Method for preparing lithium-silicon alloy cathodes

A lithium-silicon alloy and negative electrode technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as unsuitability for large-scale production, poor conductivity of active materials, volume expansion/shrinkage, etc., to achieve strong lithium ion supply capacity and improve Effects of improving cycle life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

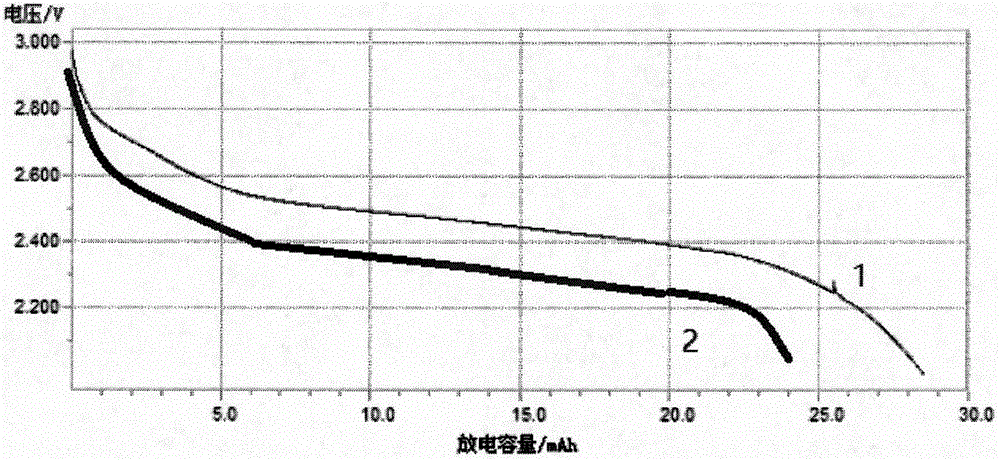

Embodiment 1

[0015] In dry air with a relative humidity lower than 0.5%, 22.50 g of silicon powder (Tianjin Chemical Reagent Supply and Marketing Company) with a purity of 99.9% and 150 meshes and 1.39 grams of lithium powder with a purity of 99.99% and 150 meshes (Tianjin Zhongneng Lithium Industry Co., Ltd.) g into a 250ml ceramic grinding pot, add 10 corundum balls with a diameter of 5mm, fill with 99.999% argon gas to seal, install on a ball mill, and ball mill for 4 hours at a speed of 30 rpm, and take it out in a sandy shape. m 2 Filling density Filling area density 150g / m 2 1. In foamed nickel (Shandong Heze Tianyu Technology Co., Ltd.) with a thickness of 2 mm, it was heated to 160° C. under a pressure of 5 MPa and kept for 1 hour, then cooled to room temperature, and taken out to obtain a lithium-silicon alloy negative electrode. Punch out a disc with a diameter of 8.5 mm and a thickness of 0.4 mm for use.

[0016] In dry air with a relative humidity lower than 0.5%, take 50 mg ...

Embodiment 2

[0021] In dry air with a relative humidity lower than 0.5%, put 14.05g of silicon powder with a purity of 99.9% and 320 meshes and 3.47g of lithium powder with a purity of 99.99% and 320 meshes into a 250ml ceramic grinding pot, add 10 corundum balls with a diameter of 5mm, Fill it with 99.999% argon gas and seal it, install it on a ball mill, and ball mill it at a speed of 30 rpm for 4 hours until it becomes sandy and take it out at 800g / m 2 Filling density Filling area density 300g / m 2 1. In foamed nickel with a thickness of 3 mm, heat it to 170° C. under a pressure of 10 MPa and keep it for 1 hour, then cool down to room temperature, and take it out to obtain a lithium-silicon alloy negative electrode. Punch out a disc with a diameter of 8.5 mm and a thickness of 0.4 mm for use.

[0022] Manganese dioxide positive electrode sheet is made with embodiment 1.

[0023] The assembly of CR1220 battery is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com