Lithium ion battery cell and preparation method thereof

A technology of lithium ion and battery cell, applied in the field of lithium ion battery cell and its preparation, can solve the problems of complex process, difficult to control alignment accuracy, low efficiency, etc., achieve process simplification, improve high-rate charge and discharge capacity, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

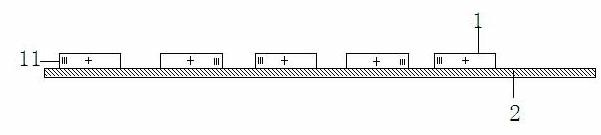

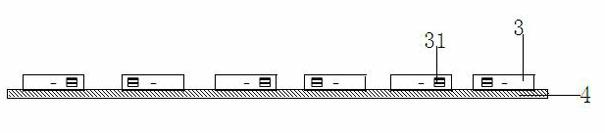

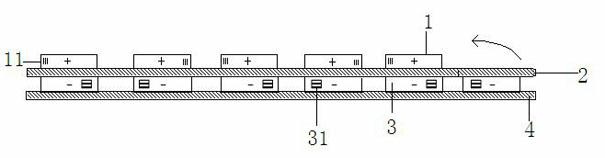

[0037] Embodiment 1: the preparation method of a kind of lithium ion cell provided by the present invention comprises the following steps: the first step, in the present embodiment, the number of sheets of positive electrode sheet 1 is less than the number of sheets of negative electrode sheet 3, and the number of sheets of positive electrode sheet The number of sheets 1 is at least 2, and each positive electrode sheet 1 is provided with a positive electrode tab 11 , and each negative electrode sheet 3 is provided with a negative electrode tab 31 . Such as figure 1 with 2As shown, the positive electrode sheet 1 with the positive electrode tabs 11 left is fixed on one side of the first separator 2 by heat sealing at intervals, wherein the initial position of the first separator 2 does not place the positive electrode sheet 1 . The negative electrode sheet 3 with the negative electrode tabs 31 left is fixed on one side of the second separator 4 by heat sealing at intervals, whe...

Embodiment 2

[0044] Embodiment 2: the preparation method of a kind of lithium-ion cell provided by the present invention comprises the following steps: the first step, in the present embodiment, the number of sheets of positive electrode sheet 1 is one more than the sheet number of negative electrode sheet 3, and negative electrode sheet The number of sheets 3 is at least two, each positive electrode sheet 1 is provided with a positive electrode tab 11 , and each negative electrode sheet 3 is provided with a negative electrode tab 31 . Such as Figure 5 with 6 As shown, the positive electrode sheet 1 with the positive electrode tabs 11 left is fixed on one side of the first separator 2 by heat sealing at intervals, wherein the positive electrode sheet 1 is placed at the initial position of the first separator 2 . The negative electrode sheet 3 with the negative electrode tabs 31 left is fixed on one side of the second separator 4 by heat sealing at intervals, wherein the initial position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com