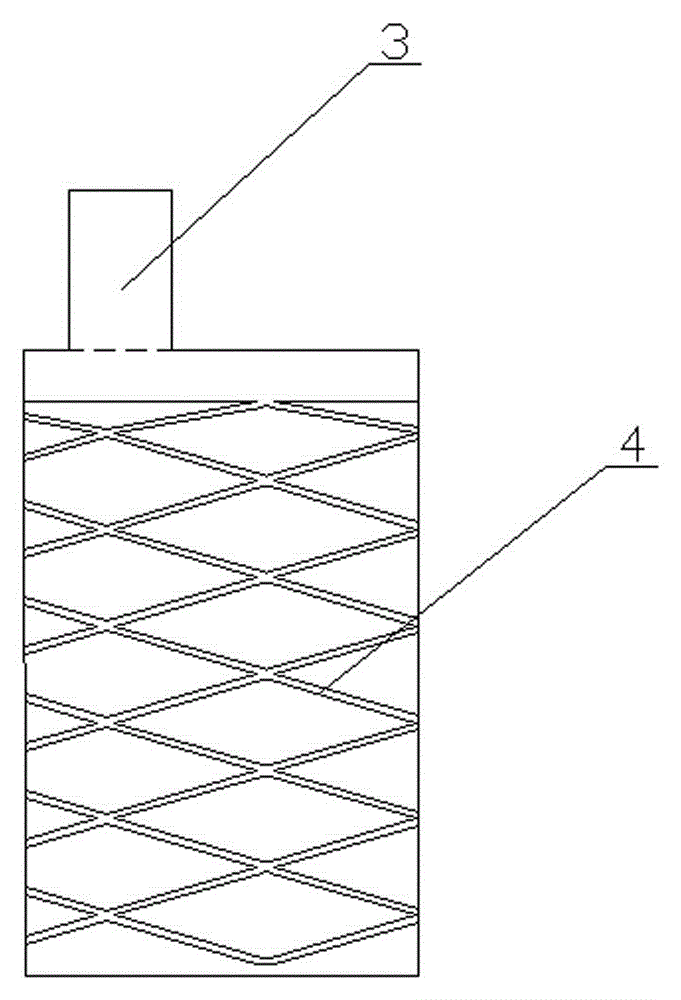

[0011] Referring to the accompanying drawings, the conductive carbon fiber felt 1 is welded together with the lead alloy rib 2, the rib 2 is embedded on the fiber felt 1, and the tab 3 is exposed (such as figure 1 ), in this example, the conductive carbon fiber felt is polyacrylonitrile-based carbon felt, with a grammage of 120g / ㎡.mm and a thickness of 2-4mm, which is pressed by winding and interwoven short polyacrylonitrile fibers. The tabs and the lead alloy ribs are made of lead-tin alloy, and the ribs 2 are staggered into rectangles (such as figure 2 ), the vertical spacing is 8mm, the horizontal spacing is 15mm, and the thickness is 2-4mm. The size of the grid is [thickness*width*height (total height)]3*146*130(150), or ribs 4 are staggered into a rhombus (such as image 3 ). Utilize the negative plate produced by the present invention to replace the negative plate of the original battery into several 12V60Ah (L2) starter batteries, the weight of the battery has droppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com