High-capacity nickel-cobalt-lithium manganate precursor and preparation method thereof

A nickel-cobalt-lithium-manganese-oxide, high-capacity technology, applied in the field of high-capacity nickel-cobalt-lithium manganate precursor and its preparation, can solve problems such as easy self-discharge, poor sphericity of crystal nuclei, and low tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

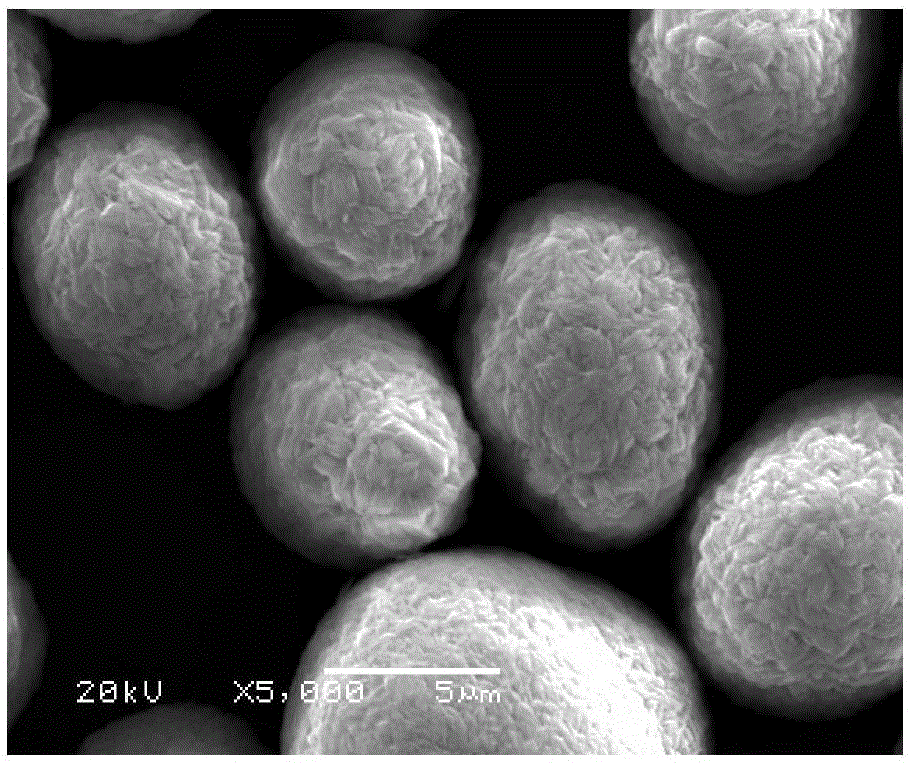

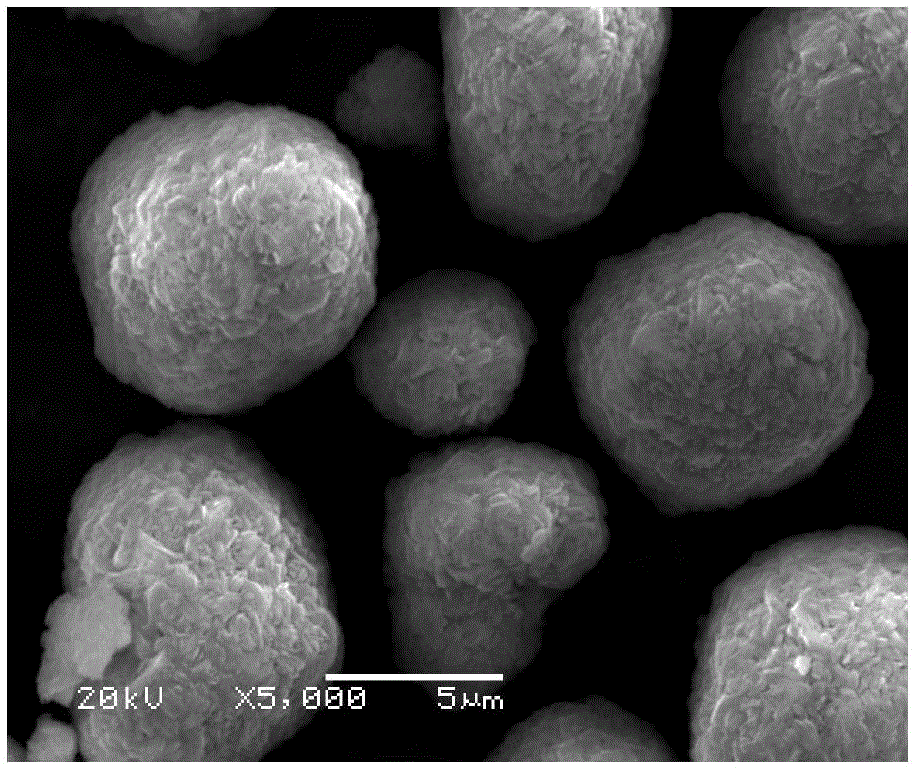

Image

Examples

preparation example Construction

[0025] The preparation method of this high-capacity nickel cobalt lithium manganese oxide precursor comprises the following steps:

[0026] (1) Select nickel, cobalt, and manganese soluble salts as raw materials, and the chemical formula of the high-capacity nickel-cobalt lithium manganate precursor prepared is Ni x co y mn z (OH) 2 , where (0.5≤x≤0.9, 0.05≤y≤0.2, 0.05≤z≤0.3, x+y+z=1) is made into a metal mixed salt solution according to the molar ratio x:y:z, and pure water is mixed with a certain mass The complexing agent and lye are mixed to form the reaction bottom liquid, and then the mixed metal salt solution, complexing agent, and lye are respectively added into the reactor with a metering pump in a molar ratio of 1.1:1:2.3 to mix and react. The reaction system adopts high and low speed control in stages. After 15 hours of reaction feed, age for 1 hour, then filter to separate solid and liquid, and then wash, first wash with pure water for 30 minutes, then wash with...

Embodiment 1

[0040] Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor preparation:

[0041] The selected nickel-cobalt-manganese salt raw materials are nickel sulfate, cobalt sulfate, and manganese sulfate, and then a 1.5mol / L, 30°C nickel-cobalt-manganese mixed salt solution is prepared according to the molar ratio of 8:1:1. The lye is 6mol / L sodium hydroxide aqueous solution, which is used as a reaction precipitant. The complexing agent adopts 8mol / L ammonia water as the reaction complexing agent.

[0042] Before starting the kettle, add pure water, the above-mentioned ammonia water and the above-mentioned lye to the clean reaction kettle at a volume ratio of 80:1 to 2:1 to form the reaction bottom liquid, wherein the total concentration of ammonia in the reaction bottom liquid is 2.5g / L , The pH of the bottom solution is about 12.3. Submerge the stirring paddle, raise the temperature to 40°C, and stir at a speed of 100r / min.

[0043] Respectively, the previously prepared nickel-cobalt-mangan...

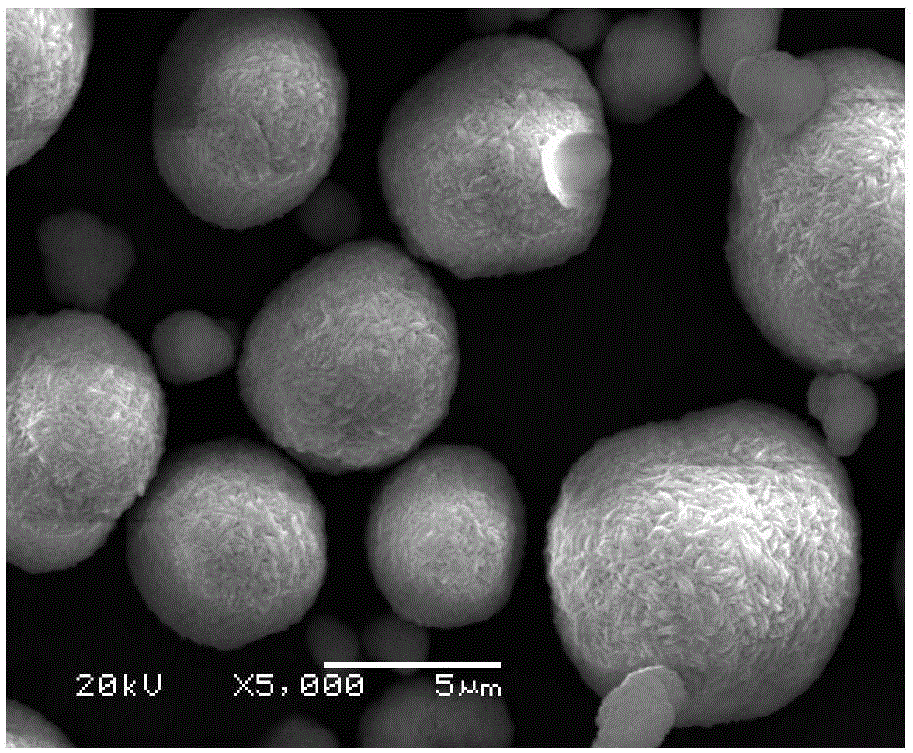

Embodiment 2

[0046] Ni 0.8 co 0.15 mn 0.05 (OH) 2 Precursor preparation:

[0047] The preparation of the high-capacity nickel-cobalt-lithium manganese oxide precursor uses soluble nickel-cobalt-manganese salt as the preparation raw material, the nickel salt is nickel chloride, the cobalt salt is cobalt chloride, and the manganese salt is manganese chloride. Prepare a 1.5mol / L nickel-cobalt-manganese mixed salt solution according to the molar ratio of 8:1.5:0.5. The lye (precipitating agent) adopts aqueous sodium hydroxide solution with a concentration of 6mol / L. The complexing agent adopts ammonia water, the concentration is 8mol / L.

[0048] Before starting the kettle, add pure water, ammonia water and lye to the clean reaction kettle at a volume ratio of 80:1 to 2:1 to form the reaction bottom liquid, wherein the total concentration of ammonia in the reaction bottom liquid is 2.3g / L, and the bottom The liquid pH is about 12.2. Submerge the stirring paddle, raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com