Patents

Literature

57results about How to "Protection from erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

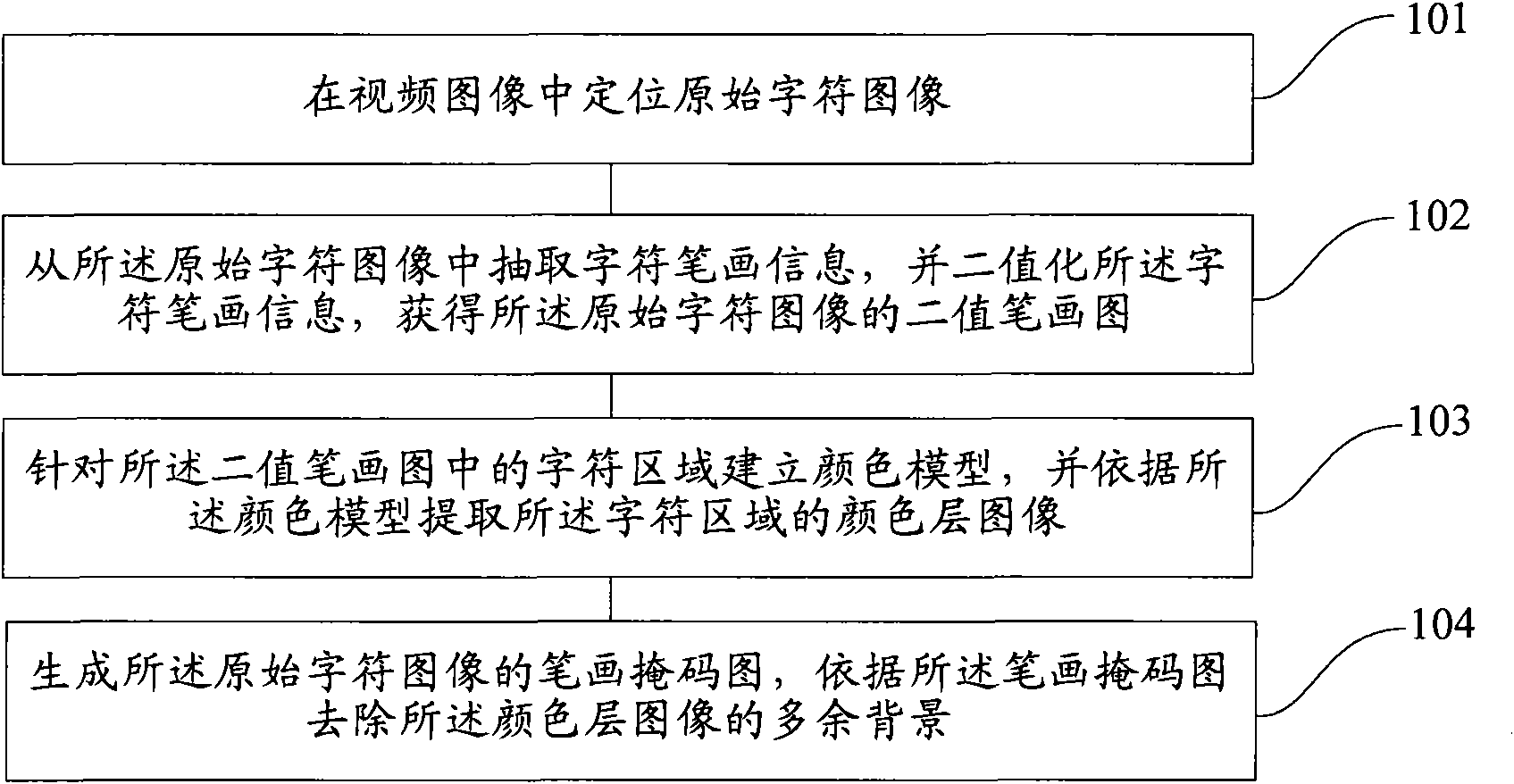

Method and device for segmenting characters from video image

InactiveCN101599124AGood character segmentationProtection from erosionCharacter and pattern recognitionColor modelAnalysis method

The invention discloses a method for segmenting characters form a video image, which comprises the following steps: positioning an original character image in the video image; extracting character stroke information from the original character image, obtaining a binary stroke image of the original character image according to the character stroke information; establishing a color model aiming at a character region in the binary stroke image, extracting a color layer image of the character region according to the color model; and removing excess backgrounds and noise by using an improved connection body analysis method with stroke masks so as to obtain the target character image. The invention has little computation and good property and can rapidly and accurately segment the characters from the video image of the complex backgrounds without machine learning.

Owner:HANVON CORP

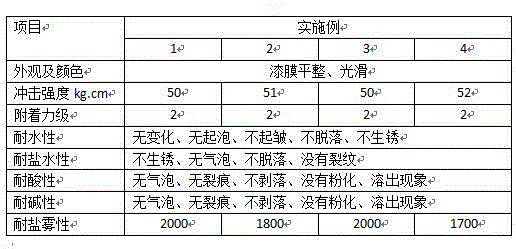

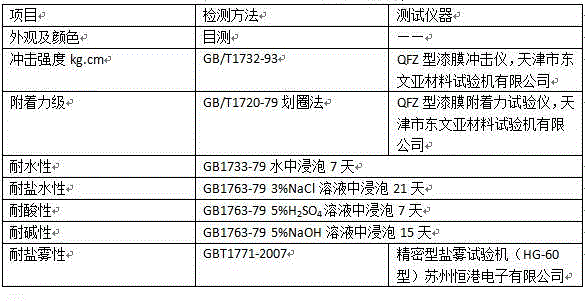

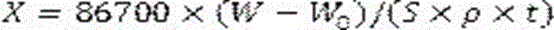

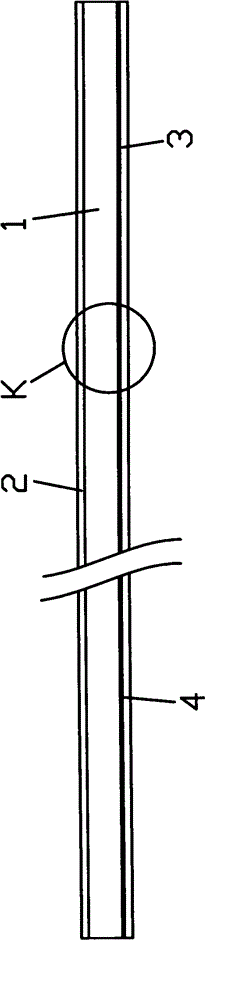

Ocean epoxy zinc-rich anti-corrosion powder coating and preparation method thereof

ActiveCN104087125AImprove conductivityImprove thermal conductivityAnti-corrosive paintsPowdery paintsEpoxyPolyvinyl alcohol

The invention provides an ocean epoxy zinc-rich anti-corrosion powder coating and a preparation method thereof. The coating is prepared from the following raw materials: E-12 epoxy resin, novolac epoxy, trimethyl hexamethylenedi, polyvinyl butyral, dimethyl imidazole, aminopropyl triethoxy silane, zinc powder, aluminum powder, graphene, ethylene bis stearamide, polyethylene wax powder, an antioxidant DNP, and compound filler. The preparation method comprises the following steps: uniformly mixing zinc powder, aluminum powder and graphene, adding aminopropyl triethoxy silane, stirring to disperse so as to obtain a component A, mixing the E-12 epoxy resin, novolac epoxy, polyvinyl butyral and polyethylene wax powder, preheating, cooling down to room temperature, mixing the component A, the mixture and the rest raw materials, carrying out melt extrusion by virtue of an extruder, tabletting, carrying out air cooling, grinding into powder, and sieving. The coating can protect a steel structure from being corroded by various corrosive media for a long term, is non-toxic, pollution-free and salt mist resistant, and has strong adhesive force and shock resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

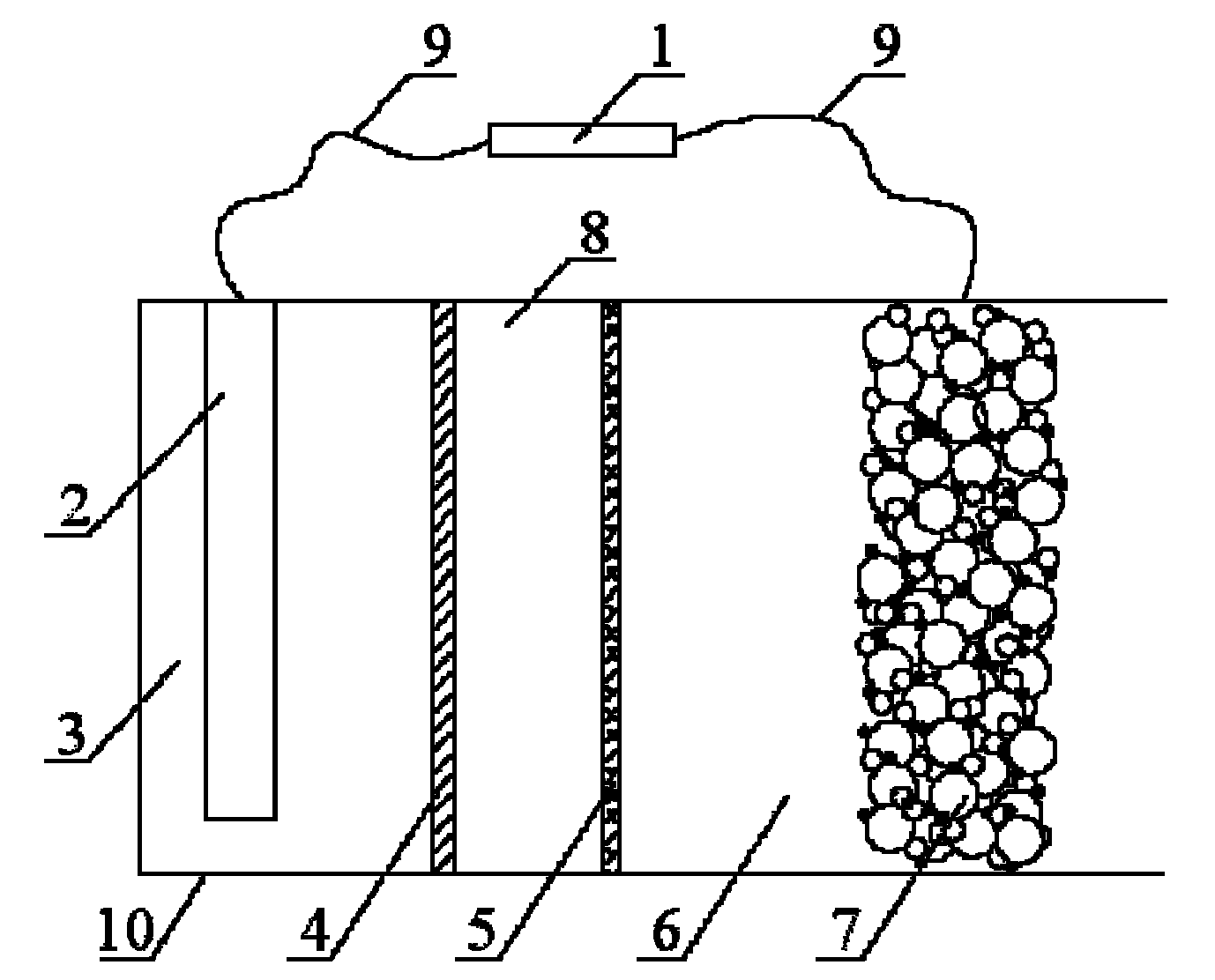

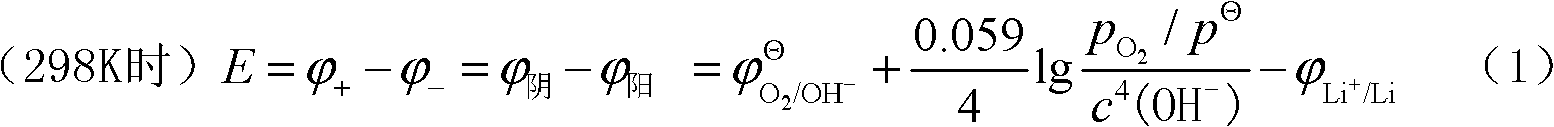

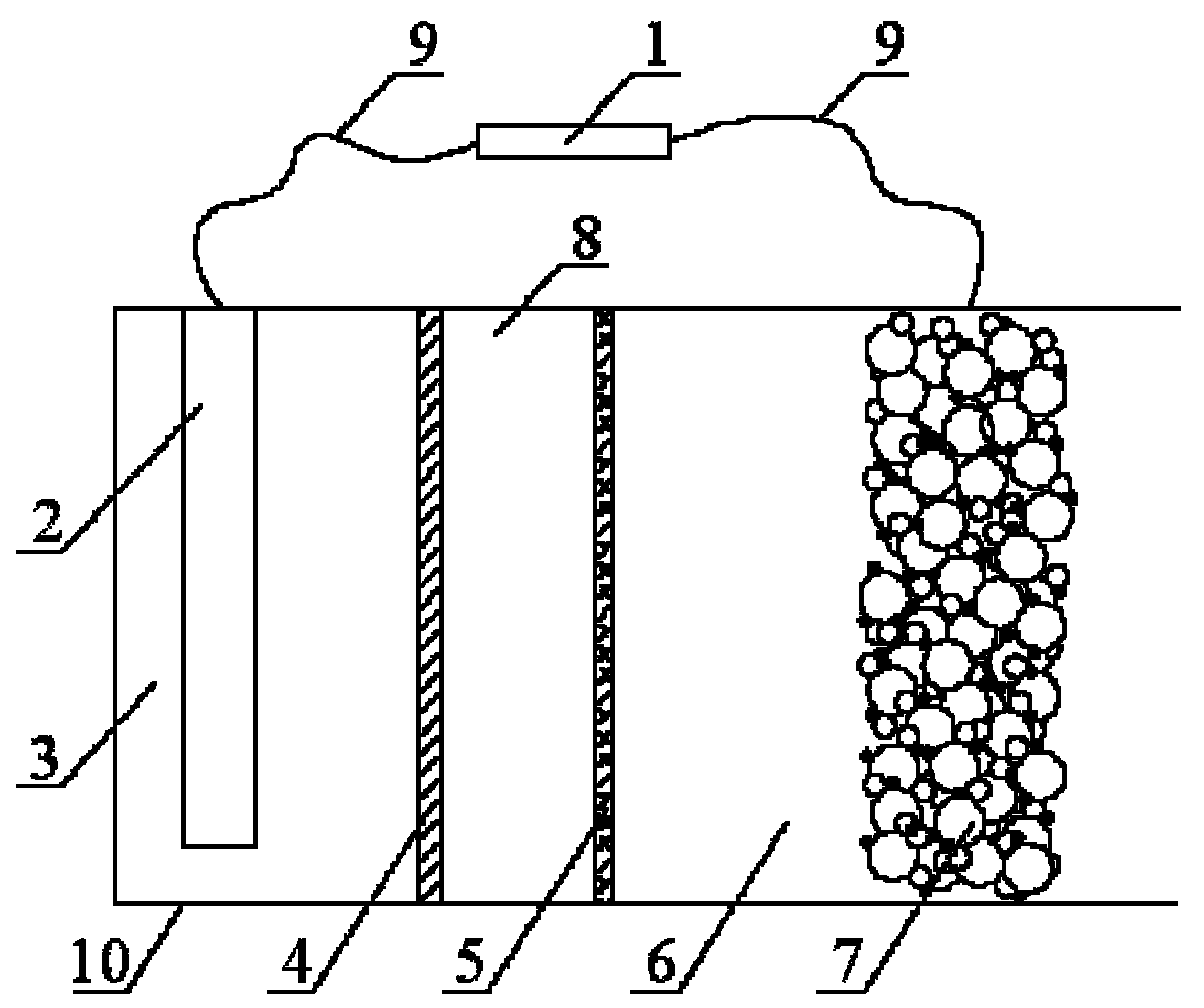

Lithium/air battery

InactiveCN102157763AProtection from erosionReduce corrosionFuel and primary cellsCell electrodesMetallic lithiumElectrochemical window

The invention discloses a lithium / air battery which belongs to the chemical power source field and is designed for solving the technical problem anode metallic lithium corrosion, high possibility of power failure and bad cycle performance of the existing lithium air battery. A shell is divided into an anode room, a buffer room and a cathode room by a solid inorganic electrolyte membrane and a diaphragm. The lithium / air battery uses a hydrophobic ionic liquid as an anode electrolyte, which has the advantages of non-volatile, high conductivity, wide electrochemical window, low melting point and moderate viscosity, and can prevent the metallic lithium from being corroded by water and oxygen. The cathode uses a water base-weak acid-buffer solution with the Ph of not less than 4 and not more than 5 as the electrolyte; compared with a neutral or alkaline electrolyte, the water base-weak acid-buffer solution ensures that the average discharge voltage (0.1-0.2V) can be improved, a discharge plateau can be prolonged, and the corrosion of the strongly alkaline electrolyte to the solid inorganic electrolyte membrane is reduced; and a cathode discharge product is a water-soluble LiOH which cannot deposit on the surface or in the duct of the cathode to cause power failure, and is good in cycle performance.

Owner:HARBIN INST OF TECH

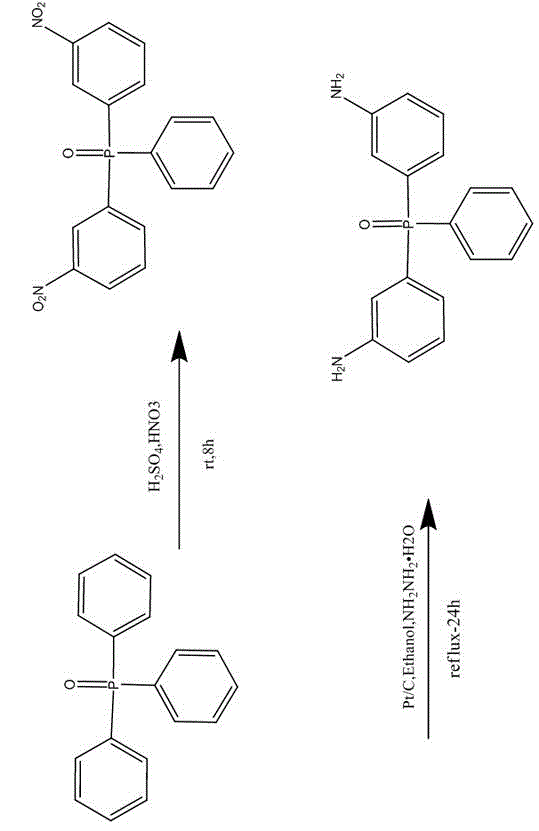

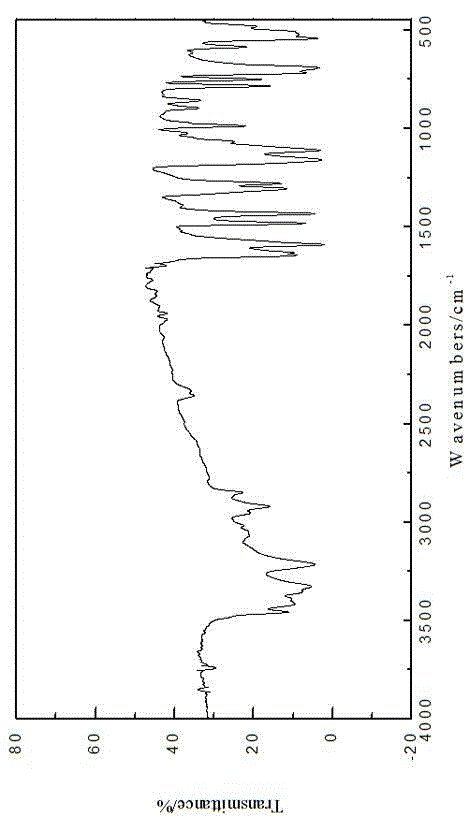

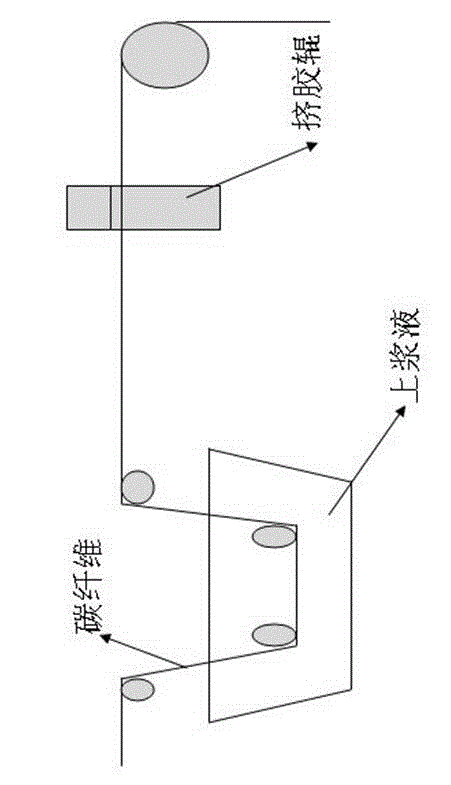

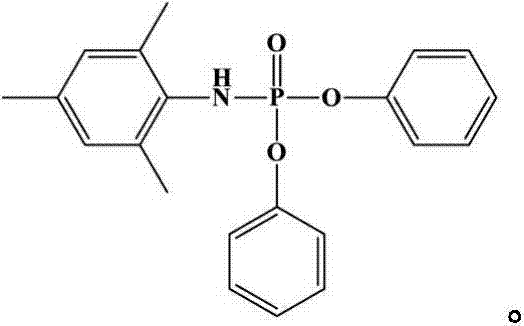

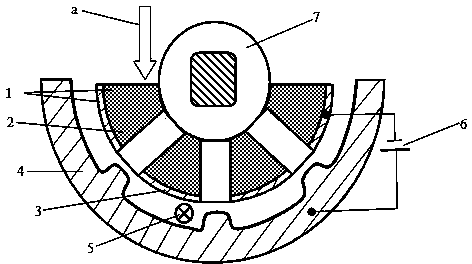

Preparation method of carbon fiber interface atomic-oxygen-resistant phosphorous coating

ActiveCN104099785AProtection from erosionHigh resistance to atomic oxygenCarbon fibresGroup 5/15 element organic compoundsPhenyl groupFiber

The invention discloses a preparation method of a carbon fiber interface atomic-oxygen-resistant phosphorous coating. The method comprises the steps as follows: an epoxy resin and bis(3-aminophenyl)phenyl phosphine oxide mixture is dissolved in an acetone solvent to prepare a sizing agent, sizing coating treatment is performed on bare fibers, the mass ratio of acetone to the mixture in the sizing agent is in a range of (100-20):1, and the weight ratio of epoxy resin to bis(3-aminophenyl)phenyl phosphine oxide in the mixture is in a range of 1:(0.2-0.4). According to the preparation method of the carbon fiber interface atomic-oxygen-resistant phosphorous sizing coating, when the space is eroded by atomic oxygen, a phosphoric ester layer can be formed on the surface, so that the carbon fiber surface is protected against erosion by the atomic oxygen. The carbon fiber interface coating has the higher atomic oxygen resistance and can improve the bonding performance to the epoxy resin. The method is simple in technological preparation condition and simple and convenient in after-treatment process.

Owner:HARBIN INST OF TECH

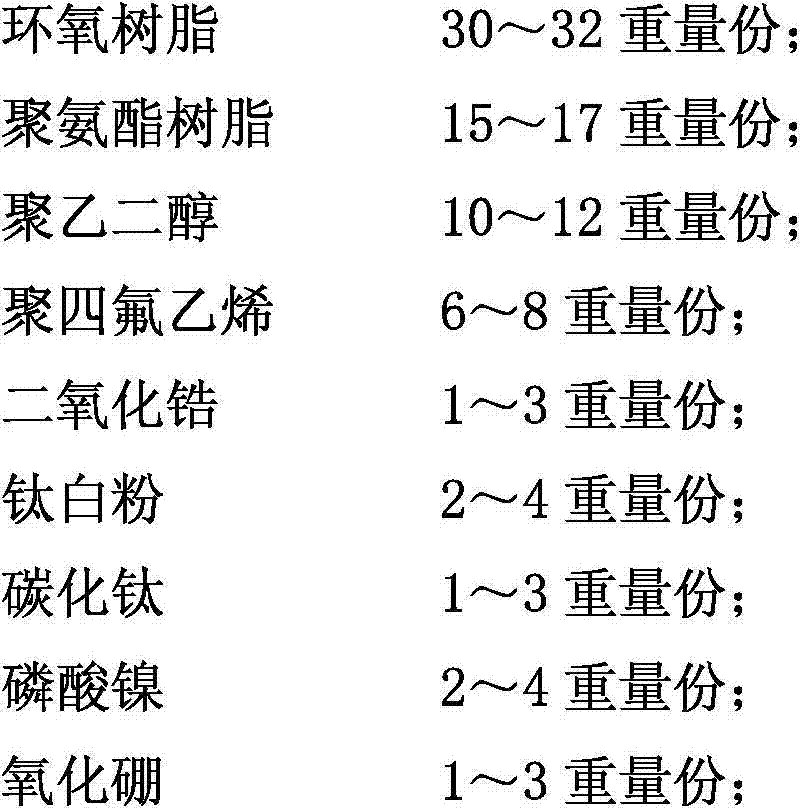

Anti-aging anti-corrosion paint used for road lamp

ActiveCN104513589AExtended service lifeHigh mechanical strengthFireproof paintsAnti-corrosive paintsNickel phosphateEpoxy

The invention discloses anti-aging anti-corrosion paint used for a road lamp. The anti-aging anti-corrosion paint comprises the following materials: epoxy resin, polyurethane resin, polyethylene glycol, polytetrafluoroethylene, zirconium dioxide, titanium dioxide, titanium carbide, nickel phosphate, boric oxide, flame retardants and ethyl acetate. The anti-aging anti-corrosion paint takes advantages of various kinds of macromolecule resin with different molecular weights, the mechanical strength, the adhesive strength, the anti-corrosion performance, the high-temperature resistance, the weather resistance and the anti-aging performance of the paint are effectively improved after combination of various of resin, so the paint can stand long-term sun and rain exposure, has long service life, cannot crack or discolor, and can protect the road lamp against corrosion for a long time; meanwhile, the improved flame retardants are introduced, so the flame retardance of the paint film of the road lamp is improved, the safety performance of the paint is further improved, the road lamp can be effectively protected at high temperature or on other dangerous situations such as a fire, and the paint can prevent inside circuits of the road lamp from being influenced.

Owner:江苏中丽新材料有限公司

High-purity carbon fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN110105075AProcess preparation cycle shortenedReduce manufacturing costFiberChemical industry

The invention provides a high-purity carbon fiber reinforced silicon carbide composite material and a preparation method thereof and belongs to high-temperature high-purity composite materials and advanced manufacturing technologies thereof. The composite material can be applied to the fields of semiconductor, solar energy, optoelectronics, machinery, metallurgy, chemical industry, materials and the like. The preparation method comprises the steps that carbon fiber felt and a carbon fiber cloth are subjected to purification treatment first, pyrolysis of carbon and SiC interface phase deposition are alternately carried out on the surfaces of the carbon fiber felt and carbon fiber cloth, and then prepared high-purity ceramic slurry is sprayed onto the surface of the carbon fiber felt or carbon fiber cloth containing a composite coating by means of a spraying method; stacking, needling, drying and solidifying are carried out to obtain a composite material blank, and the blank is subjectedto high-temperature carbonization treatment, purification treatment and densification treatment to obtain the high-purity carbon fiber reinforced silicon carbide composite material. The preparation method shortens the preparation cycle and reduces the production cost; the composite material prepared by means of the preparation method has the impurity content lower than 10 ppm, the density higherthan 2.20 g / cm<3> and the bending strength higher than 150 MPa.

Owner:湖南兴晟新材料科技有限公司

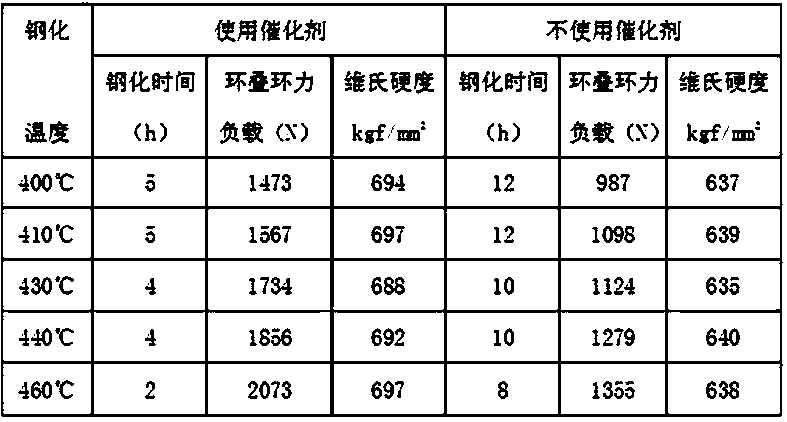

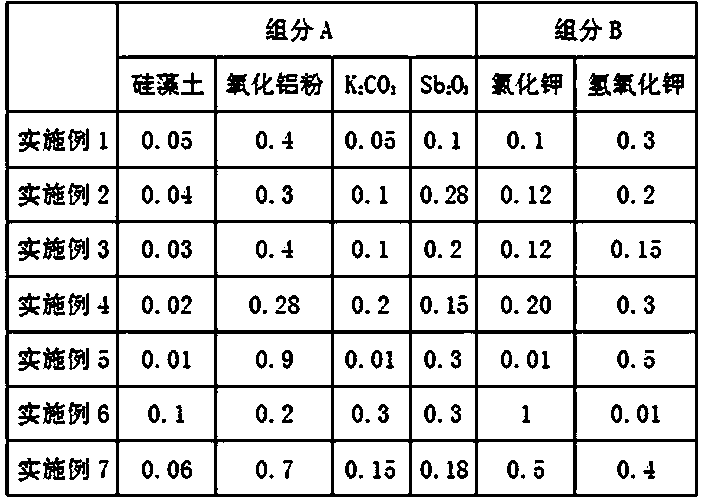

Catalyst for chemical reinforcement of glass, and preparation method of reinforcement liquid thereof

ActiveCN104326648AHigh strengthImprove surface scratch resistanceGlass tempering apparatusPotassium chloride 10%Potassium hydroxide

The invention relates to a catalyst for chemical reinforcement of glass, and a preparation method of a reinforcement liquid thereof, and belongs to the technical field of the chemical reinforcement of the glass. The catalyst comprises, by weight, 30-100 parts of a component A and 10-100 parts of a component B. The component A is prepared from the following components by weight: 1-10 parts of diatomite, 20-90 parts of alumina powder, 1-30 parts of potassium carbonate and 10-30 parts of antimonous oxide. The component B is prepared from the following components by weight: 10-50 parts of potassium hydroxide and 10-100 parts of potassium chloride. The method for preparing the reinforcement liquid comprises the steps of preparing the component A; adding the prepared component A in a potassium salt; stirring for 0.5-1 h to form a first mixed salt; then adding the component B in the first mixed salt; stirring for 0.5-1 h; and standing for 1-2 h to obtain the reinforcement liquid. The catalyst and the reinforcement liquid can significantly shorten glass reinforcement time and reduce production cost, and can obviously enhance hardness, strength and scratch resistance of the glass.

Owner:北京远大信达科技有限公司

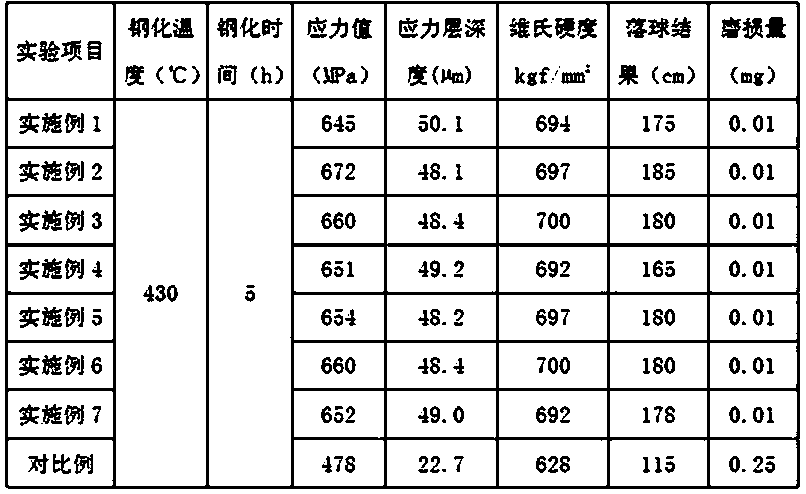

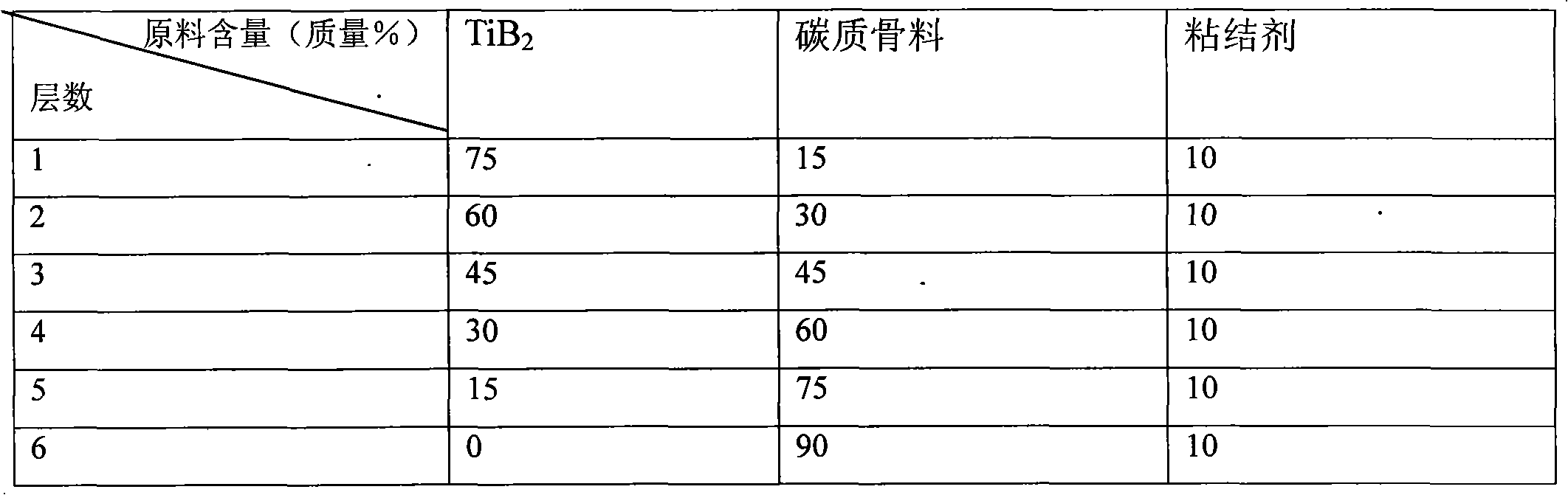

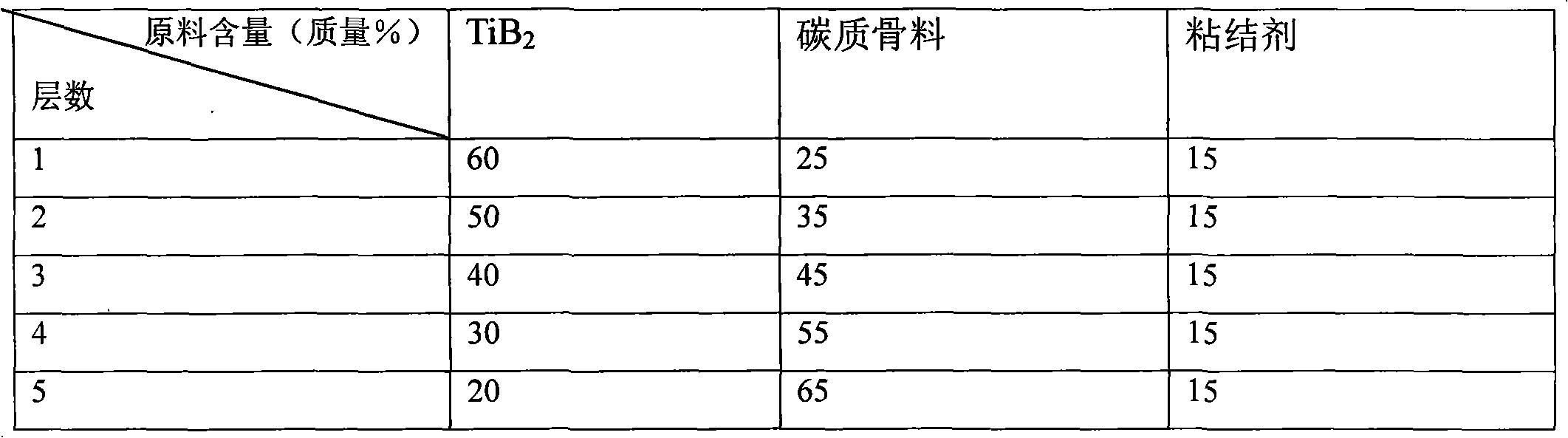

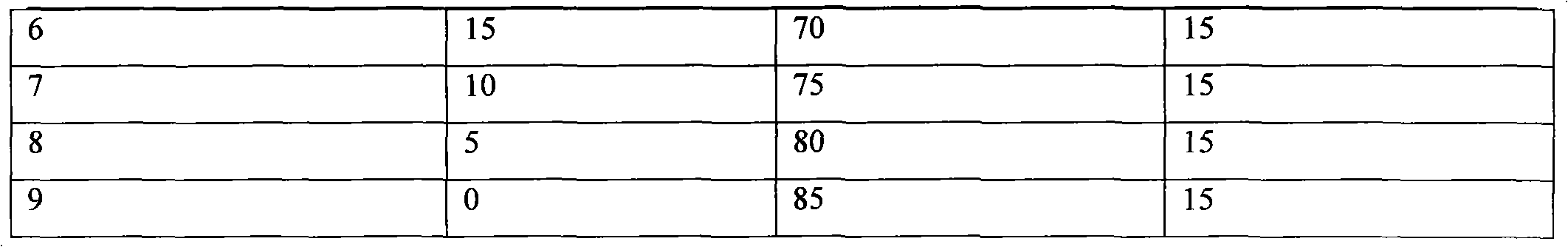

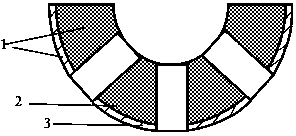

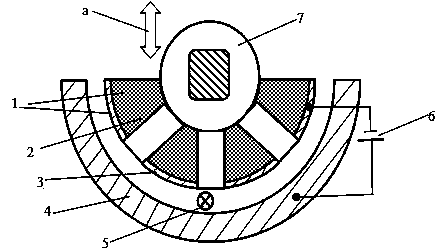

Preparation method of TiB2/C gradient cathode material for aluminum electrolytic bath

InactiveCN101608321AImproved working characteristics of the working faceImprove working characteristicsContinuous mixingMaterials science

The invention relates to a preparation method of TiB2 / C gradient cathode material for an aluminum electrolytic bath, which belongs to the technical field of electrolytic aluminum. The adopted raw materials comprise TiB2, carbon aggregate and cementing agent. The procedure is continuous dosing, continuous mixing and paving and adopts the sequence as follows: the content of the TiB2 in each layer sequentially increases and changes from a bottom layer to a surface layer, and the content of the carbon aggregate sequentially reduces and changes; or the content of the TiB2 sequentially reduces and changes, and the content of the carbon aggregate sequentially increases and changes; the materials paved layer by layer are hot-pressed and sintered, and then are naturally cooled to the room temperature so as to obtain the product. Because micro components of the materials prepared by the invention sequentially change, the invention can better solve the problems of easy coating shedding and the like caused by thermal mismatching of carbon and TiB2; meanwhile, the cathode material has strong sodium corrosion resistance, can remarkably improve the current efficiency of the electrolytic bath, and prolongs the service life of the electrolytic bath.

Owner:NORTHEASTERN UNIV

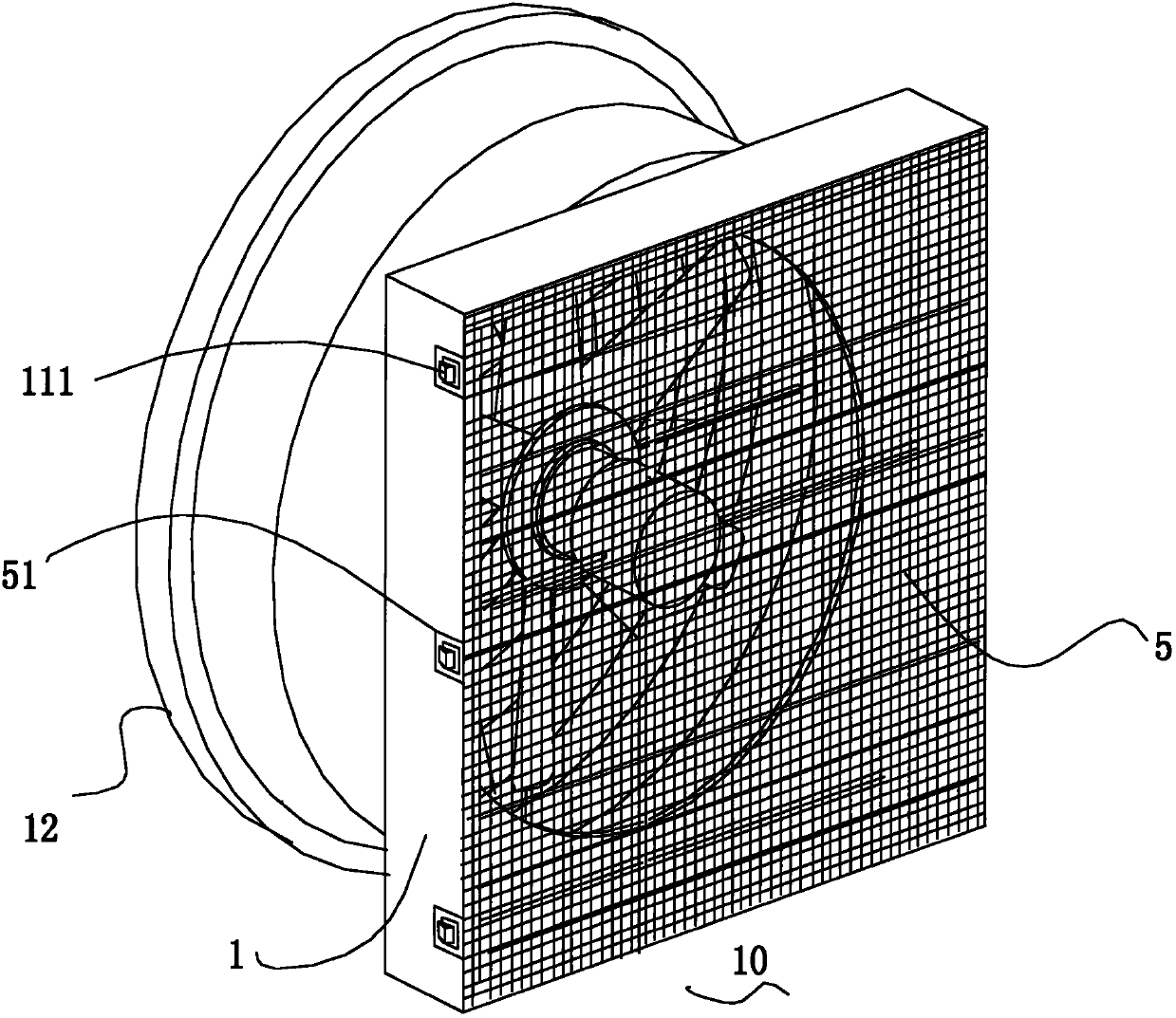

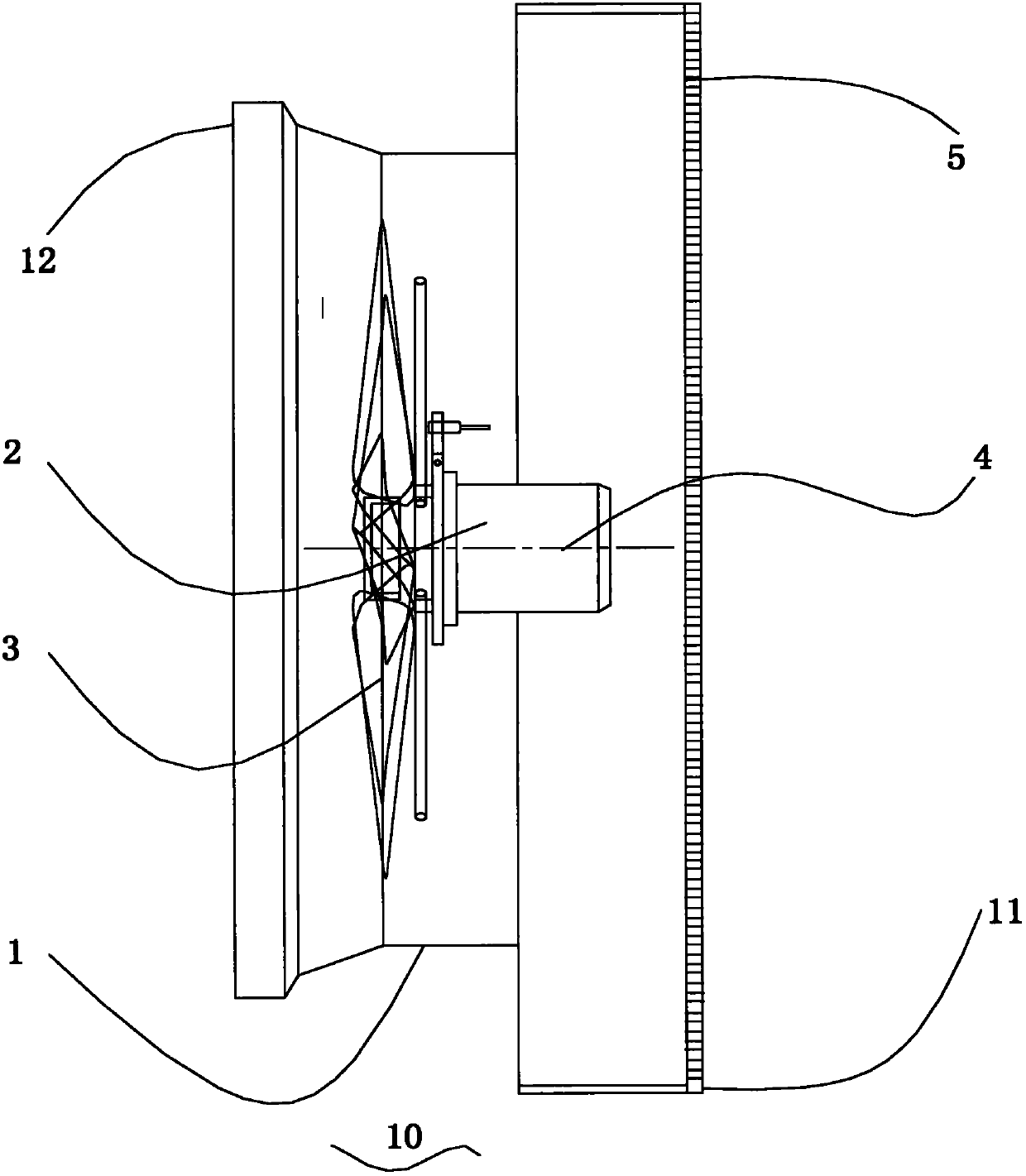

Negative-pressure fan

InactiveCN103104517AExtended service lifeReduce wind noisePump componentsPump installationsFiberDrive shaft

The invention provides a negative-pressure fan. The negative-pressure fan comprises an outer shell, a motor, fan blades and a transmission shaft, wherein the motor and the fan blades are respectively arranged in an air inlet and an air outlet at two ends of the outer shell and are connected through the transmission shaft. The fan blades are driven to rotate by the motor through the transmission shaft, and an effect of negative-pressure air exchange is achieved. A filter screen is arranged on the position of the air inlet of the outer shell. When the fan works, the filter screen is capable of filtering relatively small sundries such as dust and fibers so as to protect the fan blades and the motor from corrosion and further prolong the service life of the negative-pressure fan. Simultaneously a porous structure of the filter screen is capable of relieving intensity and speed of air currents exhausted by the negative-pressure fan, reducing wind cutting noise of the fan blades, and lowering wind cutting resistance of the fan blades so as to prolong the service life of the fan blades.

Owner:昆山俊润通风降温设备有限公司

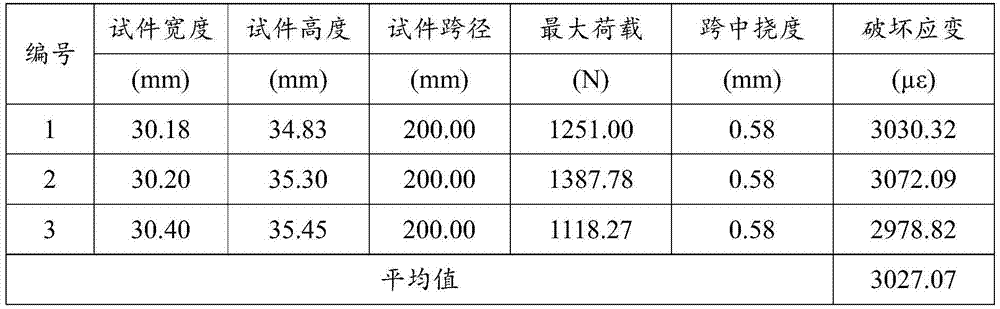

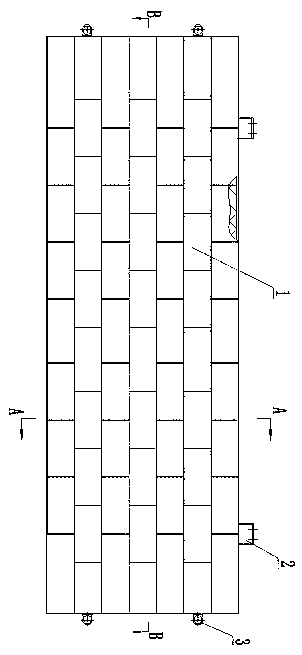

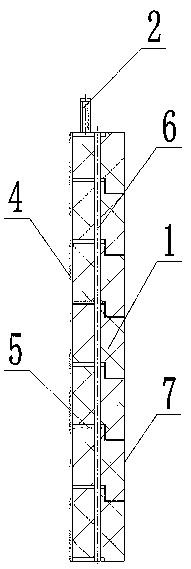

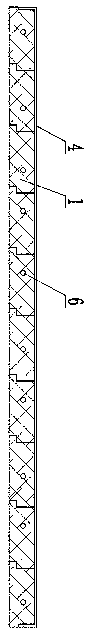

Electrochemical machining method for micro-protrusions on inner surface of sleeve part

ActiveCN103433579ALow costLow processing environment requirementsElectrochemical machining apparatusEngineeringThin sheet

The invention provides an electrochemical machining method for micro-protrusions on the inner surface of a sleeve part, belonging to the field of electrochemical machining. According to the electrochemical machining method, an elastic insulating sheet with a tiny group pore structure is utilized, one surface of the elastic insulating sheet facing to the part is subjected to conductive treatment, a tool cathode is formed by a conductive layer of the elastic insulating sheet and the elastic insulating sheet, the sleeve part is taken as a tool anode, electrolyte is filled between the cathode and the anode, and the anode and the cathode are respectively connected with a positive electrode and a negative electrode of a power supply for electrochemical machining to produce micro-protrusion structures on the inner surface of the sleeve part. By adopting the electrochemical machining method provided by the invention, the micro-protrusion structures can be formed on the inner surface of the sleeve part, and the electrochemical machining method has the characteristics of high production speed of the micro-protrusions, low cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

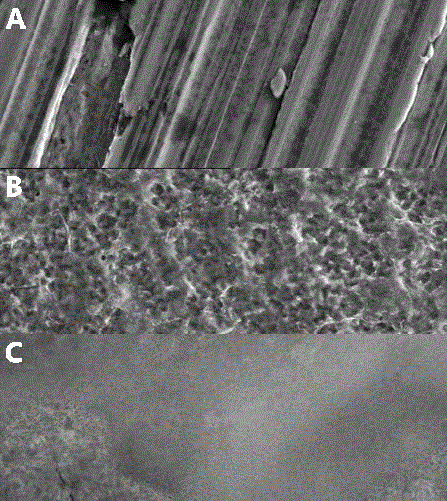

Non-phosphorus solid slow-release corrosion inhibitor

The invention provides a non-phosphorus solid slow-release corrosion inhibitor. The non-phosphorus solid slow-release corrosion inhibitor comprises 20%-30% of boric acid, 25%-35% of borax, 10%-20% of Na2O, 15%-25% of SiO2, 5% of Na2SO4 and 5% of (NH4)6Mo7O24. The corrosion inhibitor provided by the invention is the non-phosphorus corrosion inhibitor, the content of phosphate in water is decreased beneficially, and the eutrophication risk of receiving water is reduced; aiming at the acidic water quality (pH is larger than or equal to three), the medium-high-salinity water quality (the content of Cl- is smaller than or equal to 0.5mol / L) and the medium-high-alkalinity water quality (the content of CaCO3 is smaller than or equal to 250mg / L), the corrosion inhibitor is researched and developed, and corrosion of carbon steel materials in the acidic water quality environment, the medium-high-salinity water quality environment and the medium-high-alkalinity water quality environment can be effectively inhibited; and the corrosion inhibitor belongs to a slow-release medicament, and the corrosion inhibition effect of the medicament lasts for 30 days or more.

Owner:BEIJING NORMAL UNIVERSITY

Aluminum-zinc-silicon epoxy composite powder anticorrosive coating and preparation method thereof

InactiveCN104449223AReduce productionSolve the problem of self-corrosion currentAnti-corrosive paintsPowdery paintsEpoxySilicon alloy

The invention provides an aluminum-zinc-silicon epoxy composite powder anticorrosive coating and a preparation method thereof. The coating comprises the following raw materials in parts by mass: 50-60 parts of epoxy resin, 20-30 parts of aluminum-zinc-silicon alloy powder, 3-5 parts of a nano-nucleating agent, 1-2 parts of a silane coupling agent, 1-2 parts of a dispersant, 2-4 parts of a curing agent, 2-4 parts of a toughening agent, 1-2 parts of a leveling agent and 10-15 parts of filler and pigment. The preparation method comprises the following steps: fully mixing the aluminum-zinc-silicon alloy powder, the nano-nucleating agent, the dispersant and the filler and pigment, adding the silane coupling agent, stirring and ultrasonically dispersing to obtain a component I; mixing the epoxy resin, the curing agent, the toughening agent and the leveling agent, drying at 80 DEG C for 20 minutes, and cooling to the normal temperature to obtain a component II; mixing the component I with the component II, putting a mixture into an extruder for melt extrusion, grinding and screening. The coating is heat-resistant, wear-resistant and impact-resistant, and can protect a steel structure from being corroded by various corrosive mediums for a long term.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Oral care product for sensitive enamel care

ActiveUS20120288455A1Prevention of dental erosionAvoid erosionCosmetic preparationsGum massageDental enamelMouth care

Disclosed are anti-erosion oral care formulations and methods that provide erosion protection while maintaining adequate cleaning performance. The anti-erosion oral care formulations include a copolymer of a methylvinyl ether and a maleic anhydride and a metal compound or salt that becomes more soluble at acidic pH.

Owner:COLGATE PALMOLIVE CO

Asphalt pavement sticking seam repairing material and asphalt pavement sticking seam repairing belt

InactiveCN105887615AProtection from erosionFirmly connectedPaving detailsBuilding insulationsRepair materialRoad surface

The invention relates to an asphalt pavement sticking seam repairing material and an asphalt pavement sticking seam repairing belt. The repairing belt is composed of the asphalt pavement sticking seam repairing material, anti-sticking ash powder, a fine sand layer and a backing tape, wherein the asphalt pavement sticking seam repairing material is arranged on the backing tape; an anti-sticking ash sand layer is arranged on the upper surface of the asphalt pavement sticking seam repairing material; the repairing material is prepared from the following main components in parts by weight: 100 parts of petroleum asphalt, 5-15 parts of a modifying agent, 2-15 parts of a tackifier, 0.3-1 part of an anti-ageing agent, 6-20 parts of a softening agent and 40-70 parts of an enhancing agent. By virtue of the scheme, the asphalt pavement sticking seam repairing material can be used for effectively combined with pavement asphalt on the two sides of a previous pavement seam to block and cover on an asphalt pavement seam, so that a roadbed is protected from corrosion; the two sides of the previous pavement seam are connected to prevent the seam from being continually expanded; the connection between the sticking seam repairing material and a previous pavement is enhanced under the rolling of vehicles and the anti-sticking ash sand layer can prevent the sticking seam repairing material from being stuck on wheels.

Owner:宋学忠

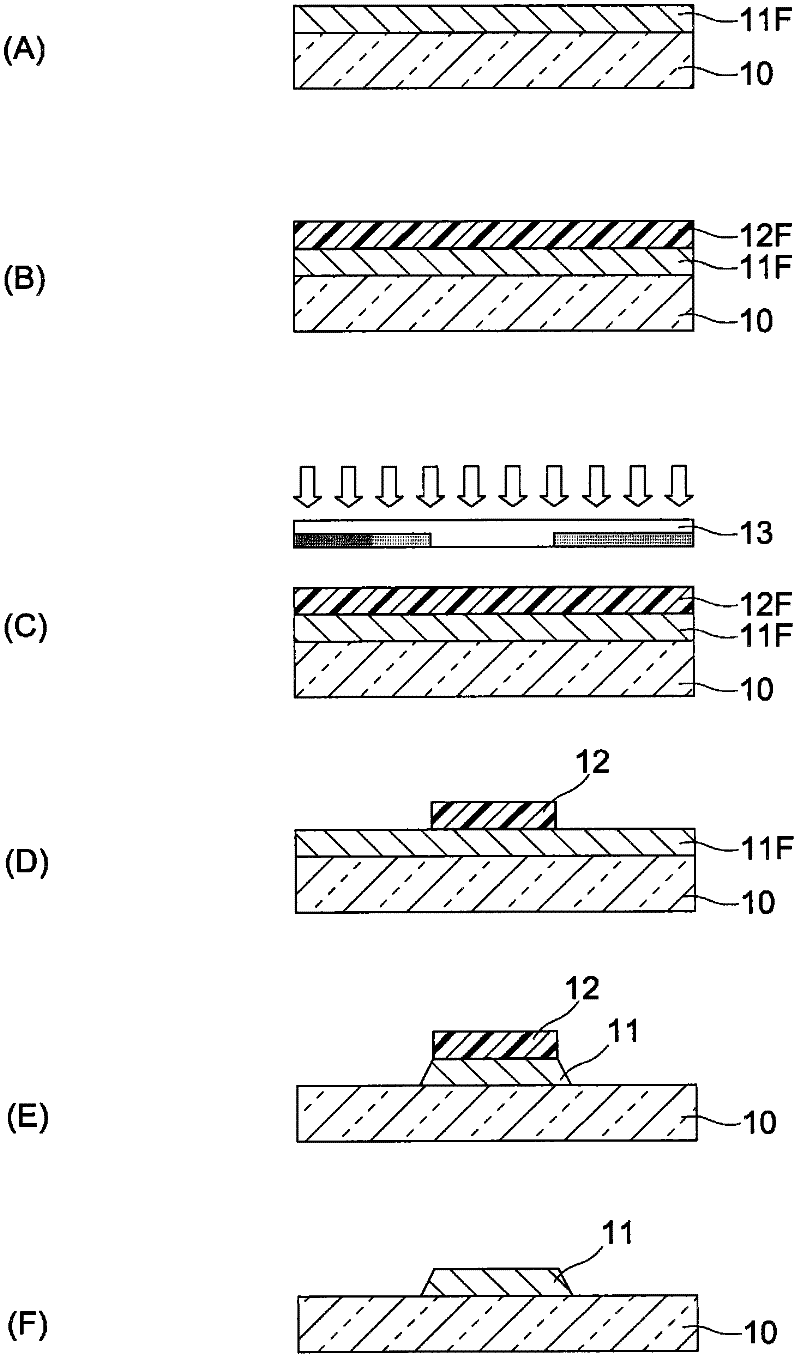

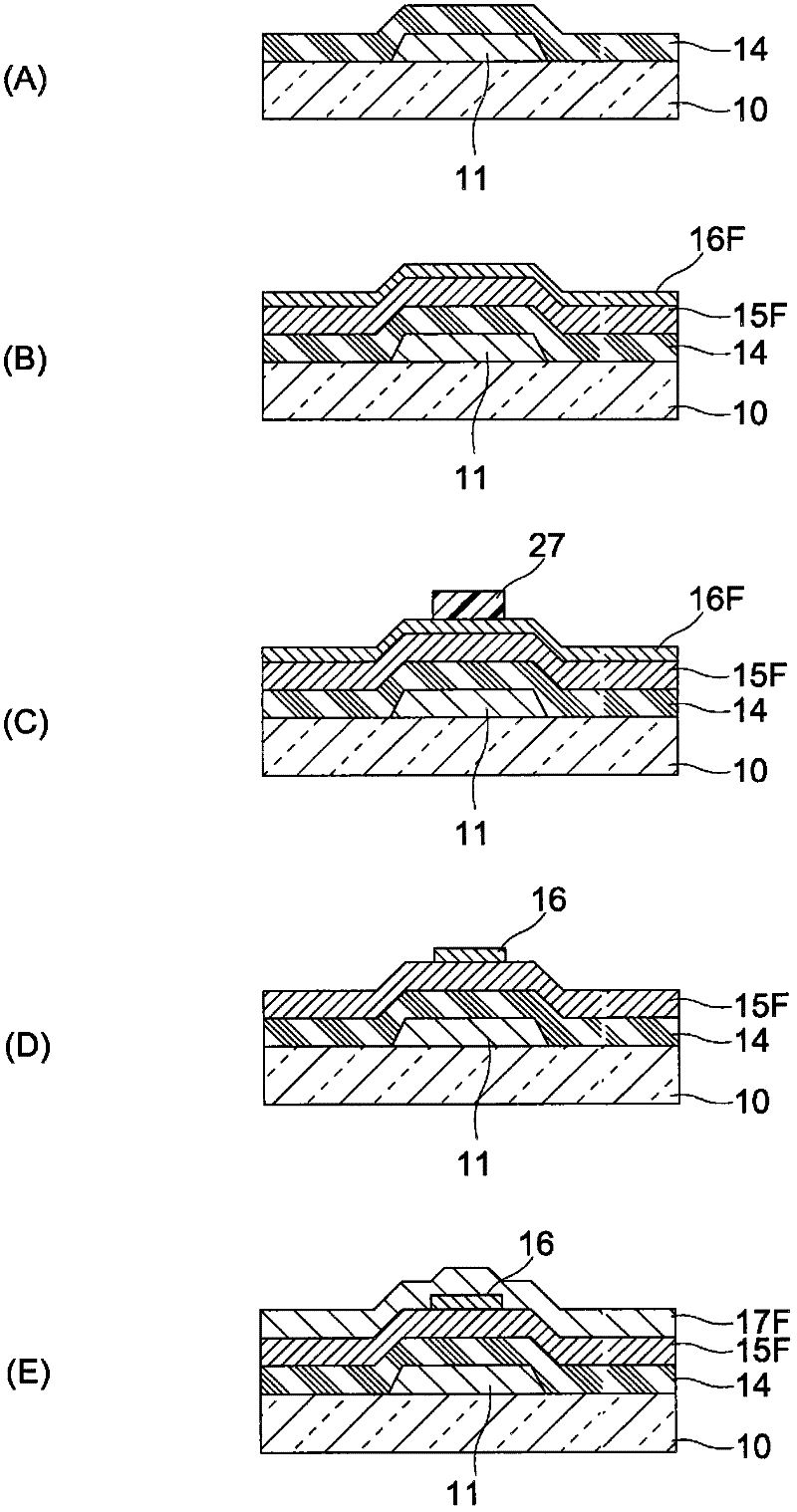

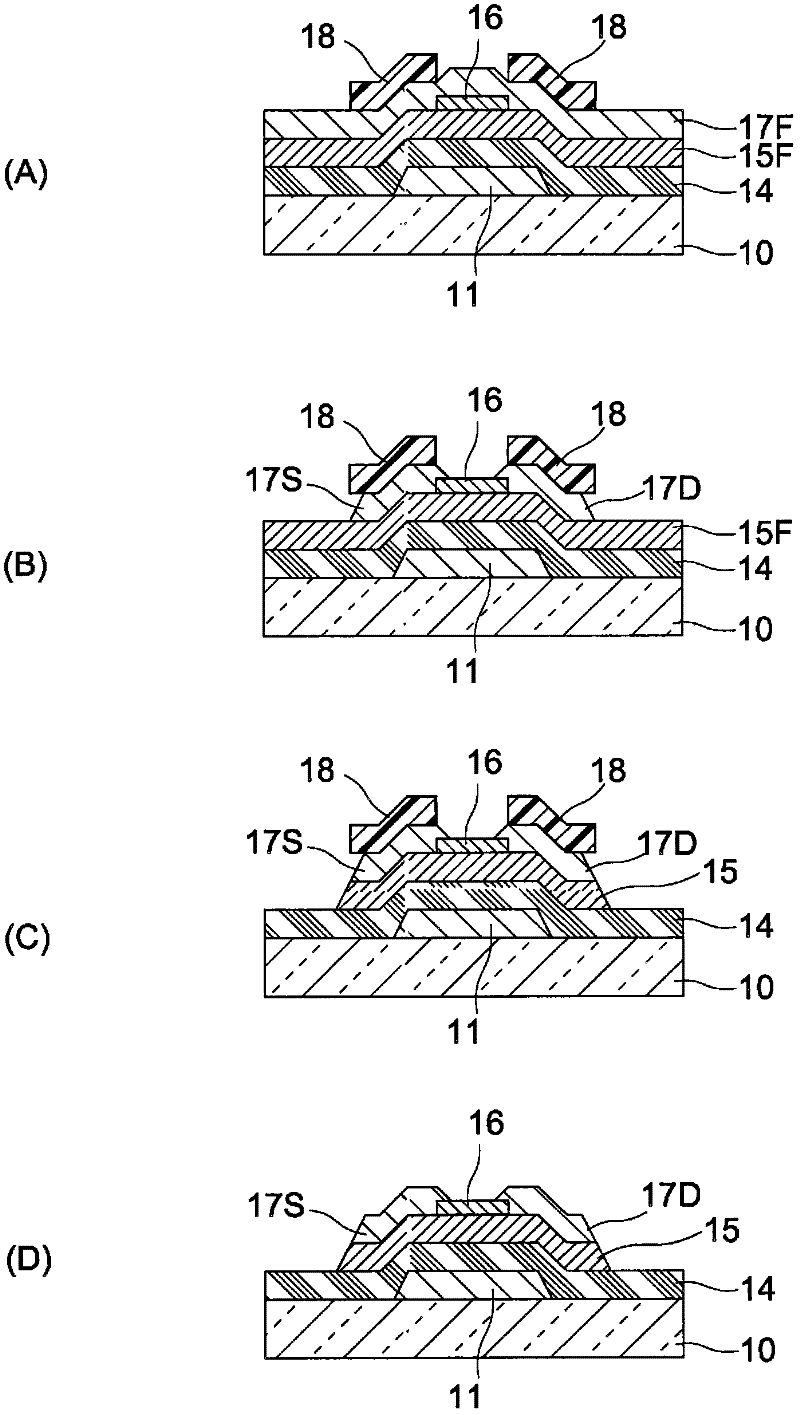

Method and device for manufacturing field-effect transistor

InactiveCN102165570AProtection from erosionTransistorSemiconductor/solid-state device manufacturingAir atmosphereEngineering

Provided are a method for manufacturing a field-effect transistor by which an active layer can be protected from an etchant without being exposed to an air atmosphere, and a device for manufacturing same. A method for manufacturing a field-effect transistor comprises a step of forming an active layer (15) (IGZO film (15F)) of In-Ga-Zn-O based composition on a base material (10) by a sputtering method, a step of forming, on the active layer, a stopper layer (16) (stopper layer forming film (16F)) for protecting the active layer from an etchant for the active layer by the sputtering method, and a step of etching the active layer with the stopper layer as a mask. By depositing the stopper layer by the sputtering method, the stopper layer can be formed without exposing the active layer to the air after the active layer is deposited. Consequently, film quality degradation caused by the adhesion of water and impurities in the air to the surface of the active layer can be prevented.

Owner:ULVAC INC

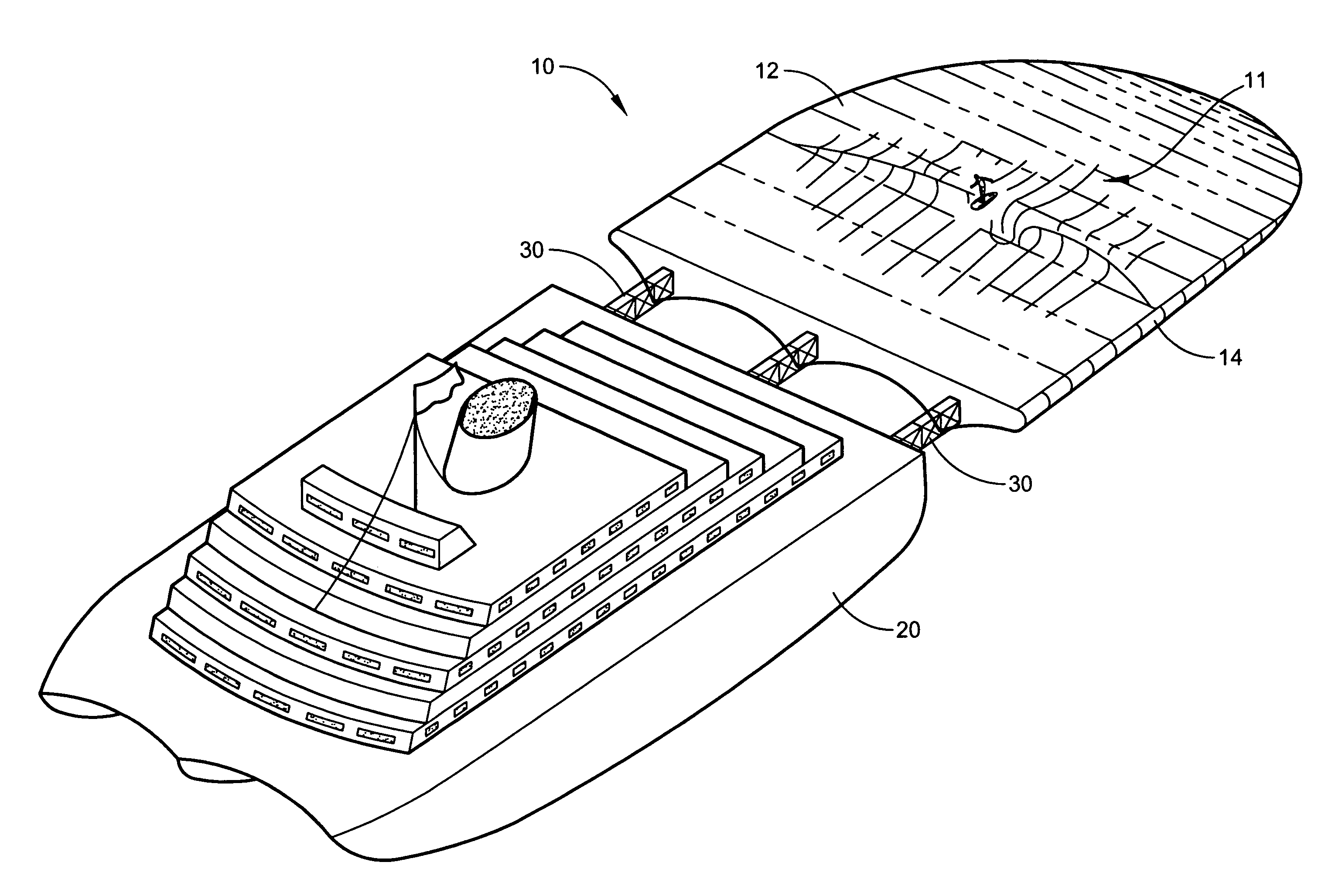

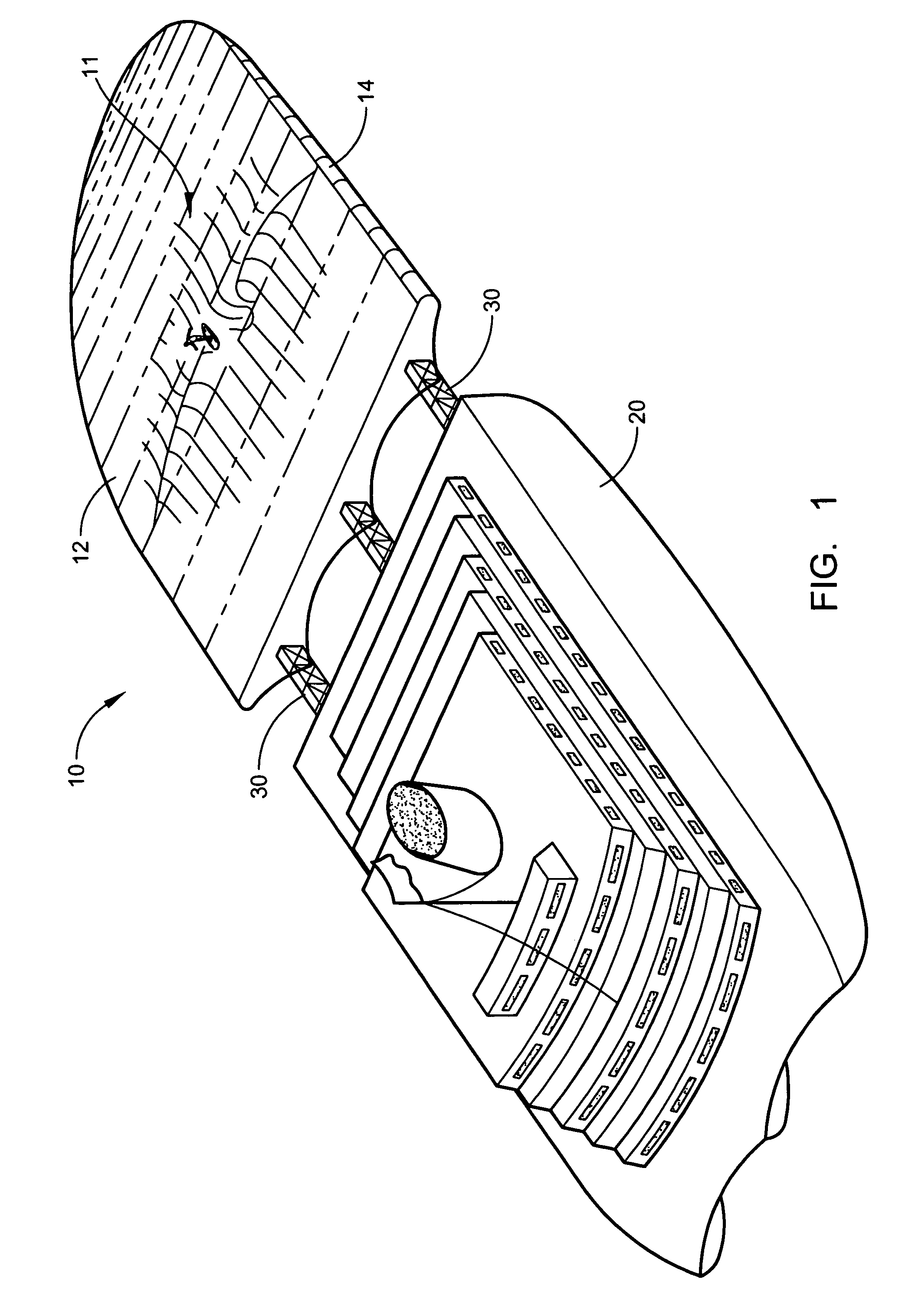

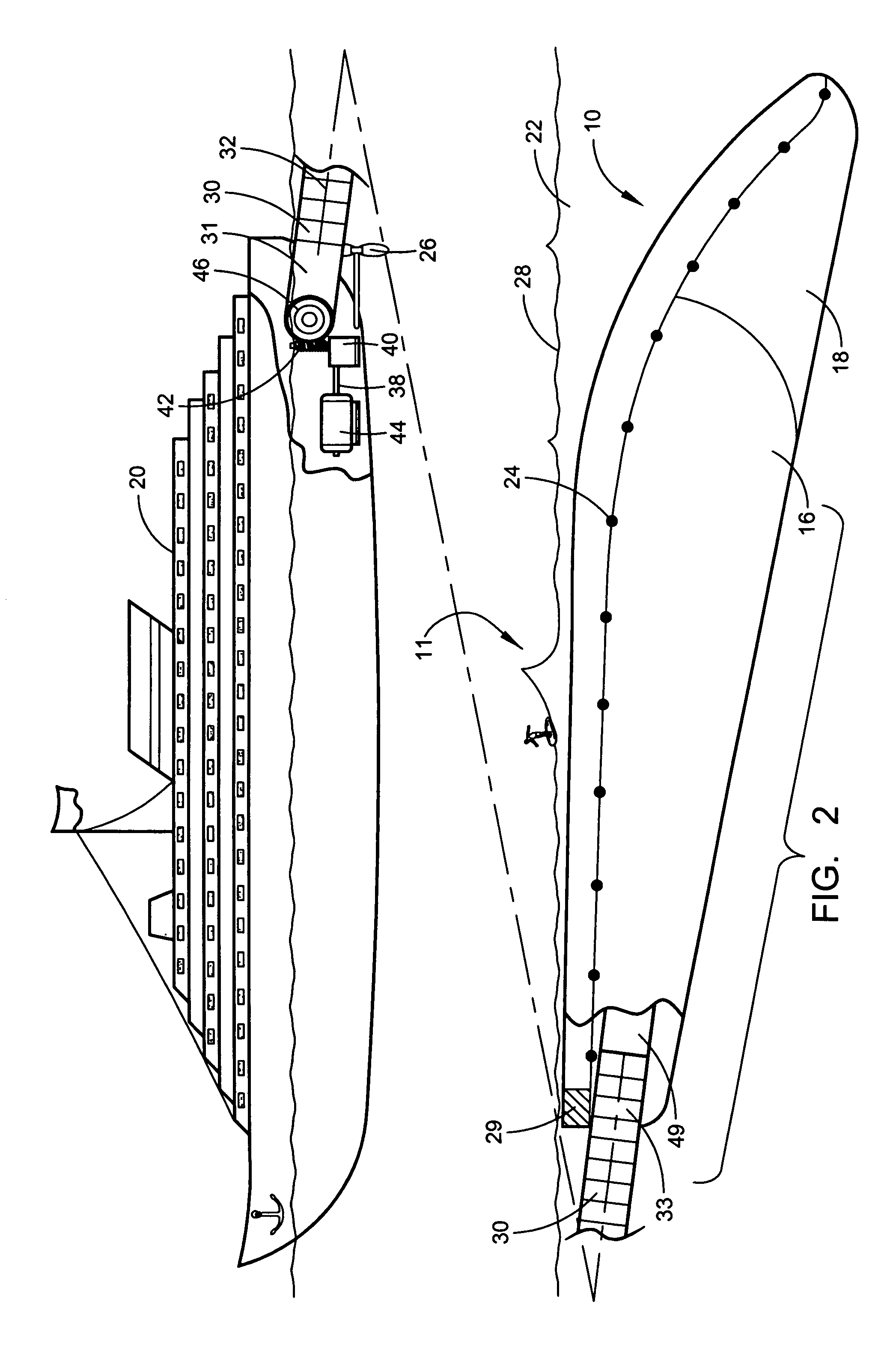

Floating oceanic surfing reef

The present invention involves an apparatus, namely a reef, used to transform ocean wave energy into preferred surfing waves. The reef is comprised of a hull having a substantially flat top surface with a vertically convex shape that preferably creates about a seventy degree tangential bow angle with the ocean surface. The bottom portion is tri-hull shaped and includes two side hulls and a center hull. The preferred embodiment is connected to a master vessel by control arms. The control arms can control the depth of the reef in water, thus controlling the wave characteristics. The control arms can also provide a ducting means for ballast pumps on the master vessel. In an alternative embodiment, the reef can be self-supporting in water. A single reef or a multiple reef configuration can be placed near shore to help prevent beach erosion by wave action, and or cause beach sand to accumulate. Several reefs can be connected for longer-lasting waves.

Owner:SAUERBIER CHARLES E

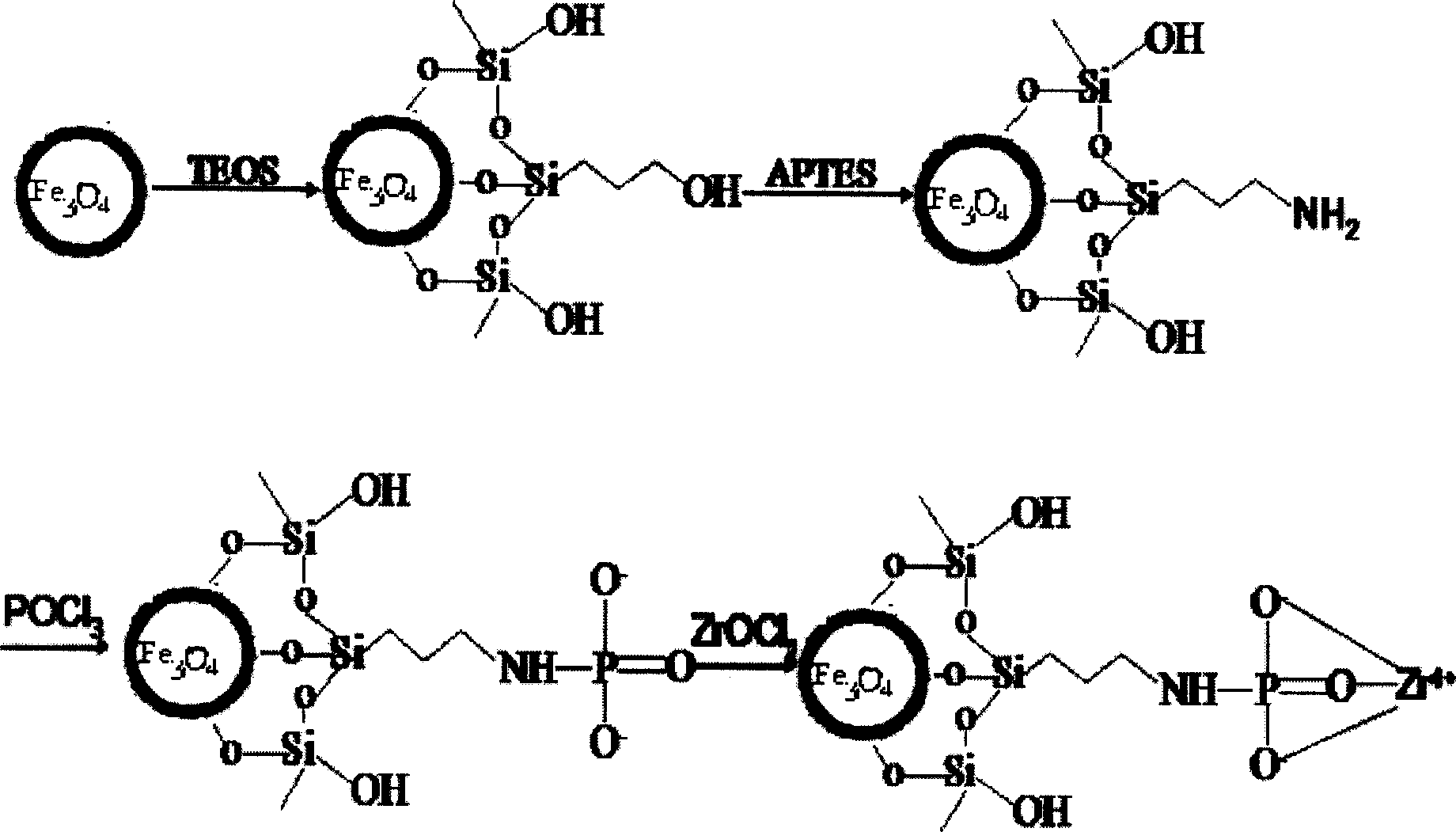

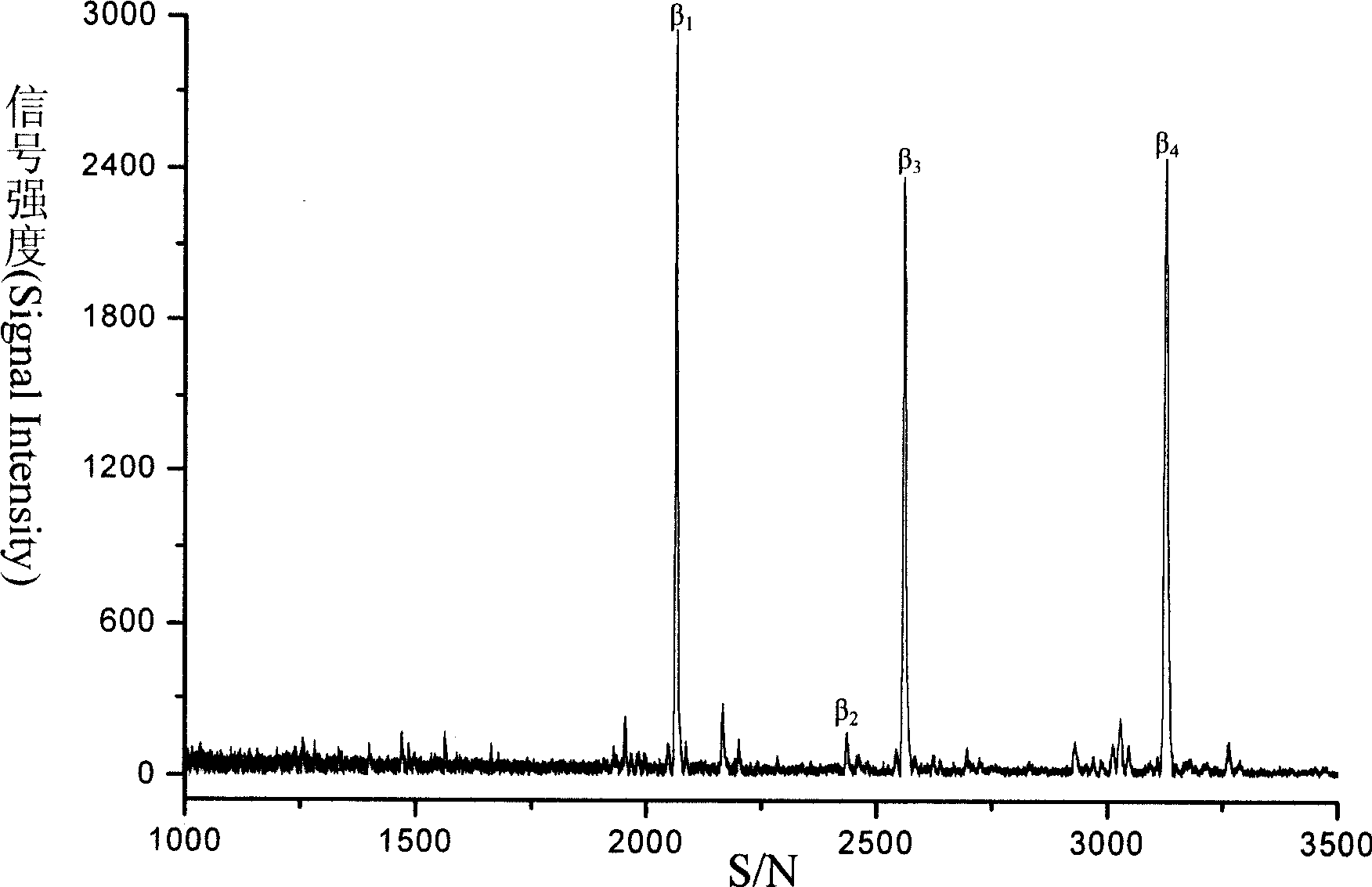

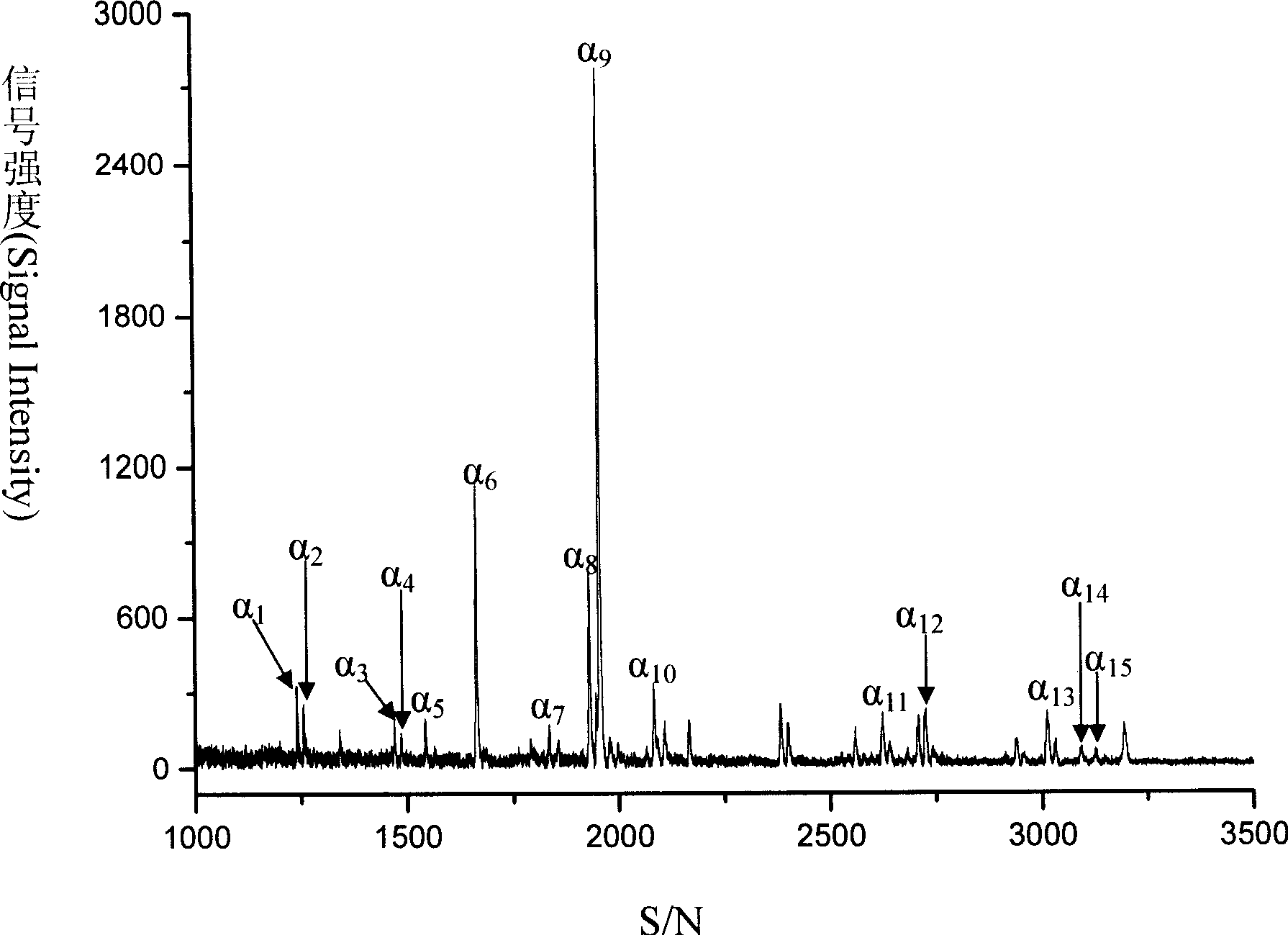

Zirconium phosphoester nano magnetic beads, as well as preparation and application thereof

InactiveCN101434641AProtection from erosionAvoid adsorptionPeptide preparation methodsPhosphateMagnetic bead

The invention relates to a phosphate zirconium nano magnetic particle with the structural representation on the right, and the preparation and application thereof; the preparation method comprises the steps that phosphate groups are induced to the surface of the nano magnetic particle which is wrapped with silicon dioxide on the surface and takes ferriferrous oxide as a magnetic inner core; then, a phosphate zirconium layer is formed on the surface by the mutual action between zirconium ions and the phosphate groups on the surface, thereby successively preparing a nano magnetic particle having high efficiency, high-selectivity separation and enrichment feature to peptide phosphate. The nano magnetic particle is mainly used for separating the enriched peptide phosphate from biological samples, with high efficiency and under the action of a magnetic field. The extracted peptide phosphate can be directly analyzed and represented by mass spectrum.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Oral care product for sensitive enamel care

InactiveUS20120308488A1Avoid erosionReduce bacterial adhesionCosmetic preparationsGum massageMouth careTooth enamel

Owner:COLGATE PALMOLIVE CO

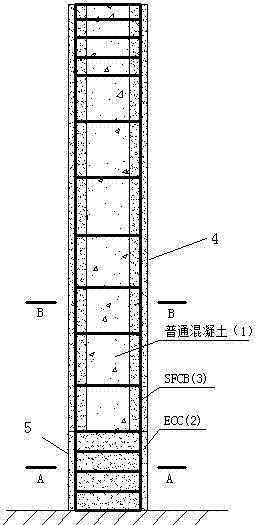

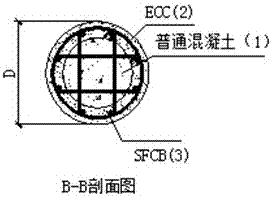

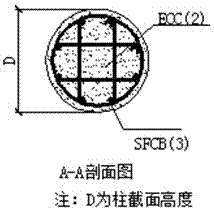

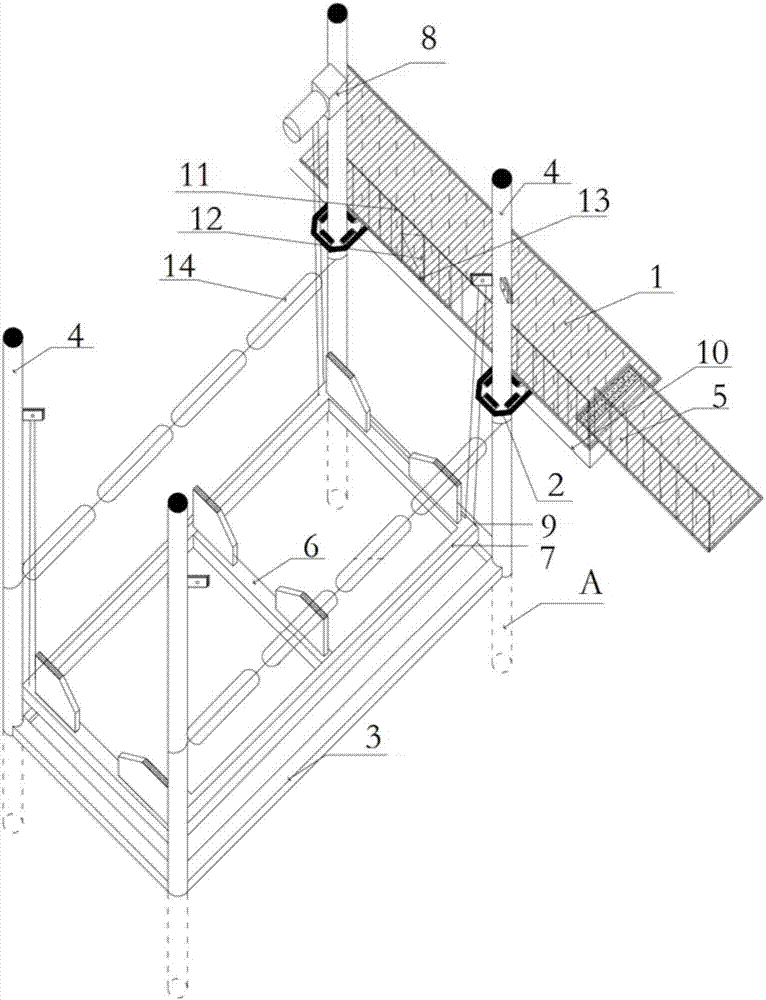

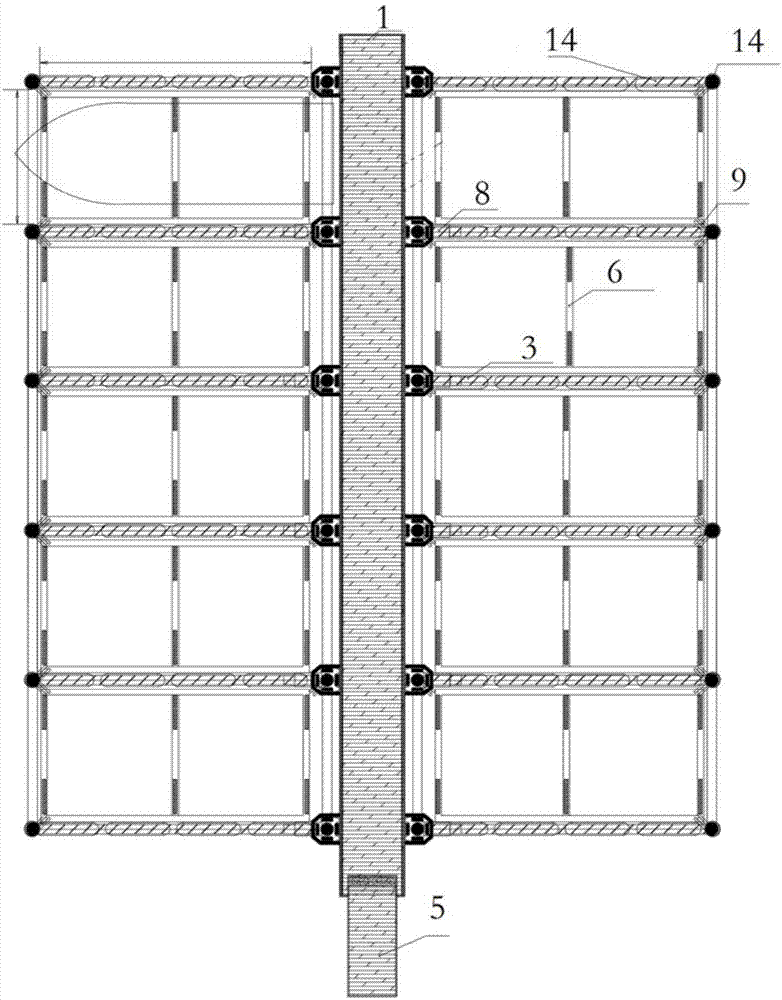

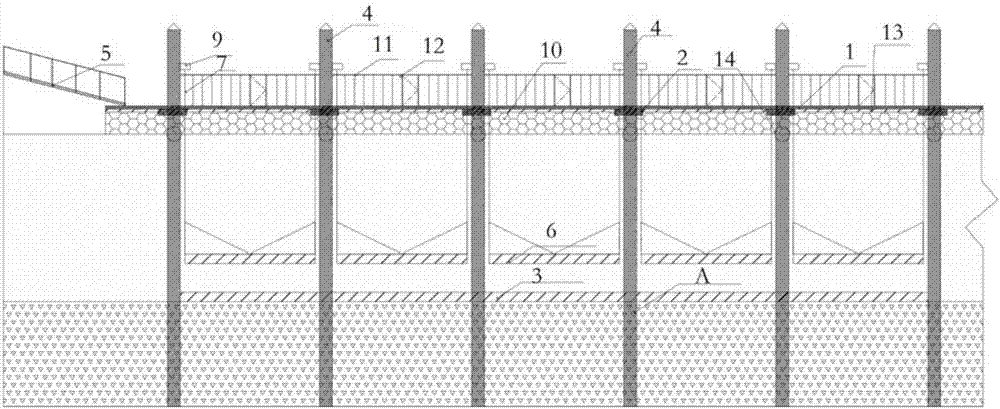

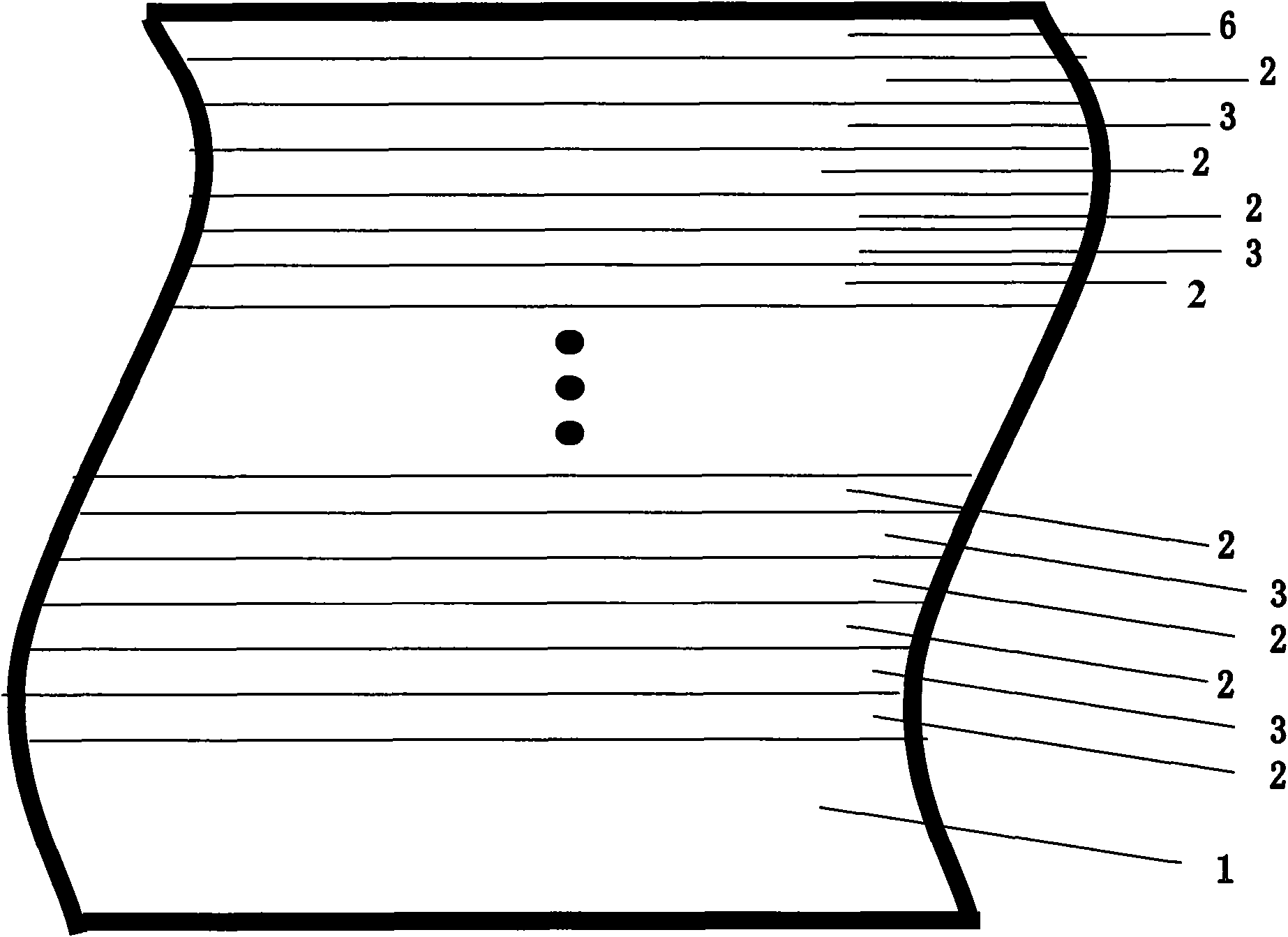

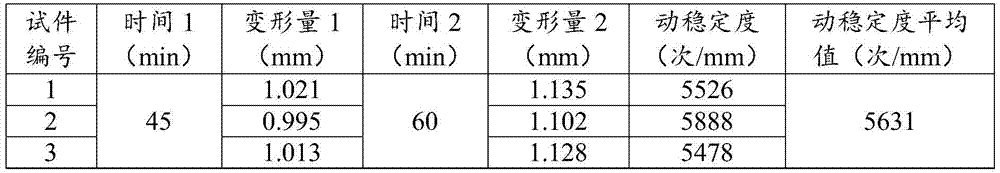

Steel fiber composite bar (SFCB) and engineered cementitious composite (ECC)-concrete composite column/ pier and preparation method thereof

ActiveCN107447646AHigh strengthStrong corrosion resistanceStrutsClimate change adaptationRebarCorrosion resistant

The invention discloses a steel fiber composite bar (SFCB) and engineered cementitious composite (ECC) concrete composite column / pier and a preparation method thereof and belongs to the technical field of building structures. On the basis of a common reinforced concrete structure, a SFCB is used for replacing a steel bar likely to be corroded, meanwhile, an ECC with excellent crack deformation resistant capability, small cracks, high tension and compression resistant capability and high corrosion resistant capability is introduced, and a concrete column is designed in sectioned and layered modes. The section within the range of the section height h to a bottom column of the column / pier is the complete ECC section, the section of the part with the height being larger than the section height h to the bottom column of the column / pier is the ECC-concrete composite section, and common concrete is arranged inside the column. An interface area does not need the particular treatment technology. By comprehensively utilizing the corrosion resistant capability of the SFCB and the excellent compression resistant and erosion resistant capability of the ECC, the SFCB and ECC-concrete composite column / pier with high bearing capability and good durable performance is formed.

Owner:YANGZHOU UNIV

Powder anti-corrosion coatings for submarine pipelines

PendingCN106147505AImprove waterproof performanceStrong adhesionAnti-corrosive paintsPowdery paintsPolyvinyl butyralEpoxy

The invention discloses a powder anticorrosion coating for submarine pipelines, which is composed of the following raw materials in parts by weight: 20-50 parts of epoxy resin, 20-50 parts of novolak epoxy resin, 5-30 parts of titanium dioxide, trimethyl 4‑10 parts of hexamethylenediamine, 1‑2 parts of polyvinyl butyral, 3‑4 parts of defoamer, 0.1‑0.2 parts of dimethylimidazole, 1‑2 parts of antioxidant DNP, aminopropyl 1-3 parts of triethoxysilane, 5-26 parts of barium sulfate, 2-10 parts of thickener, 0.5-5 parts of graphene, and 0-4 parts of colorant. The powder anticorrosion coating for submarine pipelines of the present invention can protect steel structures from corrosion of various corrosive media for a long time, is non-toxic, non-polluting, resistant to salt spray, strong in adhesion, strong in impact resistance, and low in cost, and is an environmentally friendly coating with excellent comprehensive performance. coating.

Owner:西安烨森电子科技有限责任公司

Corrosion resistant spraying coating method for outdoor cabinet base

InactiveCN110000074AImprove adhesionMeet the use requirementsPretreated surfacesPolyurea/polyurethane coatingsSpray coatingEngineering

The invention discloses a corrosion resistant spraying coating method for an outdoor cabinet base. The method comprises the steps that (1), sanding treatment is conducted on the outdoor cabinet base,and the outdoor cabinet base is soaked in an oil removing solution, washed clean by clear water and dried; (2), the dried outdoor cabinet base is placed into a phosphatizing tank to be soaked; (3), ahigh-temperature rubber belt is bonded to the outdoor cabinet base obtained in step (2), and the outdoor cabinet base is hung; (4), zinc-enriched powder coat is sprayed onto the outdoor cabinet base by adopting a friction gun or a conventional electrostatic gun, and the outdoor cabinet base is put into a convection oven to be cured for the first time after the inspection is qualified; (5), outdoorpowder is sprayed within 48 h after primer is semi-cured or gelatinized; the outdoor cabinet base is put into a curing furnace to be cured again after the inspection is qualified; (6), the outdoor cabinet body is taken down after the temperature of the surface of the outdoor cabinet base is lower than 45 DEG C, and the corrosion resistant outdoor cabinet base is obtained after the inspection is qualified. The method has the advantages that the base of the outdoor cabinet can be effectively protected to achieve the purposes of rusting preventing, corrosion resisting and prolonging the servicelife, and the demand of the long term use of an outdoor cabinet in a severe environment is met.

Owner:DONGGUAN JIAFENG MECHANICAL EQUIP

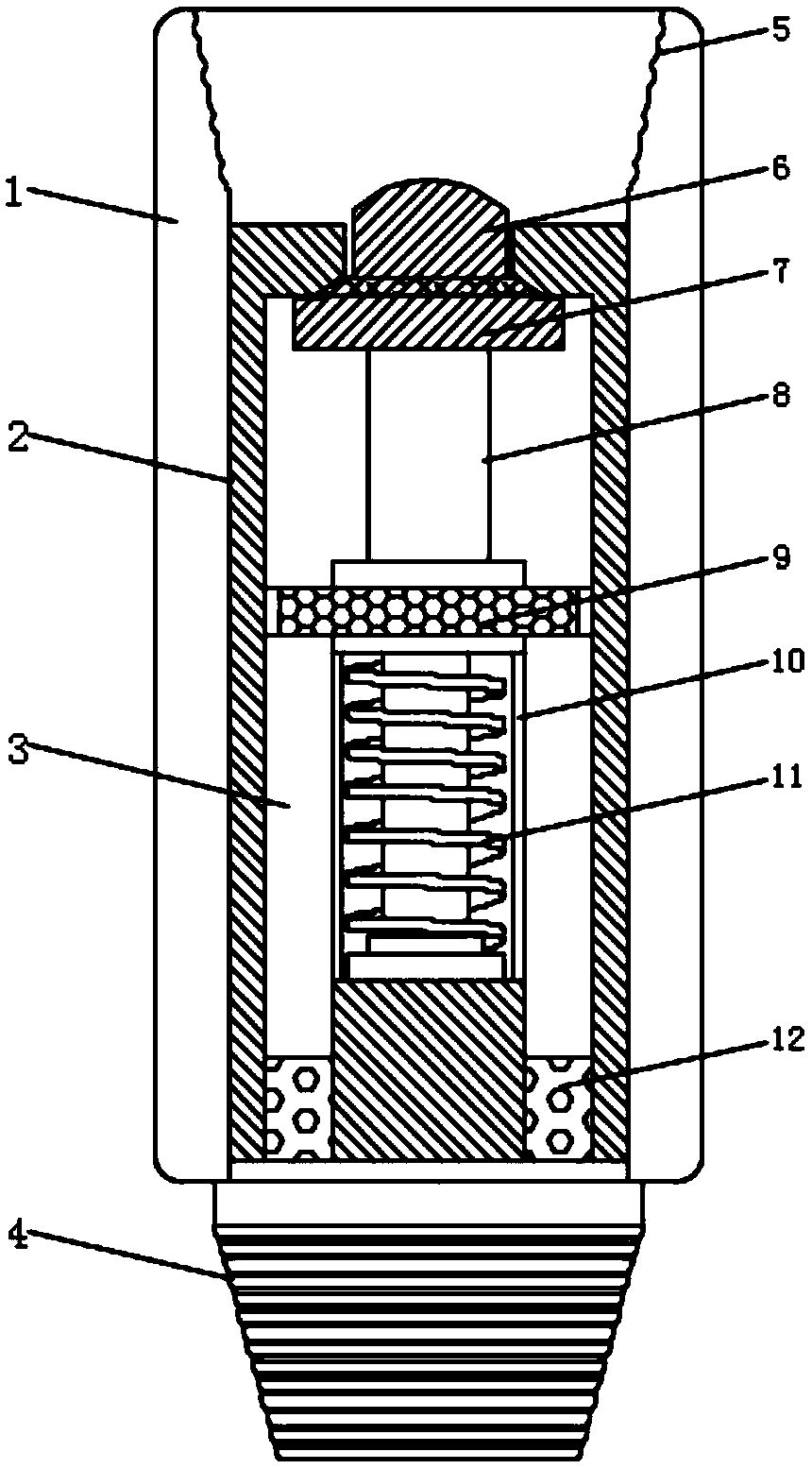

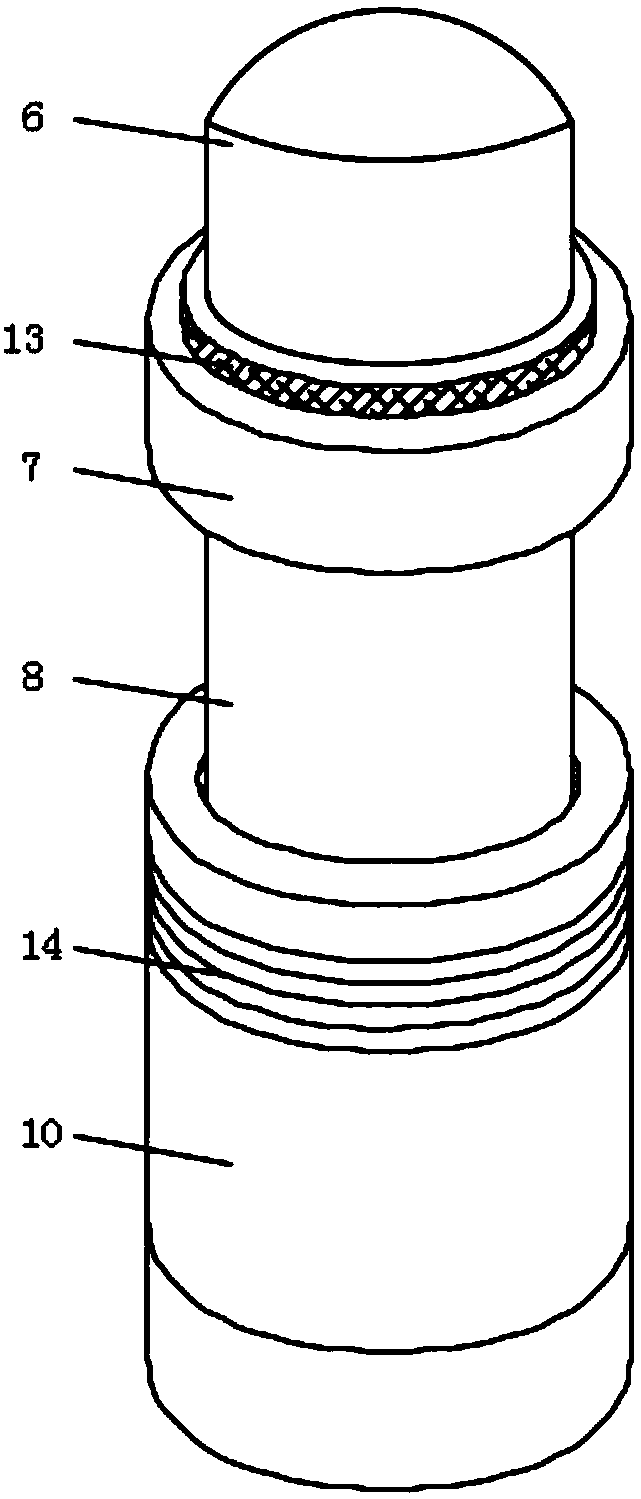

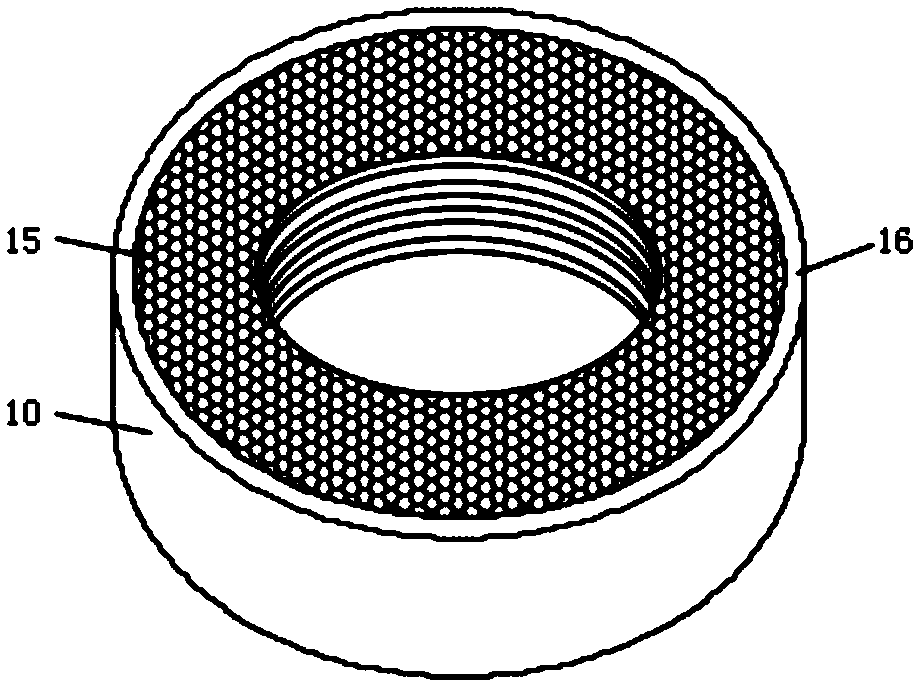

Drilling tool floating valve for well control device

The invention discloses a drilling tool floating valve for a well control device. The drilling tool floating valve for the well control device comprises a valve body and a valve core; a valve seat isfixed on the internal side of the valve body; and the valve core is mounted in the valve seat. According to the drilling tool floating valve for the well control device, as the valve seat and the valve core are arranged on the internal side of the floating valve, the valve core arranged in the valve seat consists of a piston head, a piston rod and a spring; and therefore, when a drilling fluid flows through the valve body, the spring arranged in the valve core retracts under a hydraulic effect to move a piston downwards, a sealing state of the valve seat and the piston head can be unlocked sothat a drilling fluid flows into a cavity of the valve seat, and the drilling fluid flows more smoothly via a hollowed-out structure circulation passage formed in the bottom of the valve seat; when the drilling fluid is stopped from being conveyed, the hydraulic pressure cannot impel the spring so that the spring returns to enable the piston head and the valve seat to be locked in a matched manner; as the spring is mounted in the valve core and isolated from outside, the spring can be protected against being eroded, and the service life of the valve body can be prolonged; and through adoptionof a piston type structure, the sensitivity of the floating valve is made higher.

Owner:黄涵青

Yacht marina structure

The invention discloses a yacht marina structure. The yacht marina structure comprises a trestle, fixed piles and a connection bearing beam; the fixed piles are connected with the connection bearing beam; the connection bearing beam is positioned above the underground parts of the lower parts of the fixed piles; the fixed piles and the trestle are connected with pile guides; the trestle is connected with a marina through a movable approach bridge; every four fixed piles form a ship mooring position; and the ship mooring positions can be manufactured in different sizes according to sizes of ships. The yacht marina structure fully uses the space, enhances the stability and the wind resistance, and prevents the ship sinking phenomenon.

Owner:苏州左右品牌管理有限公司

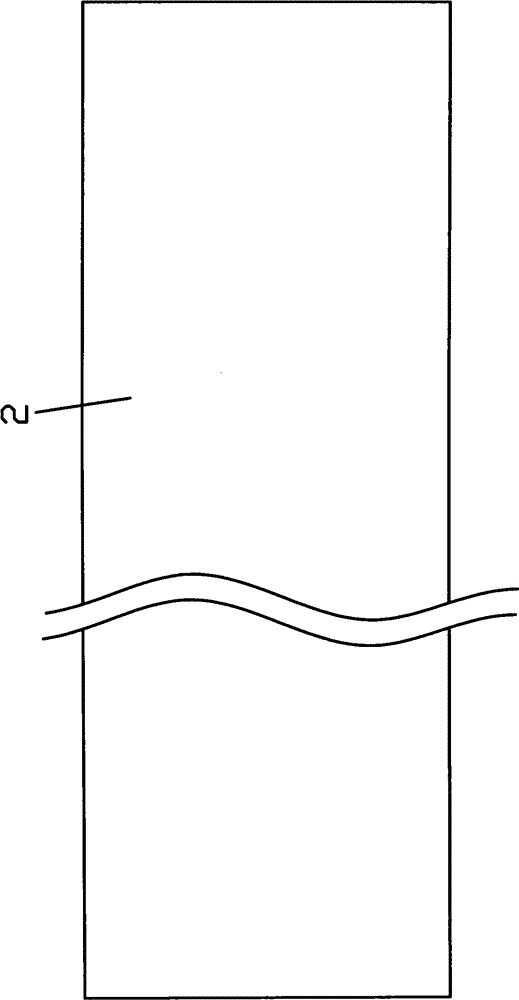

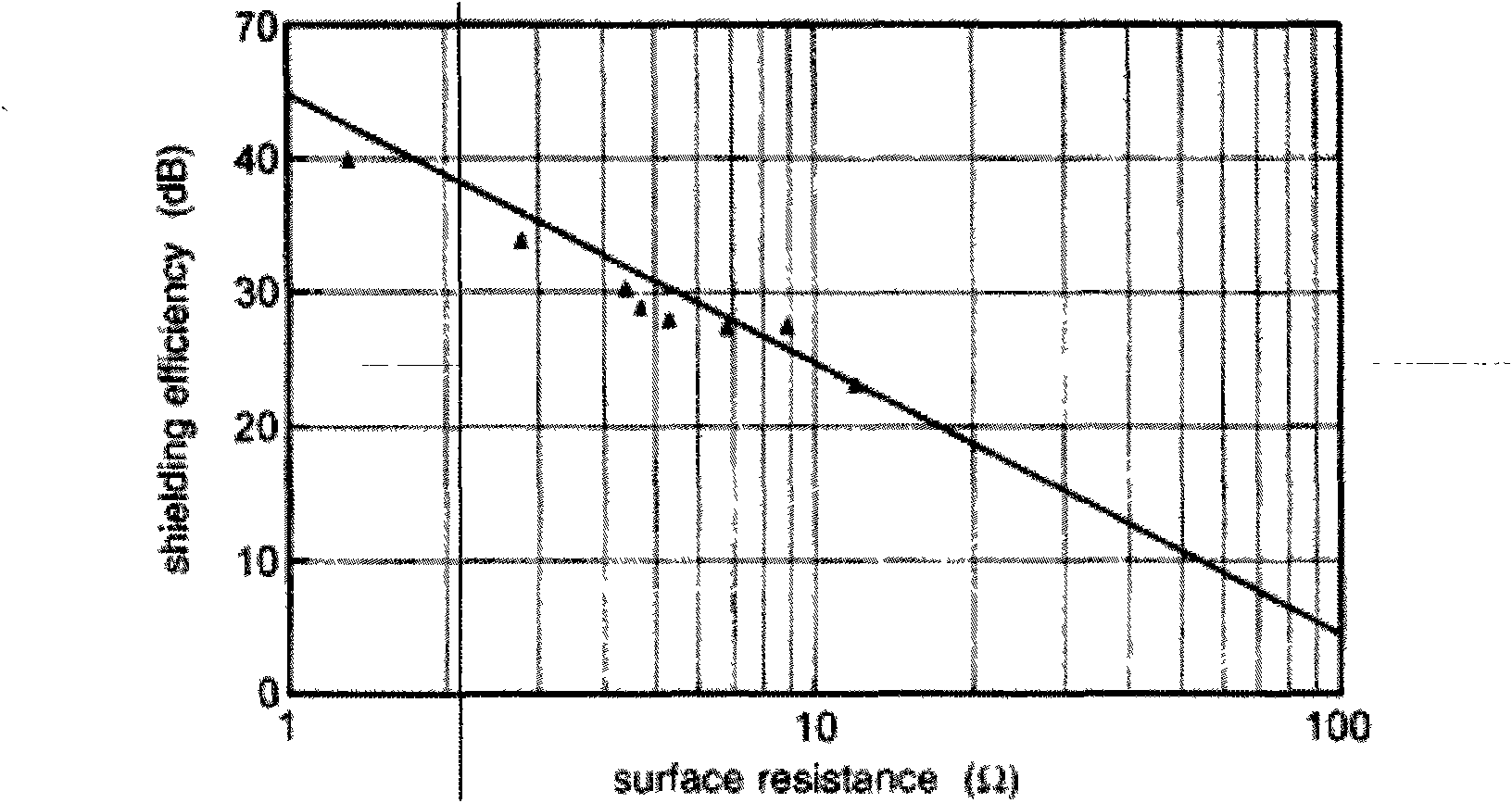

Low-resistance high-transmittance shielding film for plasma displays

InactiveCN101581810AFill in the gapsProtection from erosionSolid cathode detailsCold-cathode tubesSurface layerOptical transmittance

The invention relates to a low-resistance high-transmittance shielding film for plasma displays. The low-resistance high-transmittance shielding film comprises a bottom layer, a middle layer and a surface layer, wherein the bottom layer is a flexible organic substrate material layer (1); the middle layer is TiO2 layer (2), Ag layer (3) and TiO2 layer (2) which are repeatedly superimposed one by one for n times, wherein n is more than or equal to 3; the surface layer is an ITO layer (6); the layers are different in thickness; and honeycomb-like composite structure is adopted simultaneously between the layers. The film system structure can more conveniently realize film system matching, reduce resistivity and improve shielding effectiveness and light transmittance.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND +1

Asphalt mixing material performance enhancing agent and preparation method thereof

ActiveCN105440713AStrong anti-rutting abilityImproves rutting resistanceBuilding insulationsAsphaltMaterials science

The invention relates to an asphalt mixing material performance enhancing agent and a preparation method thereof, and belongs to the technical field of road materials. The asphalt mixing material performance enhancing agent is composed of rock asphalt and an extra additive. The mass ratio of the rock asphalt to the extra additive is larger than 9:1. The invention further provides the preparation method of the asphalt mixing material performance enhancing agent. The asphalt mixing material performance enhancing agent can be easily molten and distributed into an asphalt mixing material, the efficacy of improving performance of the asphalt mixing material can be brought into full play, the high-temperature stable performance is kept, and meanwhile the better water stability and low-temperature anti-cracking performance are achieved.

Owner:CHENGDU TELUDA TRANSPORTATION EQUIP CO LTD

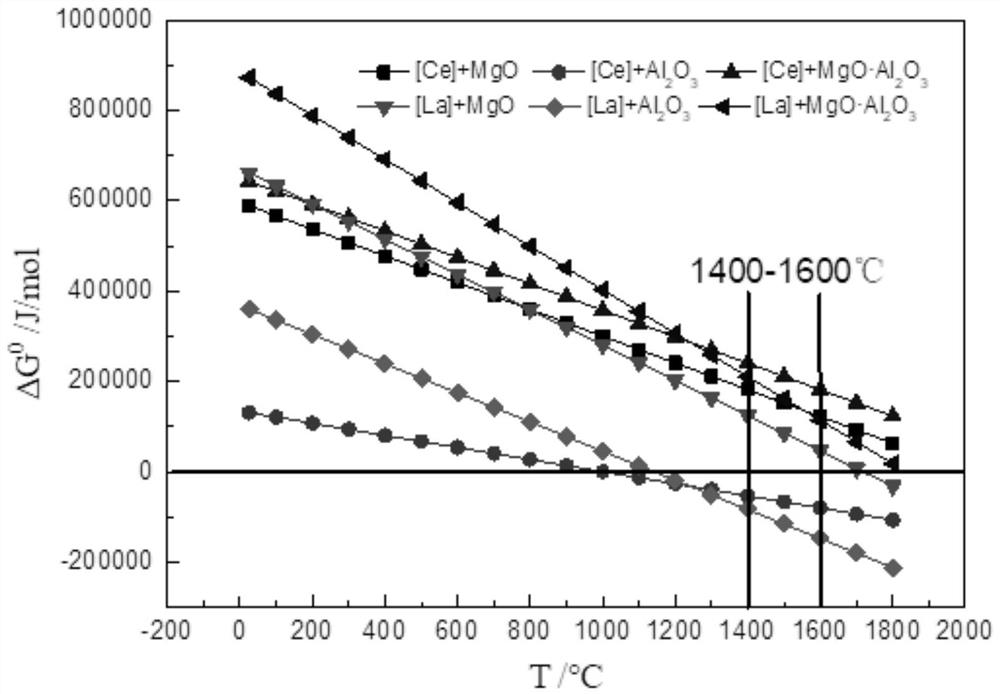

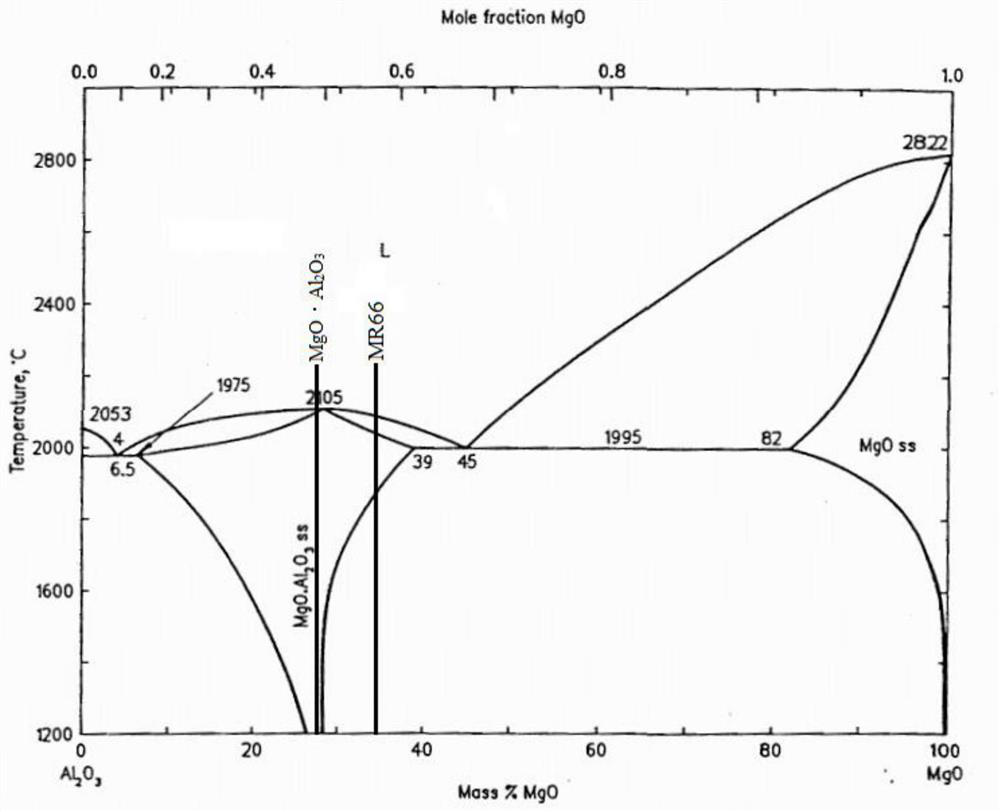

Nozzle coating for continuous casting of rare earth steel and preparation method of nozzle coating

ActiveCN114716850AReduce nodulationGuaranteed travelMelt-holding vesselsAnti-corrosive paintsContinuous castingAluminium

The invention discloses a nozzle coating for continuous casting of rare earth steel and a preparation method of the nozzle coating, belongs to the technical field of refractory materials, and solves the problem that a nozzle is nodulated and blocked in the current continuous casting process of the rare earth steel. The invention relates to a nozzle coating for continuous casting of rare earth steel, which comprises the following components: magnesium aluminum oxide and rare earth oxide, and the mass ratio of the magnesium aluminum oxide to the rare earth oxide is 83.3-94: 1.98-10; the magnesium-aluminum oxide is MgO.Al2O3 or takes MgO.Al2O3 as a main component, and contains a trace amount of MgO; the rare earth steel is steel containing rare earth cerium and / or lanthanum, and the type of the rare earth oxide is the same as that of rare earth in the rare earth steel. The nozzle coating can reduce nodulation of the submersed nozzle in the rare earth steel continuous casting process, so that the replacement frequency of the submersed nozzle is averagely reduced by more than 50%, and smooth operation of rare earth steel continuous casting is guaranteed.

Owner:CENT IRON & STEEL RES INST +1

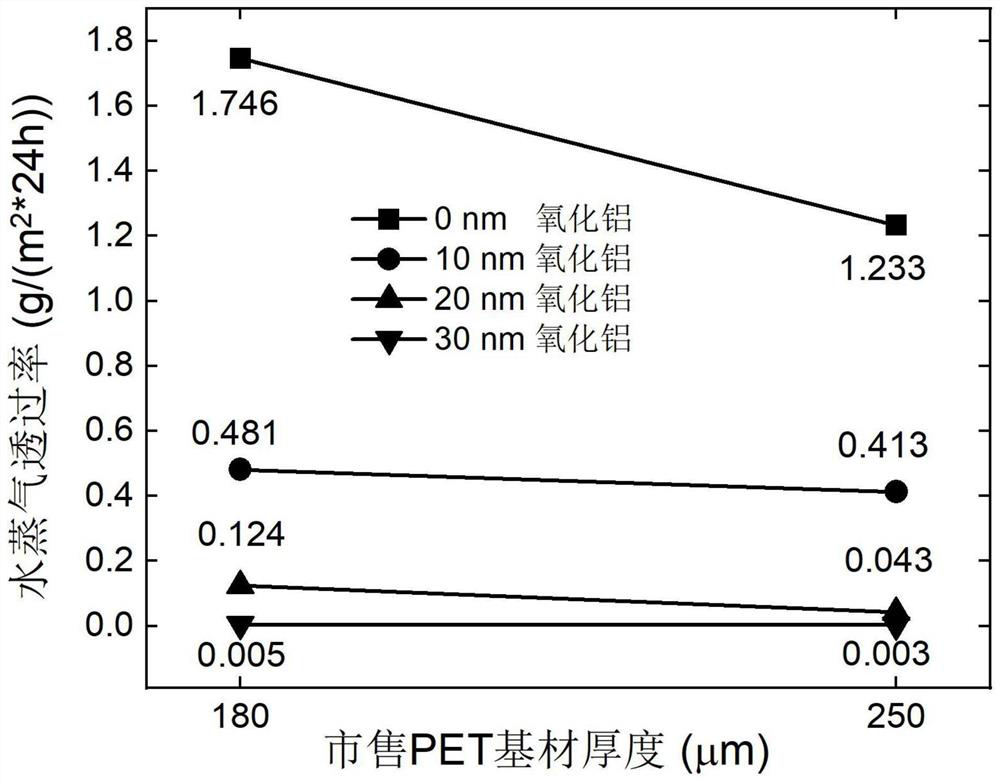

Method for enhancing water vapor barrier property of solar backboard

PendingCN113921631AImprove the protective effectBarrier ability contributes littleChemical vapor deposition coatingPhotovoltaic energy generationWater vaporFluorocarbon

The invention discloses a method for enhancing water vapor barrier property of a solar backboard, and the method comprises the following steps of: putting a material used by a supporting base material layer into atomic layer deposition equipment, and depositing an inorganic oxide on the supporting base material layer to obtain an inorganic oxide film upper layer, depositing an inorganic oxide below the supporting base material layer to obtain an inorganic oxide film lower layer, thus obtaining the solar backboard supporting base material with high water vapor barrier property; and then compounding one surface of the solar backboard supporting base material with the high water vapor barrier property with a weather-resistant fluorocarbon film layer material by using a binder to obtain the solar backboard with the high water vapor barrier property. With a commercially available conventional PET base material with the thickness of 180 microns as an example, the water vapor transmission rate of the PET base material is 1.746g / m<2>*24h, and after deposition of aluminum oxide films with the thickness of 30 nanometers on the two sides is carried out on the surface of the PET base material, the water vapor transmission rate of the obtained solar backboard is reduced to 0.005g / m<2>*24h.

Owner:SHANGHAI BONA ELECTRONICS TECH

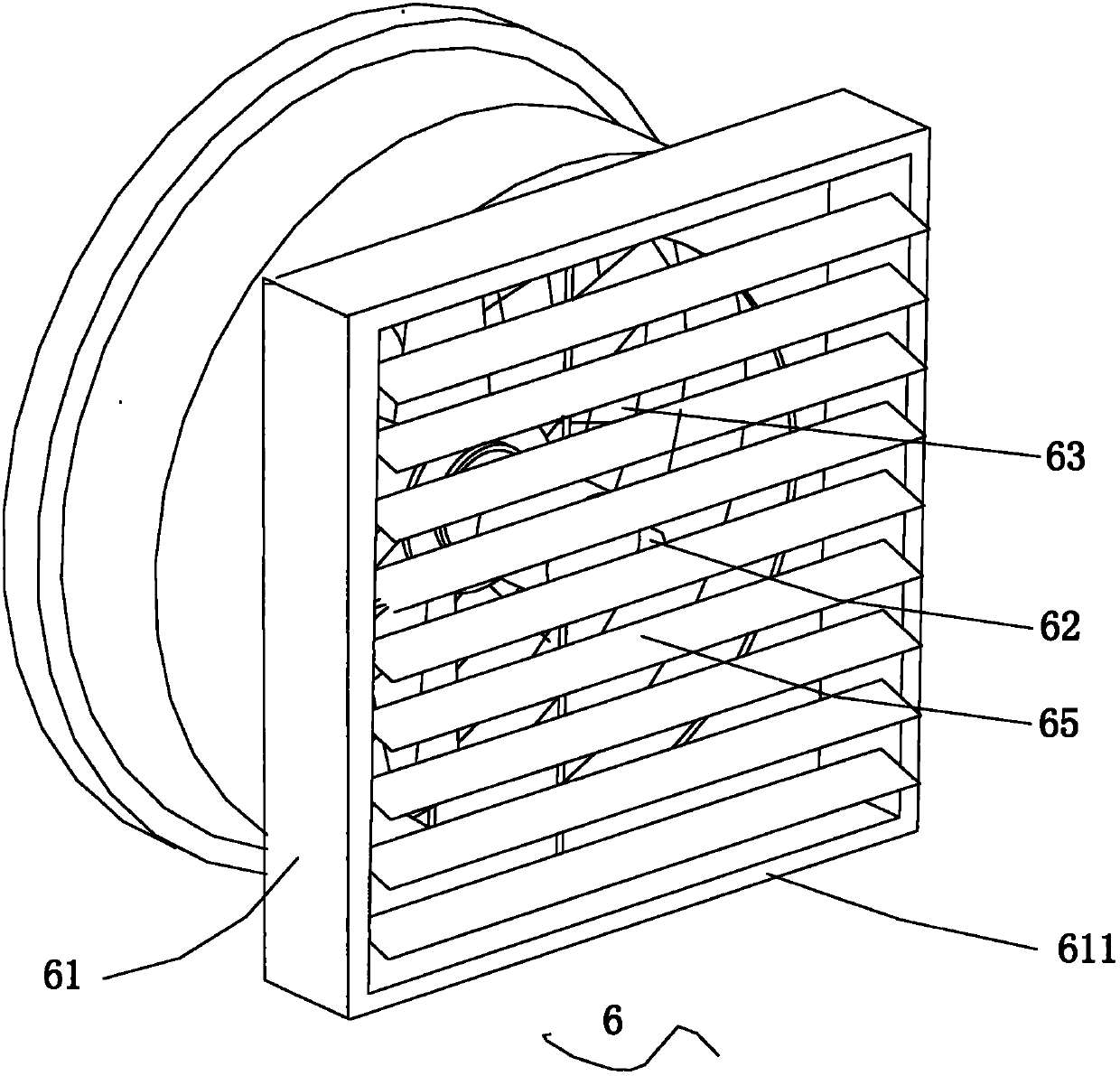

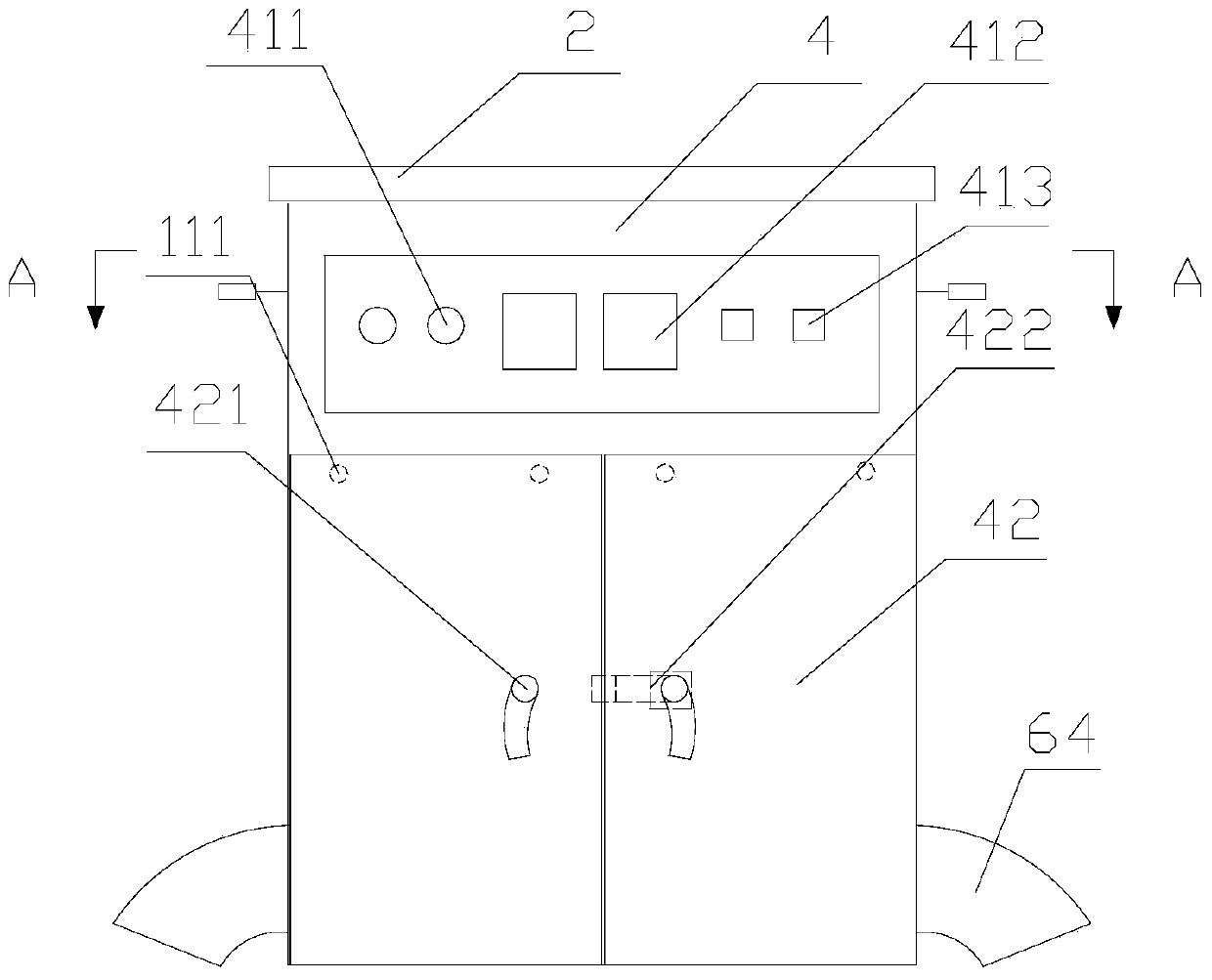

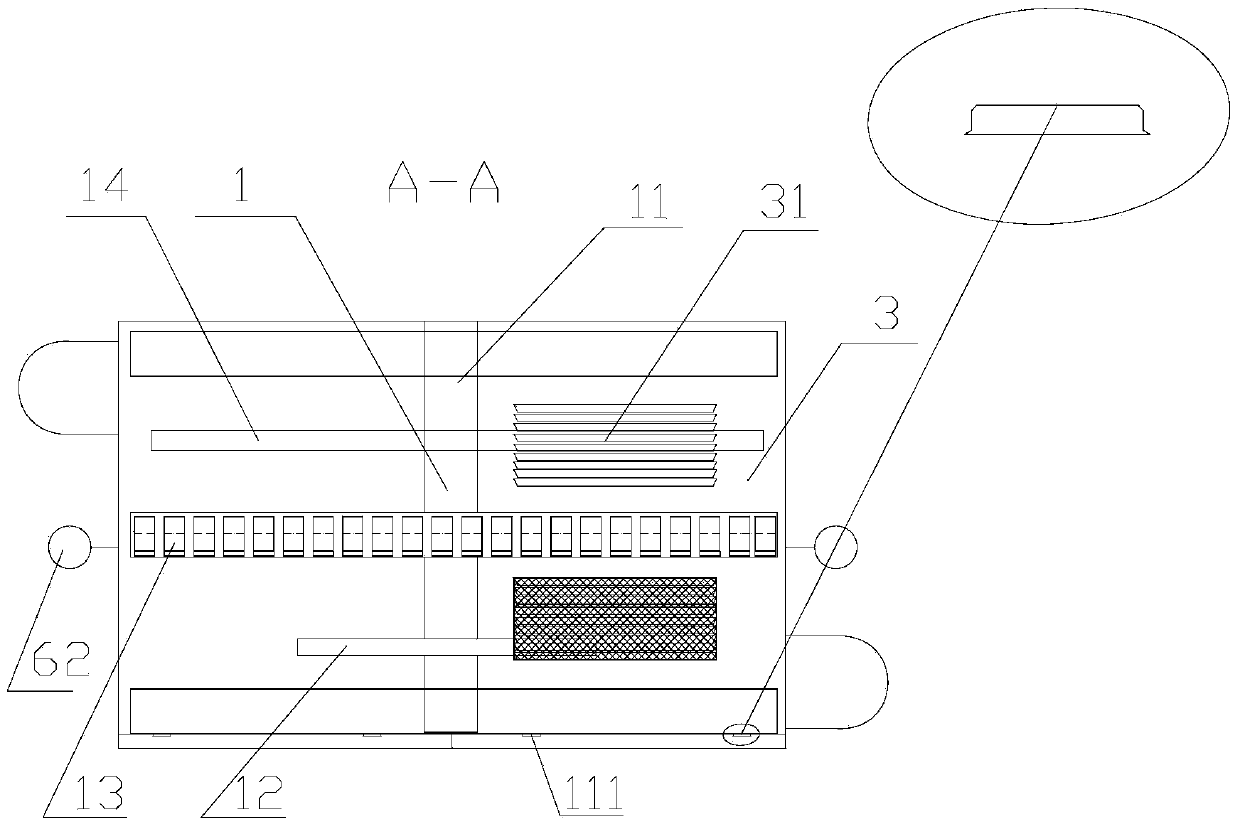

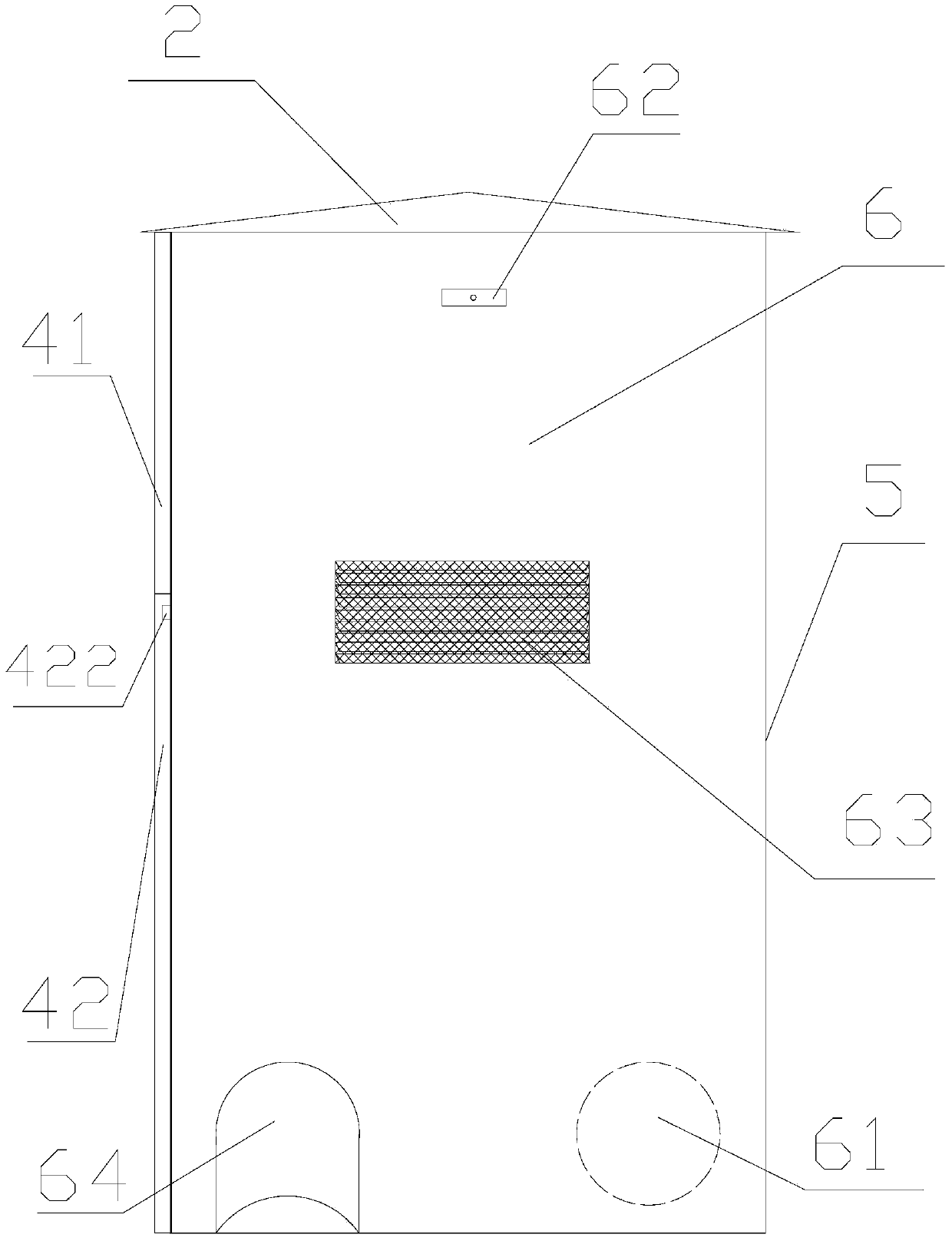

Public transformer cabinet

InactiveCN103746301AAvoid damagePrevent leakageSubstation/switching arrangement casingsEngineeringSurface plate

The invention relates to the public transformer field of a resident power supply protection type power distribution cabinet, in particular to a public transformer cabinet. The public transformer cabinet comprises a public transformer cabinet body, wherein the public transformer cabinet body (1) comprises a bracket (11); the bottom end of the public transformer cabinet body (1) is provided with a bottom plate (3) provided with a first cooling groove (31); the left side and the right side are respectively provided with a side panel (6) with a threading hole (61); and the front side is provided with one pair of cabinet body doors (42). The public transformer cabinet is characterized in that the threading holes (61) in the side panels (6) of the public transformer cabinet are provided with threading tube shields (64) of which the openings face downwards; the contact edge of the bracket (11) and the cabinet body doors (42) is provided with convex columns (111); the folding edges of the cabinet body doors (42) are provided with through holes; the convex columns (111) and the through holes are in interference fit; and the first cooling groove (31) and a second cooling groove (63) are provided with filter screens. According to the structure, the invention provides the public transformer cabinet which prevents electric leakage, rain and dust and causes the cabinet body doors to be more firmly locked.

Owner:XIANGSHAN YISHAN IND DESIGN

Long-life thermal insulation material and efficient submerged arc furnace

InactiveCN108709428AImproved resistance to twistingImprove sealingFurnace componentsBrickThermal insulation

The invention discloses a long-life thermal insulation material. The long-life thermal insulation material takes Al2O3-SiO2-series raw materials as composite main aggregates and takes raw materials such as alumina, flint clay, andalusite and kyanite as auxiliary materials, the linear change on reheating is 0.15%, and the thermal shock resistance is 70 times. According to a submerged arc furnace prepared from the material, lifting ring bases and sliding guide wheels are fixedly connected to a furnace door bottom plate, reinforcing rib plates are fixedly arranged on the furnace door bottom plate, a refractory brick is fixedly embedded between every two adjacent reinforcing rib plates, and connecting plug pins are inserted into the refractory bricks and the reinforcing rib plates in a penetrating mode; and each refractory brick is provided with a brick body inserting groove and a rib plate inserting groove and further provided with an inserting tenon groove and an inserting convex tenon,the inserting tenon grooves and the inserting convex tenons are located on the inserting faces close to the hot faces of the upper faces of the refractory bricks, and the inserting tenon grooves and the inserting convex tenons are located on the two corresponding opposite inserting faces. The furnace door structure is good in stability, the refractory bricks mesh with one another closely, and erosion and damage of high-temperature erosion gas on a furnace door body can be effectively prevented.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

Preparation method for rosin-copper composite wood preservative and application thereof

ActiveCN102069521AReduce churnExtended service lifeWood impregnation detailsPulp and paper industryWater soluble

The invention provides a preparation method for a rosin-copper composite wood preservative and an application thereof, which relates to the wood preservative and the application thereof. The invention aims to solve the problems that the loss resistance is poor and a number of adverse effects are generated on health of people and livestock and a people and livestock by taking copper salt as the wood preservative. The rosin-copper composite wood preservative comprises two parts: a disperse rosin sizing agent emulsion and water-soluble copper salt. The preparation method for the rosin-copper composite wood preservative comprises the following steps: (I) diluting the disperse rosin sizing agent emulsion by water to obtain a disperse rosin sizing agent emulsion solution; (II) dissolving the copper salt in the water to obtain a copper salt aqueous solution; and (III) compounding the disperse rosin sizing agent emulsion solution with the copper salt aqueous solution under the condition of keeping the temperature to be 5-50 DEG C and the pH value to be 4-10 to carry out full-cell process antiseptic treatment on wood. The decay weight loss rate of the rosin-copper composite wood preservative on Coriolus versicolor is 0.08-0.3 percent, and the decay weight loss ratio on wood sample Gloeophyllumtrabeum is 0.73-1.3 percent.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com