Method for enhancing water vapor barrier property of solar backboard

A water vapor barrier, solar back sheet technology, applied in electrical components, gaseous chemical plating, coatings, etc., can solve the problems of polluted environment, cell oxidation, high water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

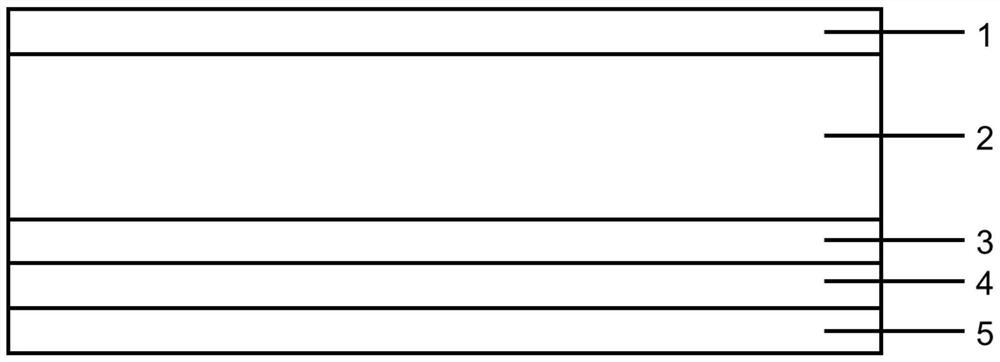

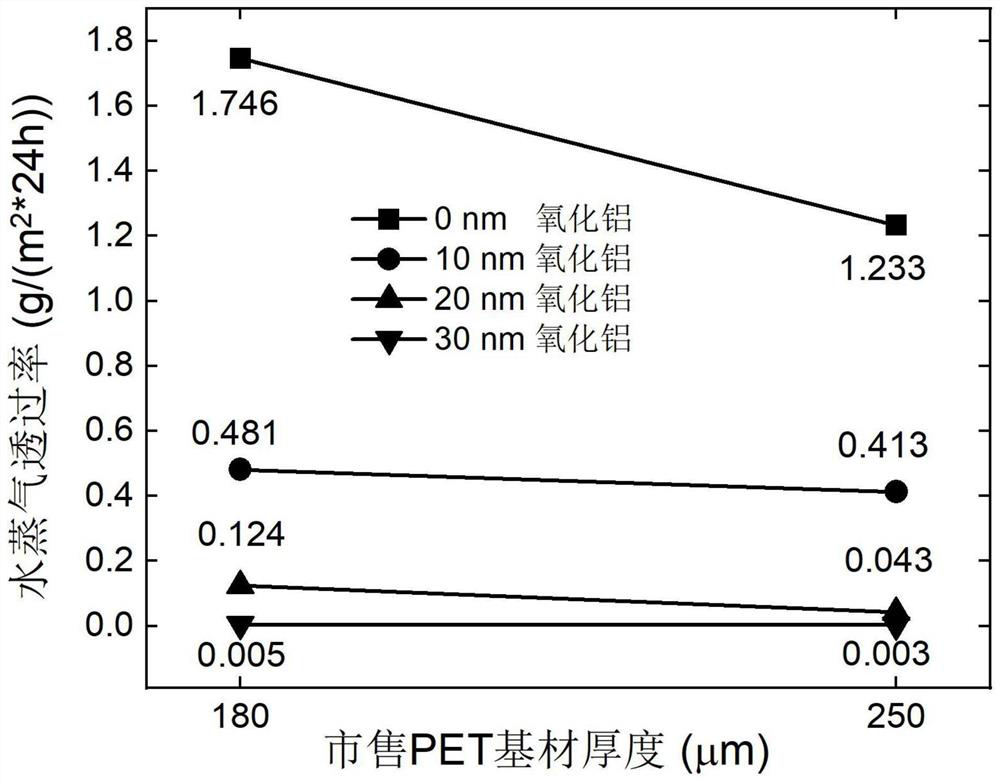

[0037] A method for enhancing the water vapor barrier of a solar backsheet, comprising the steps of:

[0038] In the first step, put the 180 micron thick PET substrate into the T-ALD deposition equipment. For the deposition of the inorganic aluminum oxide water blocking film, trimethylaluminum is used as the source of aluminum precursor, and deionized water is used as the oxidizing precursor source, the precursor source was kept at 25°C. Set the heating temperature of the deposition chamber to 120 °C. The flow rate of argon carrier gas is set to 200 standard liters per minute (sccm) when carrying the precursor source into the chamber.

[0039] In the second step, after cleaning the surface of the PET substrate, fix it on the fixture and put it into the chamber, vacuumize and wait for the temperature to stabilize to the set chamber temperature.

[0040] In the third step, aluminum oxide films with a thickness of 30 nanometers are deposited on both sides, and the reaction is s...

Embodiment 2

[0045] A method for enhancing the water vapor barrier of a solar backsheet, comprising the steps of:

[0046] In the first step, put the 250 micron thick PET substrate into the T-ALD deposition equipment. For the deposition of inorganic aluminum oxide water blocking film, trimethylaluminum is used as the source of aluminum precursor, and deionized water is used as the oxidizing precursor Body source and precursor body source are kept at 25°C. Set the heating temperature of the deposition chamber to 120 °C. The flow rate of argon carrier gas is set to 200 standard liters per minute (sccm) when carrying the precursor source into the chamber.

[0047] In the second step, after cleaning the surface of the PET substrate, fix it on the fixture and put it into the chamber, vacuumize and wait for the temperature to stabilize to the set chamber temperature.

[0048] In the third step, aluminum oxide films with a thickness of 20 nanometers are deposited on both sides, and the reaction...

Embodiment 3

[0053] A method for enhancing the water vapor barrier of a solar backsheet, comprising the steps of:

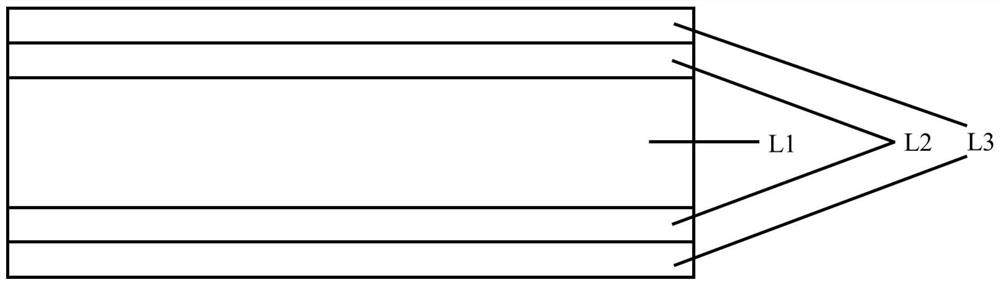

[0054] In the first step, put the 180 micron thick PET substrate into the T-ALD deposition equipment. For the deposition of inorganic aluminum oxide and titanium oxide laminated water-blocking films, trimethylaluminum is used as the source of aluminum precursors, tetrachloride Titanium is used as the source of the titanium precursor, deionized water is used as the source of the oxidizing precursor, and the source of the precursor is kept at 25°C. Set the heating temperature of the deposition chamber to 120 °C. The flow rate of the selected argon carrier gas when carrying the precursor source into the chamber is set to be 200 standard liters per minute (sccm).

[0055] In the second step, after cleaning the surface of the PET substrate, fix it on the fixture and put it into the chamber, vacuumize and wait for the temperature to stabilize to the set chamber temperature.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com