Aluminum-zinc-silicon epoxy composite powder anticorrosive coating and preparation method thereof

A composite powder and anti-corrosion coating technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., to achieve the effect of solving self-corrosion current, increasing corrosion resistance types, and reducing specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

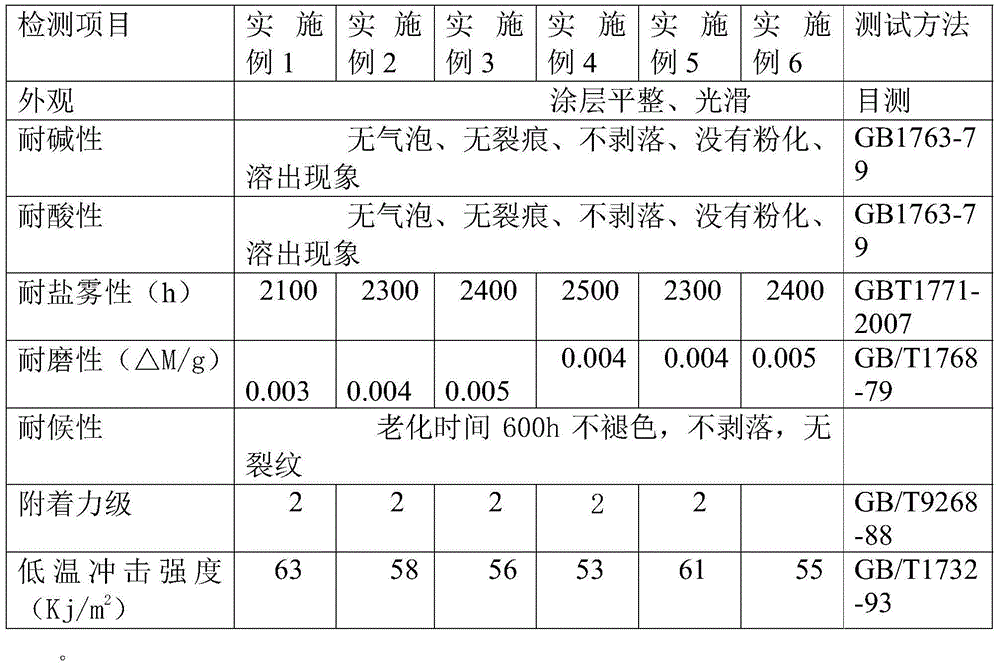

Examples

Embodiment 1

[0026] An aluminum-zinc-silicon epoxy composite powder anticorrosion coating is composed of the following raw materials in parts by weight:

[0027] 50 parts of E-12 type epoxy resin (epoxy equivalent 800), 30 parts of aluminum-zinc-silicon alloy powder (Al: 45%, Si: 3%, Re: 0.02%, Mg: 0.1%, X: 0.6%, Zn : balance), 3 parts of nano-montmorillonite, 1 part of vinyltrimethoxysilane, 1 part of water glass, 1 part of dimethylimidazole, 3 parts of polyvinyl butyral, 1 part of hydrogenated castor oil, pigments and fillers 10 servings.

[0028] The above-mentioned pigments and fillers are composed of the following raw materials in parts by weight:

[0029] 3 parts of talcum powder, 4 parts of calcium carbonate, 1 part of titanium dioxide, 1 part of quartz powder, and 1 part of zinc phosphate.

[0030] The preparation method of the above-mentioned aluminum-zinc-silicon epoxy composite powder anti-corrosion coating is as follows: after fully mixing aluminum-zinc-silicon alloy powder, ...

Embodiment 2

[0032] An aluminum-zinc-silicon epoxy composite powder anticorrosion coating is composed of the following raw materials in parts by weight:

[0033] E-12 type epoxy resin 55 parts (epoxy equivalent 600), aluminum zinc silicon alloy powder 25 parts (Al: 69%, Si: 0.2%, Re: 0.9%, Mg: 0.55%, X: 1.2%, Zn : balance), 3 parts of nano-zinc oxide, 2 parts of aminopropyltriethoxysilane, 1 part of sodium hexametaphosphate, 1 part of dicyandiamide, 2 parts of polyolefin elastomer, 1 part of cellulose acetate, pigment Filling 10 parts.

[0034] The above-mentioned pigments and fillers are composed of the following raw materials in parts by weight:

[0035] 3 parts of talcum powder, 4 parts of calcium carbonate, 1 part of titanium dioxide, 1 part of quartz powder, and 1 part of zinc phosphate.

[0036] The preparation method of the above-mentioned aluminum-zinc-silicon epoxy composite powder anticorrosion coating is as follows: after fully mixing aluminum-zinc-silicon alloy powder, nano-z...

Embodiment 3

[0038] An aluminum-zinc-silicon epoxy composite powder anticorrosion coating is composed of the following raw materials in parts by weight:

[0039] 55 parts of E-12 type epoxy resin (epoxy equivalent 800), 20 parts of aluminum-zinc-silicon alloy powder (Al: 50%, Si: 1.5%, Re: 0.4%, Mg: 0.3%, X: 0.9%, Zn : balance), 4 parts of nano aluminum oxide, 1 part of styryl trimethoxysilane, 1 part of triethylhexyl phosphoric acid, 1 part of phenolic resin, 2 parts of polybutylene succinate, 1 part of polyacrylate parts, 15 parts of pigments and fillers.

[0040] The above-mentioned pigments and fillers are composed of the following raw materials in parts by weight:

[0041] 5 parts of talcum powder, 5 parts of calcium carbonate, 2 parts of titanium dioxide, 1.5 parts of quartz powder, and 1.5 parts of zinc phosphate.

[0042]The preparation method of the above-mentioned aluminum-zinc-silicon epoxy composite powder anticorrosion coating is: after fully mixing aluminum-zinc-silicon all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com