Steel fiber composite bar (SFCB) and engineered cementitious composite (ECC)-concrete composite column/ pier and preparation method thereof

A continuous fiber and concrete technology, applied in columns, bridges, piers and other directions, can solve the problems of insufficient structural durability, easy rust, bearing capacity degradation, etc., to achieve slow strength decline, strong corrosion resistance, improved bearing capacity and The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

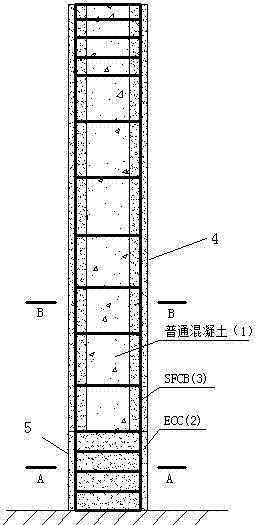

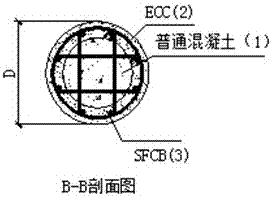

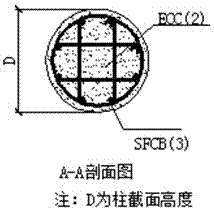

[0031]In the present invention, the steel-continuous fiber composite bar ECC-concrete composite column / pier includes ordinary concrete (1), engineering cement-based composite material ECC (2), and SFCB (3), wherein the SFCB is arranged on the engineering cement-based composite Material ECC layer, ECC column. In addition, other reinforcements should be properly arranged in the column according to the actual situation of the load borne by the structure.

[0032] The present invention will be described in detail below in conjunction with specific embodiments.

[0033] The weight ratio of each component of the cement-based composite material ECC for engineering is: cement: silica fume: fly ash: water: quartz sand: water reducer = (0.25~0.35): (0.12~0.15): (0~0.35) :(0.15~0.20):(0.2~0.3): (0.002~0.012). The fiber is polyethylene (PE) fiber, the volume content is 2.0%, the cement is P.O.42.5 cement, and the quartz sand is 100-200 mesh quartz sand.

[0034] The preparation method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com