Patents

Literature

52results about How to "No technical barriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

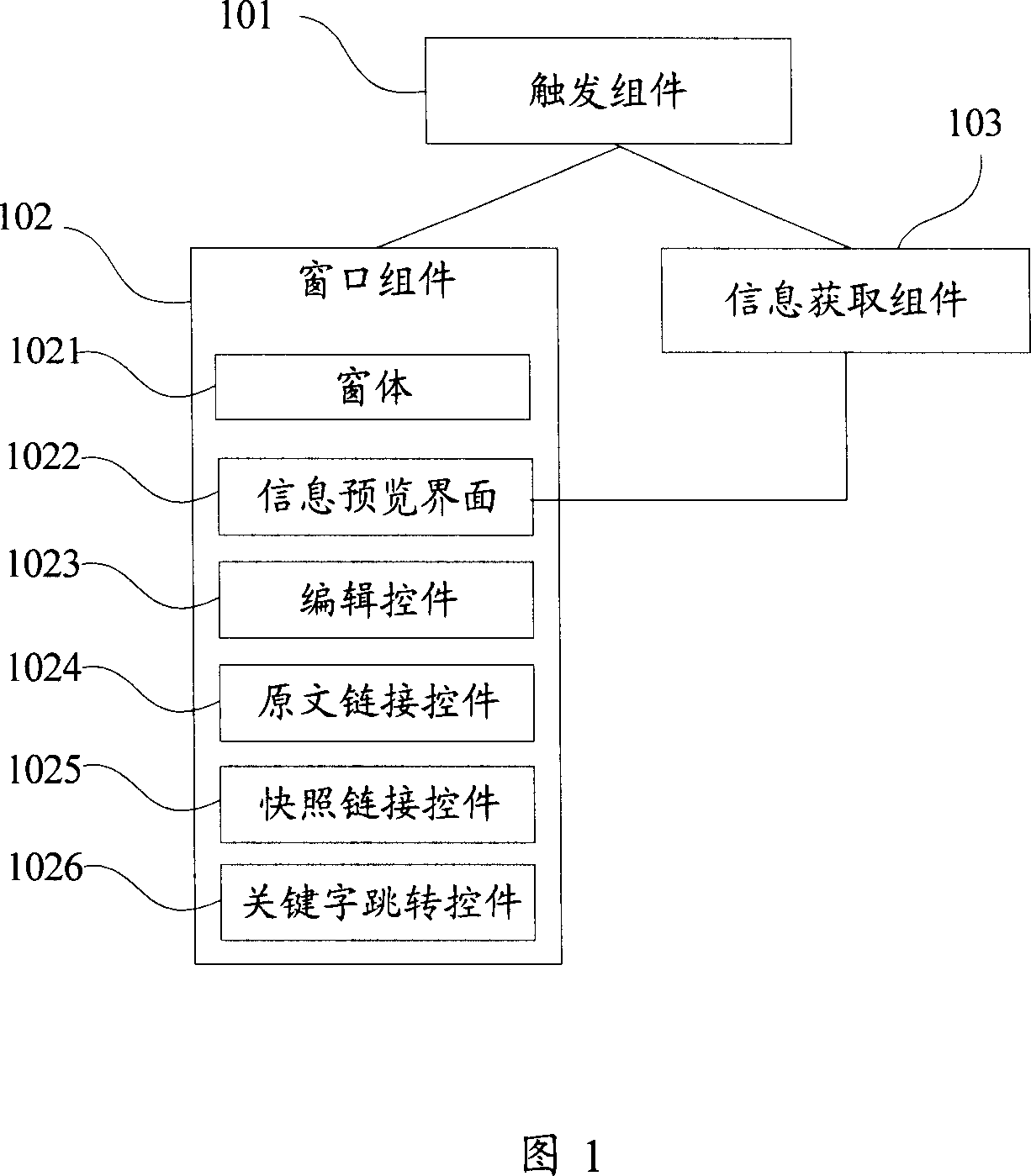

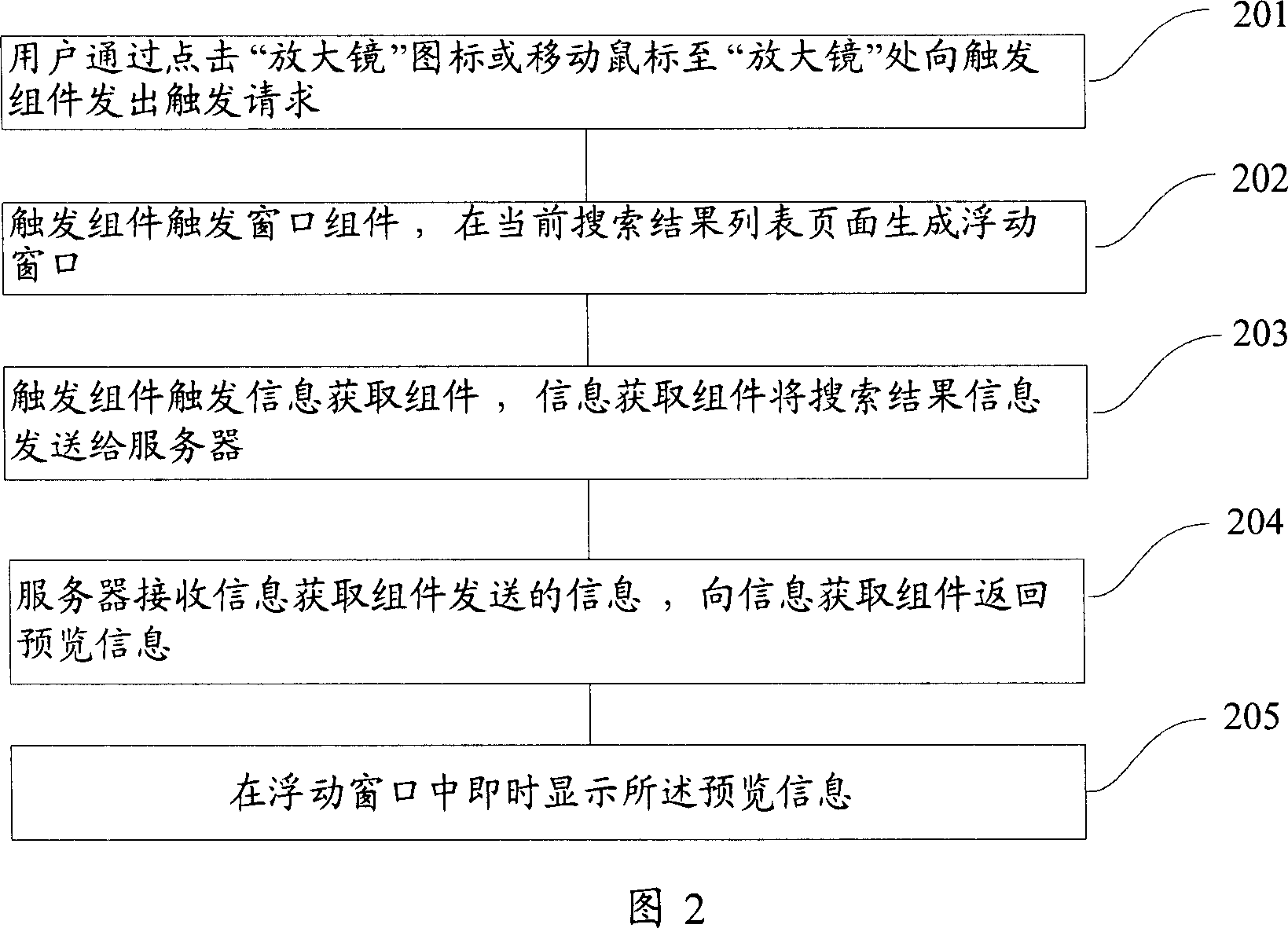

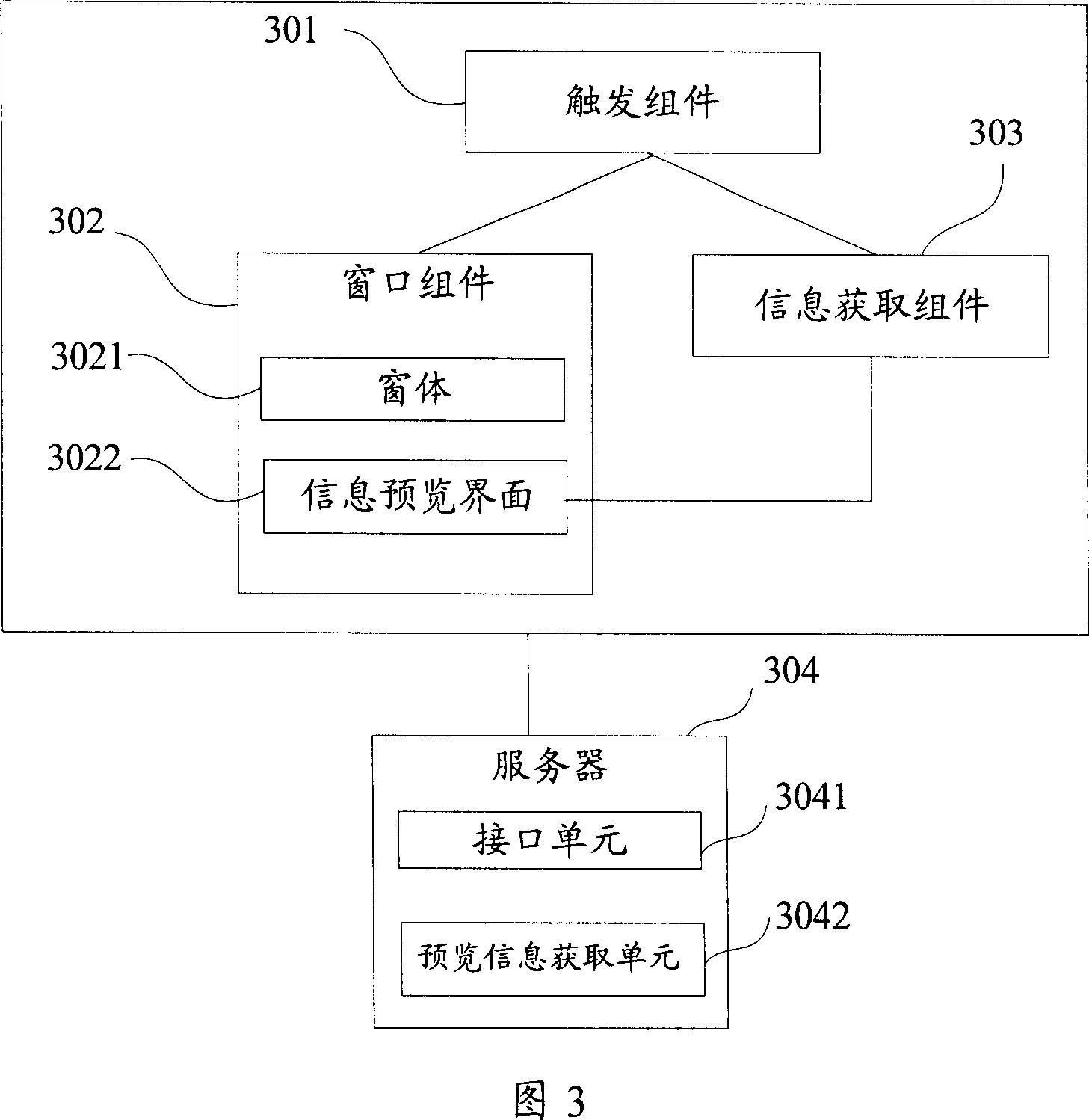

Search engine based search result fast pre-reading device

ActiveCN1924860AMeet the purpose of the queryConvenient text manipulationSpecial data processing applicationsService provisionResult list

This invention relates to search rapid previewing device, which is characterized by the following: trigger set to receive user requirement for window set and information acquirement set; window set to promptly display information on the current result list page to get the preview information including window and information preview page; the said window is to determine window display size, shape and position; the said page is to display preview information of the set; information acquiring set to connect servo research results and to display information to the page.

Owner:网易有道信息技术(北京)有限公司

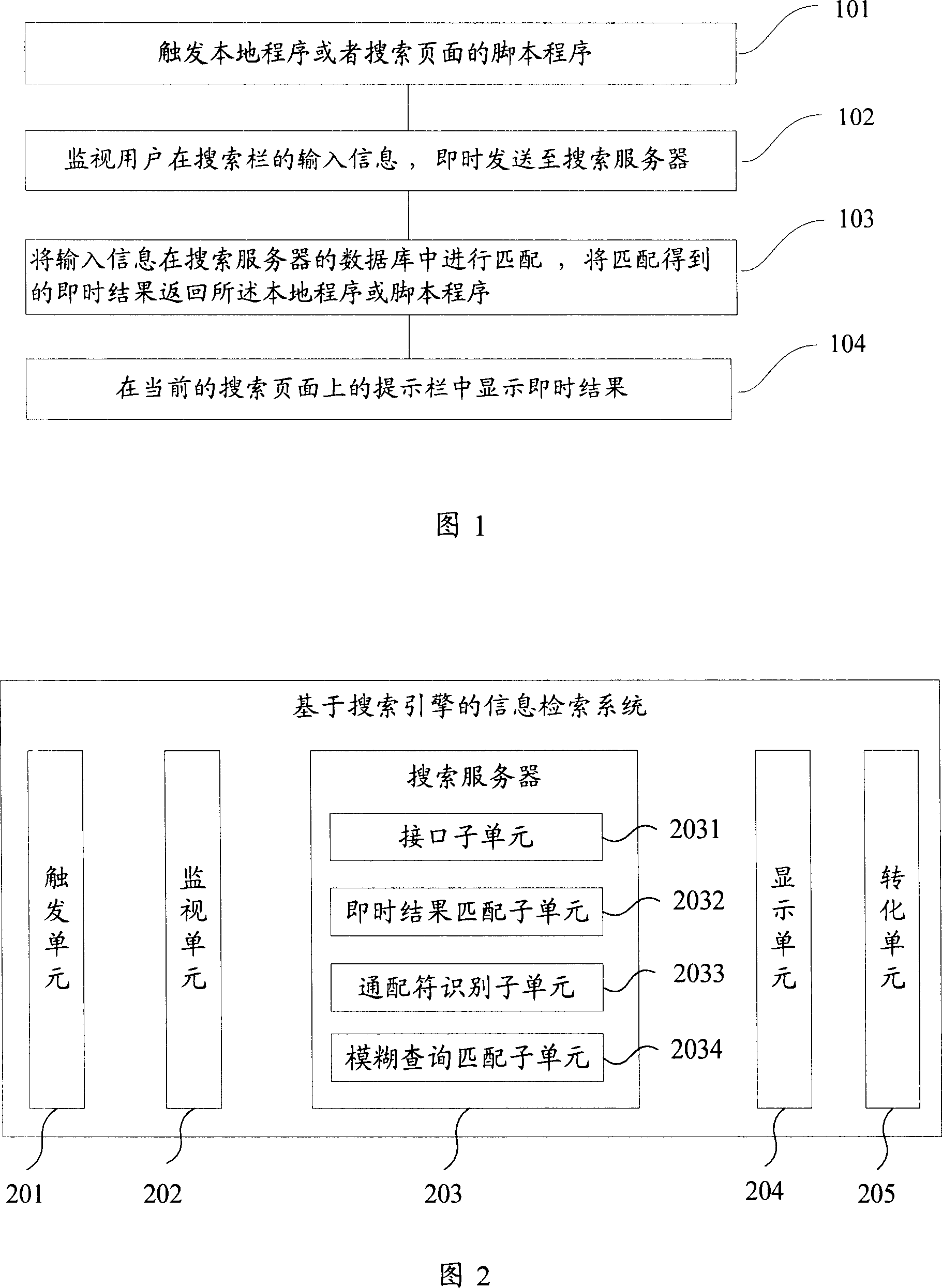

Information searching method and system based on searching engine

ActiveCN1936896AImprove query efficiencyEasy to operateSpecial data processing applicationsFuzzy queryInformation searching

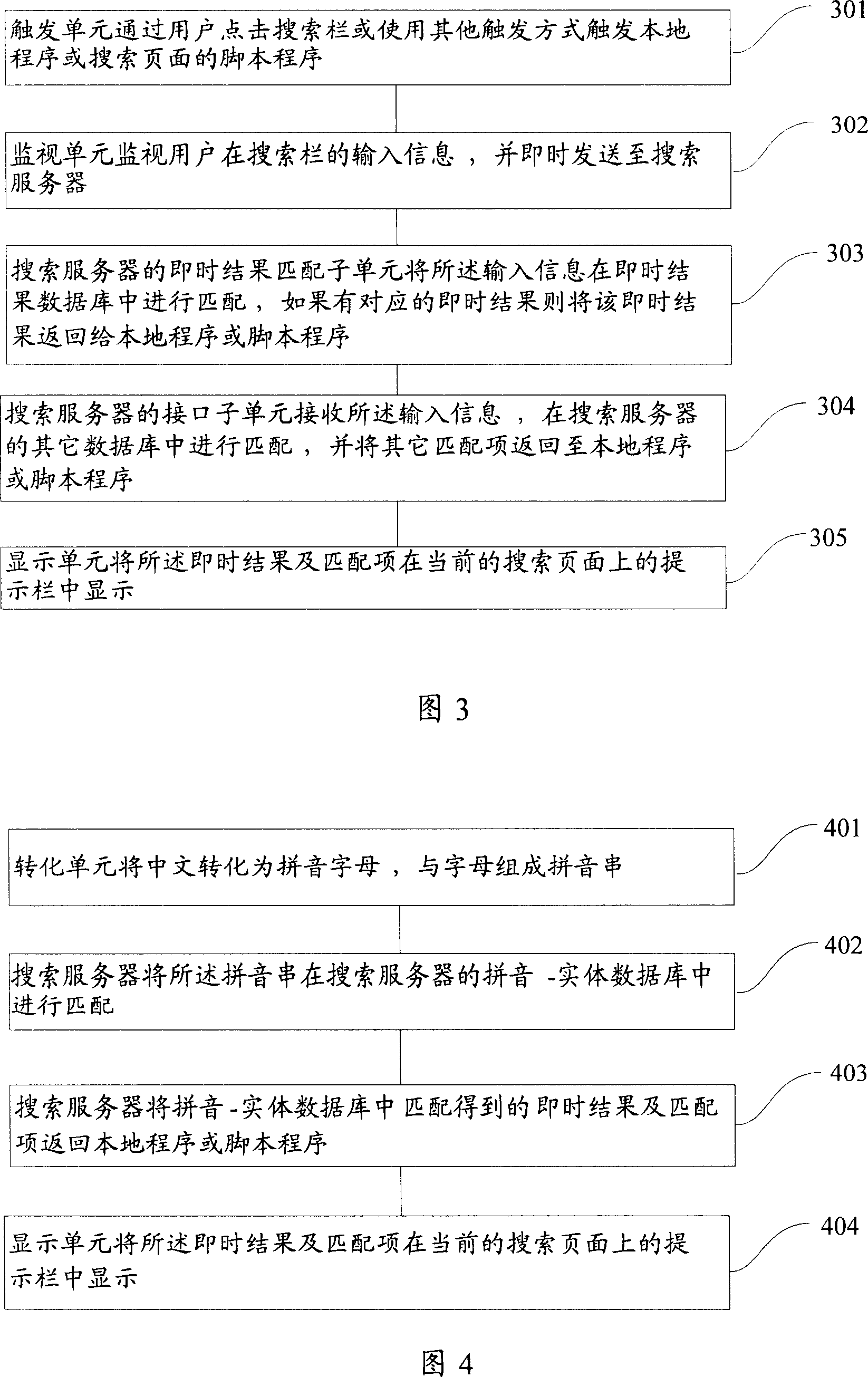

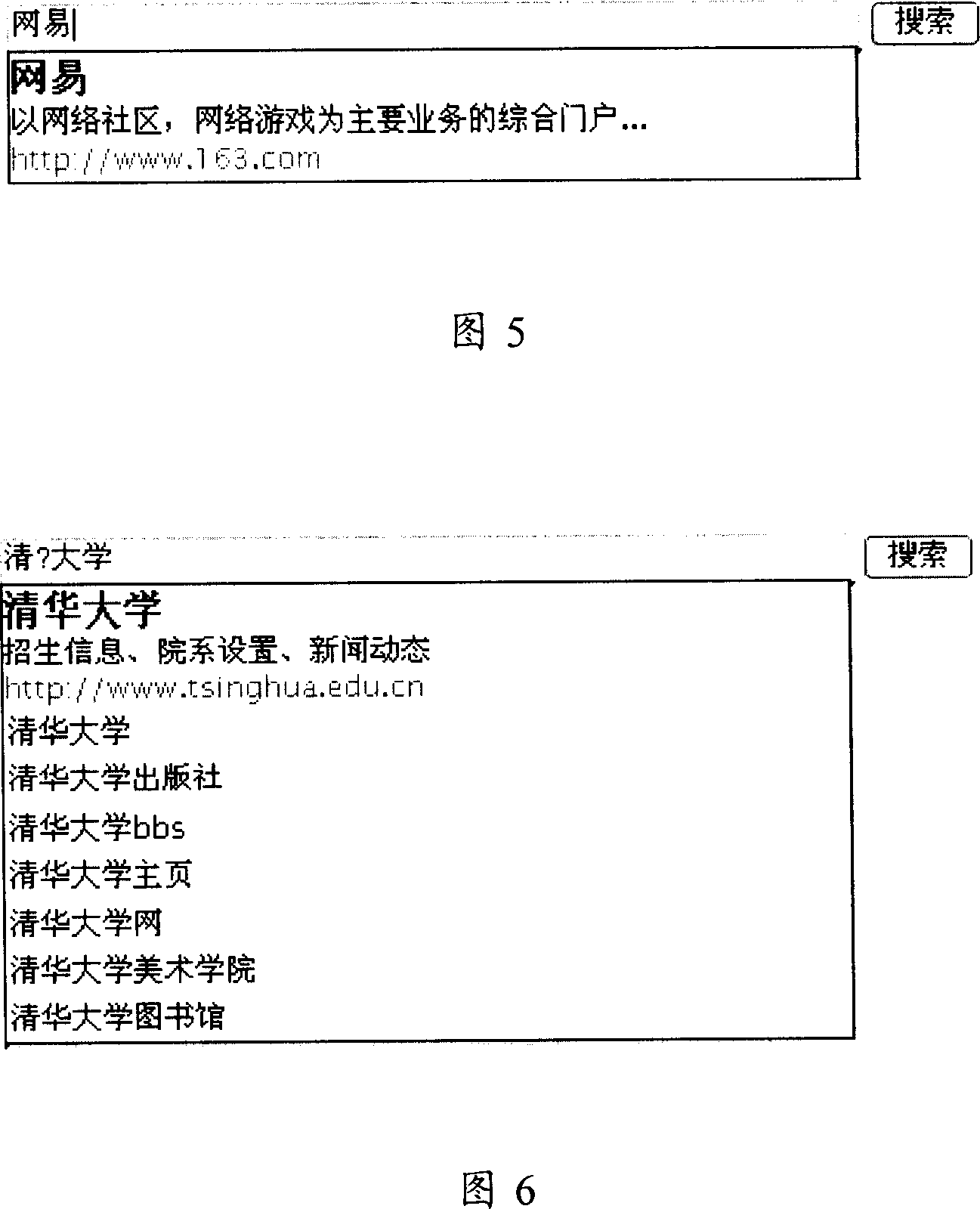

Character of the method includes following points: triggering local program or script program of searching web pages; monitoring information on search bar inputted by user, and sending the information to the search server instantly; carrying out match between the said input information and database of the search server, and returning the matched instant result back to the local program or script program; displaying the instant result on hint bar of the current search page. Using search steps for query determined through comparing simplified results, the invention increases searching speed, and makes more intuitive operations for users. Introducing fuzzy query technique and each prompting message, the invention can carry out search even user is unable to input query completely so as to help user to do query and operation further. The invention is applicable to computers, handsets and information household electric appliances. Features are: low cost and no special secret algorithm.

Owner:网易有道信息技术(北京)有限公司

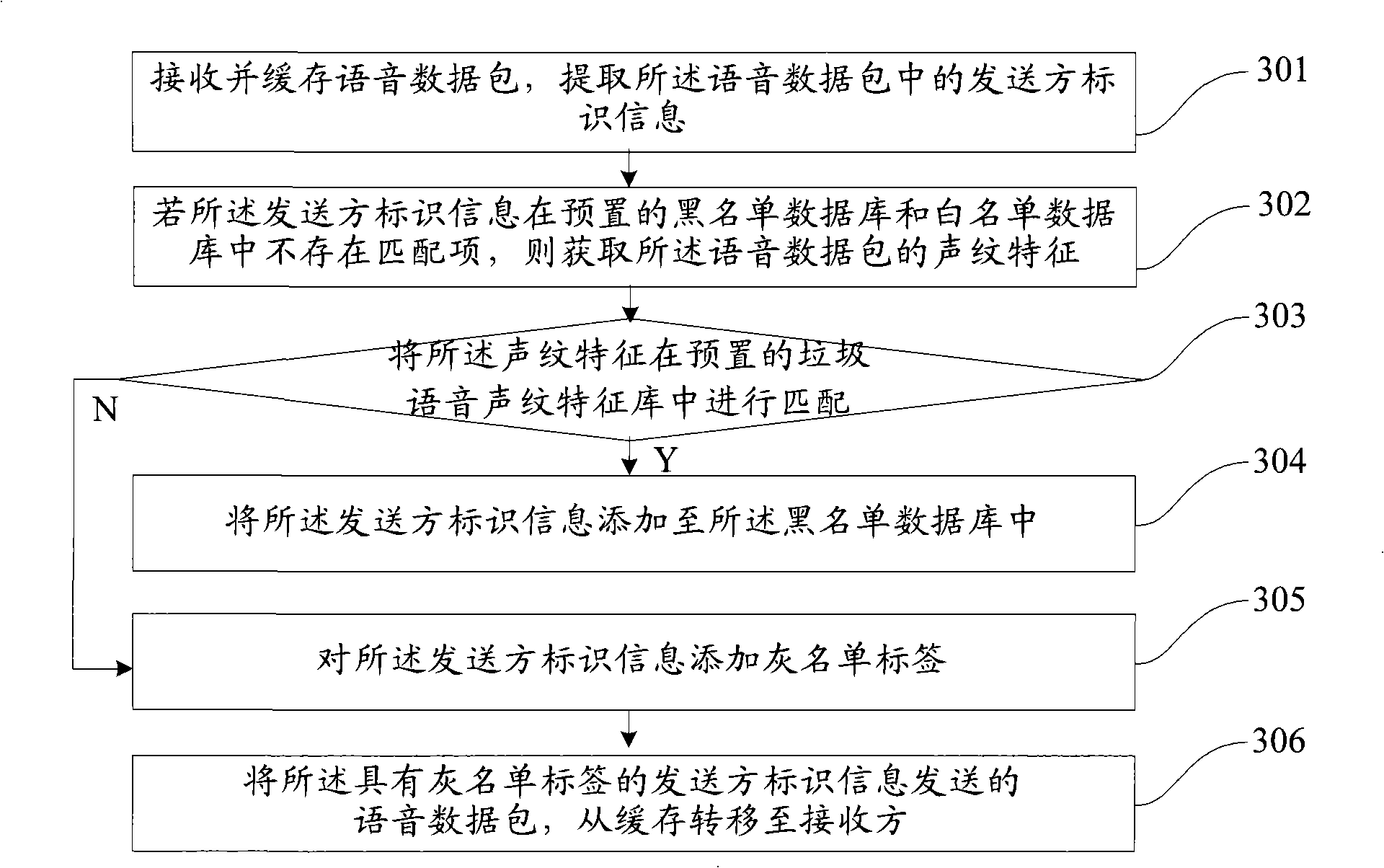

Rubbish voice filtration method and system

InactiveCN101262524AImprove recognition rateAvoid complexityInterconnection arrangementsAutomatic exchangesNetwork packetFiltration

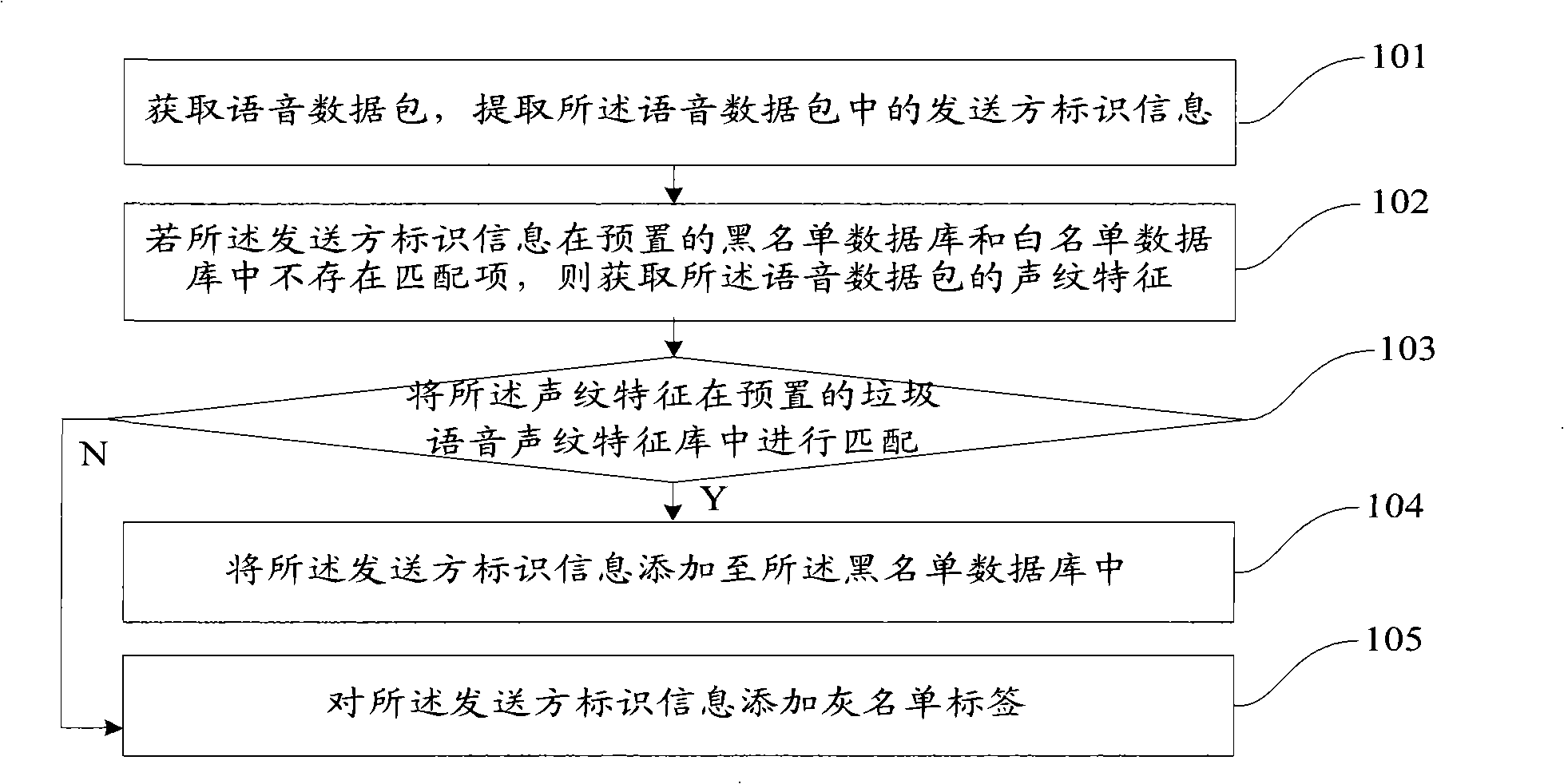

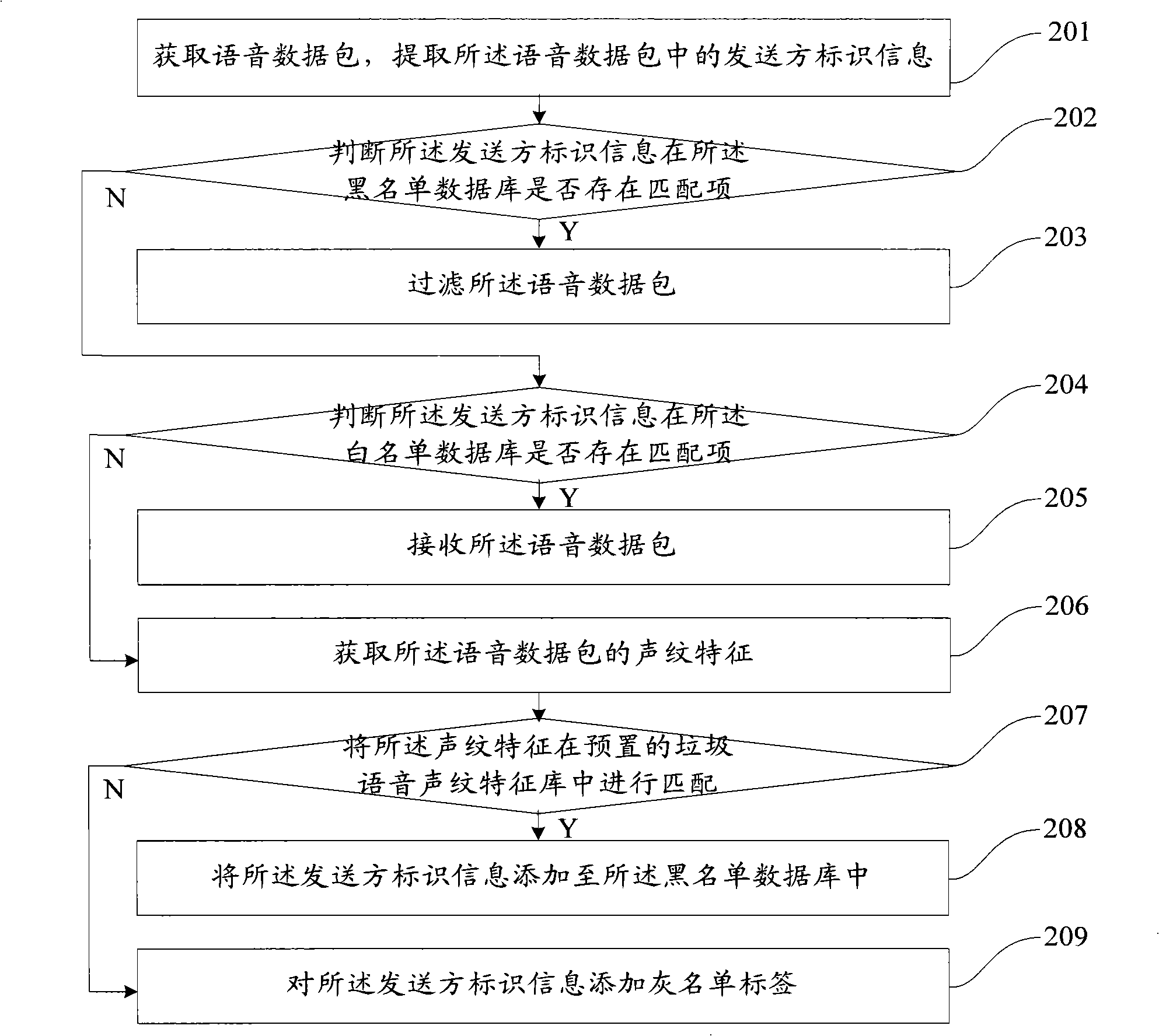

The invention discloses a filter method of rubbish voice, which comprises the following steps: audio data packet is acquired and the identification information of senders in the audio data packet is extracted; if no matching item for the identification information of the senders is found in a presetting black list data base or a white list data base, voiceprint feature of the audio data packet is acquired; if a matching item for the voiceprint feature is found in a presetting rubbish voiceprint data base, the identification information of the senders is added to the black list data base; otherwise, a gray list label is added to the identification information of the senders. The method of the invention can filter the rubbish voices in a simple, timely and accurate manner, effectively avoid attacks of the first call of the users not in the black or the white list and improve the security of applying the business of SIP protocol.

Owner:NEUSOFT CORP

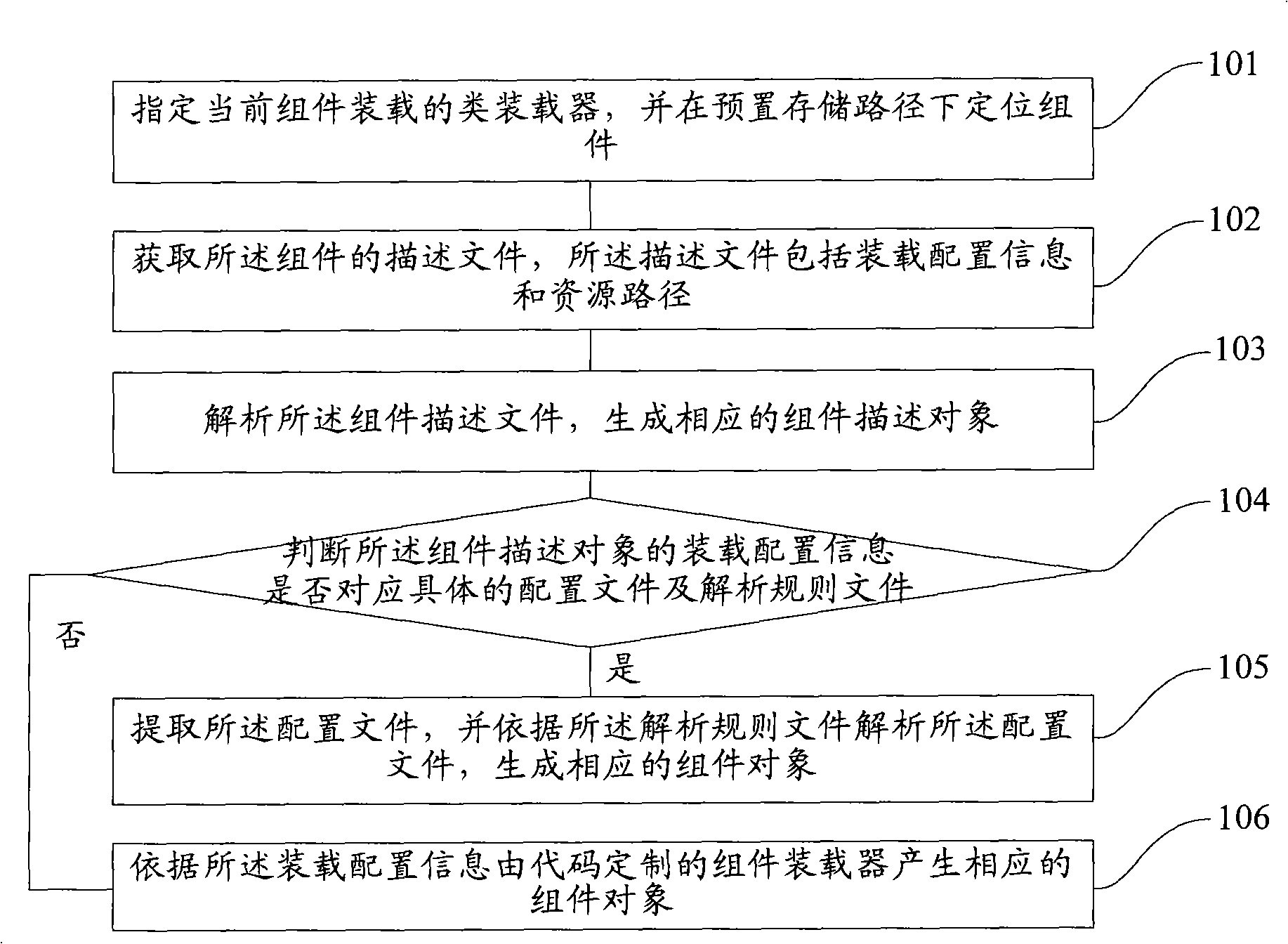

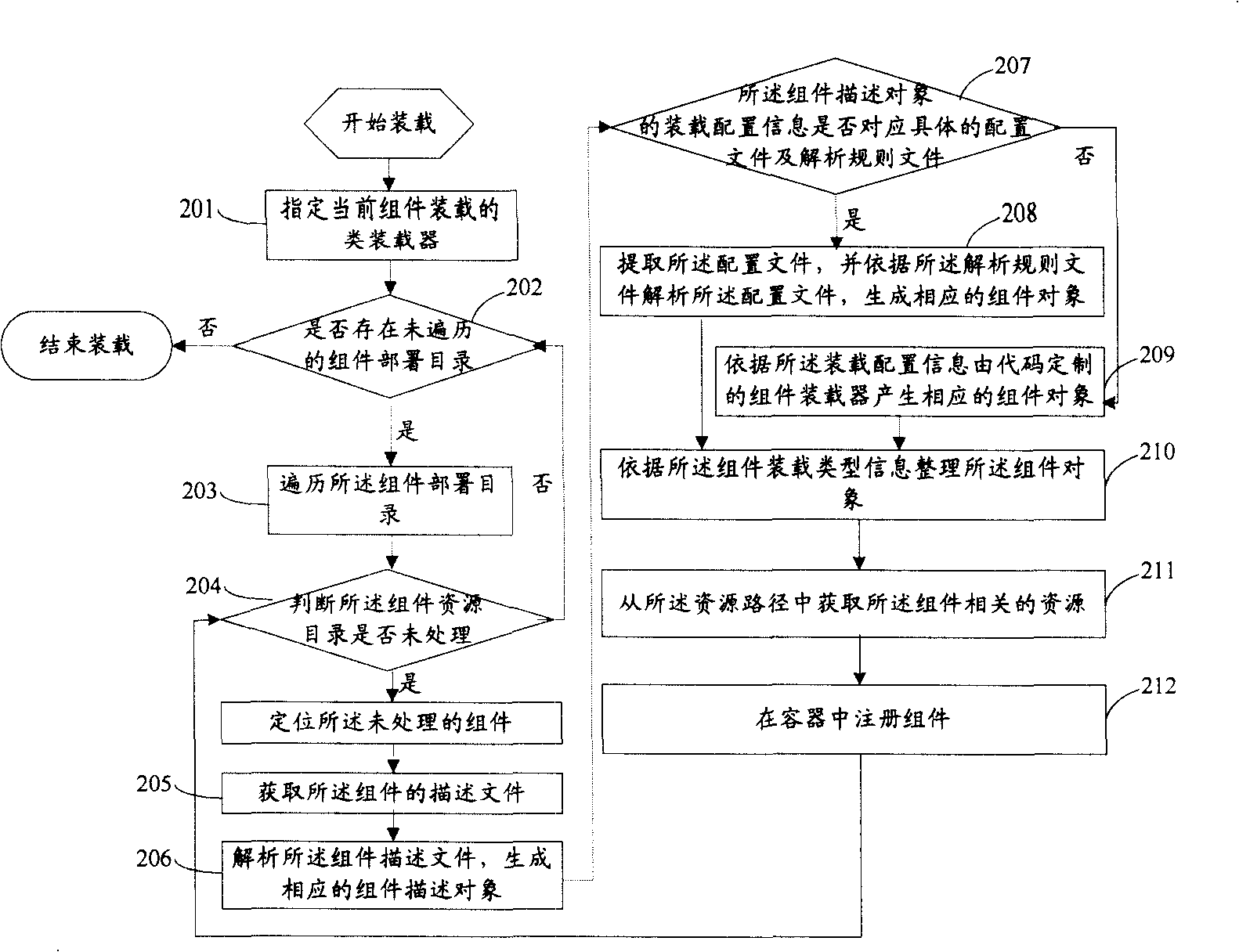

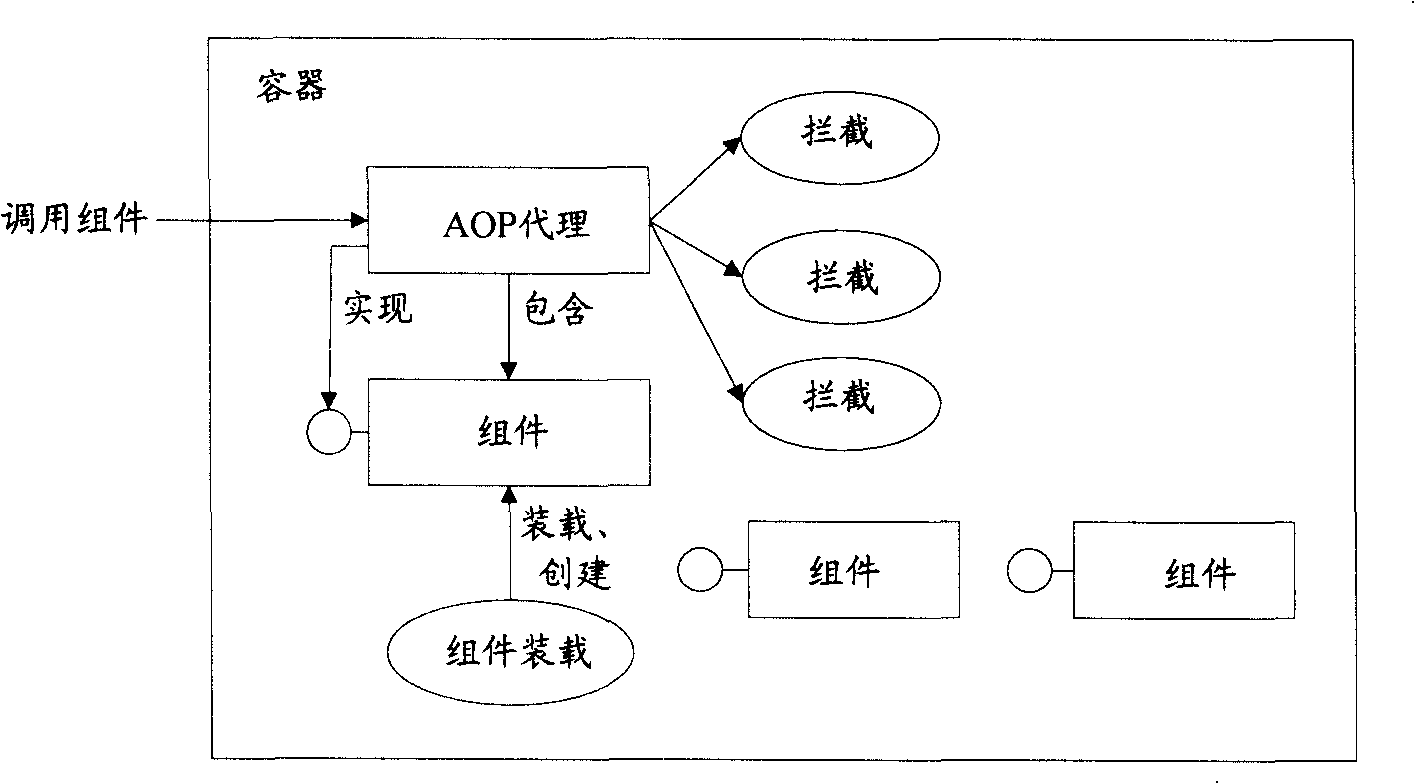

Method and device for loading component in container

ActiveCN101266542AImprove acceleration performanceIncrease flexibilitySpecific program execution arrangementsExtensibilityObject based

The invention provides a method to load module in a vessel, including: assigning a class loader loading the current module, and locating the module under an initialization store path; gaining the description document of the module, wherein, the description document includes the loading disposition information; analyzing the description document of the module, producing a corresponding module description object; judging whether the loading disposition information of the module description object corresponds to a concrete disposition file and an analysis rule document or not, if yes, then the disposition file is withdrawn, analyzes the disposition file based on the analysis rule document, and produces the corresponding module object; if not, a module loader customized by codes produces the corresponding module object based on the loading disposition information. The invention may effectively enhance the extendibility and the flexibility of the vessel under the premise of saving system resources.

Owner:CHINA CONSTRUCTION BANK

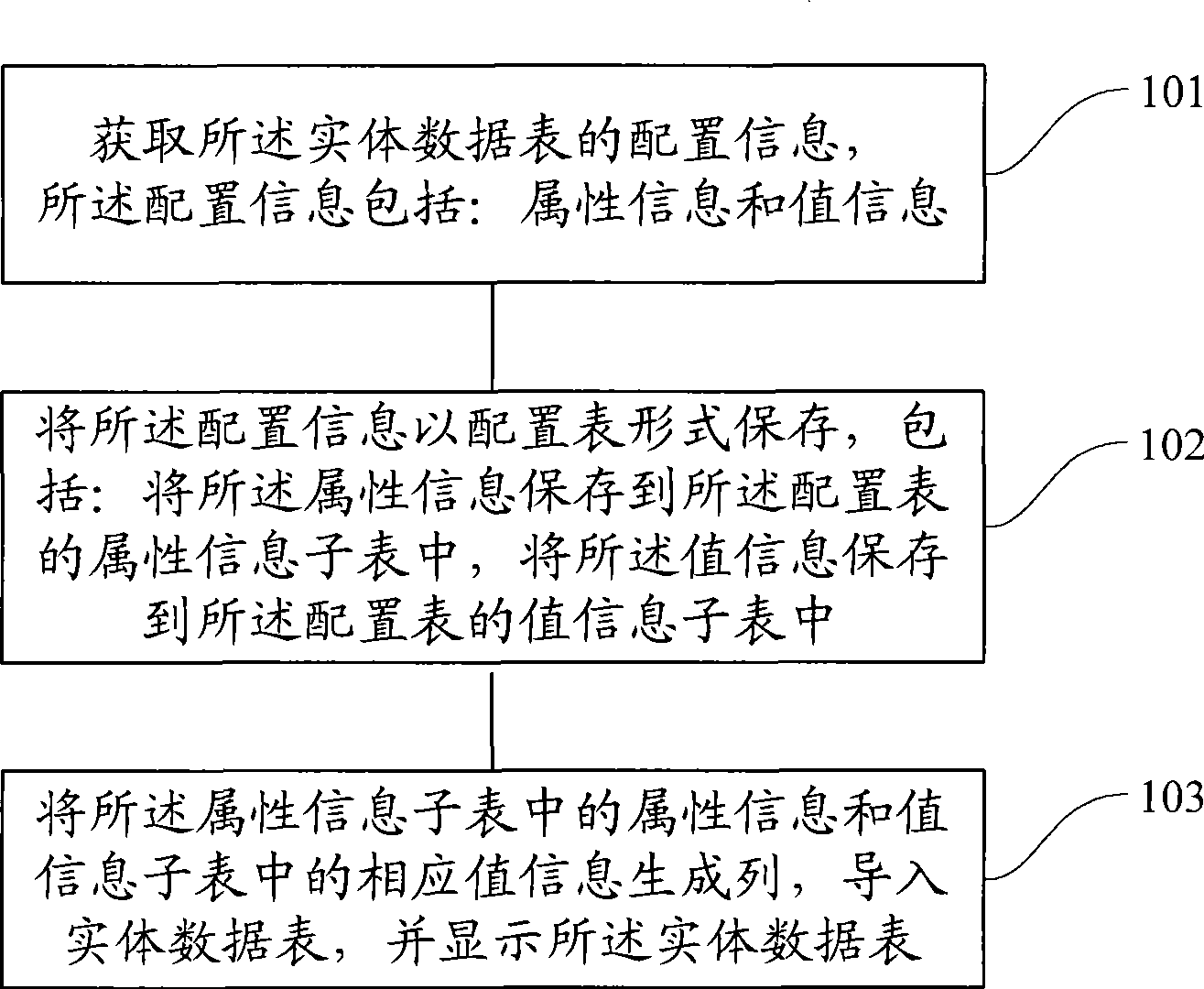

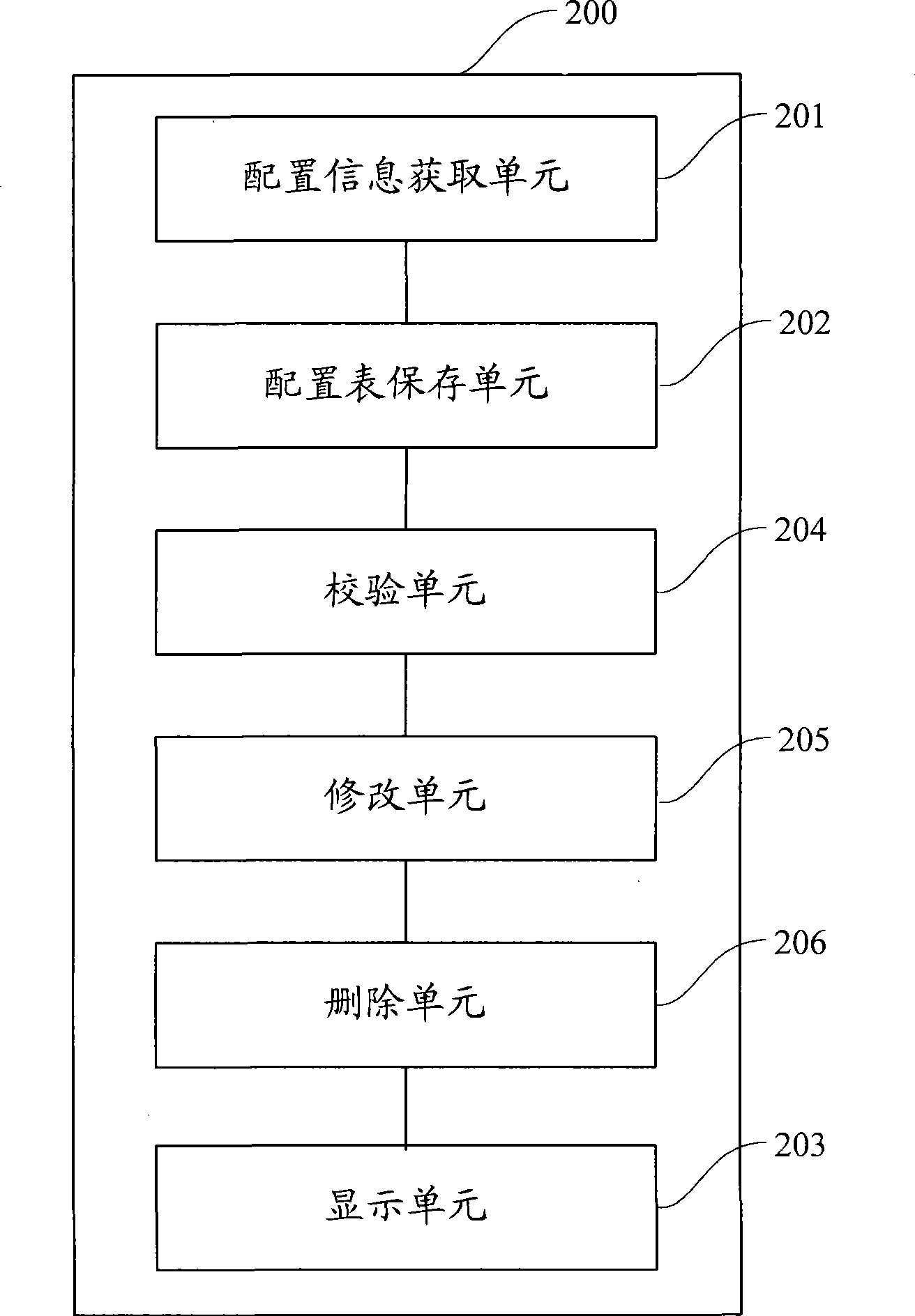

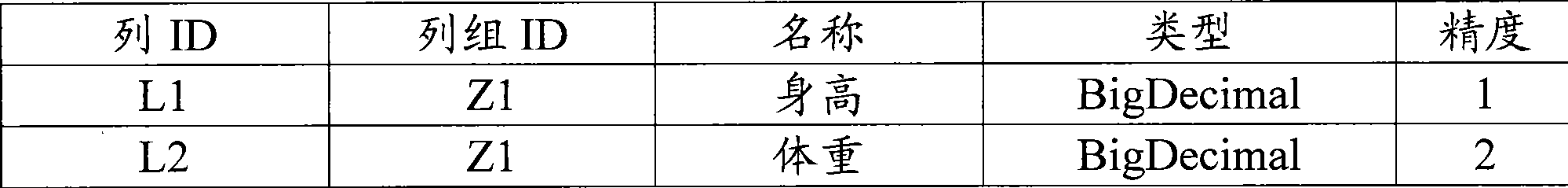

Method and system for dynamically configuring physical data table

ActiveCN101504672ASave heavy secondary developmentNo technical barriersSpecial data processing applicationsSecondary developmentDatabase

The invention discloses a method for dynamically configuring an entity data table. The method comprises: acquiring configuration information of the entity data table, wherein the configuration information comprises attribute information and value information; storing the configuration information in the form of a configuration table, namely storing the attribute information into an attribute information subtable of the configuration table and storing the value information into a value information subtable of the configuration table; and generating the attribute information in the attribute information subtable and corresponding value information in the value information subtable into columns, importing the columns into the entity data table, and displaying the entity data table. The invention correspondingly discloses a system for dynamically configuring the entity data table. The invention can meet the service demands of dynamic attributes of the data table, and avoid heavy secondary development of an initial entity data table when the variation of the attributes of the initial entity data table is required in the late operating stage.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

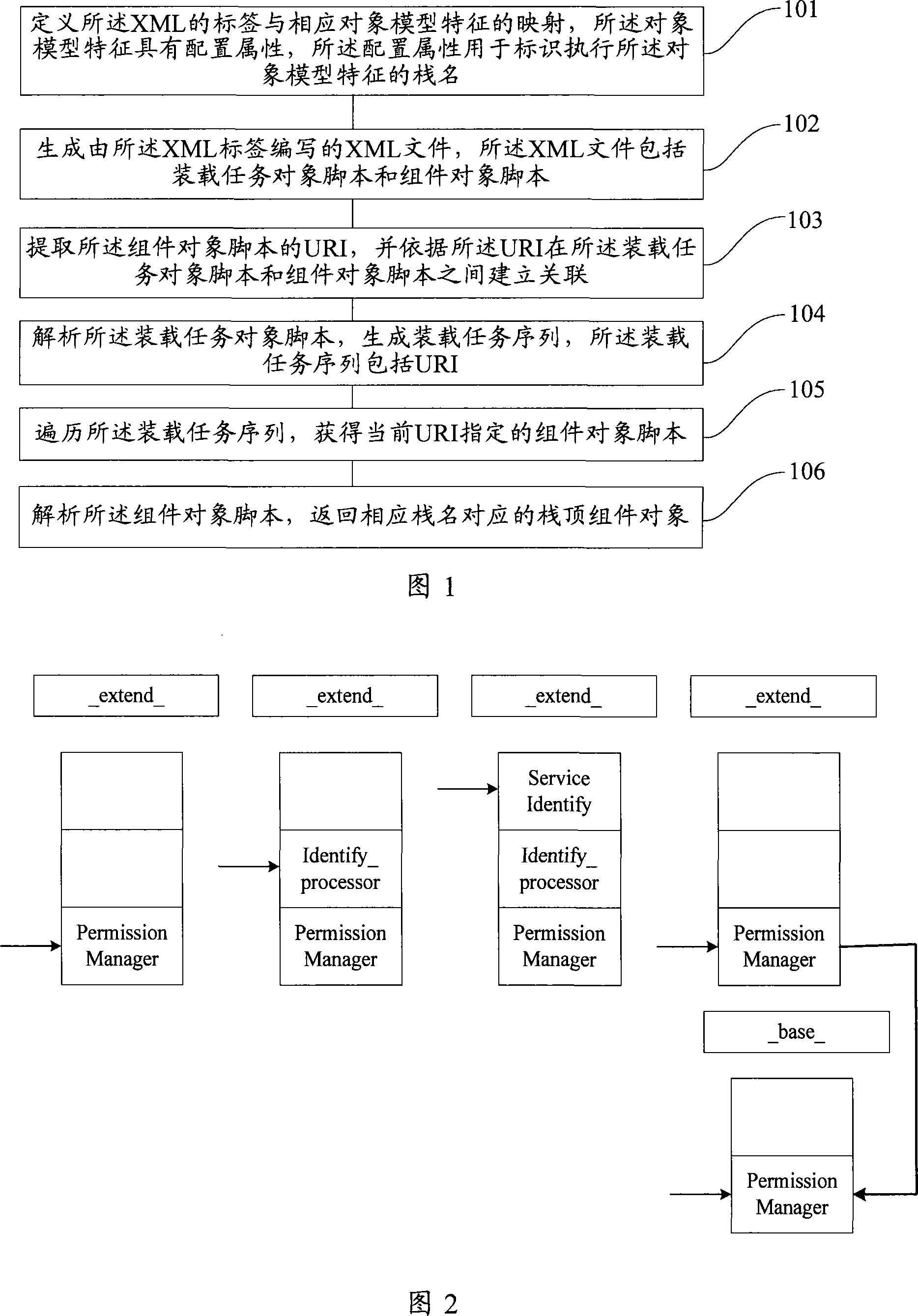

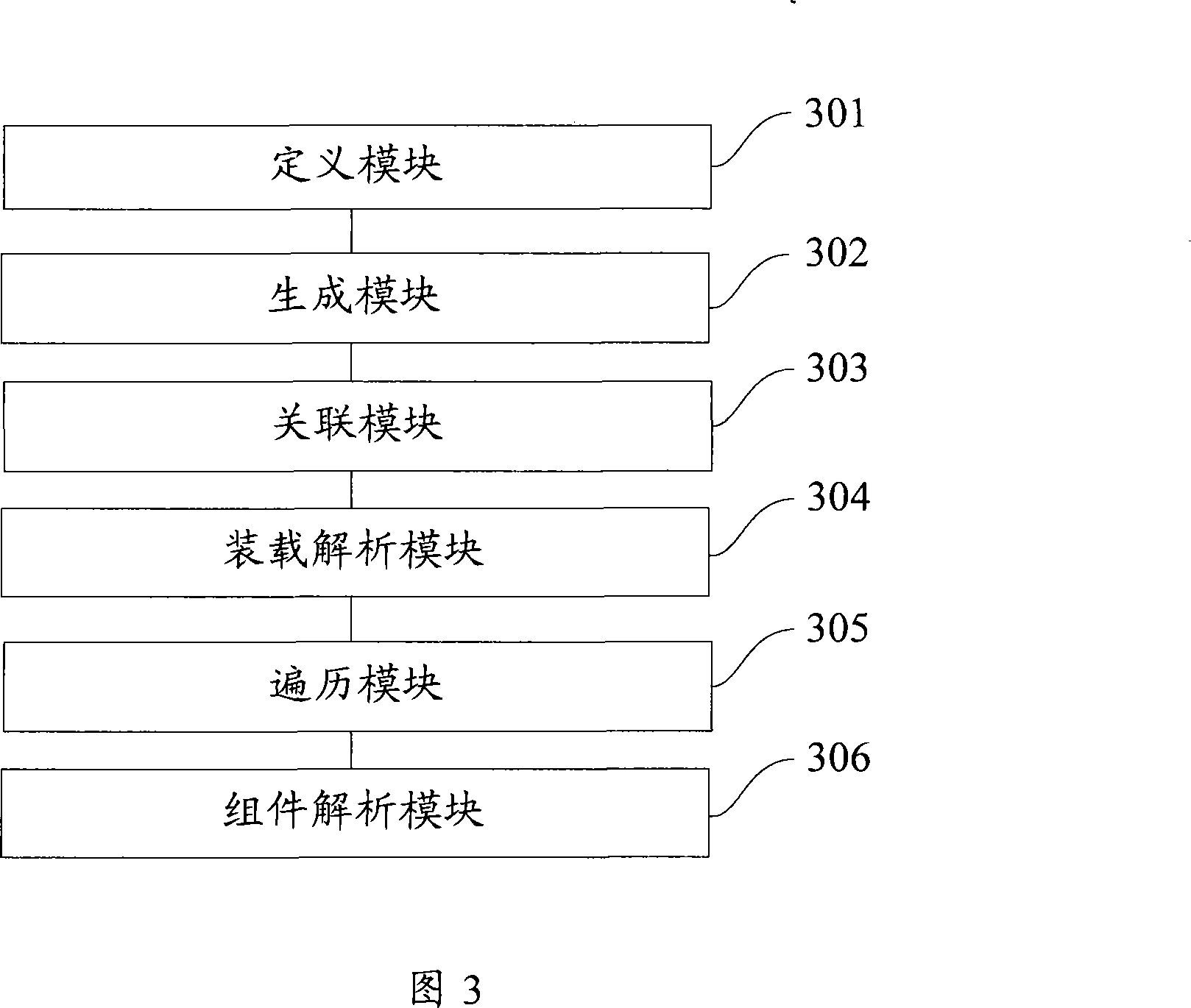

Method and device for XML document analysis

ActiveCN101221556ASimplify development workSimplify workSpecial data processing applicationsWeb document analysisDocument analysis

The invention provides an analytic method for an XML file which comprises a label used to define the XML and a mapping of the corresponding object model feature. The object model feature has a configuration attribute, the configuration attribute is used to identify a stack name for executing the object model feature; an XML file compiled by the XML label is produced and comprises a loading task object script and an assembly object script; a URI of the assembly object script is extracted, a correlation is established between the loading task object script and the assembly object script according to the URI; the loading task object script is analyzed to produce a loading task sequence, the loading task sequence comprises the URI; the loading task sequence is searched to obtain the assembly object script appointed by the current URI; the assembly object script is analyzed to return to a stack top assembly object corresponding to the corresponding stack name. The invention can simply and effectively realize the configuration and analysis of the XML file under the premise of saving system resources.

Owner:CHINA CONSTRUCTION BANK

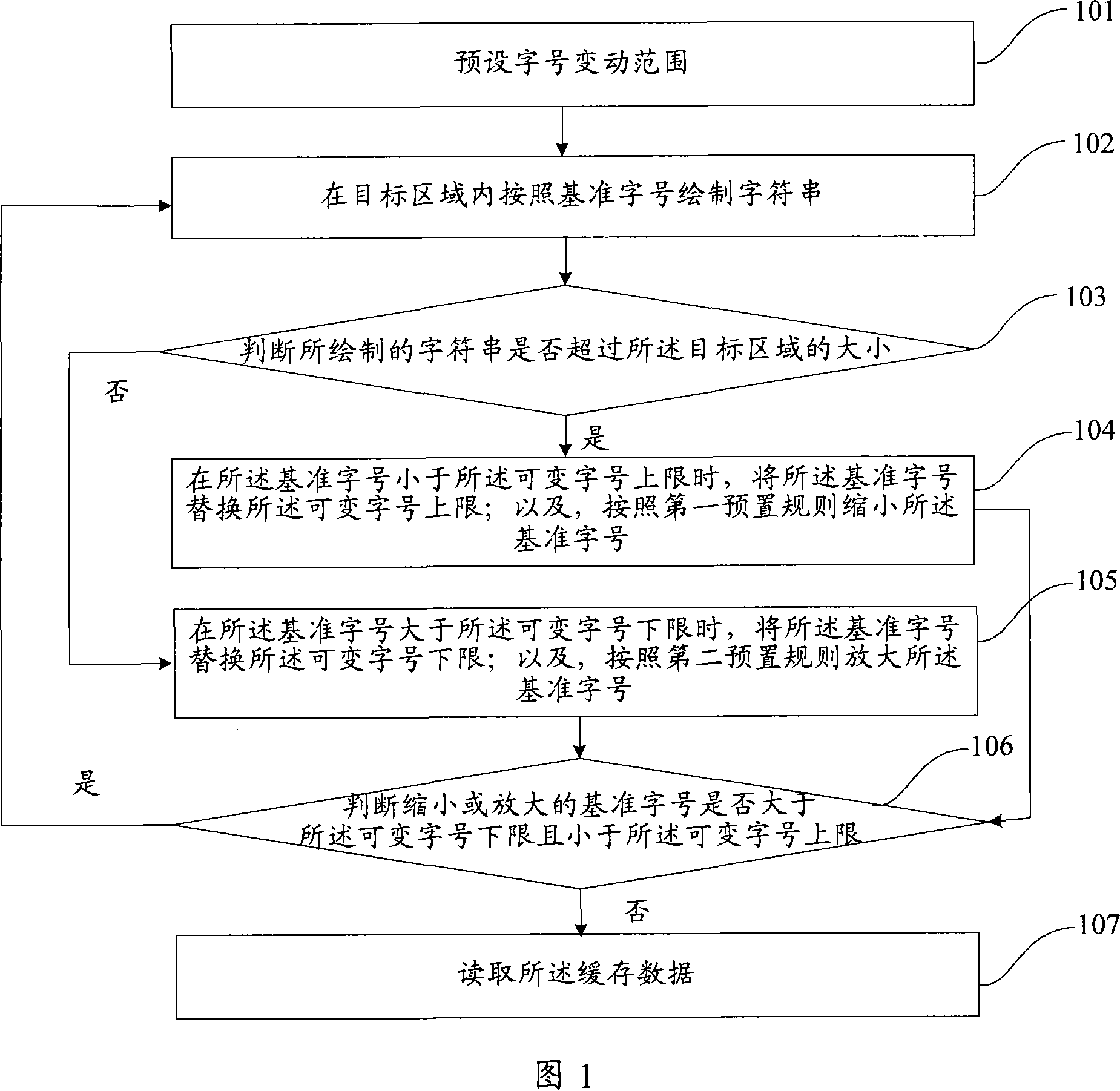

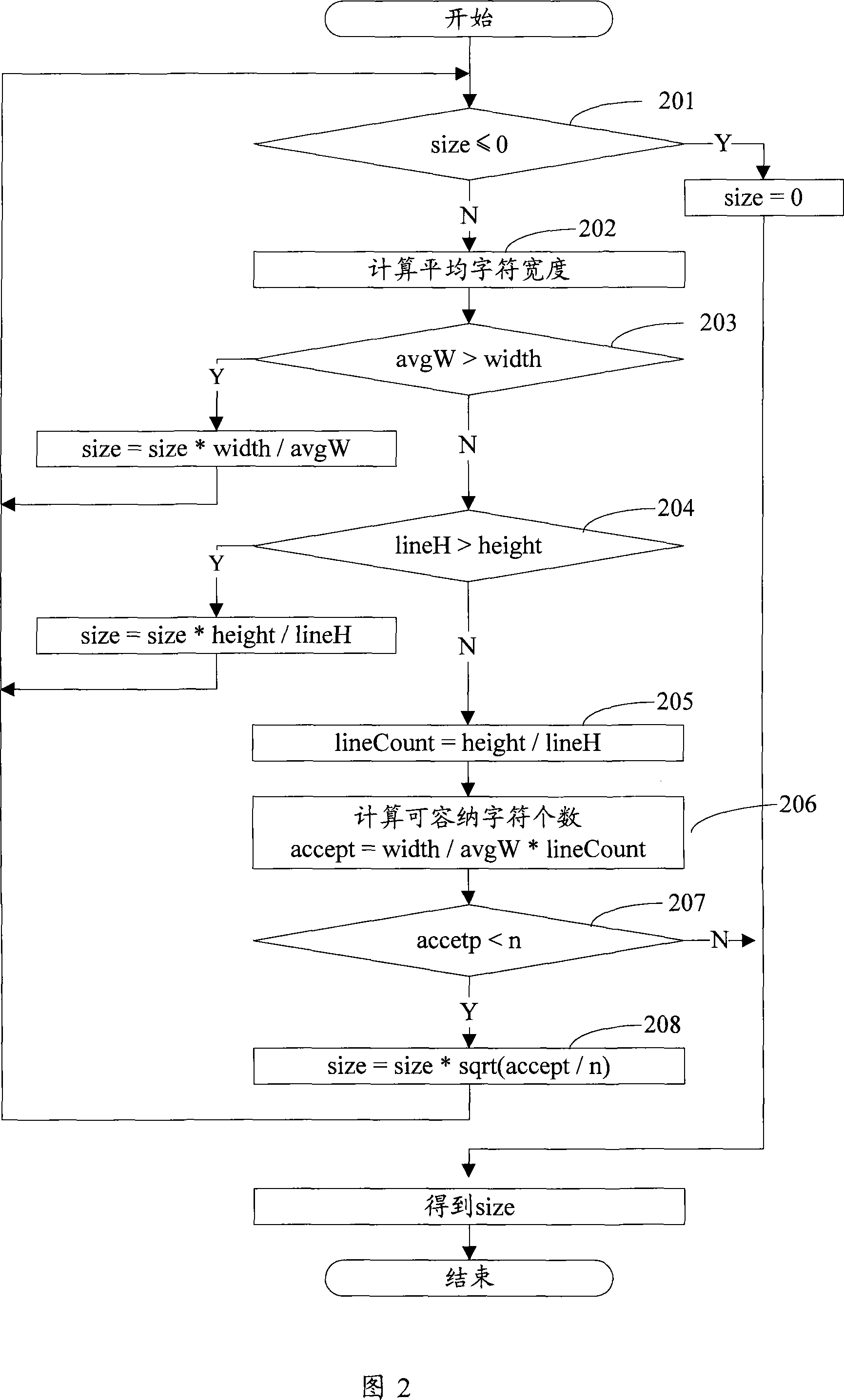

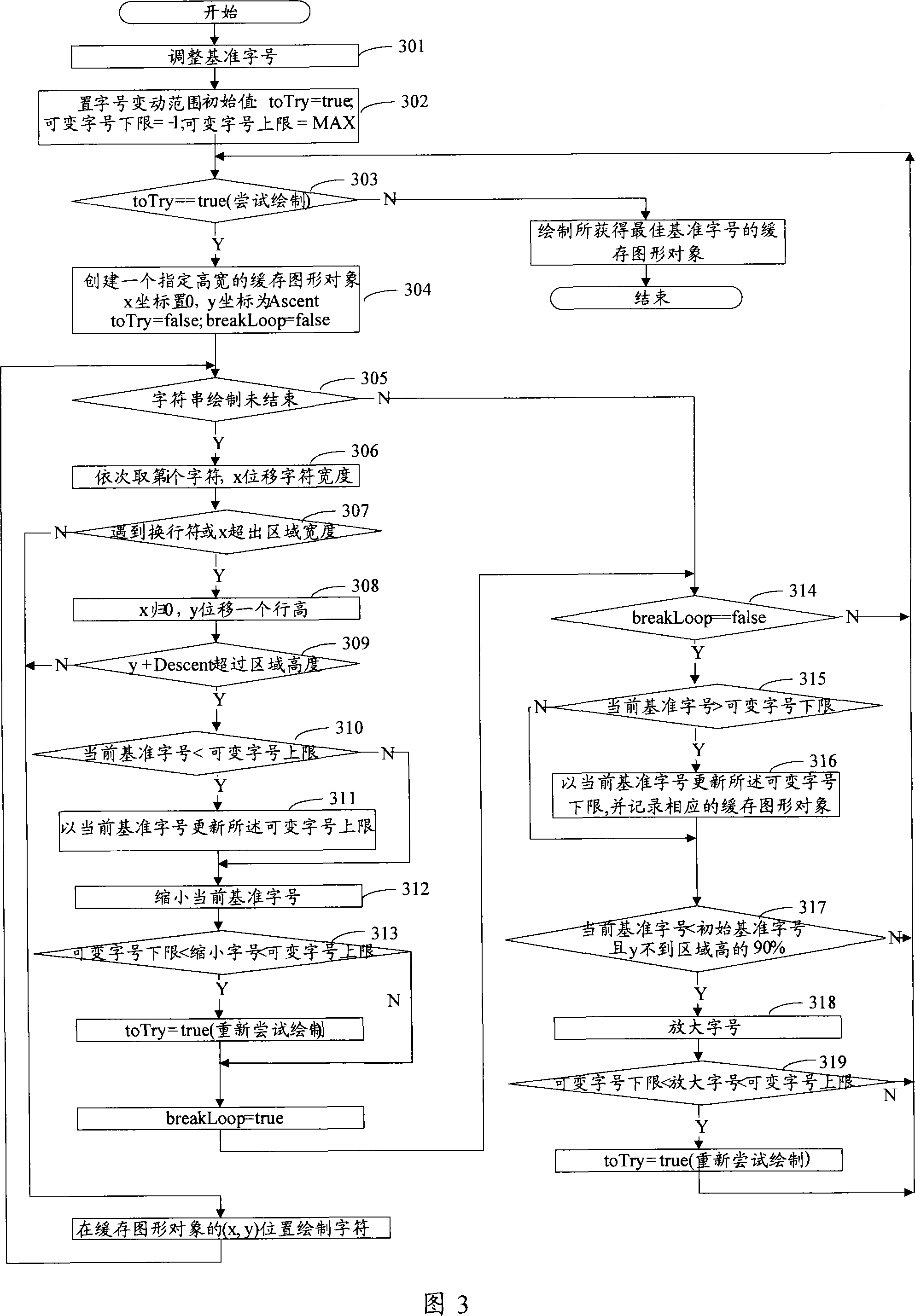

Method and device drafting character string at targeted area

ActiveCN101127035AImprove drawing efficiencyReduce waste of resourcesNatural language data processingSpecial data processing applicationsLower limitComputer graphics (images)

The utility model discloses a method of rendering character strings within object regions. The method is as follows: a font size variation range is preset; character strings are rendered according to reference font sizes within the object regions; whether the rendered character strings exceed the size of the object regions is judged; if yes, the reference font sizes replace the upper limit of the variable font sizes when the reference font sizes are smaller than the upper limit of the variable font sizes, and the reference font sizes are reduced according to a first preset rule; if no, the reference font sizes replace the lower limit of the variable font sizes when the reference font sizes are bigger than the lower limit of the variable font sizes, and the reference font sizes are enlarged according to a second preset rule; whether the reduced or enlarged reference font sizes are within the variation range of the font sizes is judged; if yes, the character strings are re-rendered within the object regions. The utility model can simultaneously realize line wrap and font reduction filling within object regions, while ensuring the efficiency of rendering character strings.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

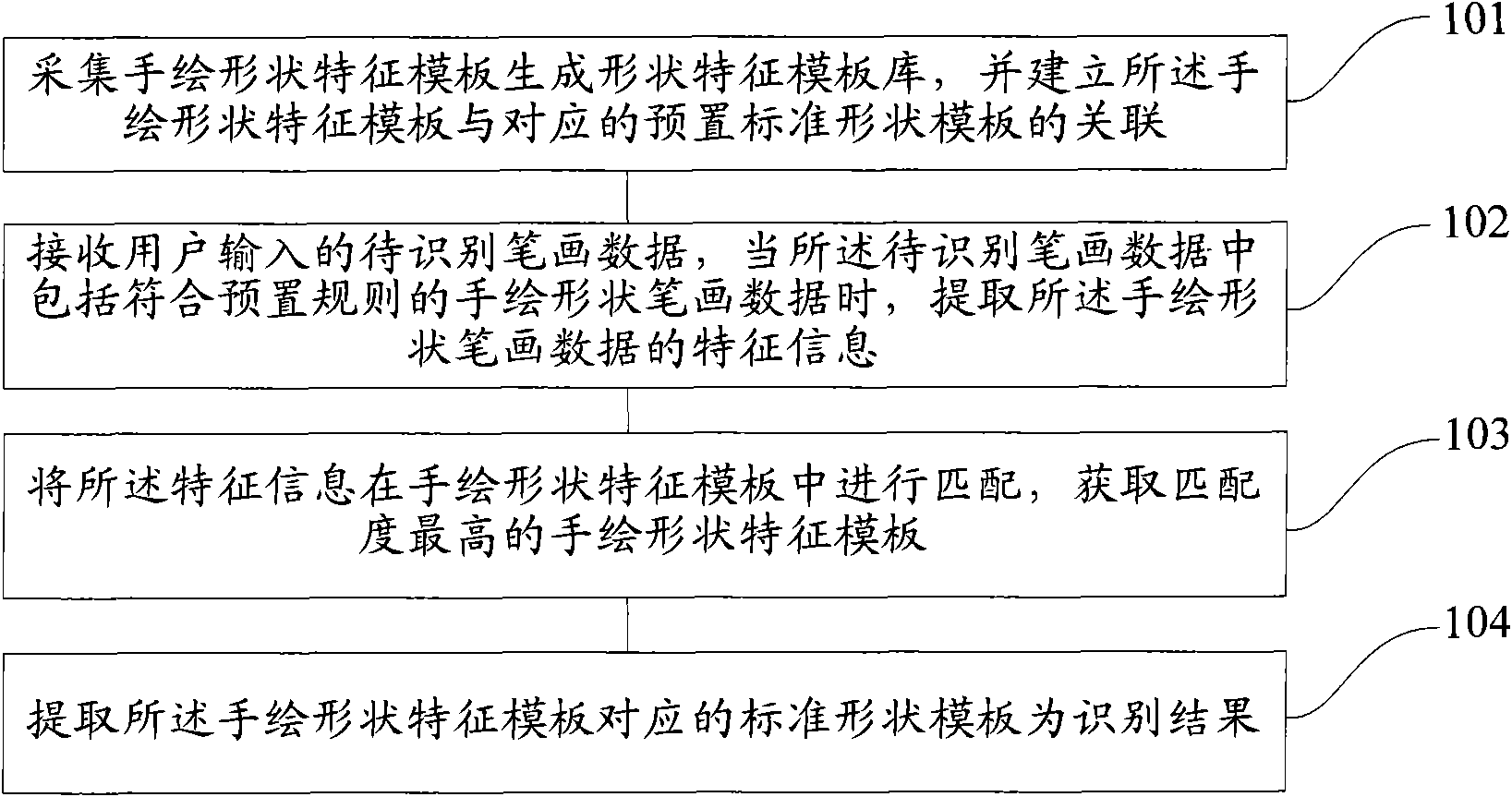

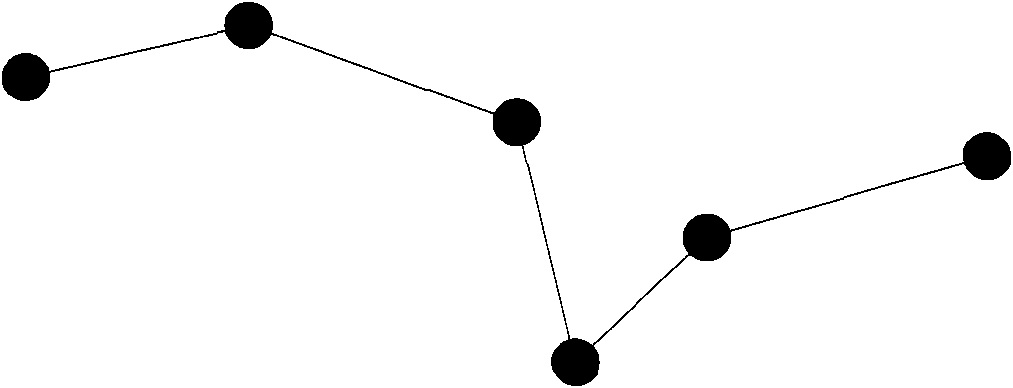

Method for recognizing hand-painted shapes and device thereof

ActiveCN101593270AEasy to operateImprove user experienceCharacter and pattern recognitionPattern recognitionUser input

Owner:HANVON CORP

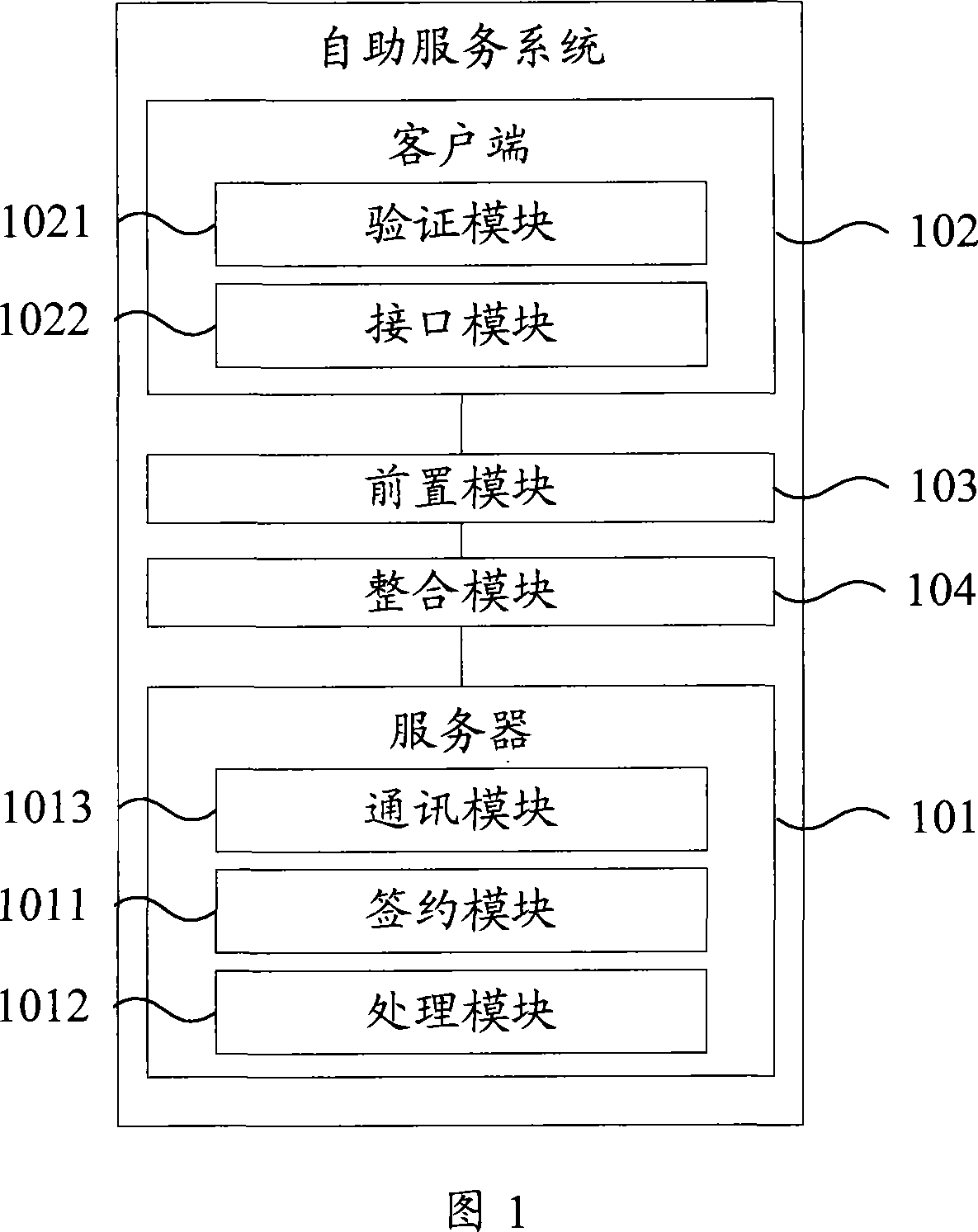

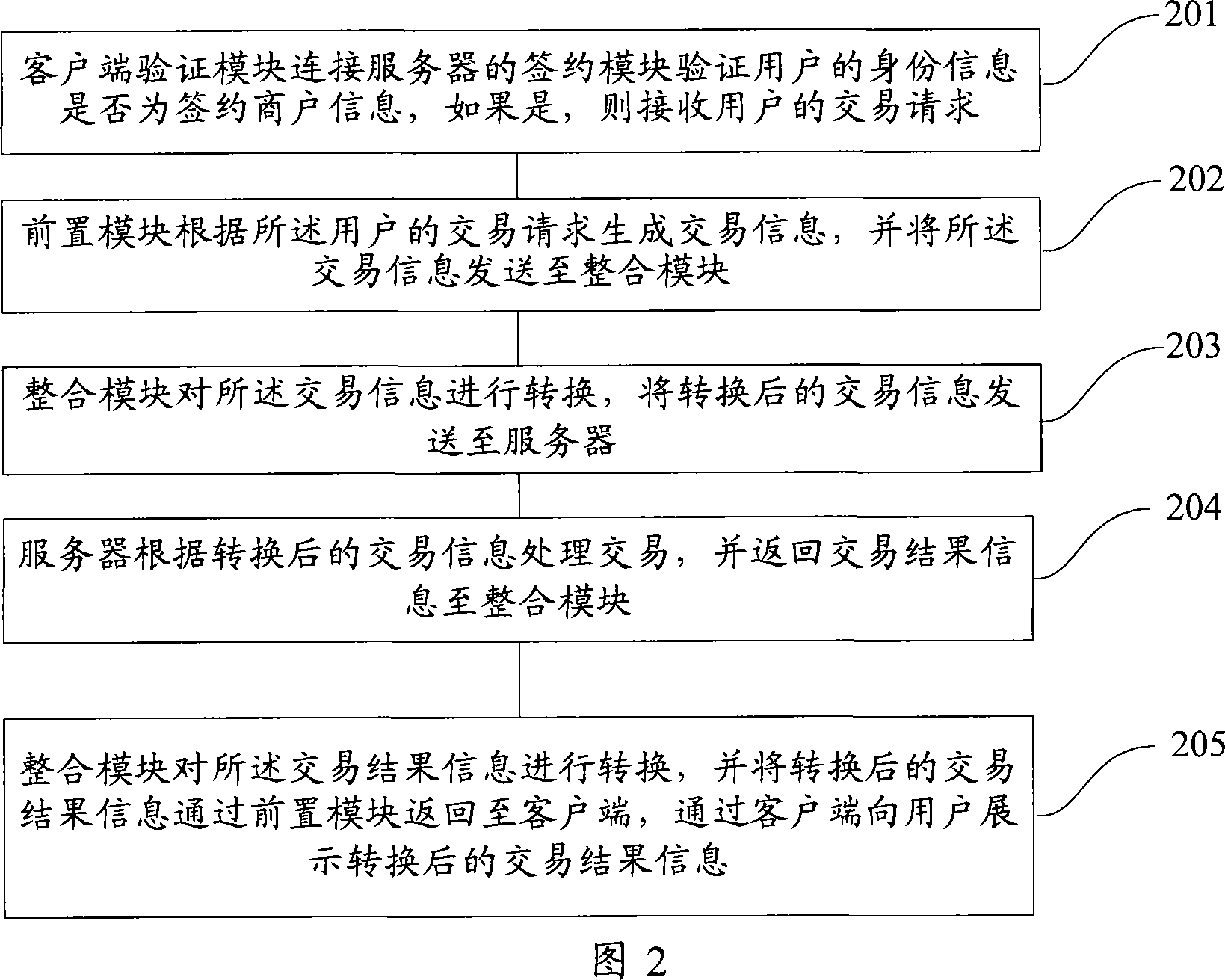

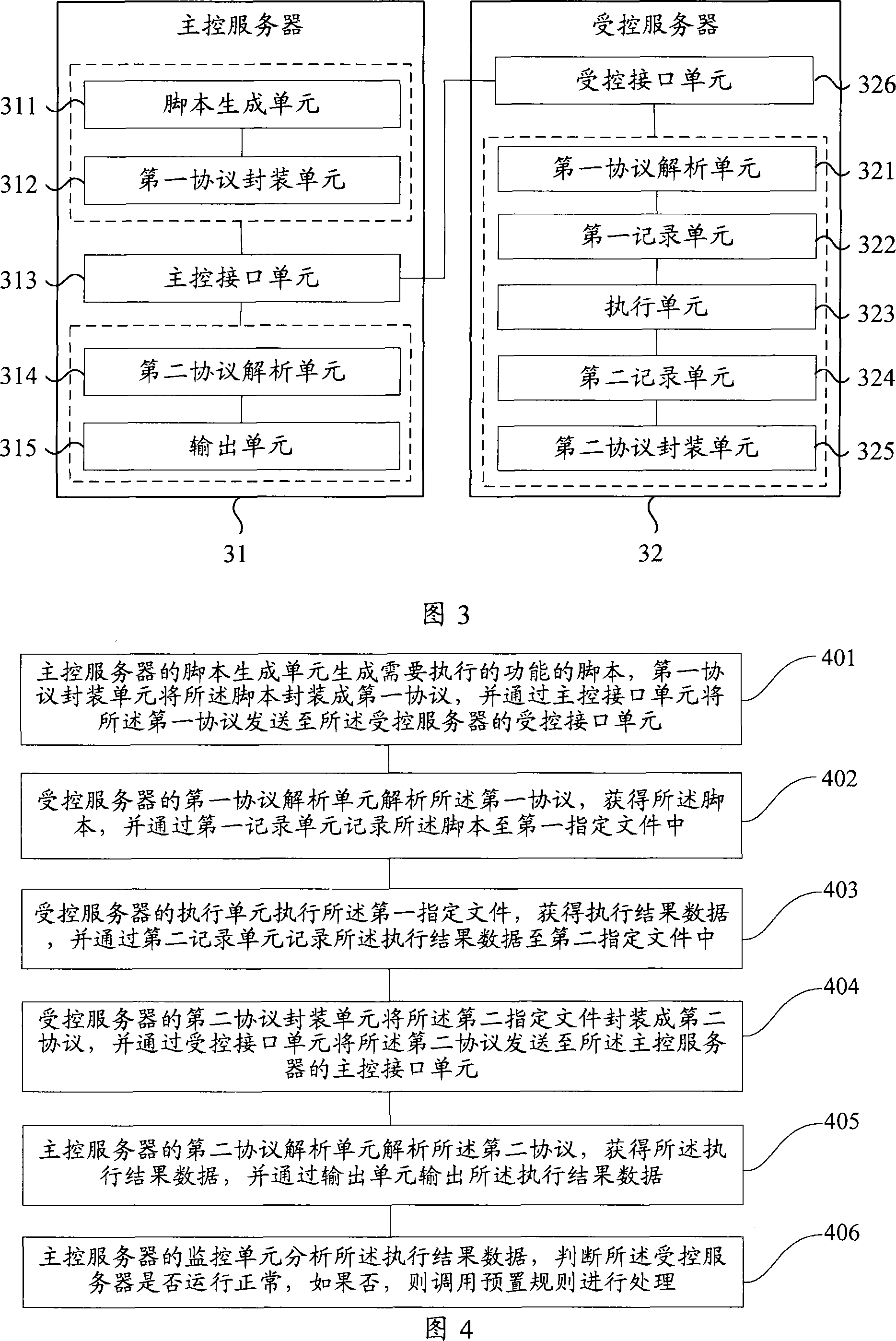

Self-aid service system and on-line transaction method

InactiveCN101079172AAdd self-service functionalityMeeting Self-Service NeedsComplete banking machinesPayment architectureSelf-serviceComputer science

The invention discloses a self-service system, which comprises the following parts: server, customer end, integrated mode, prefix module to generate trading information according to trading request for user to transmit the trading information to the integrated mode, wherein the prefix mode receives the trading result information from the integrated mode and transmits the information to customer end; the integrated mode switches the trading information and trading result information, which transmits the switched trading information to server and returns the switched trading result information to the prefix mode. The invention can satisfies the self-service need of large-scale trading market and material flow cantor, which ensures the system security.

Owner:CHINA CONSTRUCTION BANK

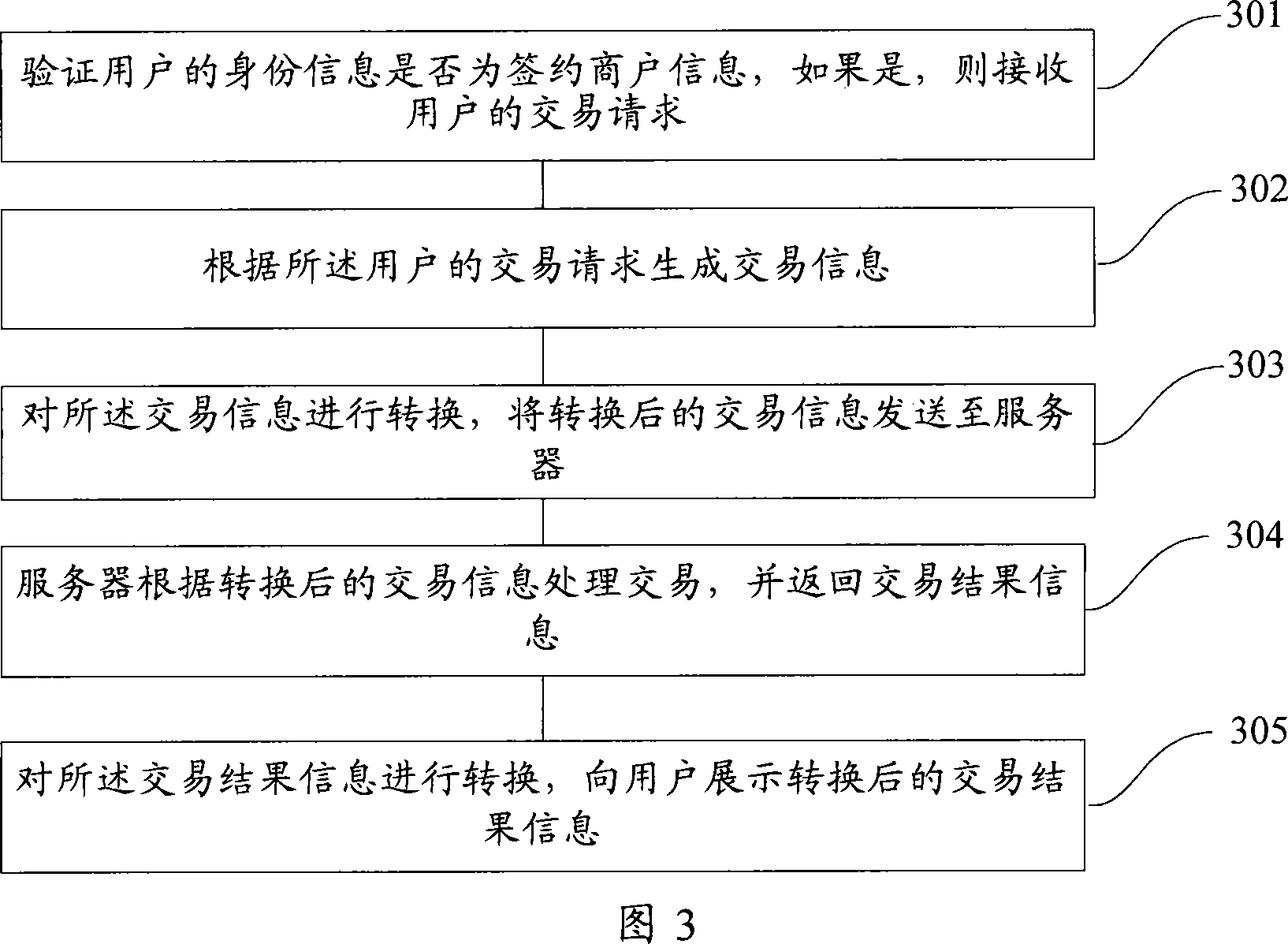

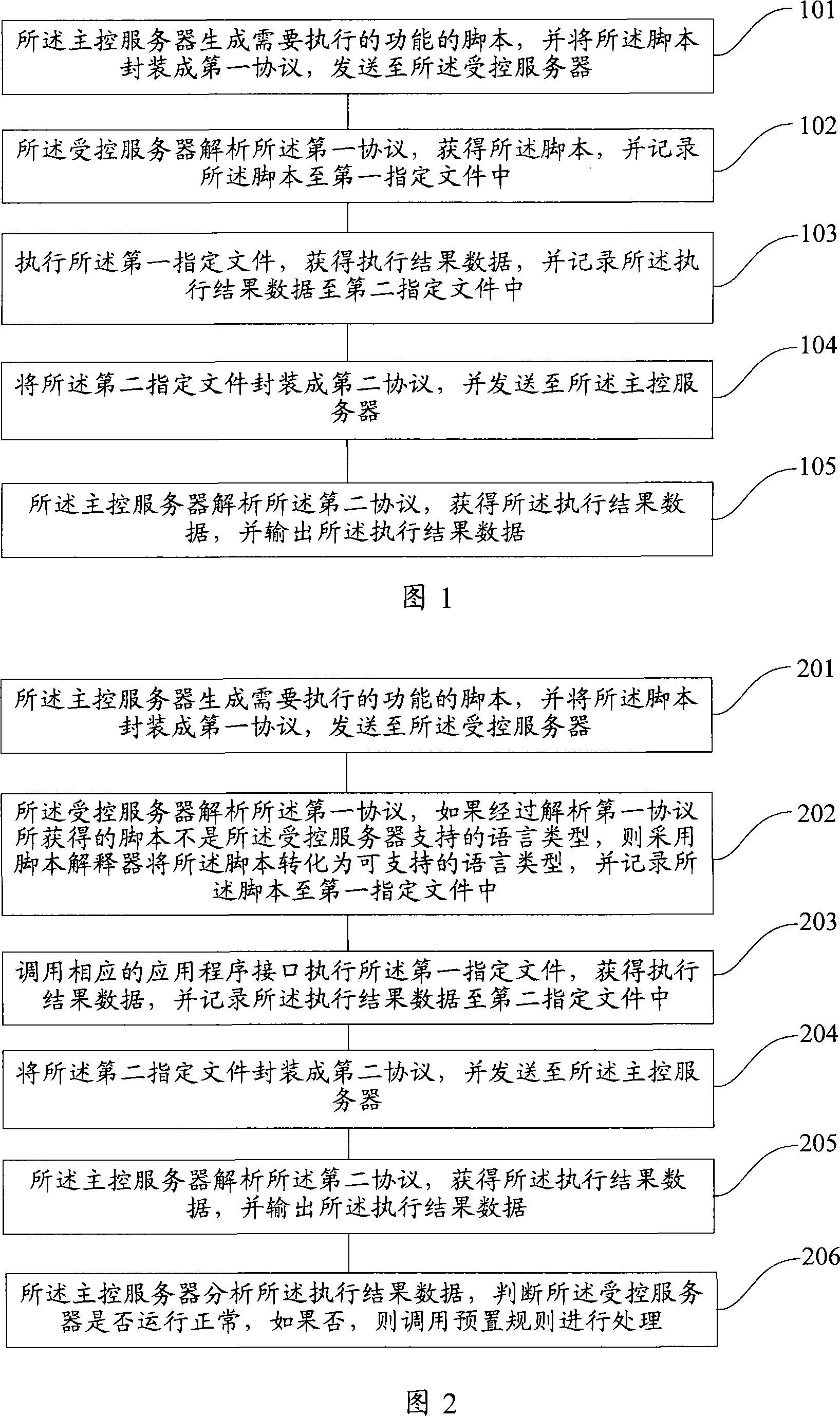

A server management method and a server management system

InactiveCN101123616AQuick responseReduce time spentData switching detailsEmbedded systemManagement system

The invention discloses a server management method, which comprises that a main control server generates a functional script, which needs to be executed; the script is encapsulated into a first protocol and is transmitted to a controlled server; the controlled server parses the first protocol to obtain the script and record the script to a first appointed file; the first appointed file is executed to obtain executing result data and record the executing result data to the second appointed file; the second appointed file is encapsulatd into a second protocol and is transmitted to the main control server; the main control server parses the second protocol to obtain the executing result data and output the executing result data. The invention is applied in an interaction process of the main control server and the controlled server, so as to implement all action contained in the script at one time. Thus, the interaction efficiency of the main control server and the controlled server is effectively improved, the response speed of the server is accerlarated and the resource occupation time is decreased.

Owner:BEIJING KINGSOFT SOFTWARE +1

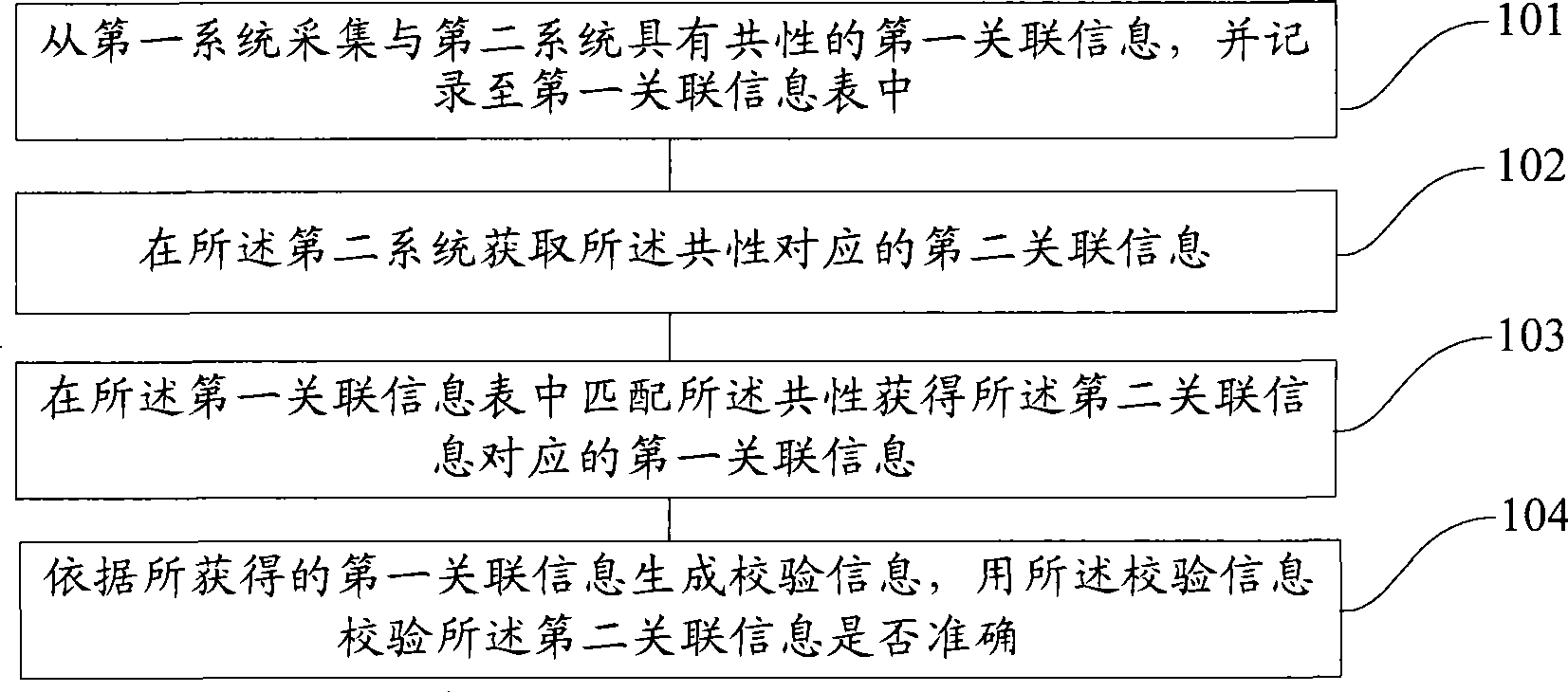

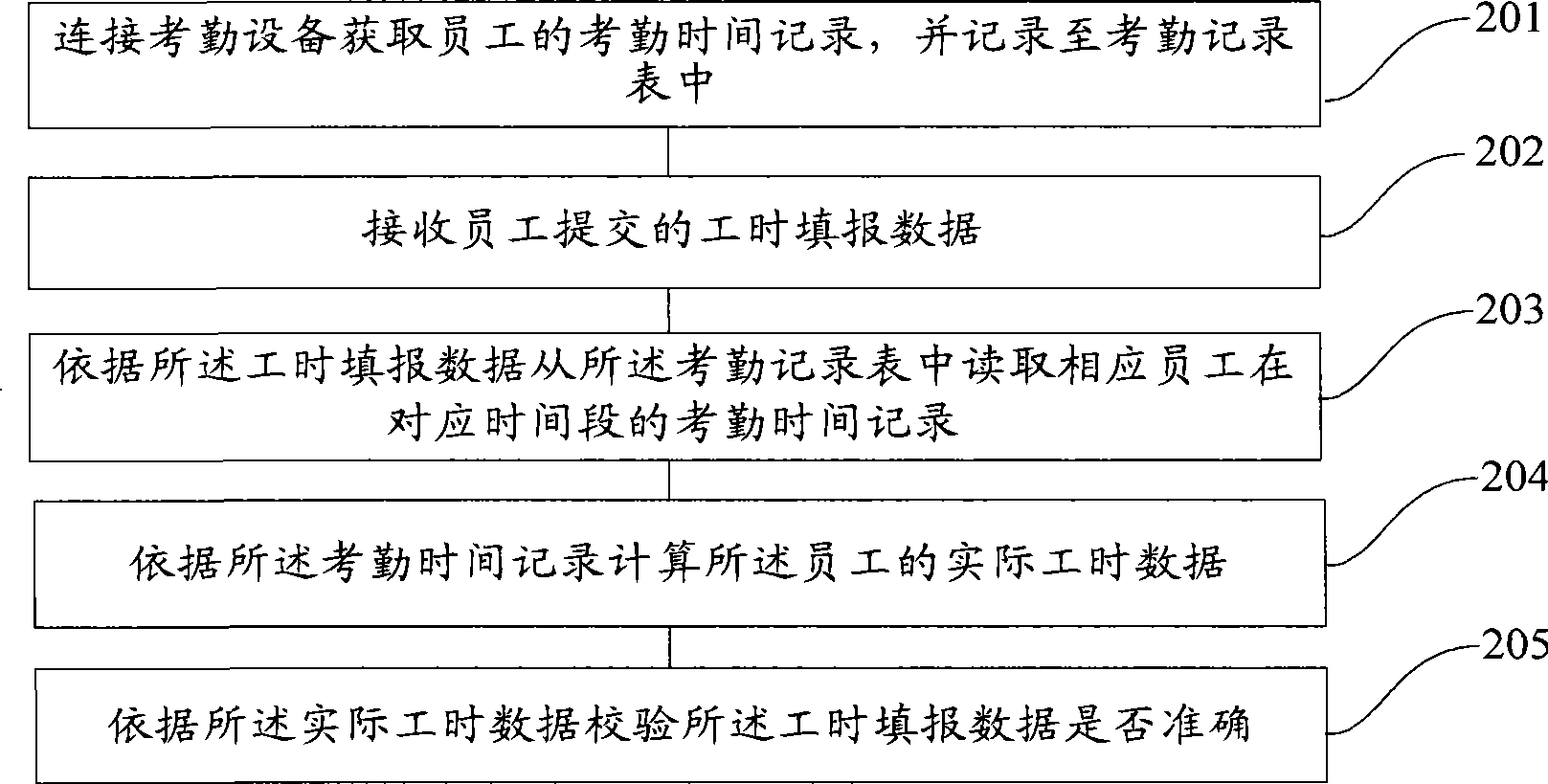

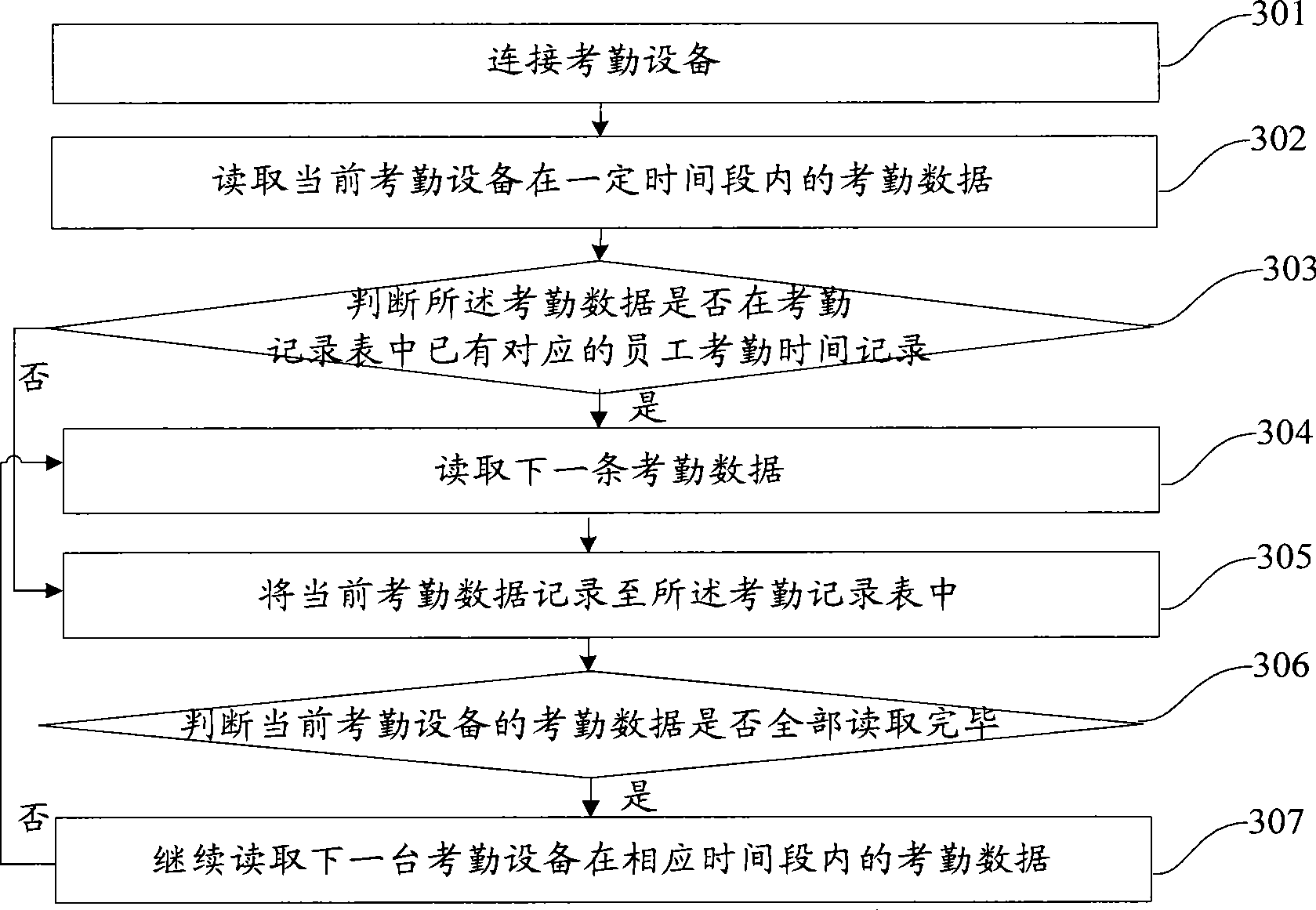

Method of calibrating data accuracy, device and labour hour data verification system

InactiveCN101364291AImprove Calibration AccuracyImprove verification efficiencyResourcesSource Data VerificationVerification system

The invention discloses a checking method for data accuracy, a device and a working hour data checking system, wherein, the checking method comprises the following steps: first correlative information having the commonness with a second system is acquired from a first system and is recorded in a first correlative information table; second correlative information corresponding to the commonness is gotten from the second system; the first correlative information corresponding to the second correlative information is obtained in the first correlative information table through matching the commonness; checking information is generated according to the first correlative information, and the checking information is utilized to check whether the second correlative information is correct. The checking method, the device and the working hour data checking system can ensure the accuracy of the data to be checked and increase the checking efficiency.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

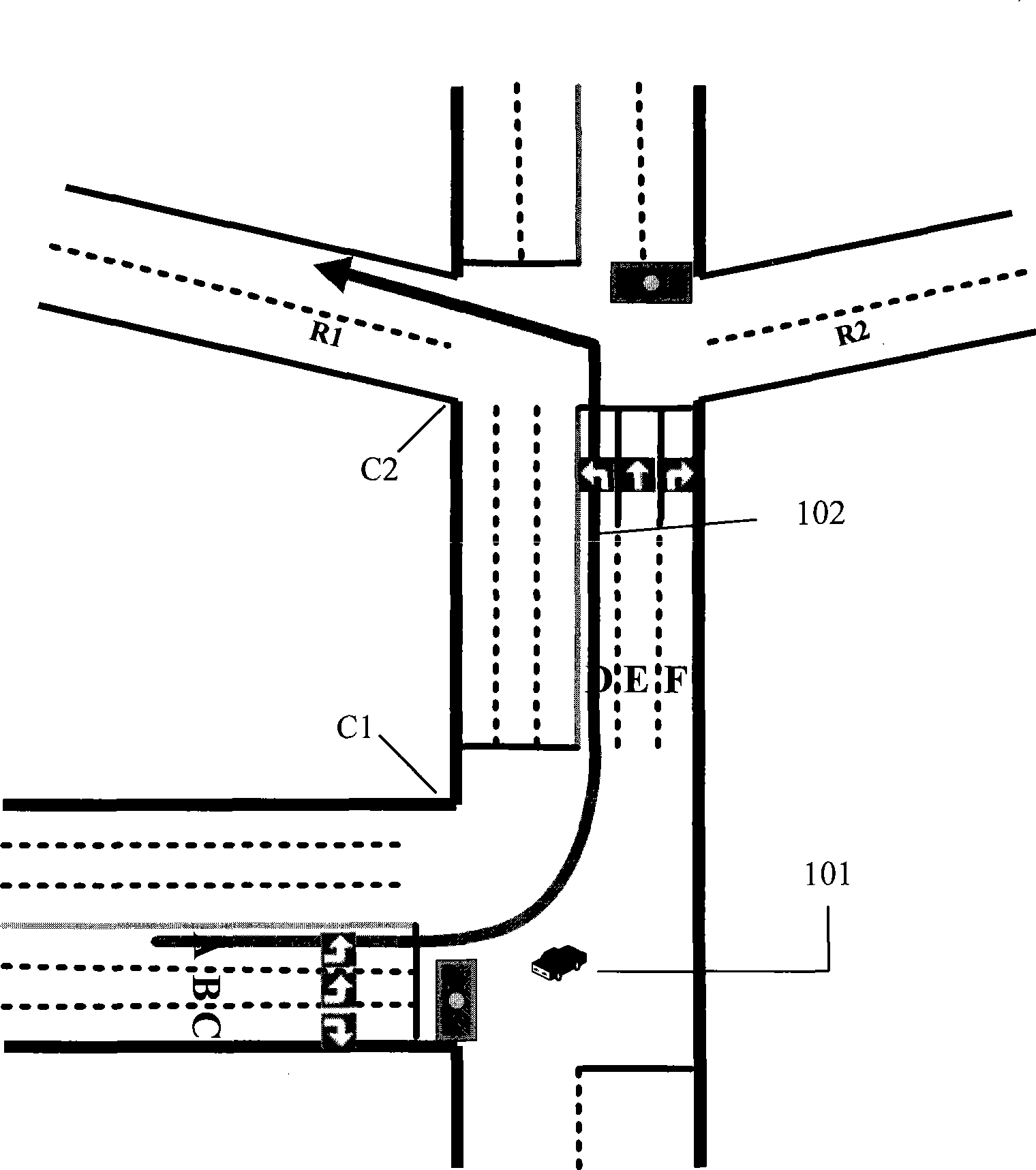

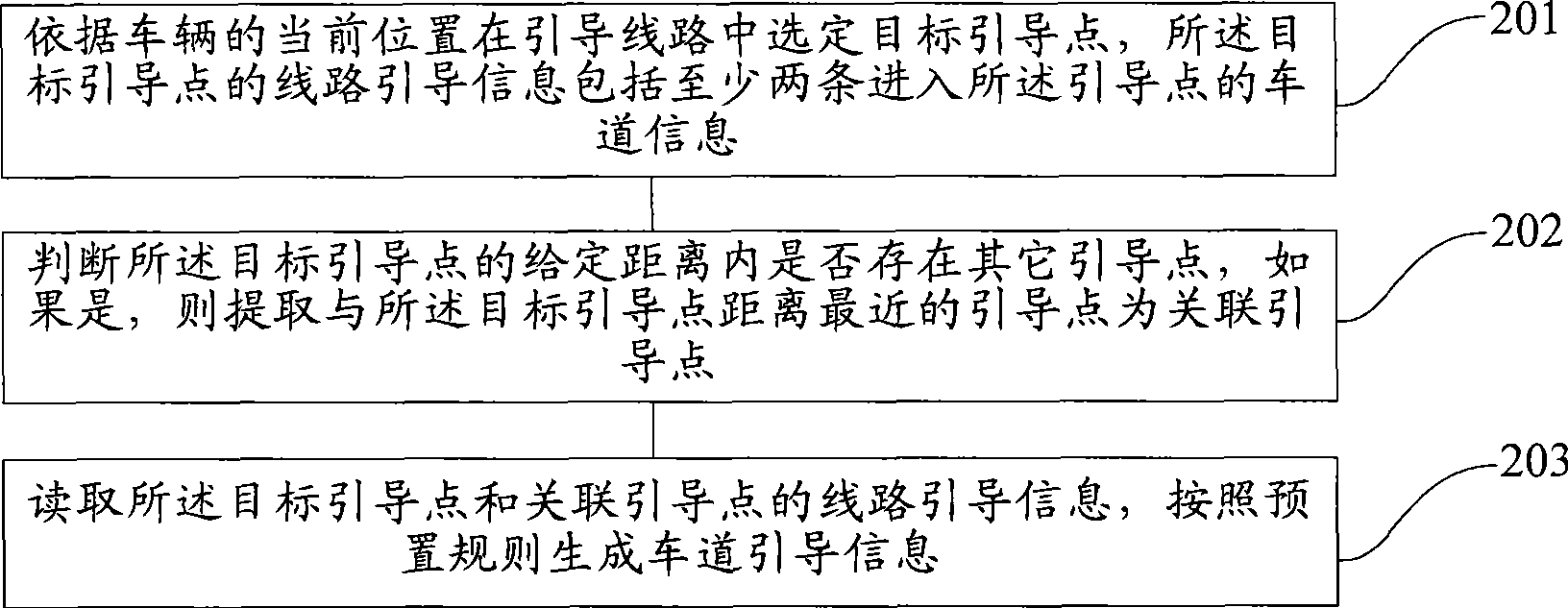

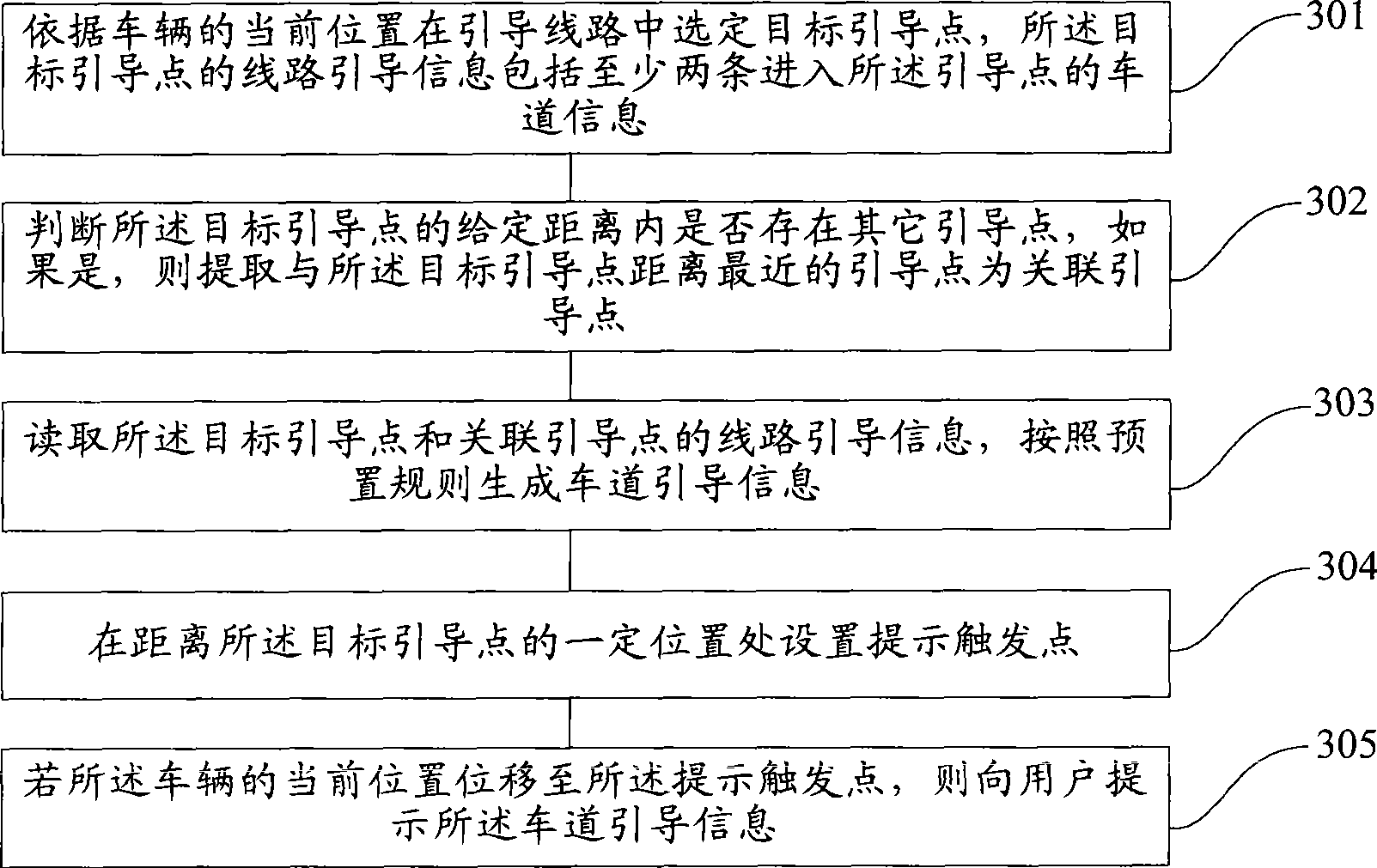

Processing method and apparatus for vehicle navigation and vehicle navigation system

ActiveCN101469992AReduces the possibility of deviating from the guide lineImprove user experienceInstruments for road network navigationNavigation systemComputer science

The invention discloses an automobile navigation processing method, comprising: according to the prior position of an automobile, selecting a target guide point in a guide lane, while the lane guide information of the target guide point comprises the information of at least two lanes accessing into the guide point; judging if there is other guide points exist in an appointed distance from the target guide point, if there is, extracting the guide point nearest to the target guide point as a correlative guide point; reading the lane guide information of the target guide point and the correlative guide point; generating lane guide information according to preset laws. The automobile navigation processing method can provide accurate lane guide information, avoid users deviating guide lanes and provide good application feel for users.

Owner:NEUSOFT CORP

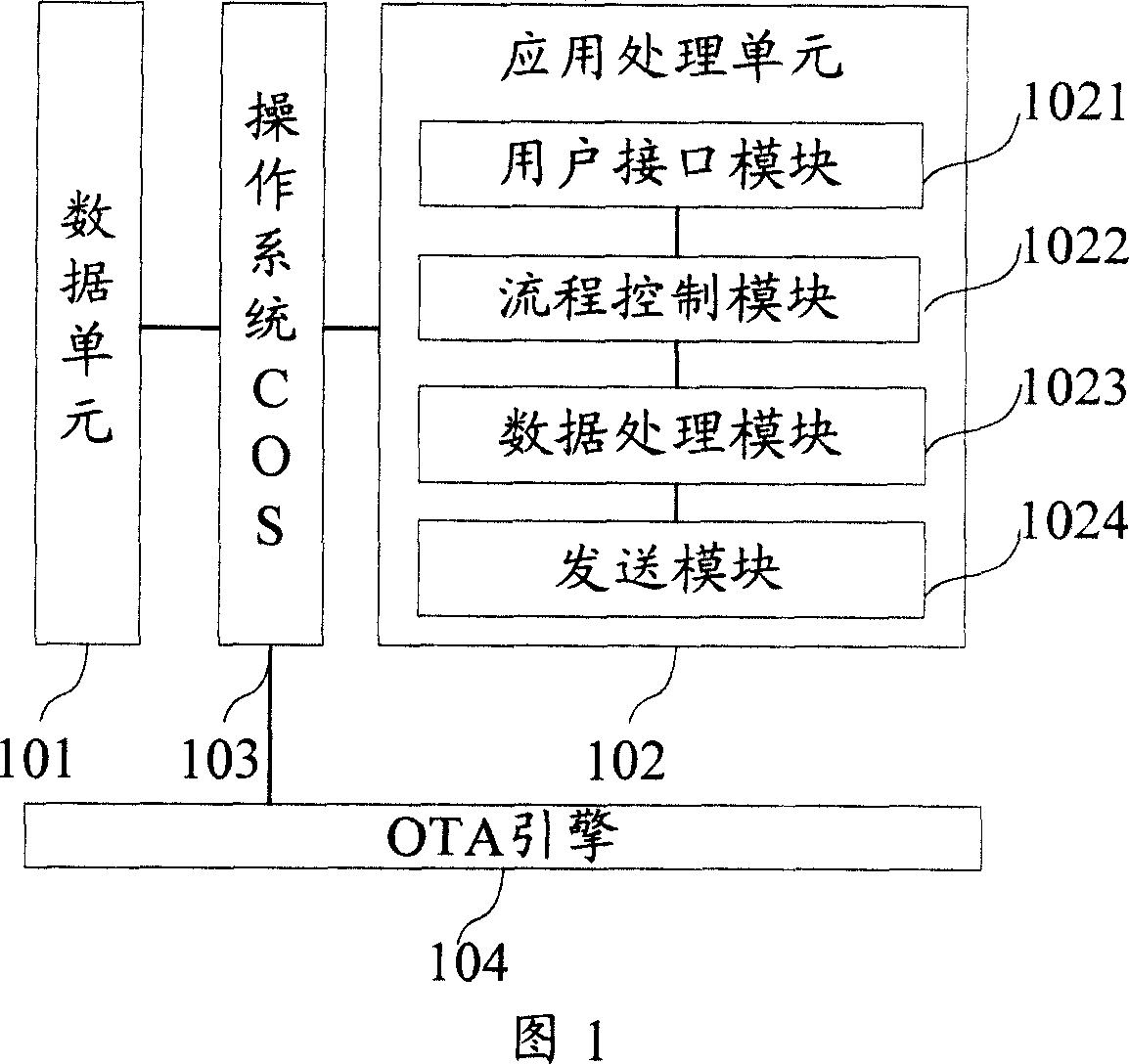

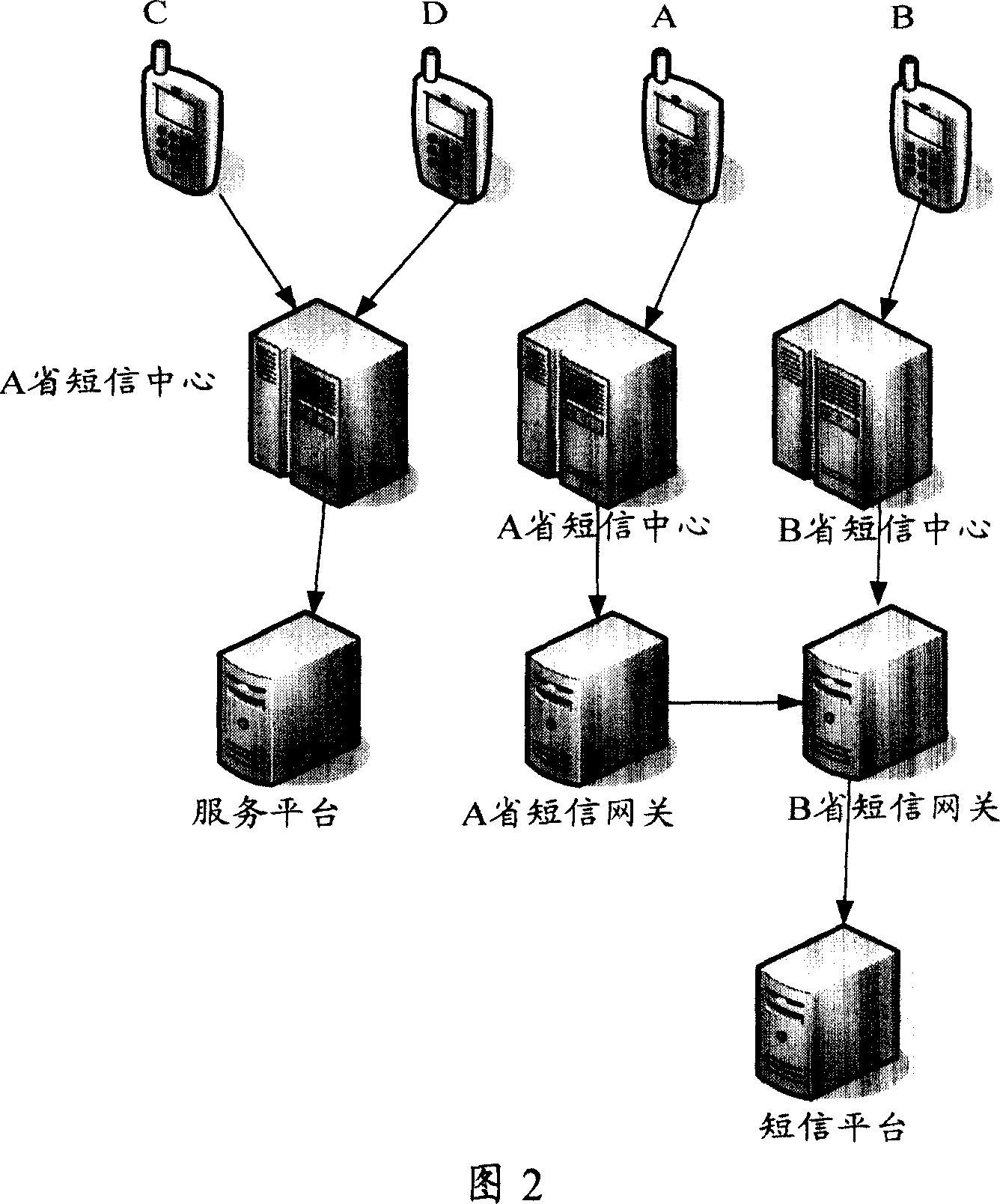

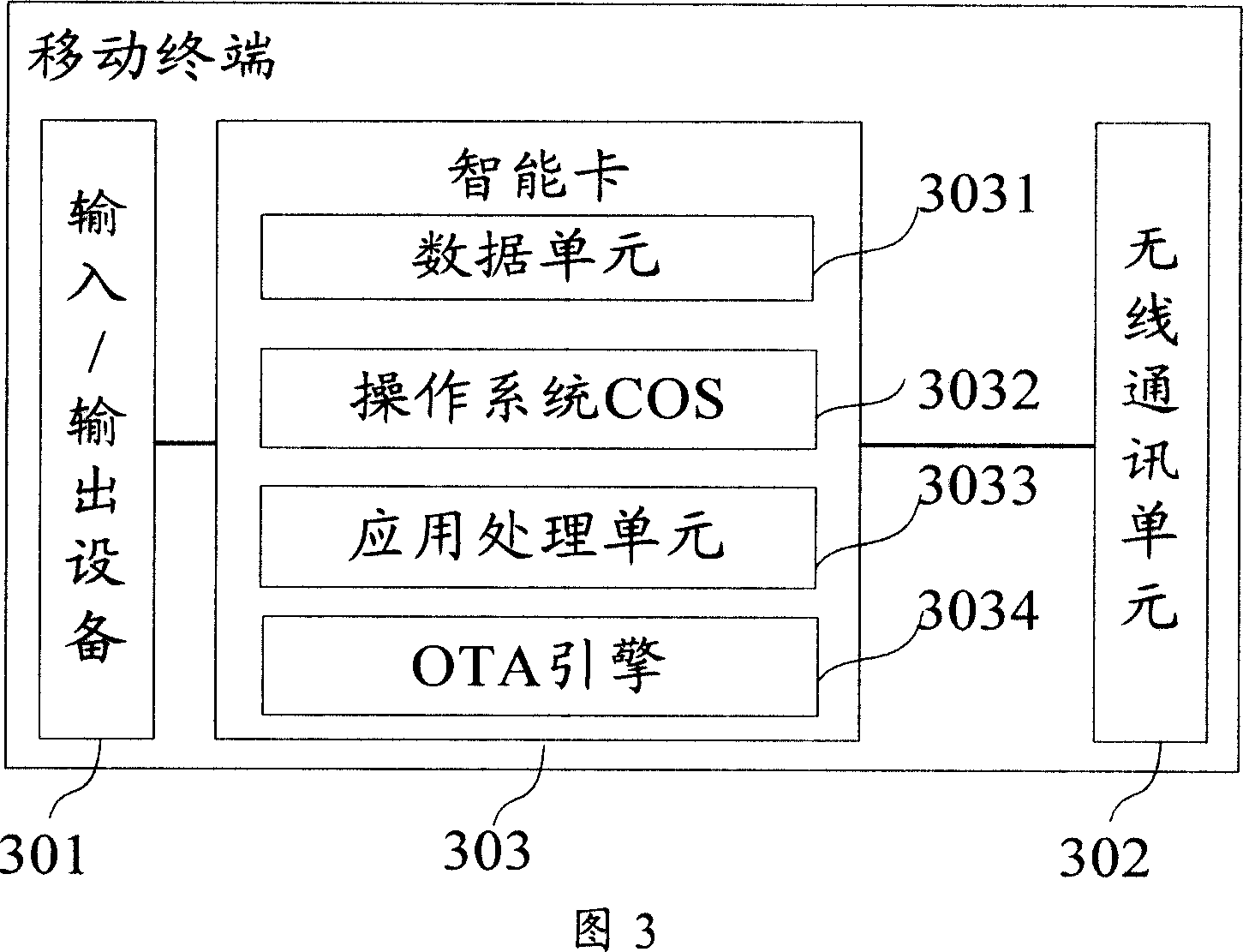

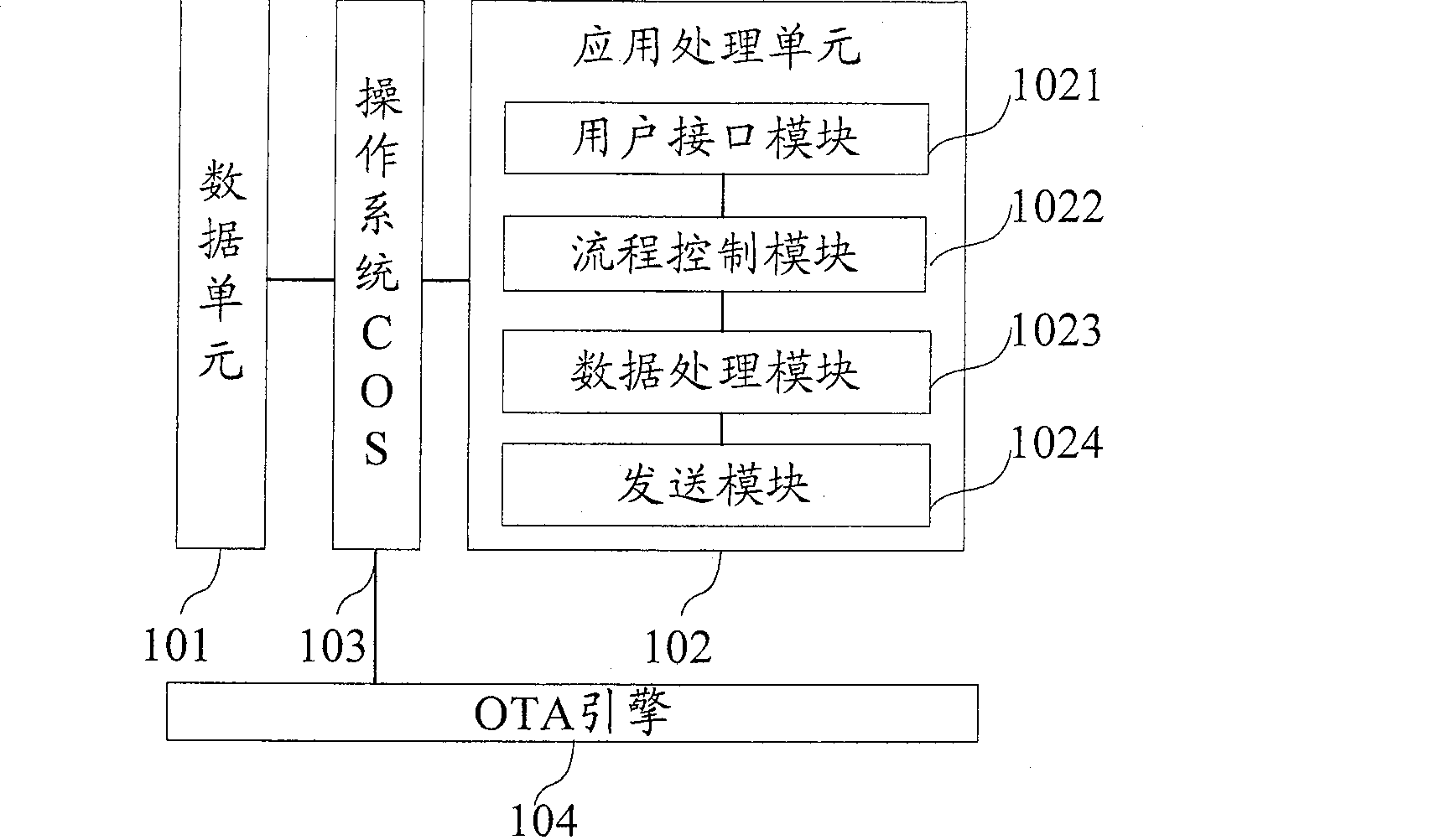

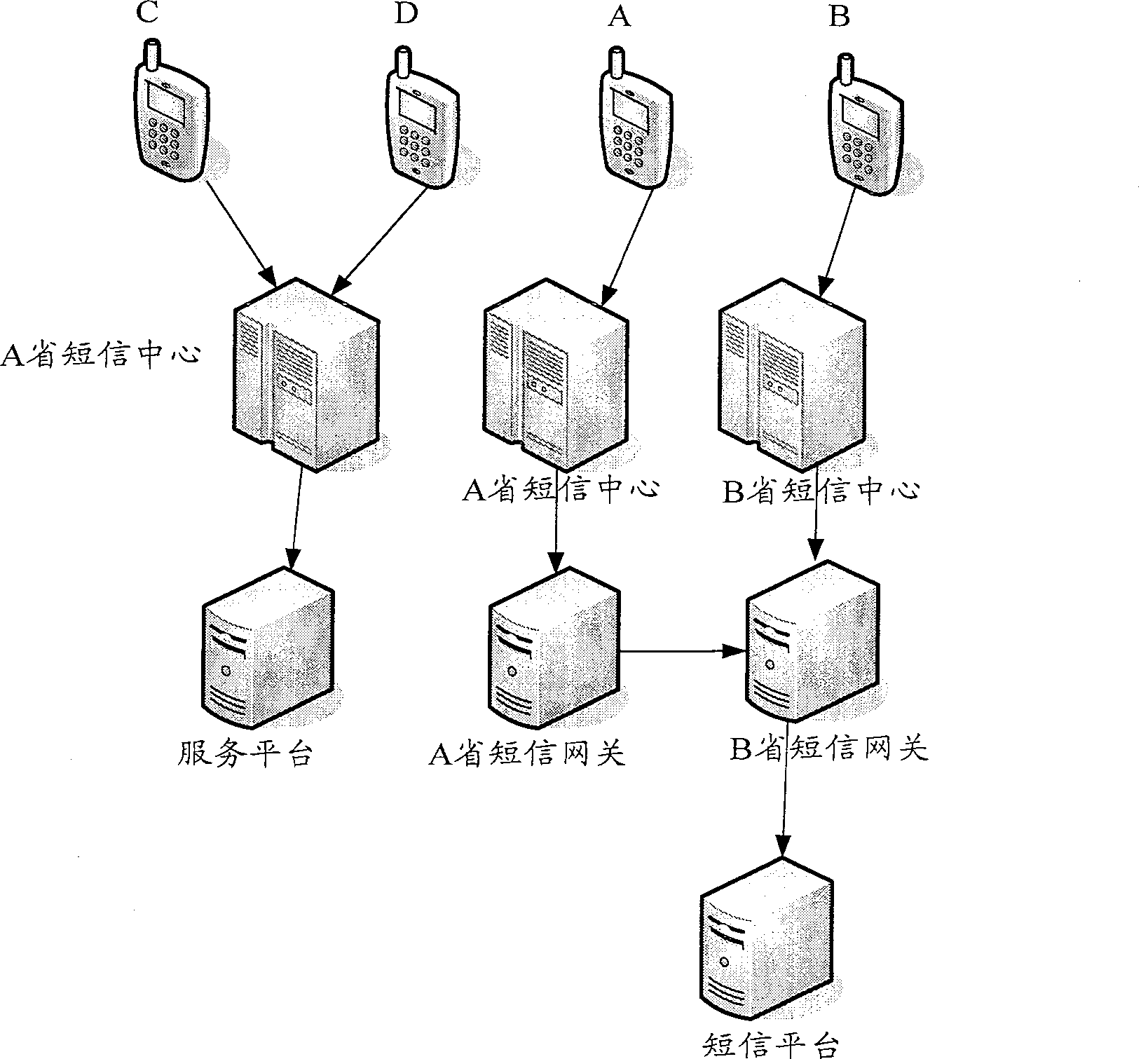

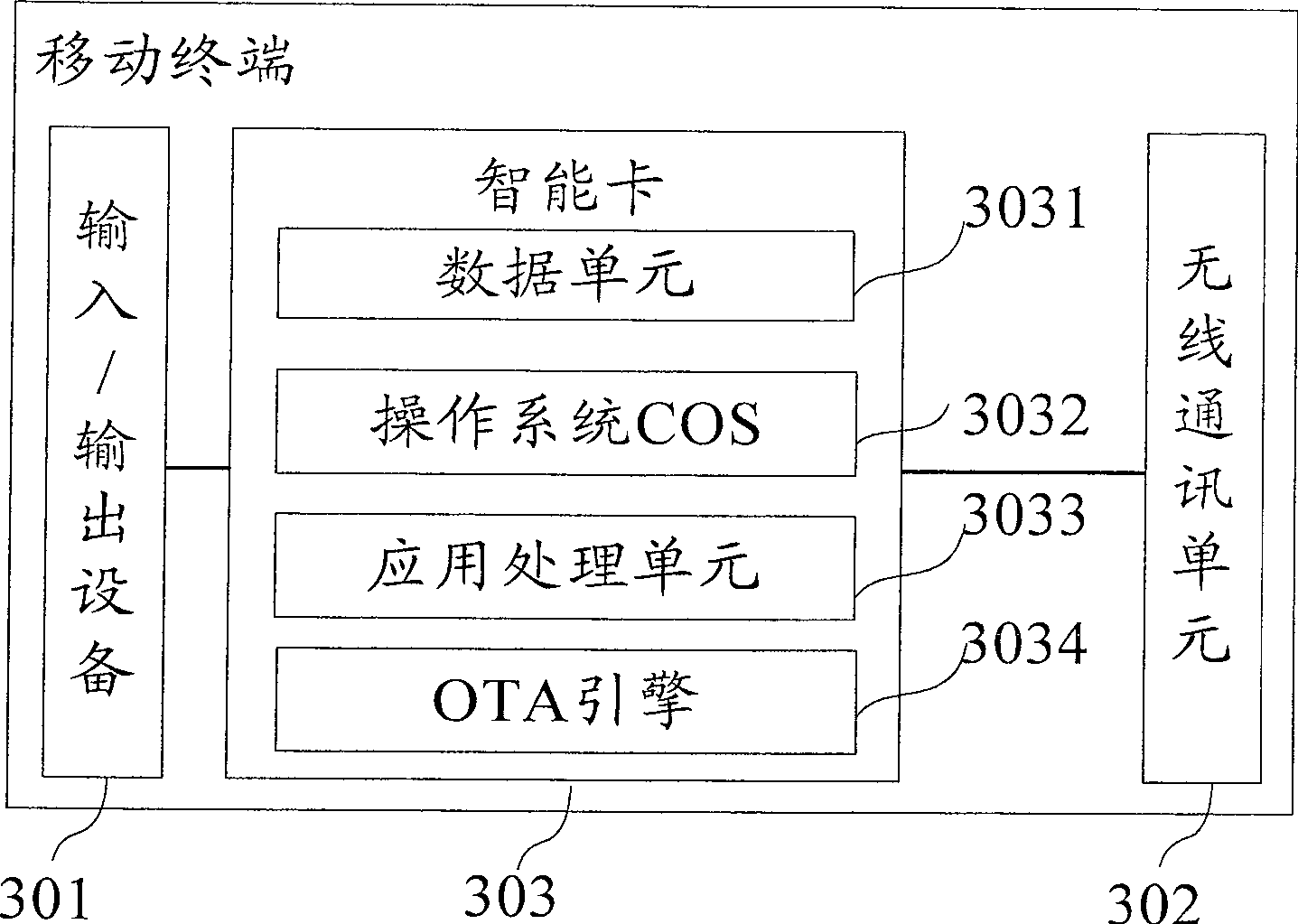

Smart card, terminal, system and method for field data acquisition

InactiveCN101043678ALower barriers to useImprove experienceTelephonic communicationRadio/inductive link selection arrangementsComplete dataOperational system

The disclosed intelligent card in a mobile terminal for on-site data collection comprises: a data unit to store data and configuration parameter, an application process unit to call the configuration parameter and data and receive user input to complete the data processing, and a COS to package data into SMS for transmission and complete data interaction between the process unit and intelligent CPU and the data unit. This invention has well security and stability, and fit to different mobile terminals.

Owner:DIGILINX TECH CO LTD +1

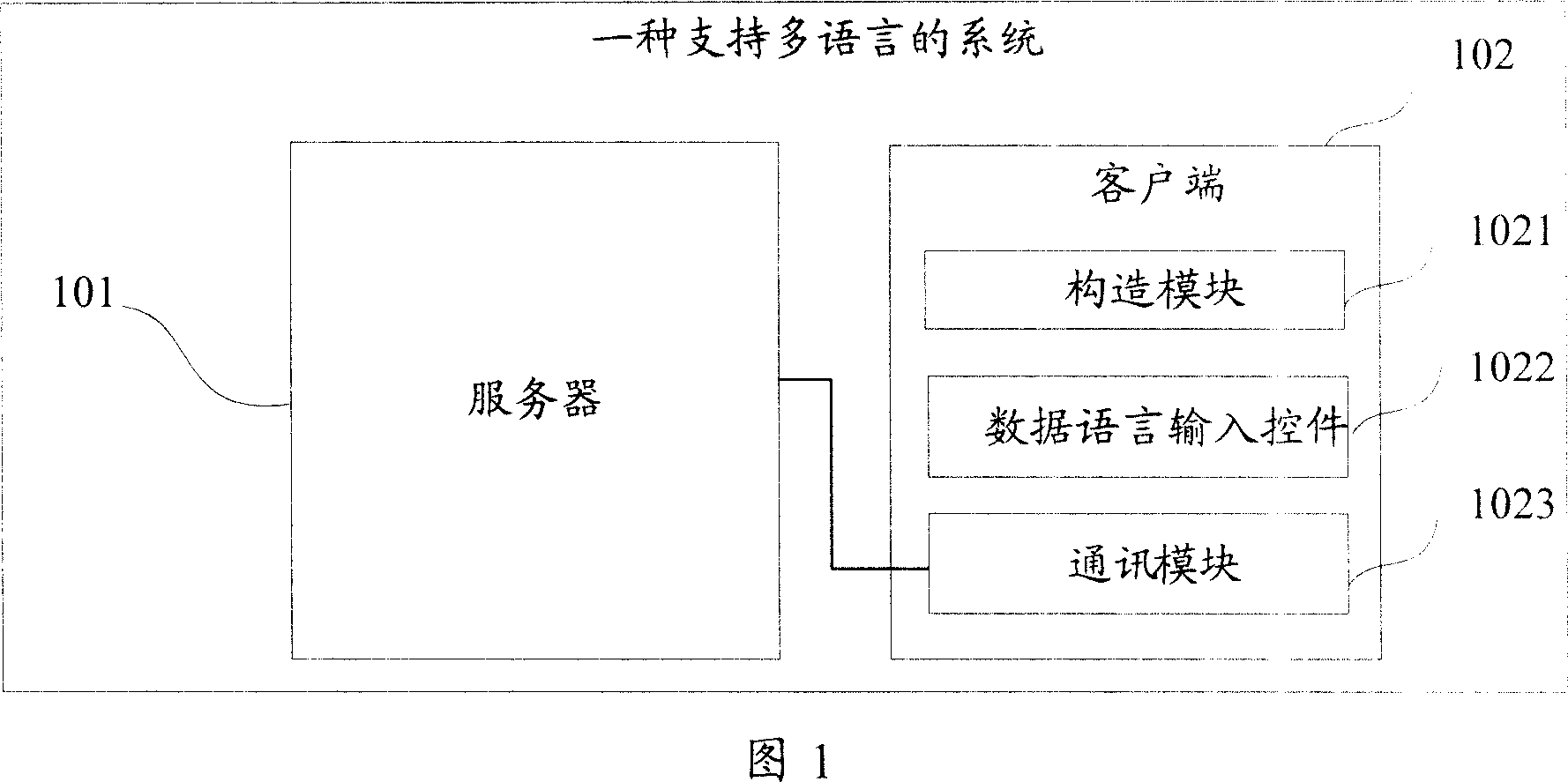

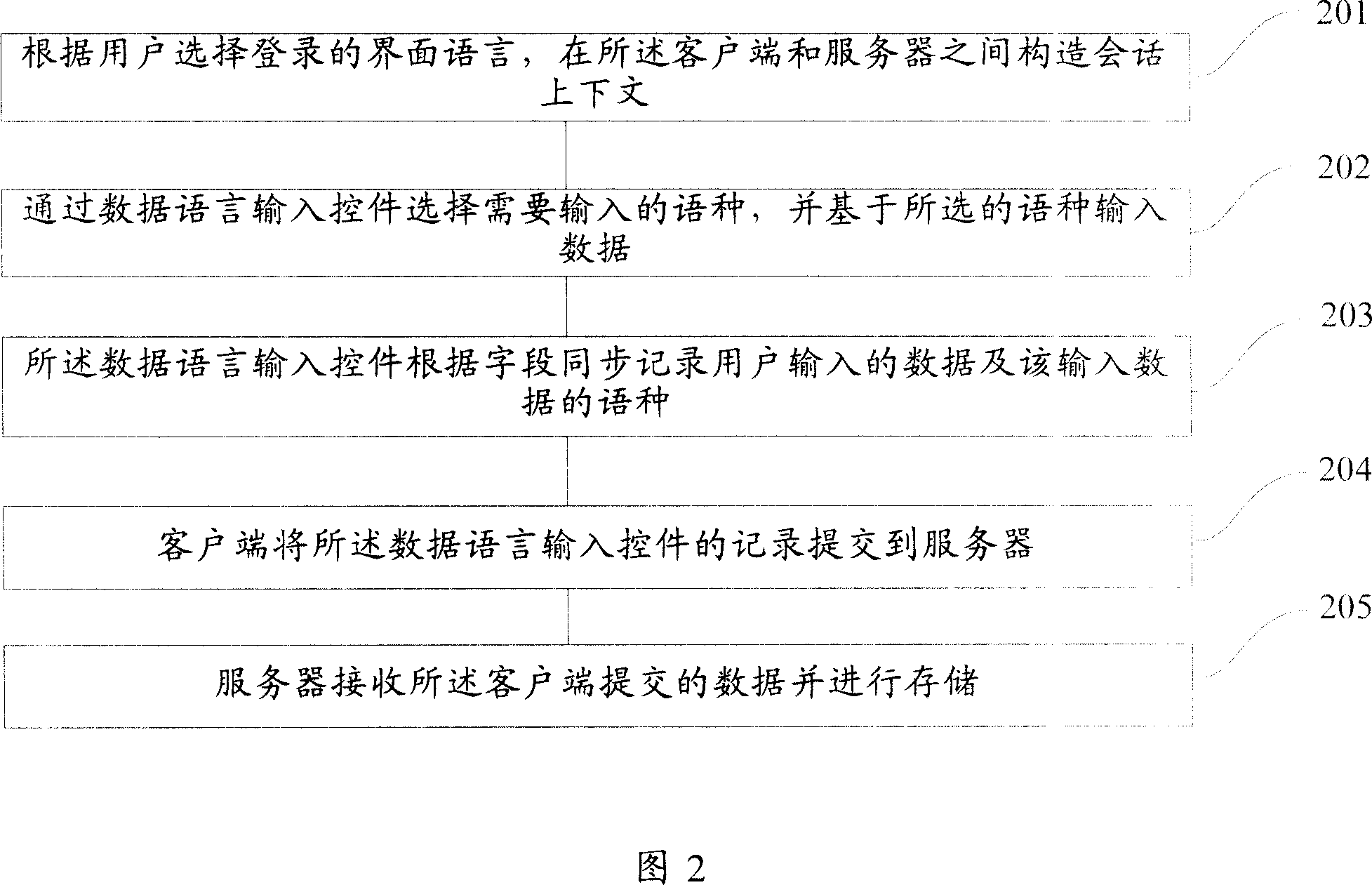

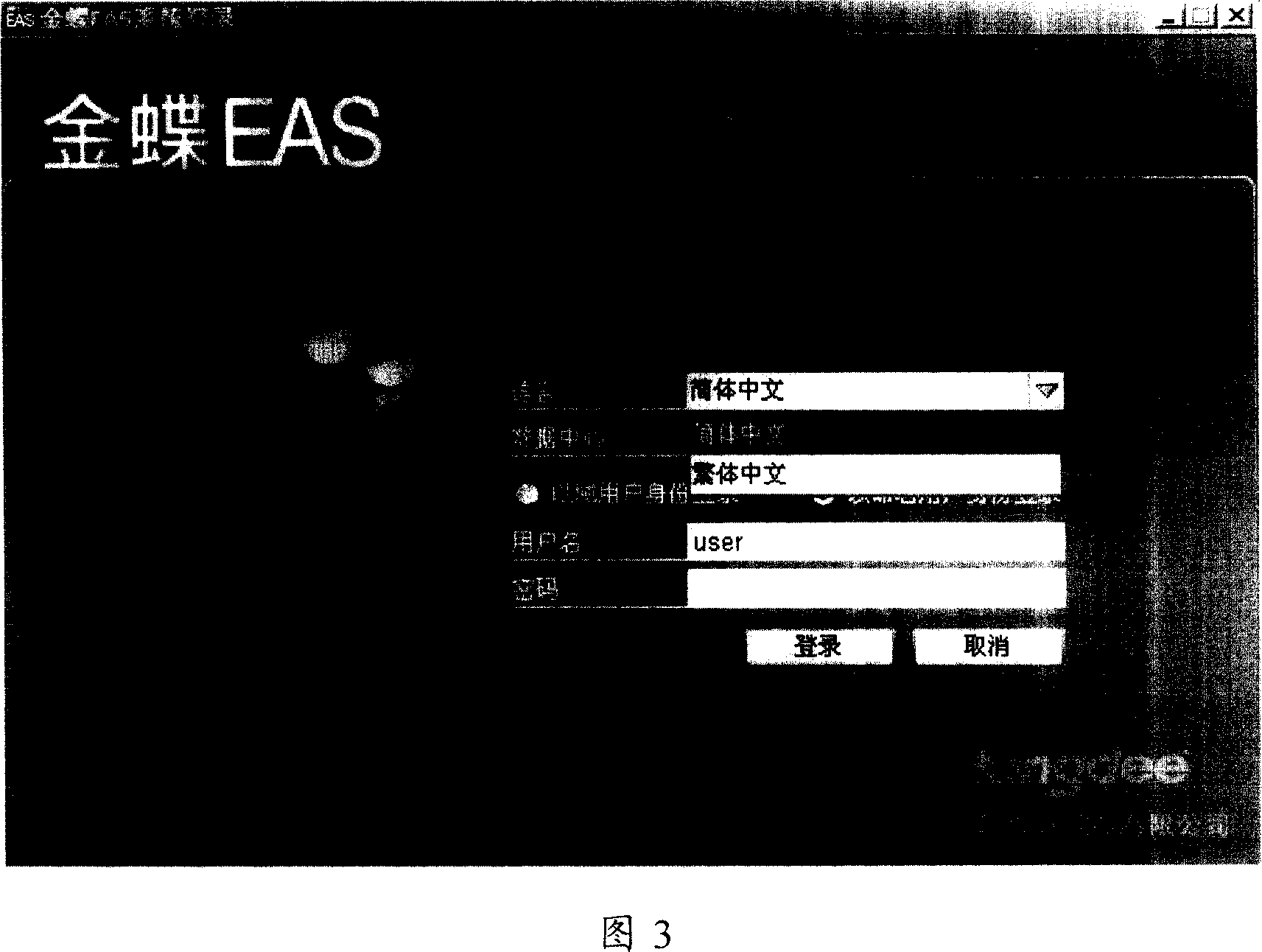

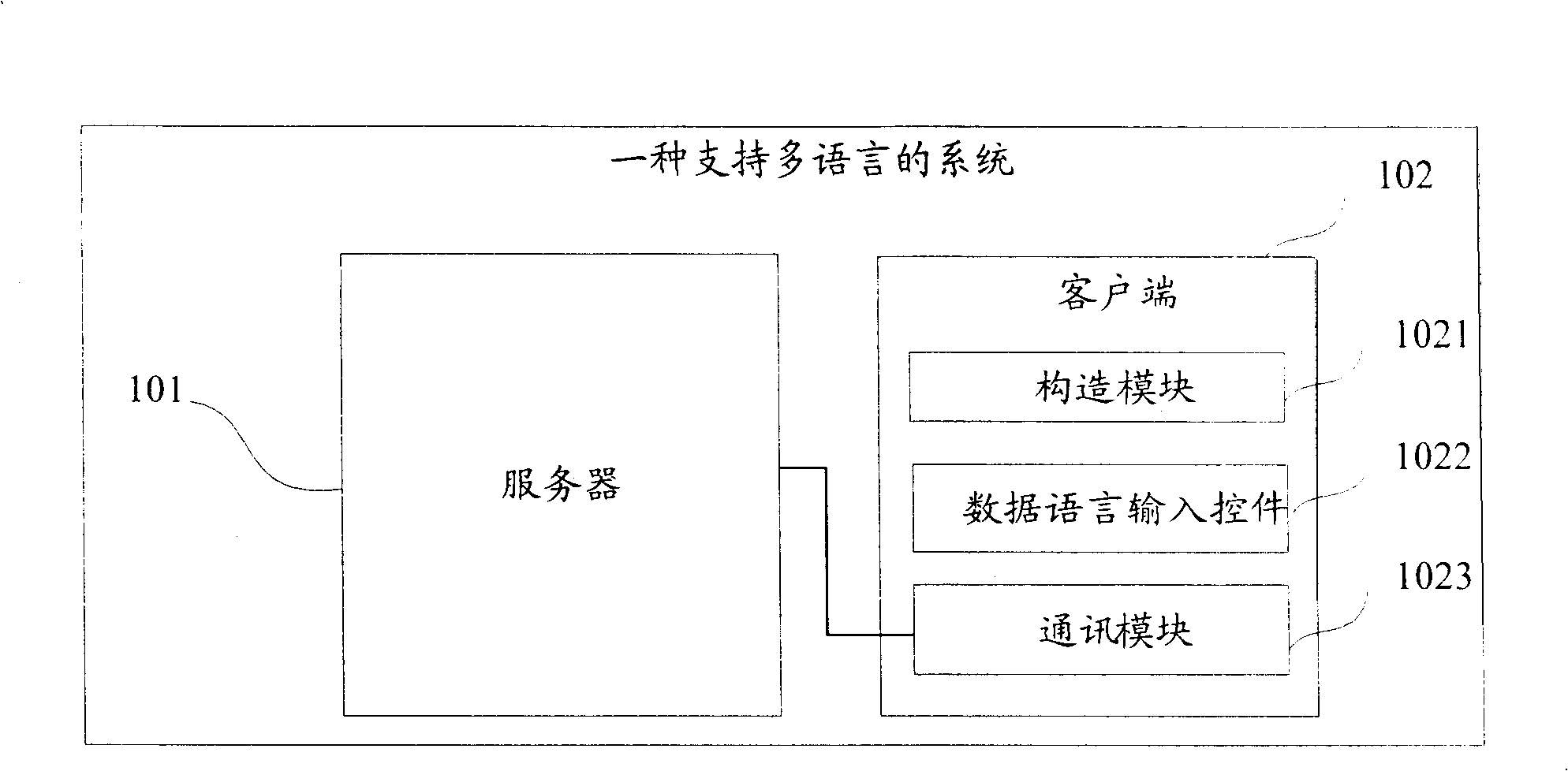

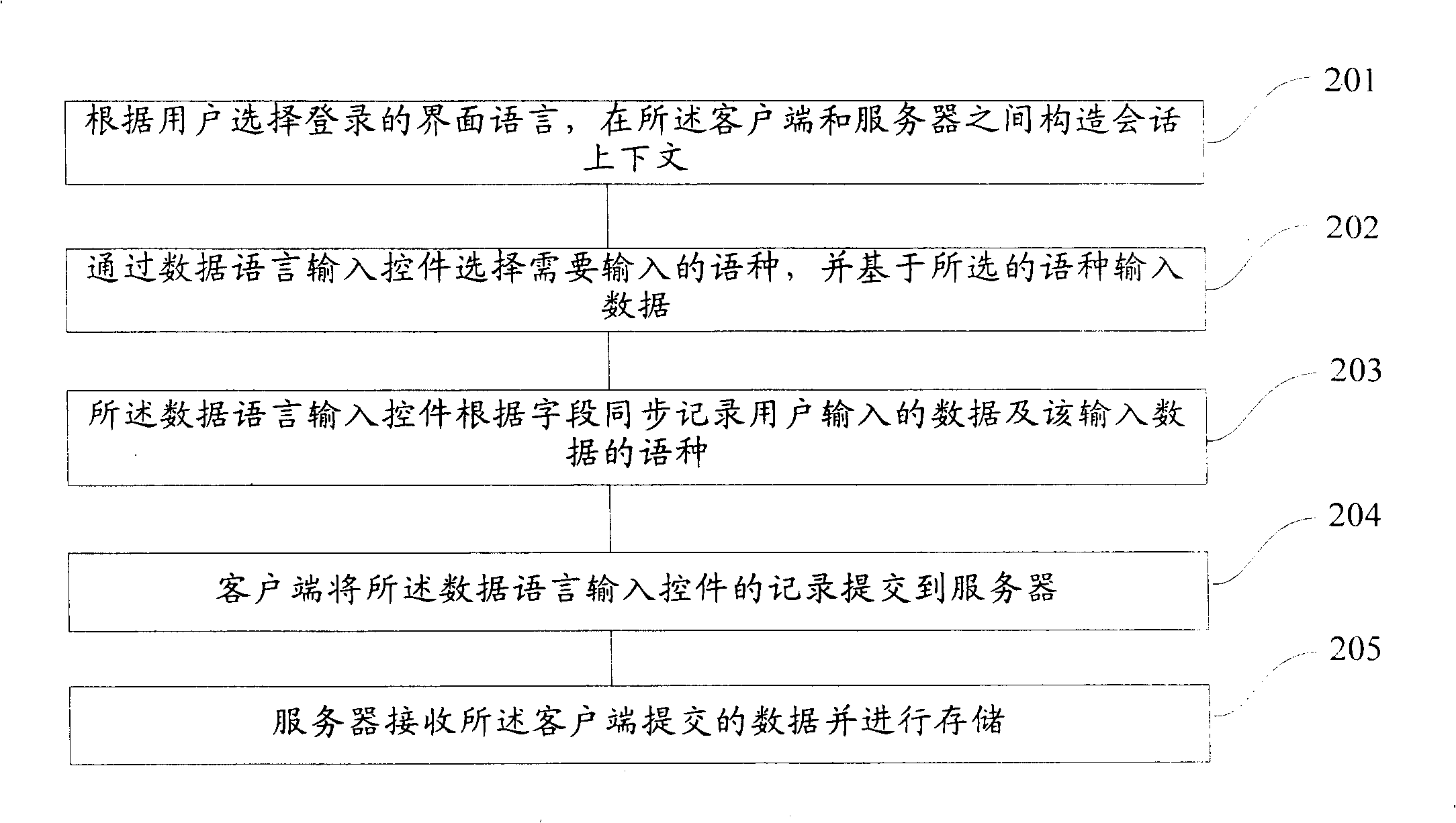

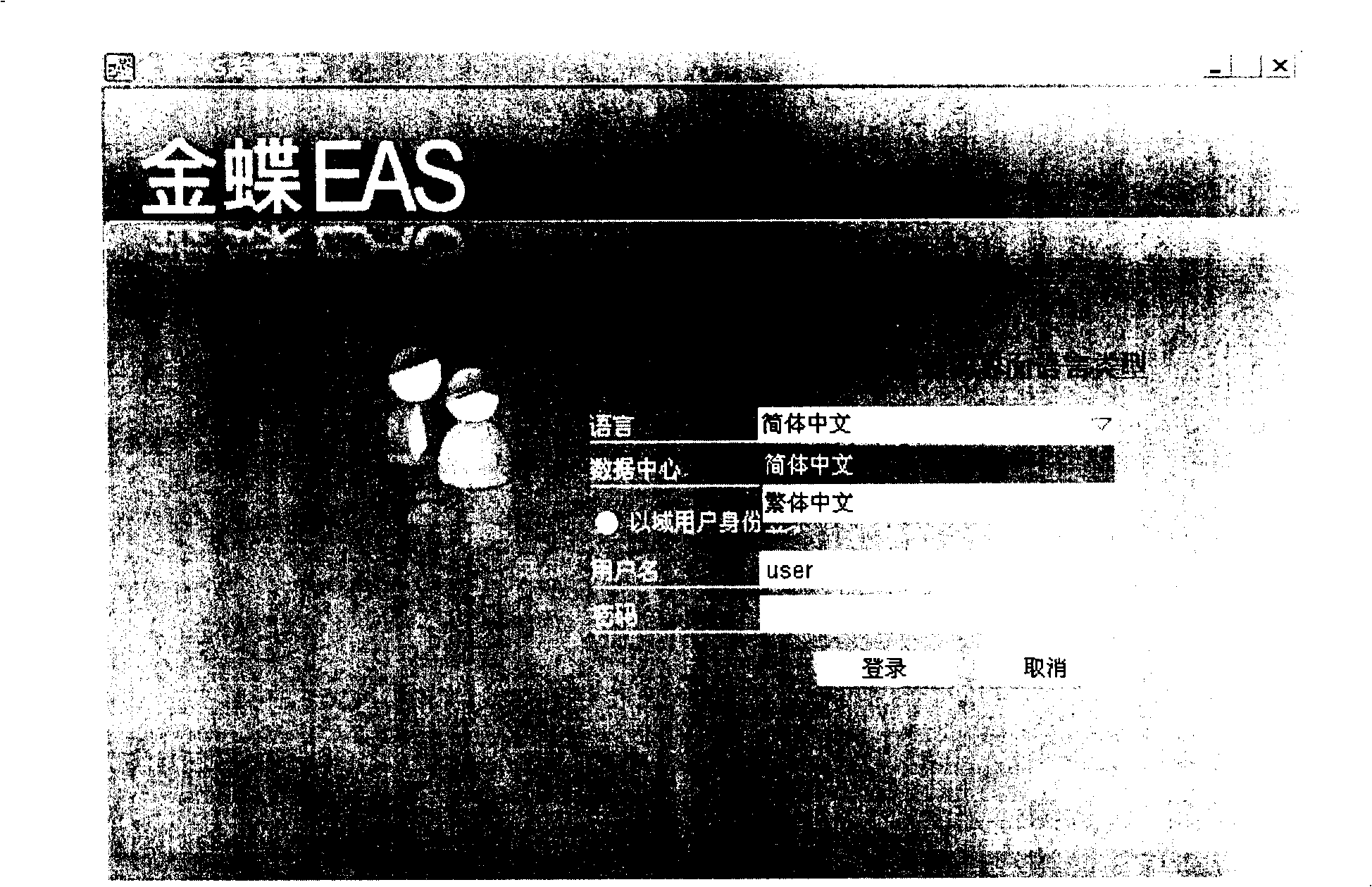

System for supporting multi-language and method for inputting and reading multi-language data

ActiveCN1975668ASave spaceSave resourcesSpecific program execution arrangementsMulti languageUser input

The invention is a system to support multiple languages, which comprises: server: which is used to store language information and data from clients; client: which includes construction module, data language input controller and communication module. The construction module includes variables to store interface language information and data language information respectively, which are used to construct the context of the conversation between client and server based on the choice of login interface language that users select; data language input controller consists of option sub module and record sub module; option sub module is used to provide with users the options of languages; record sub module is used to record user input data and the language used; mentioned communication module is used for the communication with server.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

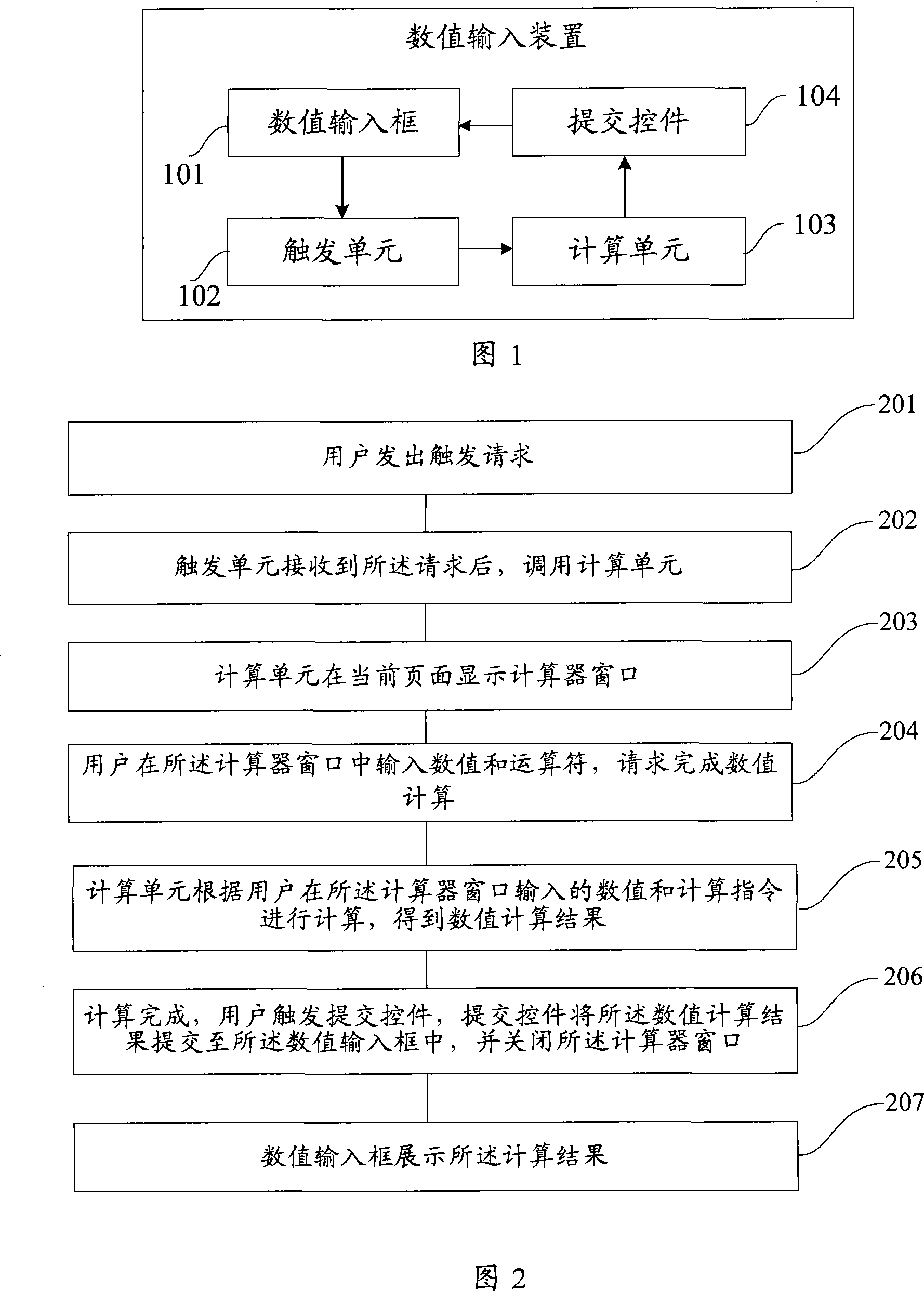

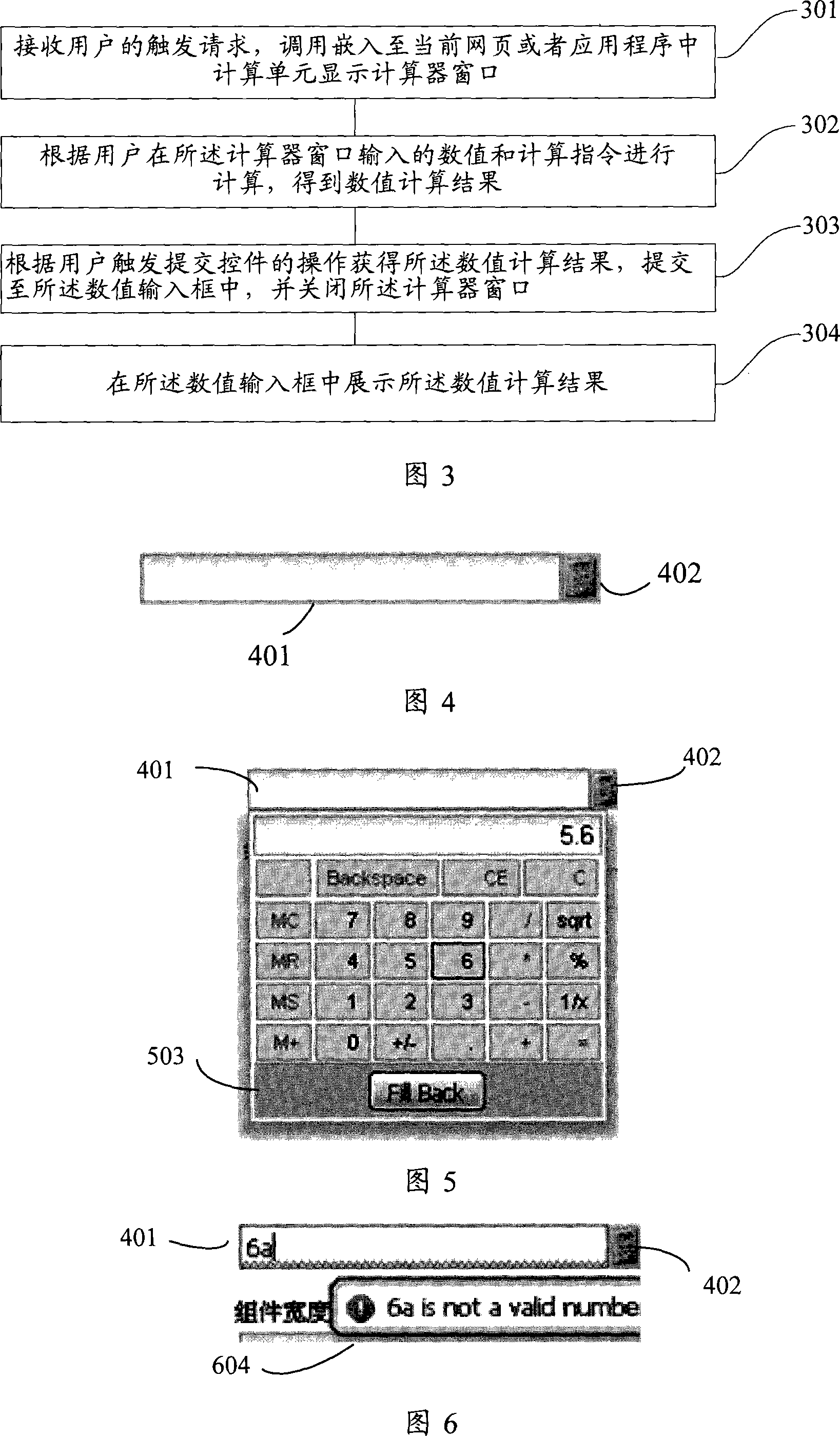

Numerical value input device and method for numerical value input using the device

InactiveCN101105750AImprove operational efficiencyReduce the burden onSpecific program execution arrangementsSpecial data processing applicationsApplication softwareWeb page

The invention discloses a numeric input device, which can be embedded in the present webpage or application program. The invention comprises a numeric input frame, a trigger unit, a computing unit and a submitting controller. The numeric input window, which is located in the present webpage or application program, is used for receiving numeric input and displaying the calculation results. The trigger unit receives user's trigger requirement and calls the computing unit, which is embedded in the present webpage and application program. The computing unit displays the calculator window, calculates the result according to the numbers inputted by user in the calculator window and user's calculating orders. The submitting controller gets and submits the results to the numeric input window. By combining the numeric input window and the computing unit, the invention saves system resources and improves the efficiency of user's operation.

Owner:SHENZHEN KINGDEE MIDDLEWARE

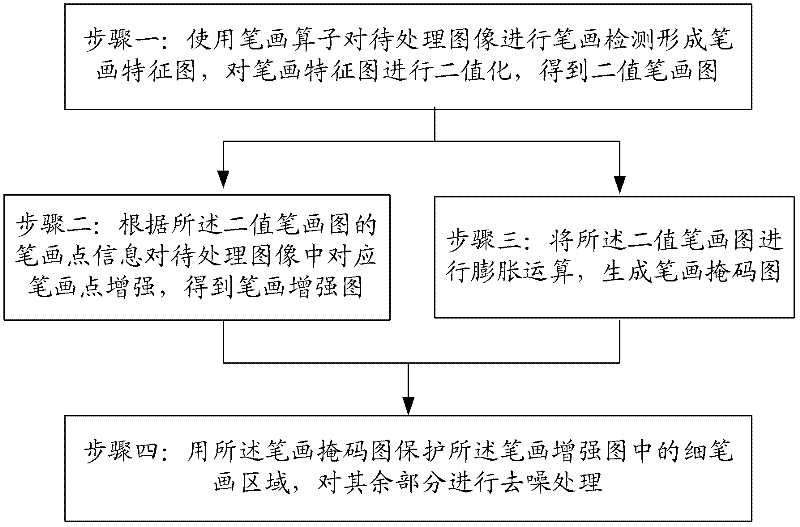

Text Image Enhancement Method and System Based on Stroke Operator

ActiveCN102270340AImprove reading skillsSmall amount of calculationImage enhancementPhysical therapyOptical character recognition

The invention provides a method and a system for enhancing a text image based on a stroke operator. The stroke operator is introduced into image enhancement processing, strokes and background can be intelligently distinguished through the stroke operator, the stroke is deepened, and the background is denoised, so that the aim of enhancing a reading effect can be effectively fulfilled; moreover, the stroke operator, binarization and expansion operation are adopted, so the calculation amount is small, the performance is good, and the real-time requirement can be met; moreover, the technology is easy to implement, technical barriers are avoided, the method and the system are low in cost and risk and have a wide application range, can be used for image enhancement in a handheld reader, and can also be used for the image preprocessing step for optical character recognition.

Owner:SHANGHAI ZHANGMEN TECH

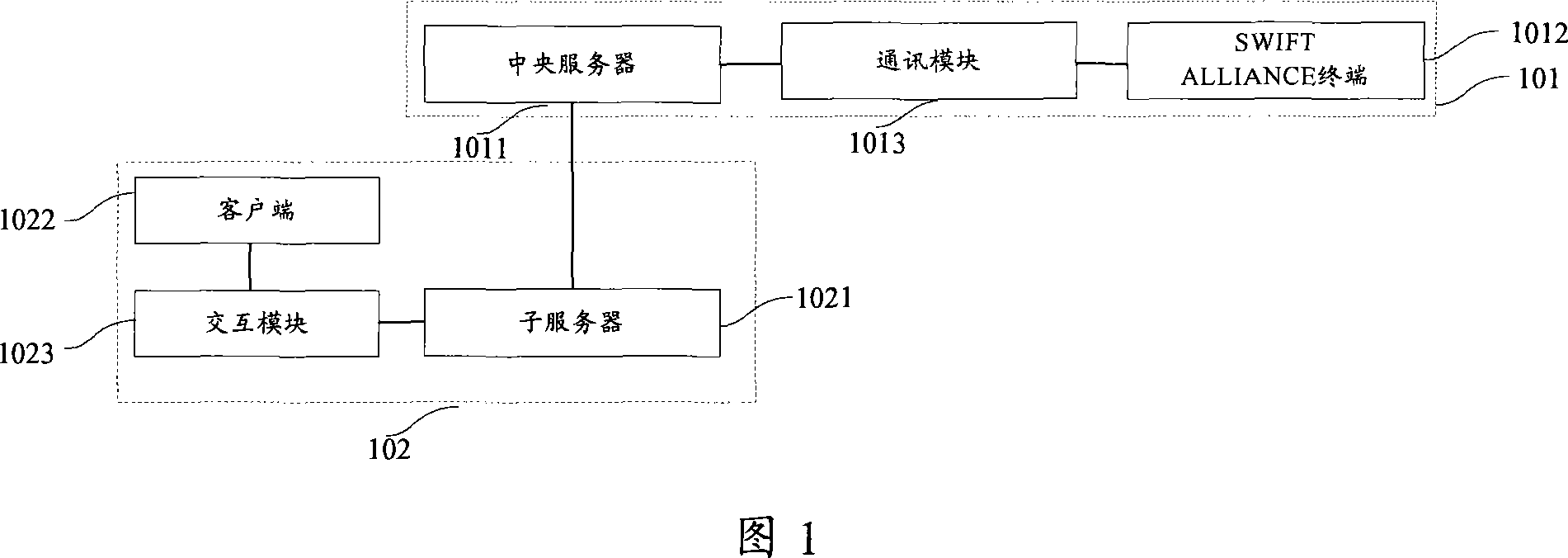

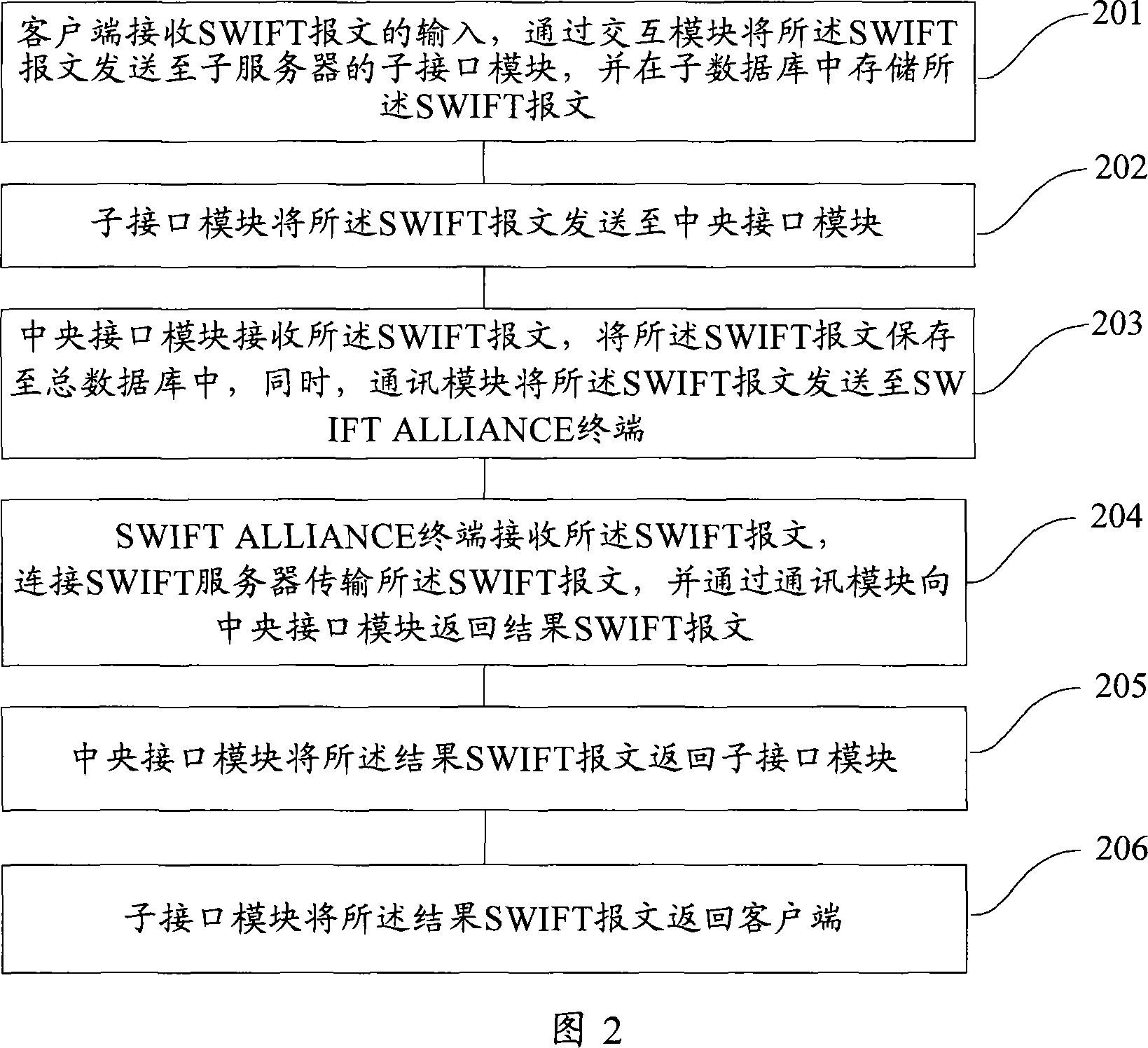

System for processing SWIFT message

ActiveCN101075967ALow costReal-time sending and receivingData switching networksSecuring communicationClient-sideHandling system

The system comprises: a central system comprising a central server, a SWIFT ALLIANCE and a communication module; and a slave system comprising a slave server, at least one client side and an interaction module. The invention effectively reduces the cost by creating a slave system and a central system so as to change the currently-used technical solution where each branch respectively set up the terminal.

Owner:CHINA CONSTRUCTION BANK

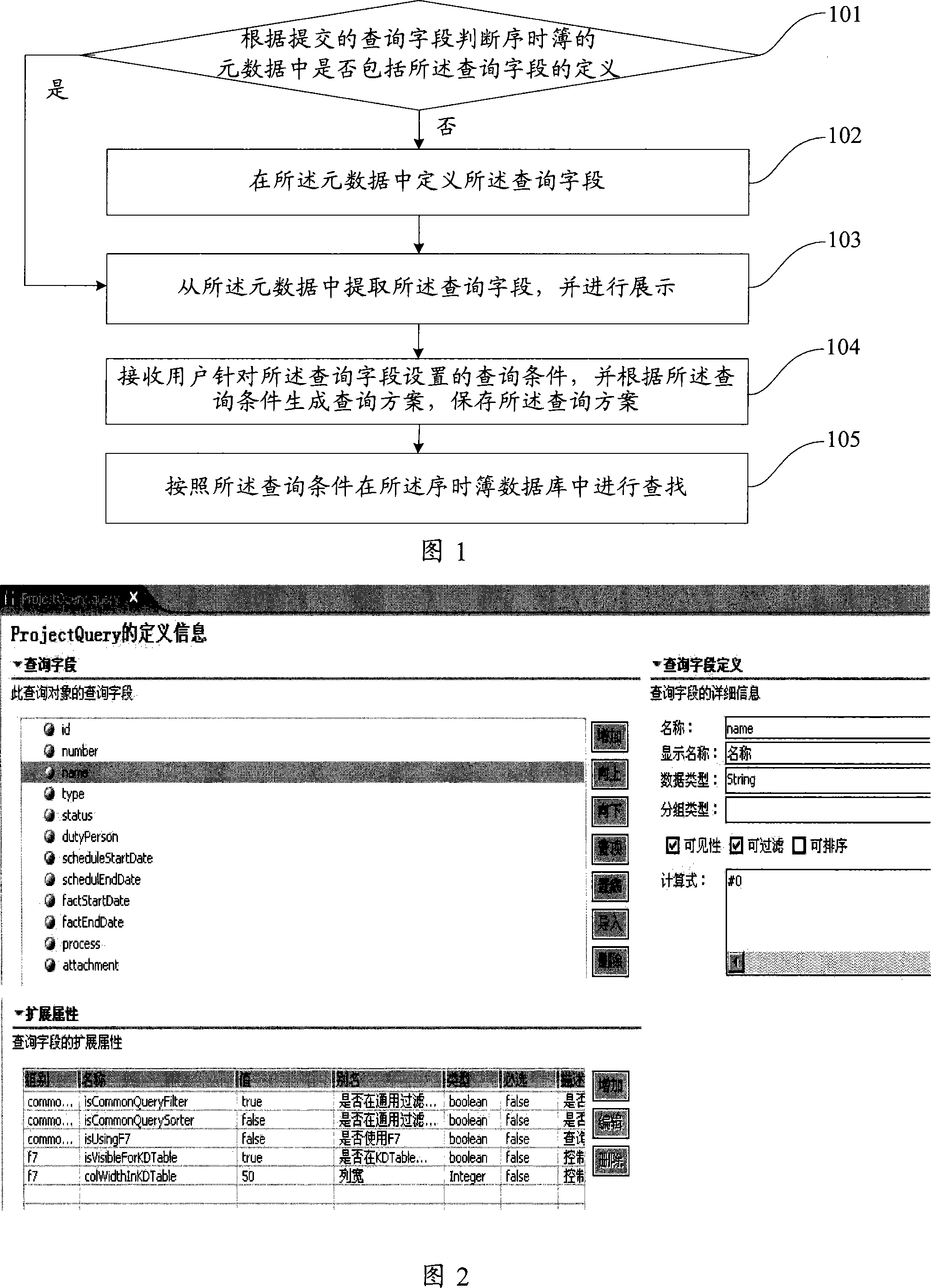

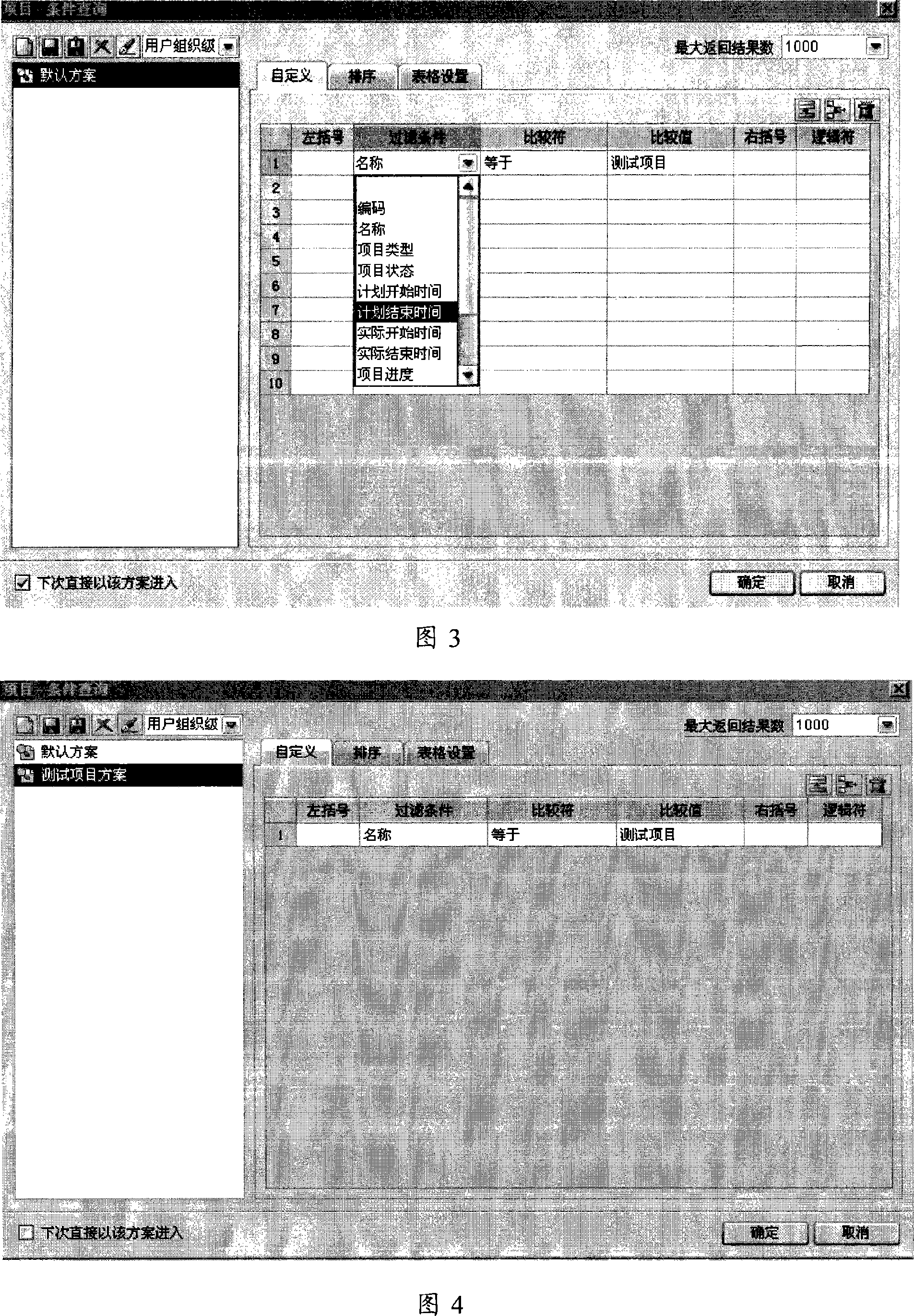

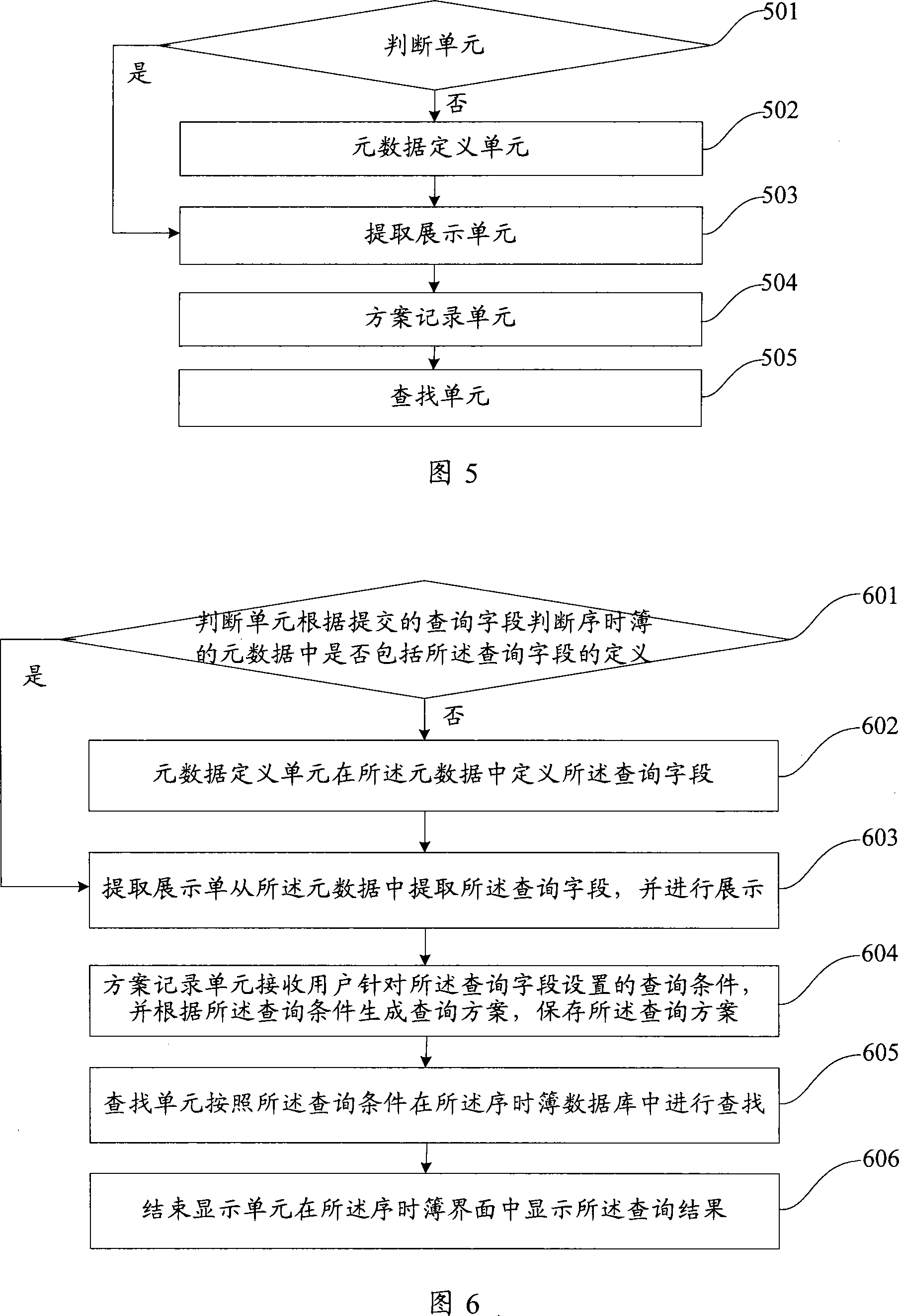

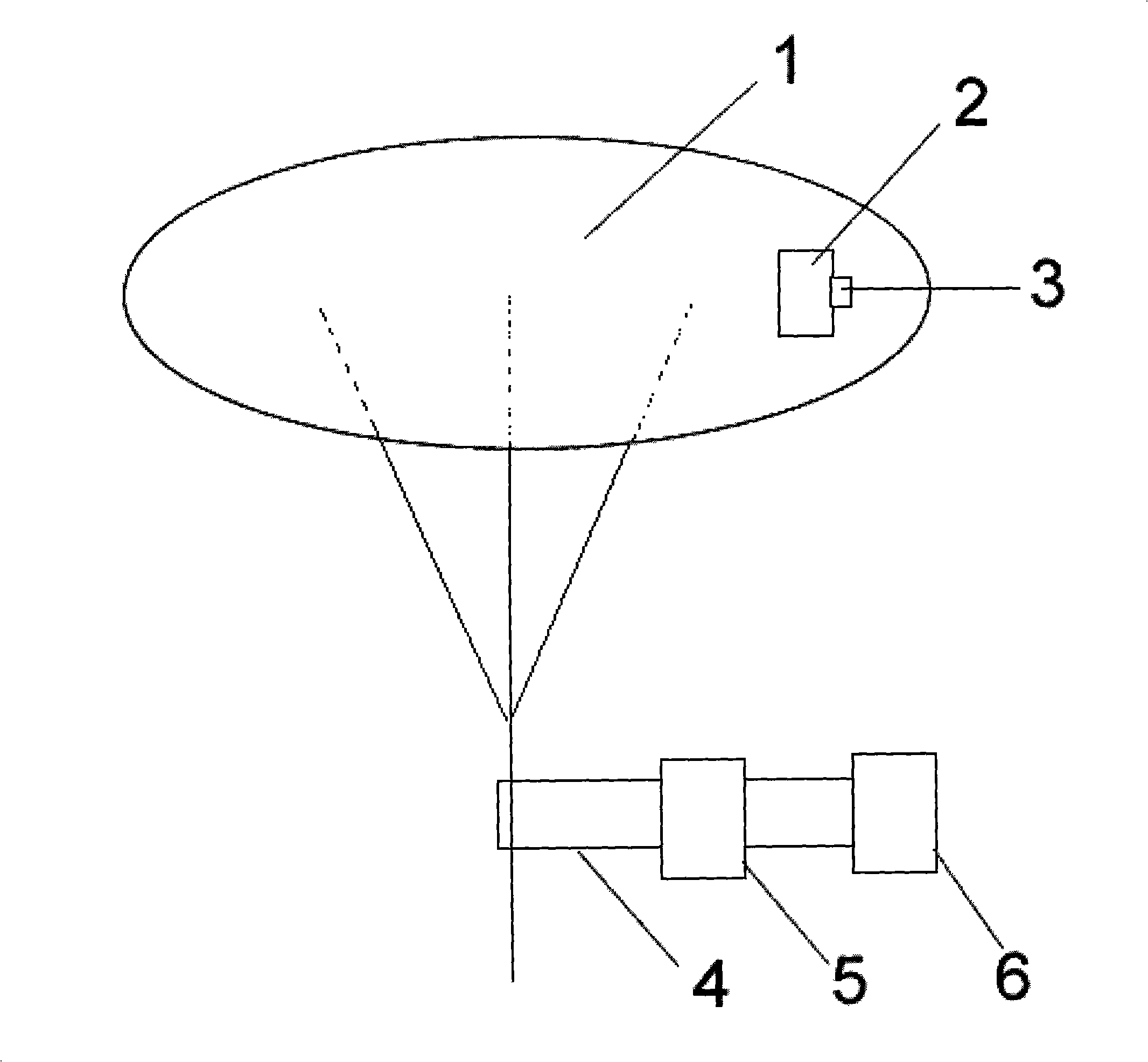

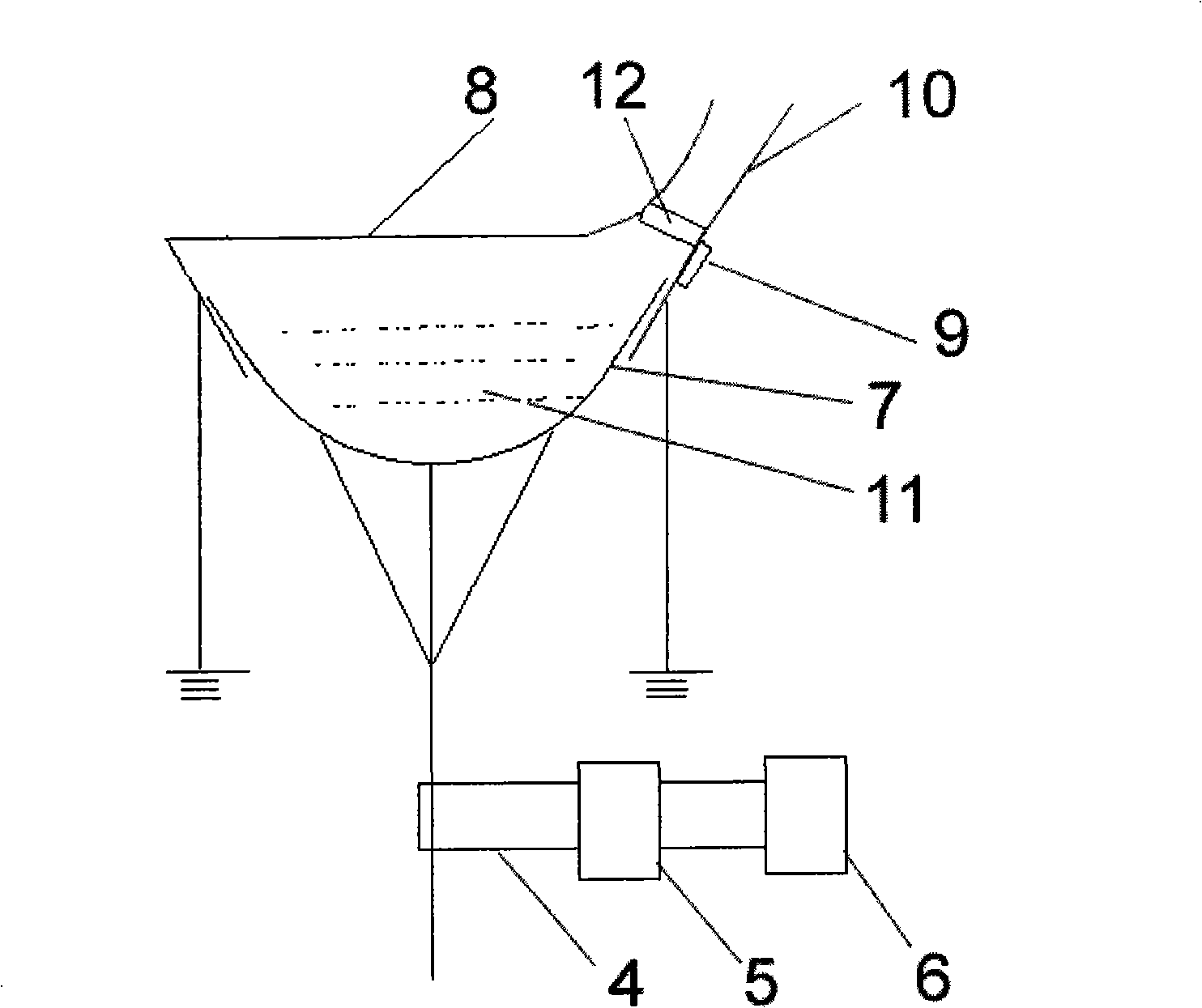

Chronological book inquiry method and device

ActiveCN101145164AExtensible attributesImplement dynamic settingsSpecial data processing applicationsQuery planMetadata

The present invention discloses a query method of a chronological book, including the following steps: S1, whether the definition of a query field is included in the metadata of the chronological book is decided according to the submitted query field, if so, S3 is then executed, and if not, S2 is then executed; S2, the query field is defined in the metadata and S3 is executed; S3, the query field is extracted from the metadata and displayed; S4, query conditions are set by adoptive users based on the query field, and a query plan is generated based on query conditions, and the query plan is saved; S5, a search is conducted in the chronological book database according to the query conditions. The present invention can set query conditions flexibly and utilize the query conditions repeatedly.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

Emission method and device

InactiveCN101294782AIncrease the distance of the assist phaseSimple structureSling weaponsHigh energyWeapon system

The invention discloses a launching method and a launching device. A method of rotating a rotator is adopted. The launching method is mainly used for launching a carrier aircraft and various spacecrafts; moreover, the launching method can be used for launching various missiles and high-energy weapon systems. The invention manages to overcome the existing problems of various catapults for aircraft carriers based on a novel concept. Meanwhile, compared with an electromagnetic rail gun, the launching device has no need for super-energy launch and manages to solve the power problem which is difficult to overcome for the electromagnetic rail gun, and the power of the launching device far exceeds that of the an electromagnetic rail gun, and creates the future of a novel weapon system.

Owner:孟英志

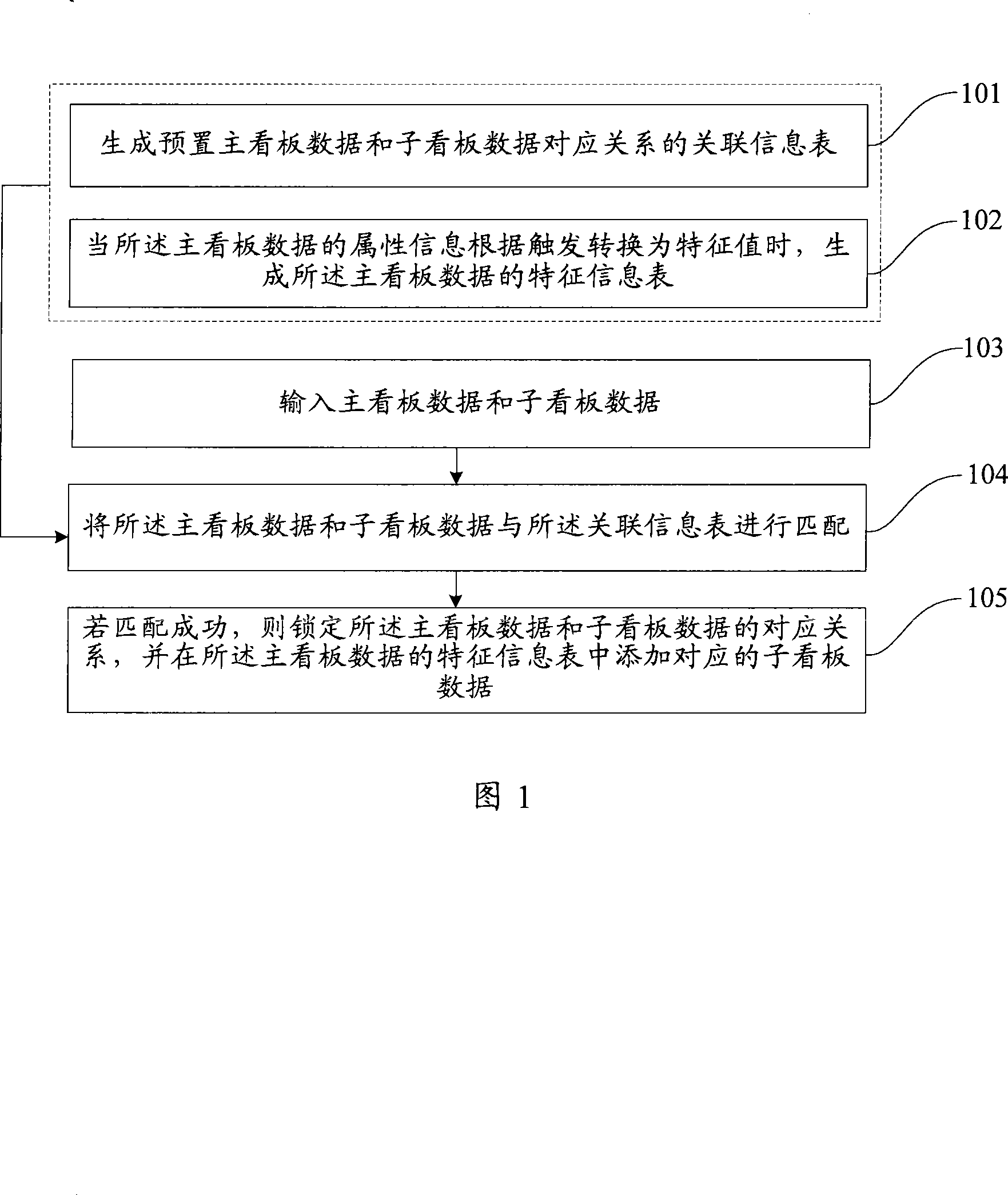

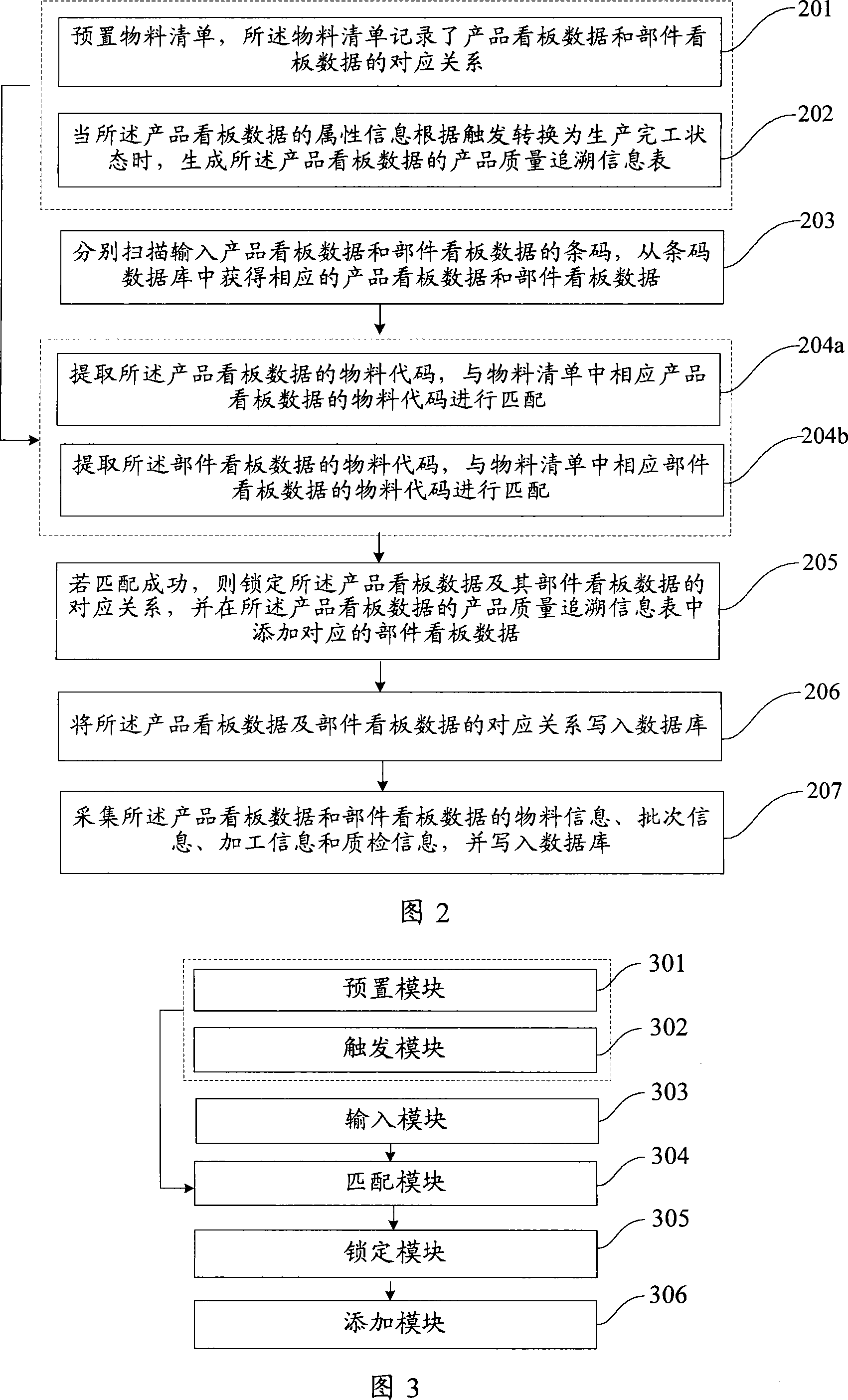

Kanban data processing method and kanban data processing system

InactiveCN101169846AGuaranteed timelinessGuaranteed accuracyResourcesSpecial data processing applicationsData processing systemData science

The invention provides a signboard data processing method. The signboard data includes main signboard data and sub signboard data. The main signboard data has property information. The method includes generating a correlated information table preset corresponding relations of the main signboard data and the sub signboard data; generating a characteristic information table of the main signboard data when the property information of the main signboard data is triggered to be converted to the characteristic value; inputting the main signboard data and the sub signboard data; matching the main signboard data and the sub signboard data with the correlated information table; and locking the corresponding relation of the main signboard data and the sub signboard data and adding corresponding sub signboard data into characteristic information table of the main signboard data when the matching is success. The invention can ensure real-time, accuracy and integrity of the data to save man load cost and reduce failure chance.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

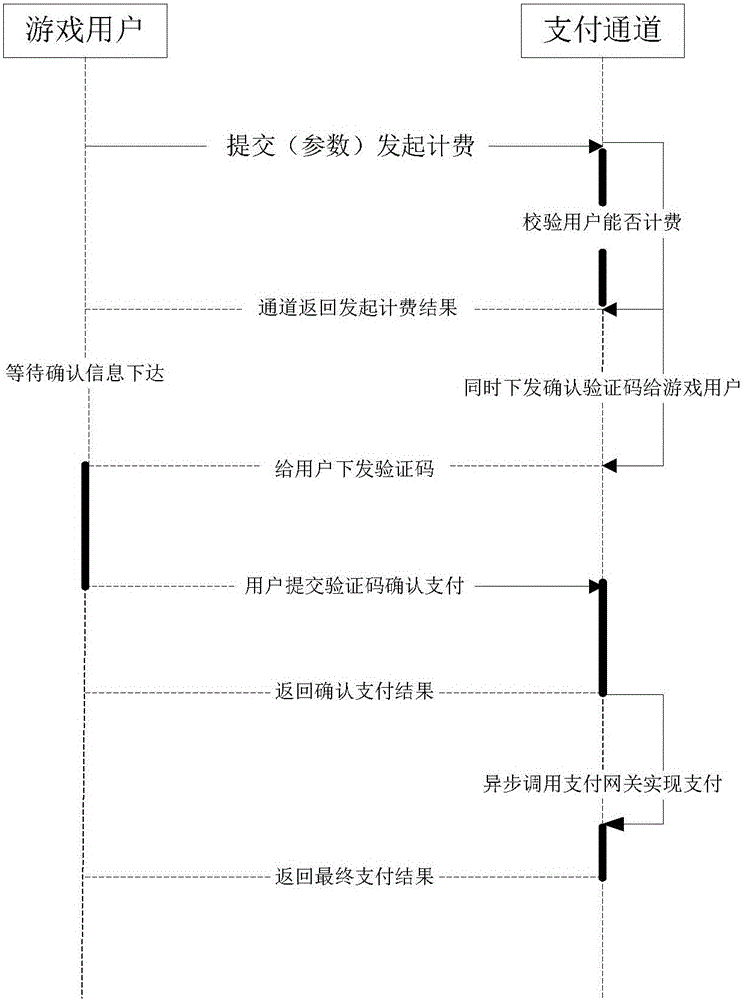

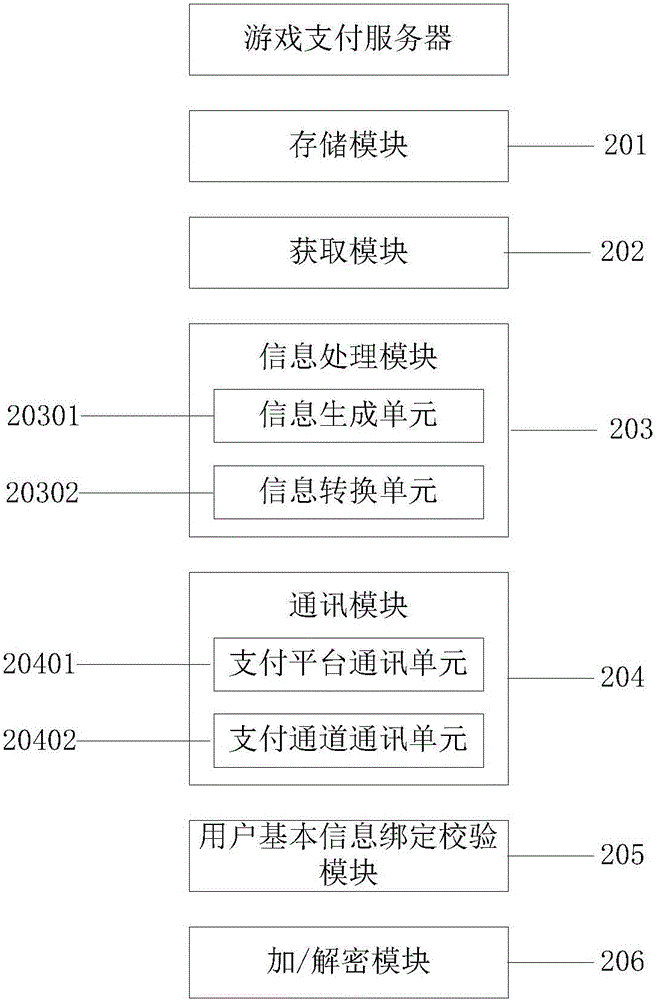

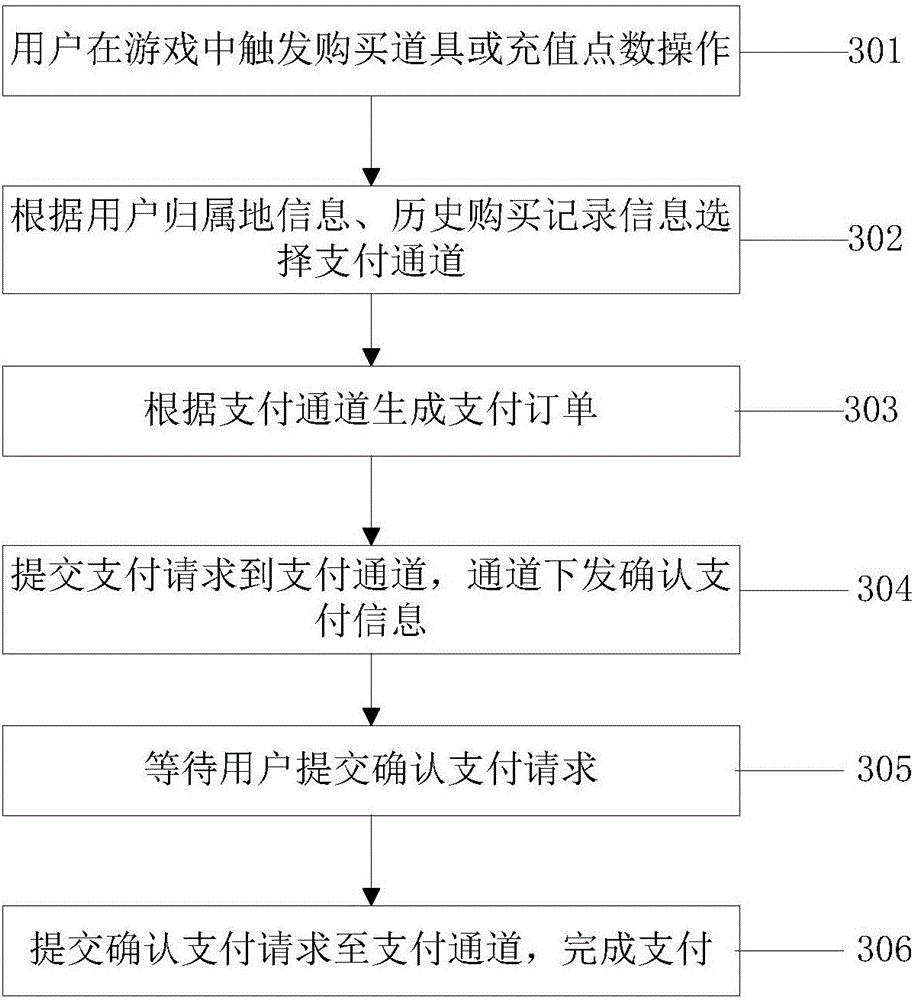

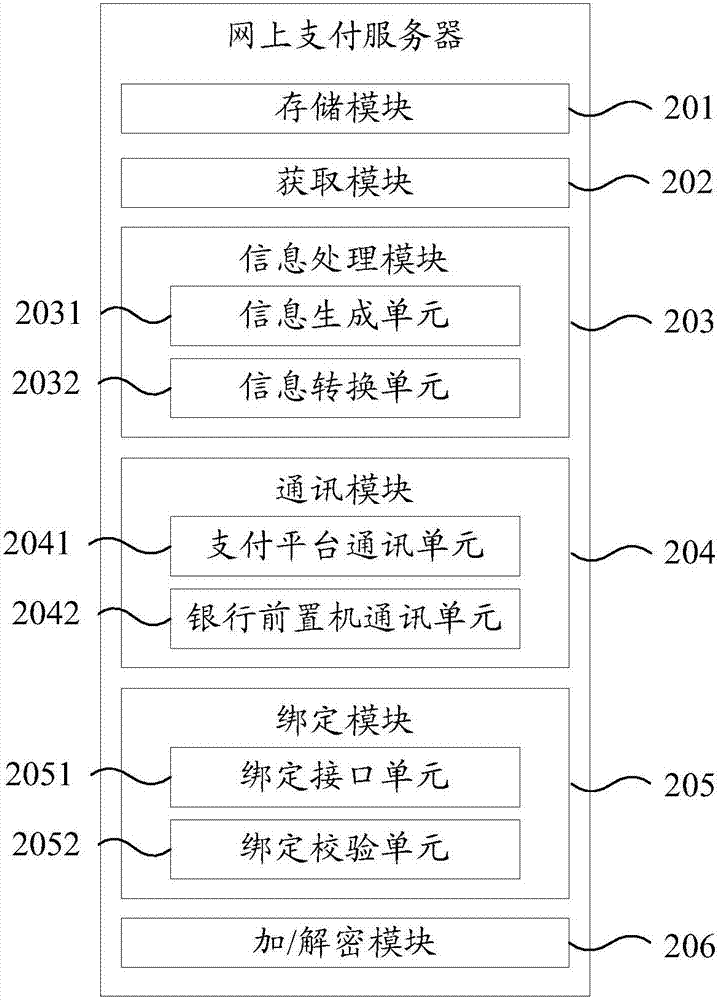

Mobile phone game payment server, payment method and payment system

InactiveCN105844467AImprove efficiencyImprove communication efficiencyProtocol authorisationUser verificationUser privacy

The present invention discloses a mobile phone game payment server, payment method and payment system. The mobile phone game payment server comprises a storage module, an acquisition module, a communication module and a user basic information binding calibration unit; the payment system includes the mobile phone game payment server and a payment platform; and the payment platform includes a user calibration module, an order generation module, a payment interface module and a game payment server. The mobile phone game payment server, payment method and payment system are high in safety and communication efficiency, are able to reduce the probability errors caused by misoperation, greatly improve the user payment success rate and the user experience effect, improve the user privacy information safety and payment safety and effectively ensure the system stability and the user purchase stability, are simple in technology realization and rapid and convenient to access, have no technical obstacles and greatly reduce the development cost and the operation risk.

Owner:北京展鸿软通科技股份有限公司

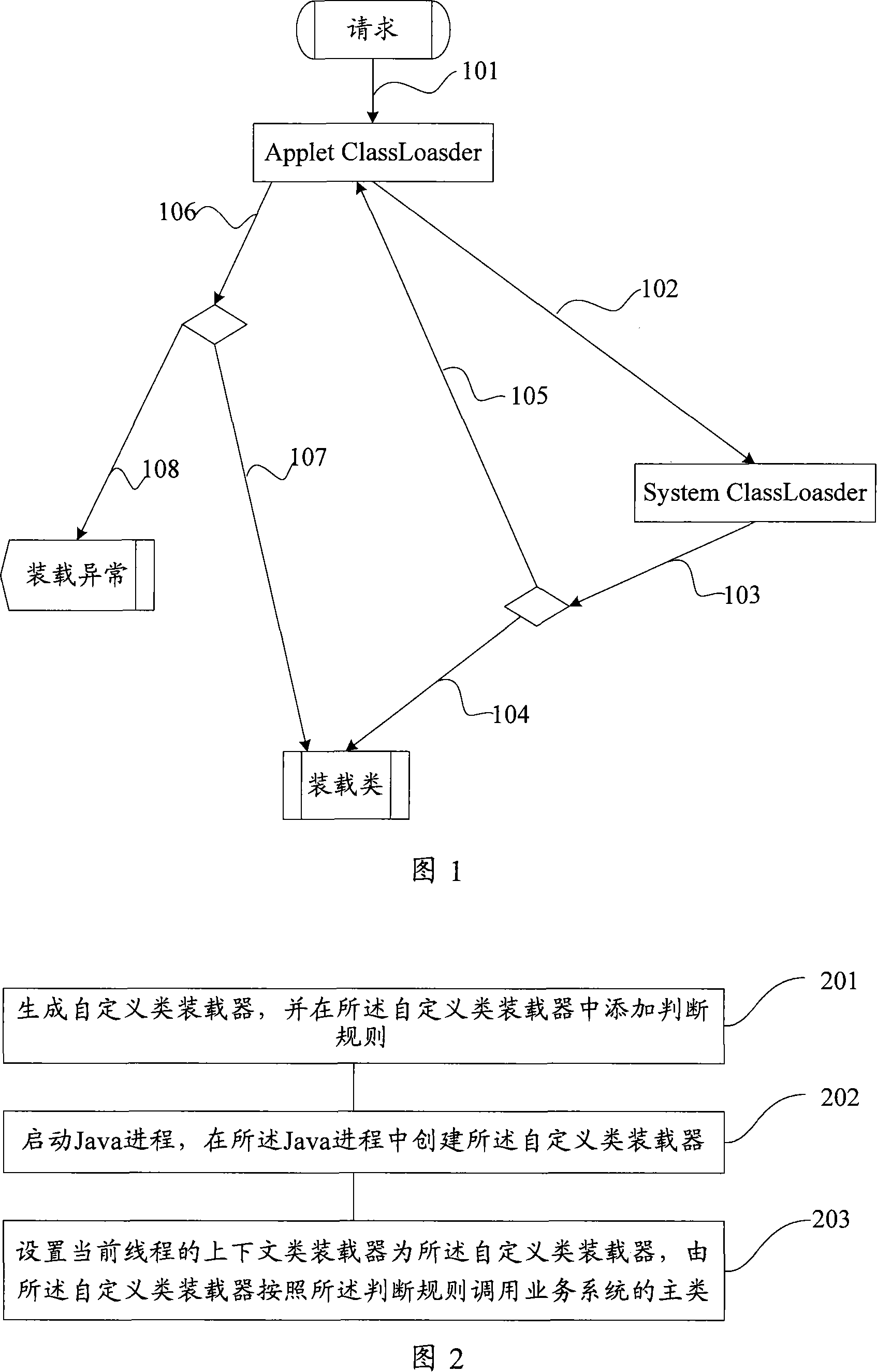

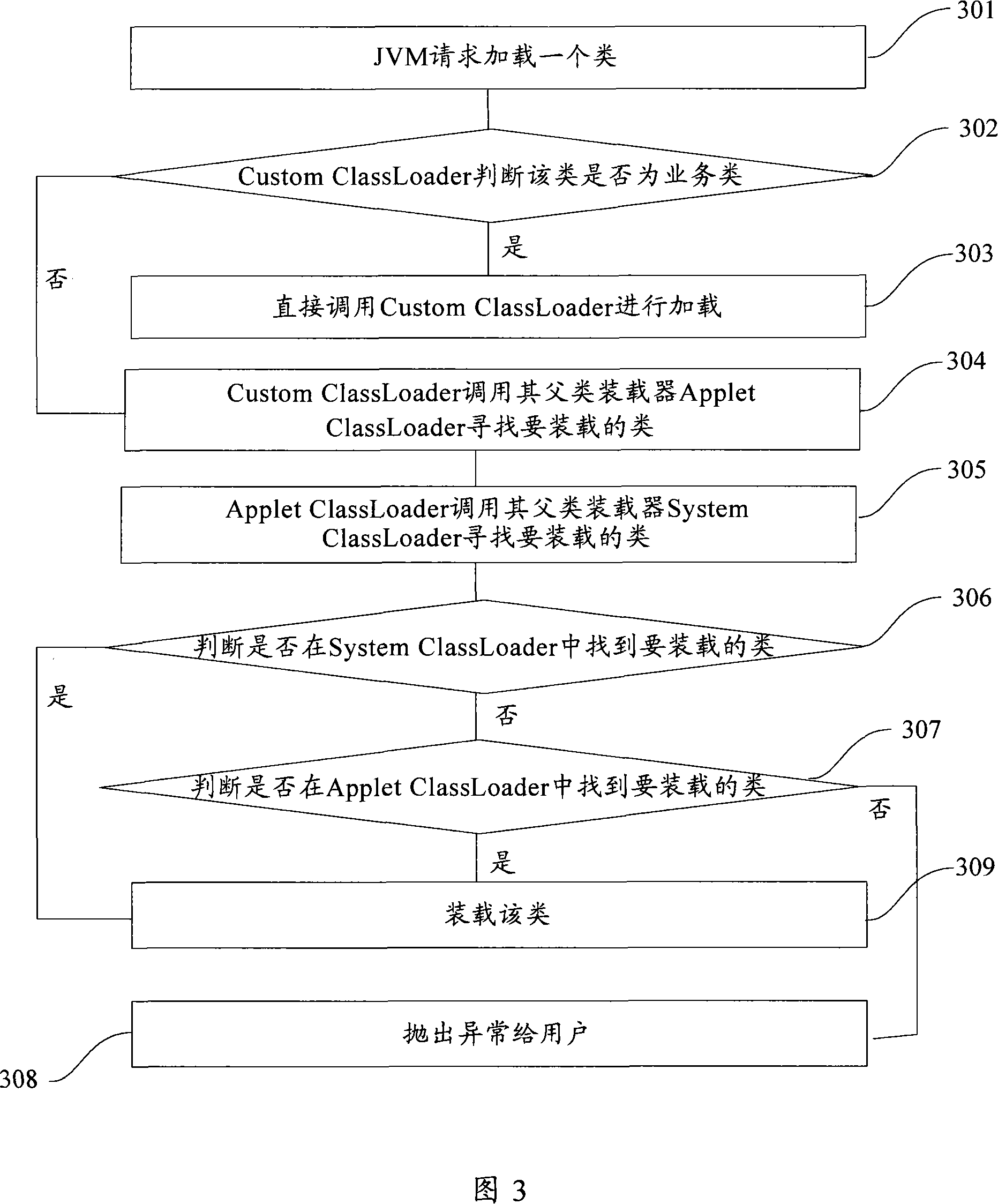

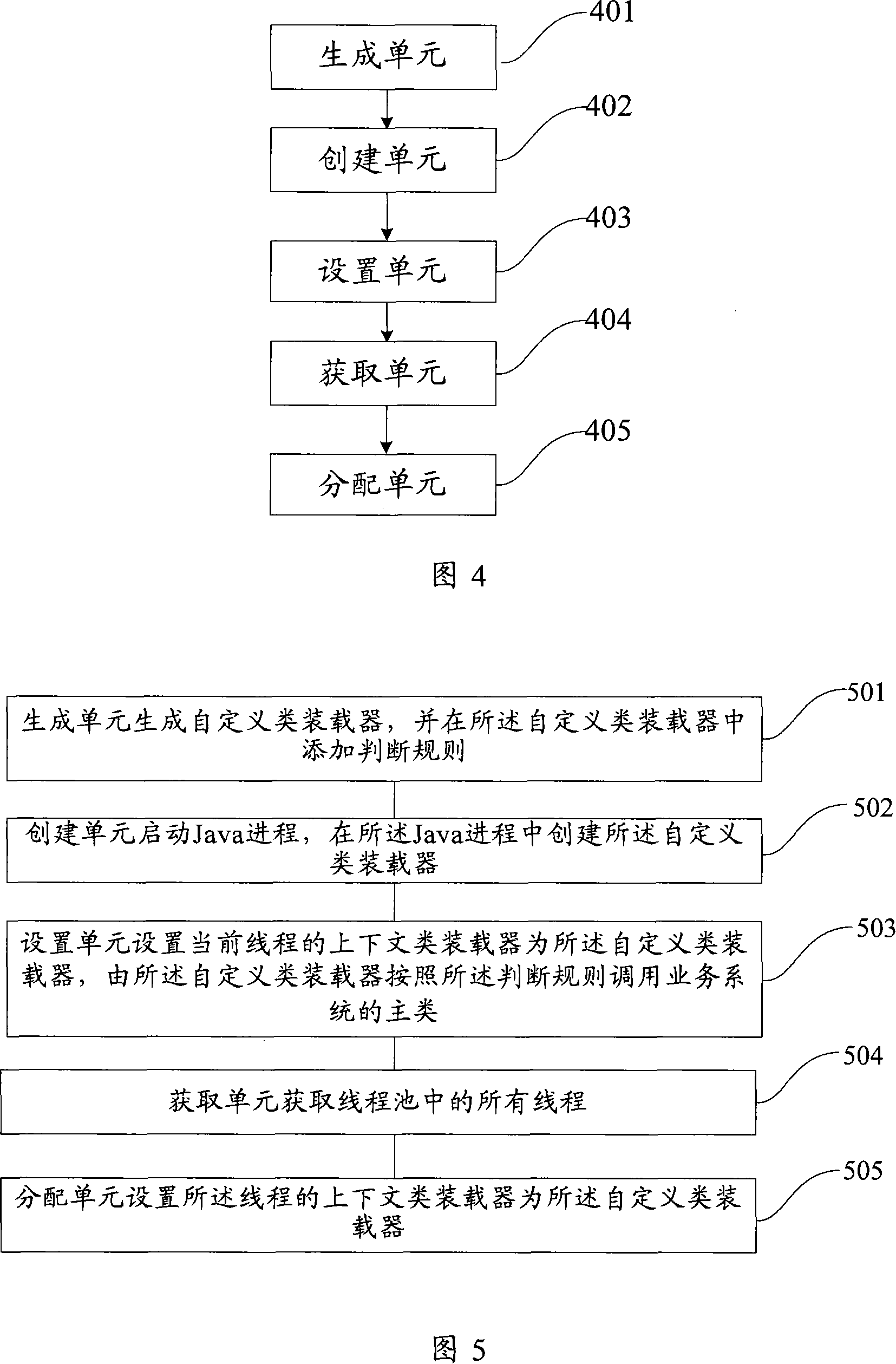

Method and device for class loading process

InactiveCN101118497AImprove loading efficiencyReduce loading pressureMultiprogramming arrangementsProgram loading/initiatingJavaSoftware engineering

The present invention discloses a class loading processing method, including a produced user-defined class loader in which a rule of judgement is added; after a Java process is initiated, the user-defined class loader can be founded in the Java process; a context class loader which sets the present thread is the user-defined class loader, and a main class of an operation system is taken by the user-defined class loader according to the rule of judgement. By changing the prior process of the class loading, namely, for non-operation class, the prior process loading is adopted, for operation class, loading in other father class loader step-by-step is not needed, loading in the user-defined class loader is OK, so that the loading stress of the Applet class loader is decreased, and the class loading efficiency is improved greatly. Furthermore, since the present invention makes the user-defined class loader can be realized by being appointed in relevant thread, an overfull system resource cannot be occupied, and an additional system configure is not needed.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

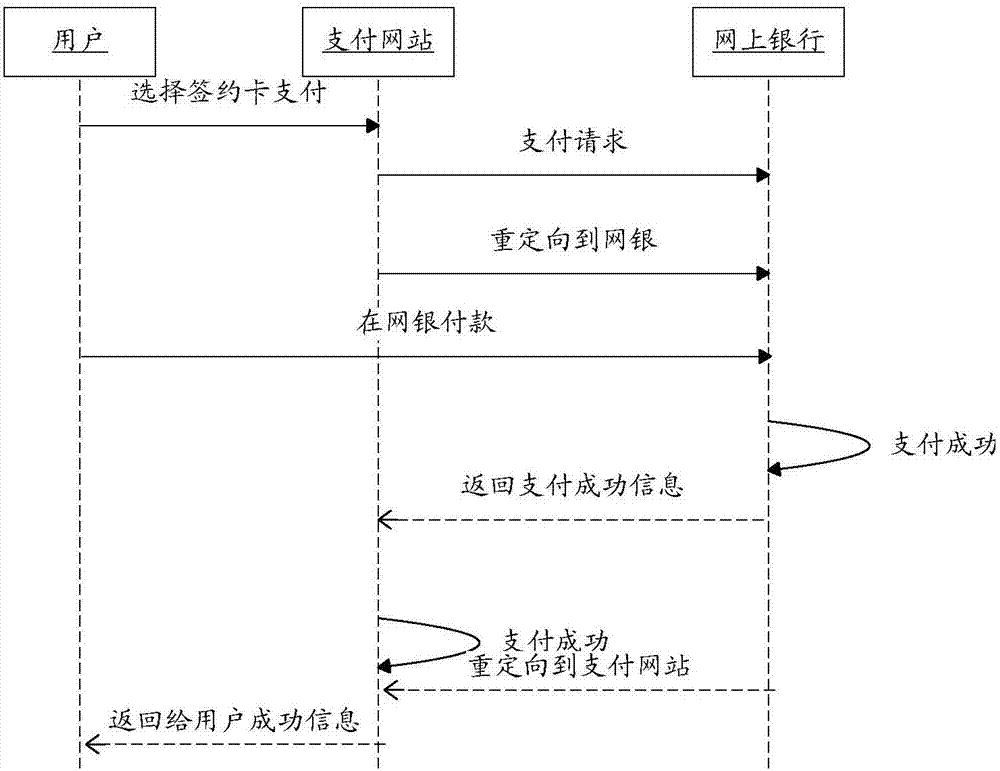

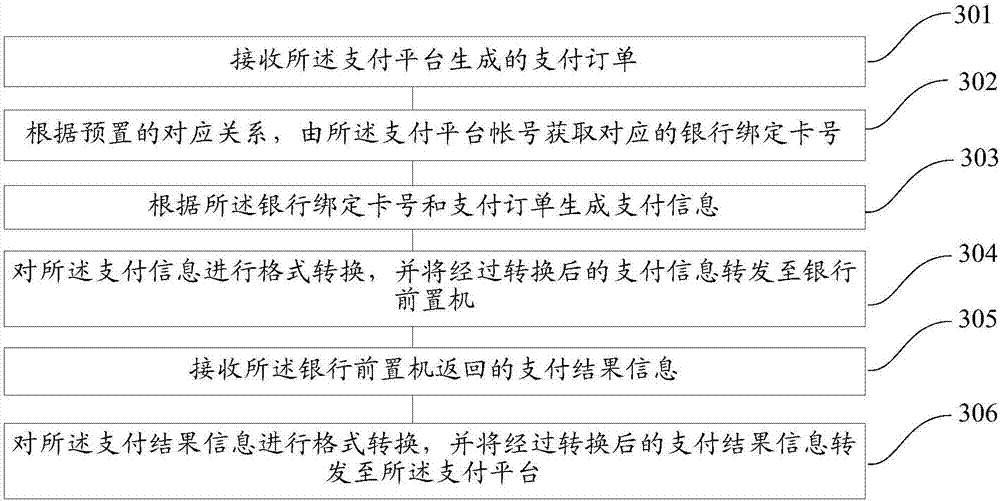

Online payment method, apparatus and system

PendingCN107423964AImprove efficiencyImprove communication efficiencyProtocol authorisationWorld Wide WebInternet bank

Owner:ADVANCED NEW TECH CO LTD

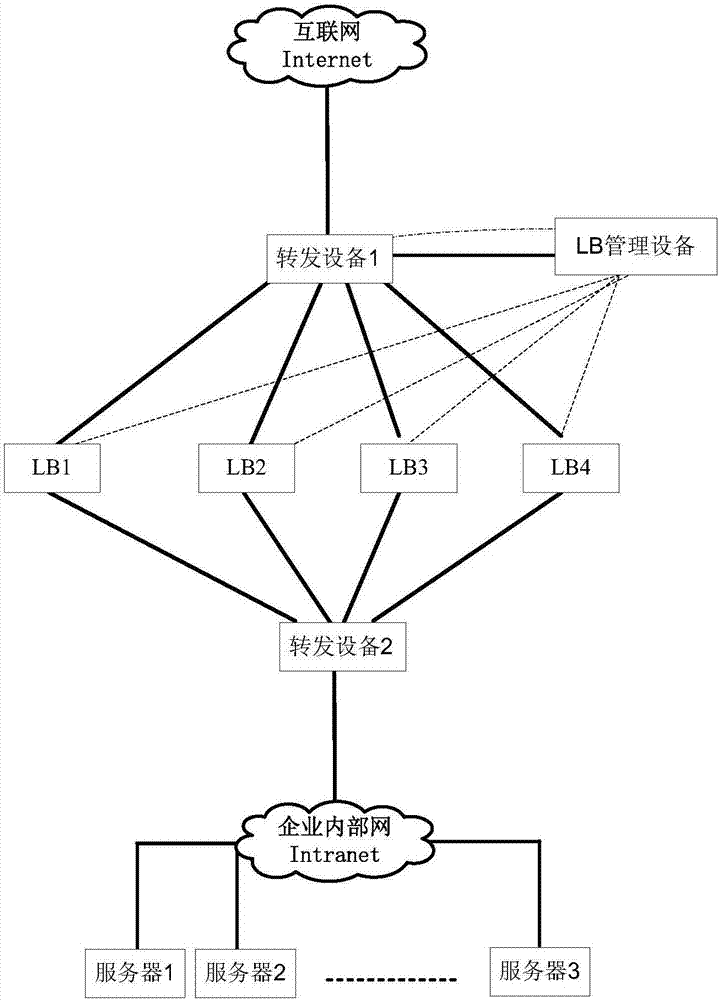

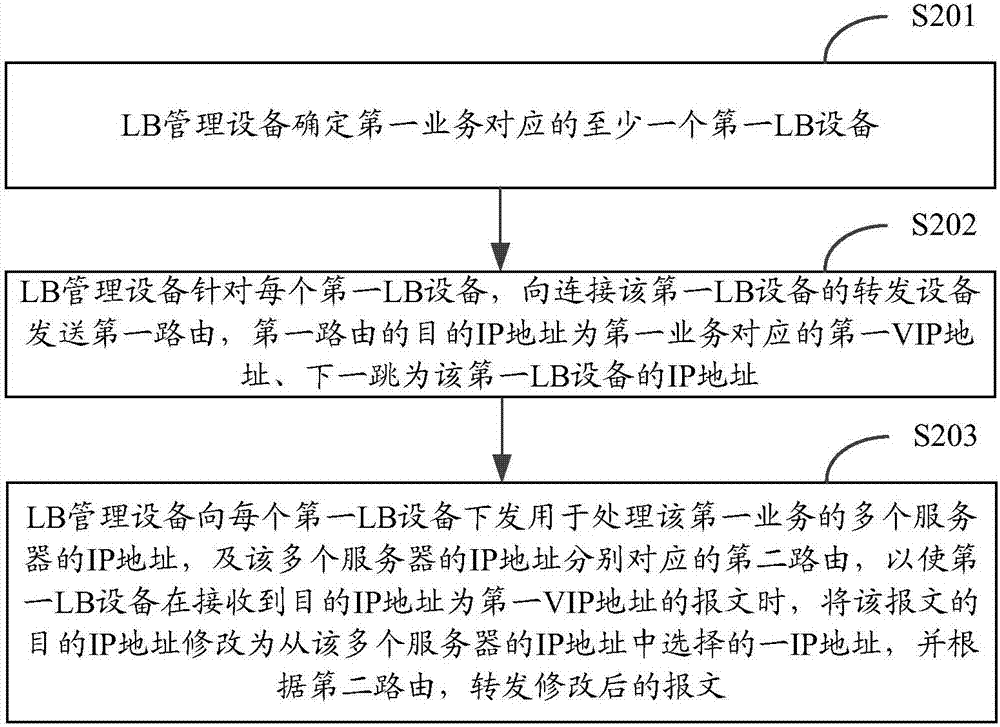

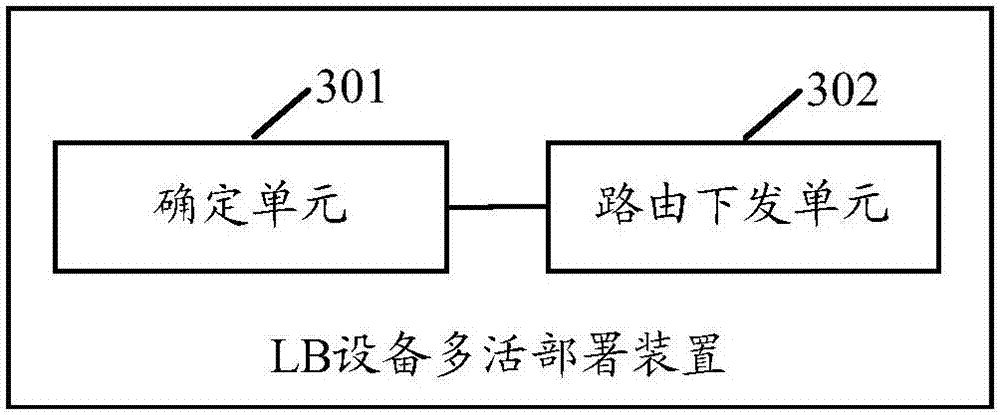

Multi-active deployment method and device for load balancing devices

InactiveCN107547394ARealize load sharingReduce in quantityData switching networksDistributed computingVirtual IP address

The invention provides a multi-active deployment method and device for load balancing devices. The method is applied to an LB management device which is connected with forwarding devices and multipleLB devices. The method comprises the steps that at least one first LB device corresponding to first services is determined; for each first LB device, a first route is sent to the forwarding device, wherein a destination IP address of the first route is a first virtual IP address corresponding to the first service, and the next hop of the first route is an IP address of the first LB device; IP addresses of multiple servers for processing the first services and second routes corresponding to the IP addresses of the multiple servers respectively are sent to each first LB device, so that when thefirst LB device receives a message of which a destination IP address is the first virtual IP address, the first LB device modifies the destination IP address of the message to be one IP address selected from the IP addresses of the multiple servers and forwards the modified message according to the corresponding second route.

Owner:NEW H3C SECURITY TECH CO LTD

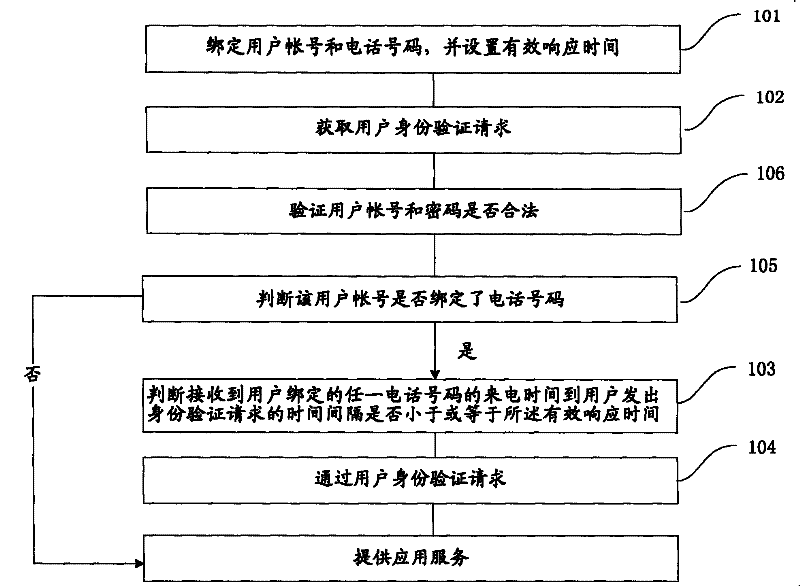

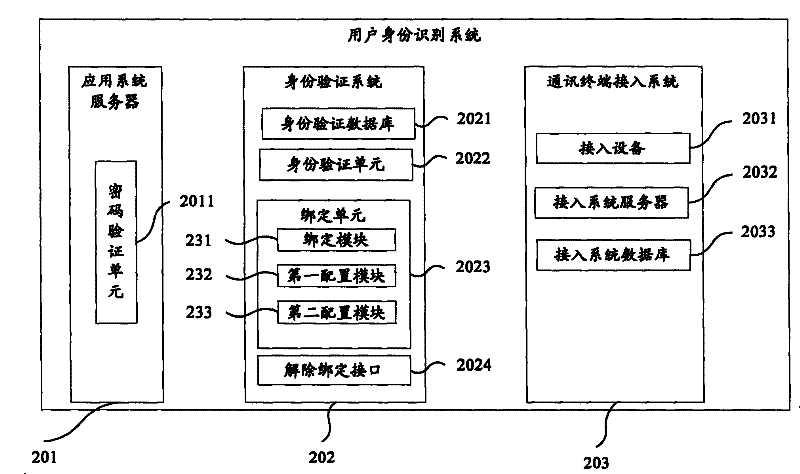

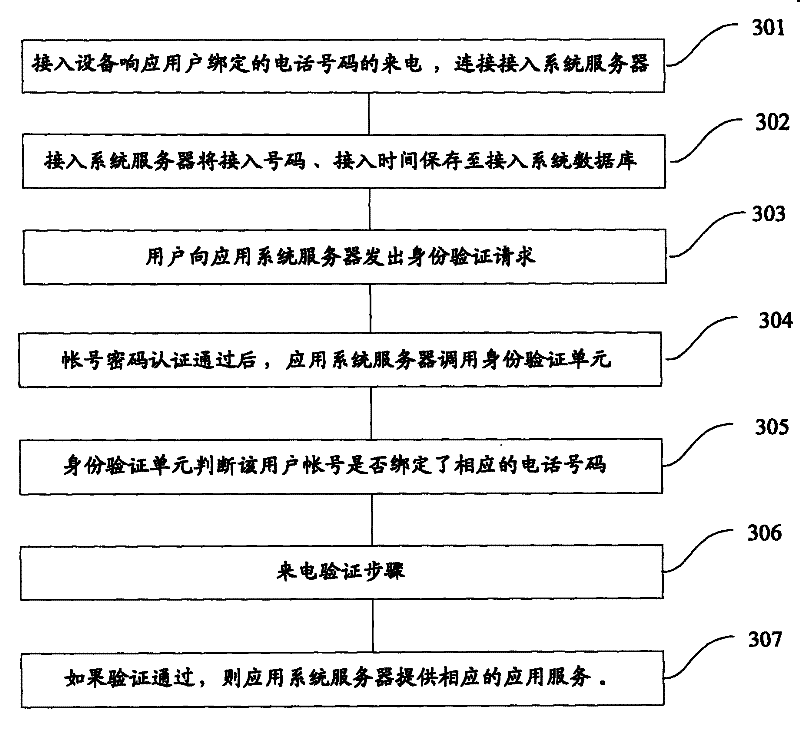

User identification identifying method and system

ActiveCN1921390BProtection against the possibility of theftImprove securityUser identity/authority verificationIdentity recognitionEngineering

The invention relates to a user identification recognize method. Wherein, it is characterized in that: it comprises bonding user account and telephone number, and setting the effective response time; obtaining user identification check request, which comprises user account information; judging if the time space from the incoming time of received telephone number to the time that user sends out identification request is not higher than said effective response time; if it is, passing the user identification check request. The invention can support general communication terminal, without additional device to reduce the cost. And when user calls the service telephone of operator, the telephone could not be connected, to save cost; and user only needs to dial the service number.

Owner:NETEASE INFORMATION TECH(BEIJING) CO LTD

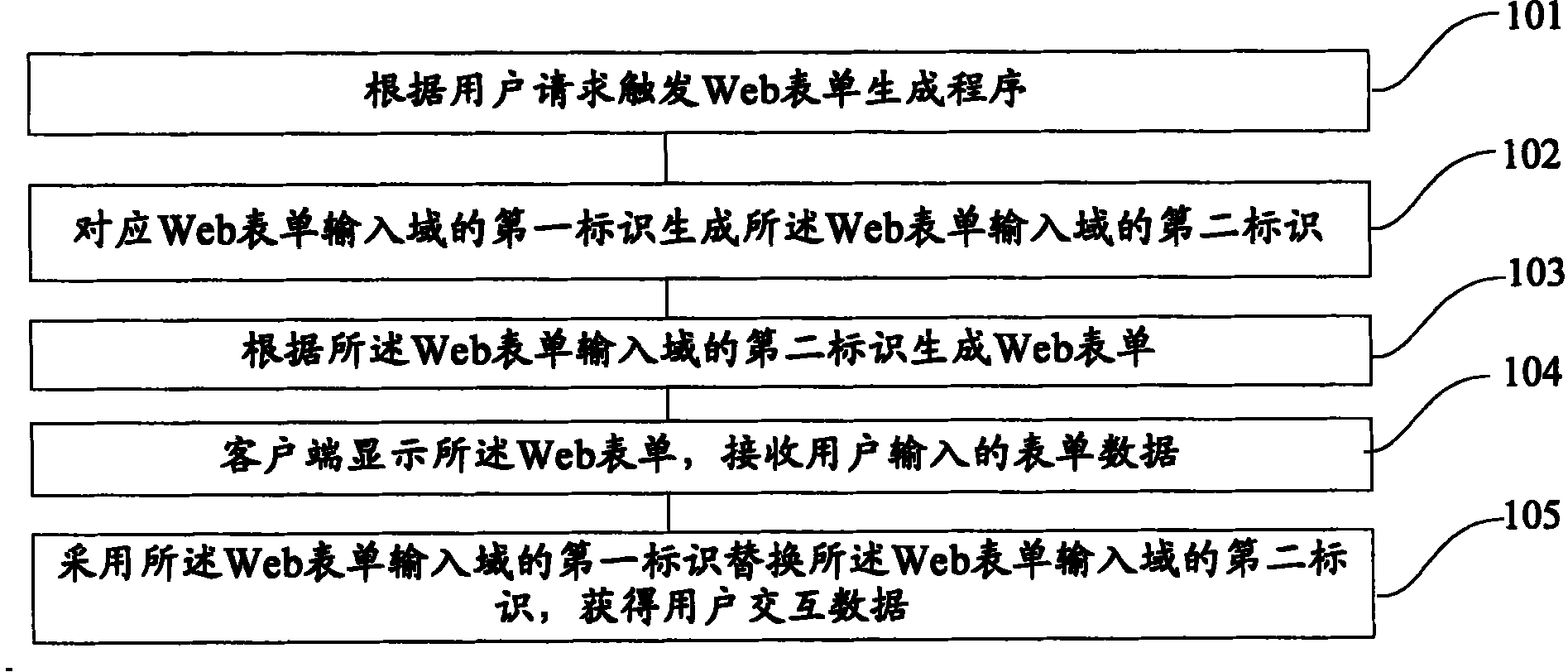

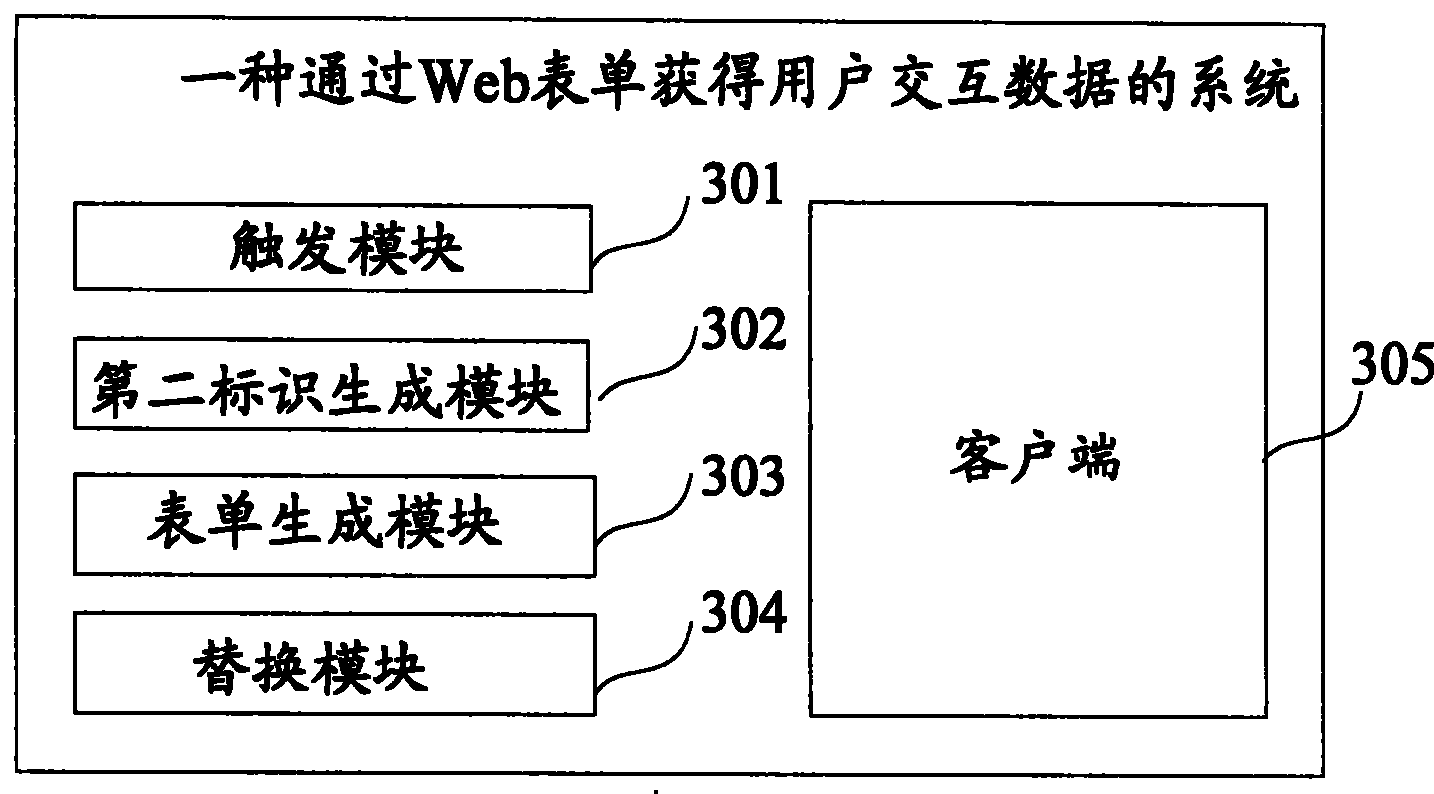

System and method for obtaining user interactive data by Web table list

ActiveCN101227451BAutofill implementationAutofill PreventionTransmissionSpecial data processing applicationsUser inputWeb tables

Owner:ADVANCED NEW TECH CO LTD

Smart card, terminal, system and method for field data acquisition

InactiveCN100499930CLower barriers to useImprove experienceTelephonic communicationMessaging/mailboxes/announcementsComplete dataOperational system

The disclosed intelligent card in a mobile terminal for on-site data collection comprises: a data unit to store data and configuration parameter, an application process unit to call the configuration parameter and data and receive user input to complete the data processing, and a COS to package data into SMS for transmission and complete data interaction between the process unit and intelligent CPU and the data unit. This invention has well security and stability, and fit to different mobile terminals.

Owner:DIGILINX TECH CO LTD +1

Method for selecting sandstone uranium mine dominant horizon

PendingCN111738562AEasy to operateShort analysis timeCharacter and pattern recognitionColor/spectral properties measurementsRock coreKaolinite

The invention belongs to the field of uranium ore exploration, and particularly discloses a method for selecting a sandstone uranium ore dominant horizon. The method comprises the following steps: performing hyperspectral core scanning on a drilling core of a sandstone uranium ore deposit by using core hyperspectral scanning equipment; performing data inversion on the hyperspectral rock core scanning image to obtain ferric iron, organic matters, total clay content and kaolinite content; constructing a relation curve of the mineral content changing along with the depth by utilizing the data such as the ferric iron content obtained by inversion and combining the scanning depth; and selecting the dominant horizon of the sandstone uranium mine by using the constructed content change curve. According to the method, sample collection is not needed, and operation steps are simple; laboratory analysis does not need to be carried out, and the working efficiency is improved; the characteristic of high spectral quantization capability is fully utilized, and the result quantization level is high; and spectral data is easy to obtain, testing is cheap, and cost can be saved.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Aluminum alloy casting furnace

InactiveCN107876744ANo air tightness requirementEasy to manufactureMolten metal supplying equipmentsHydrogenAtmospheric pressure

The invention relates to an aluminum alloy casting furnace which comprises a liquid transfer chute, a mechanical pump, a ceramic filtering plate, a refining degassing device, an aluminum alloy liquidlevel detection device, a furnace body, a top heating device or a bottom heating device, a feeding hole and a furnace door. When the furnace is used, an aluminum alloy liquid or a solid aluminum alloyis fed into the furnace body through the feeding hole after the furnace door is opened, and is heated to a certain process temperature through the top heating device or the bottom heating device; hydrogen is removed through the refining degassing device, impurities are removed through the ceramic filtering plate, the aluminum alloy liquid is lifted through the mechanical pump, and the lifted aluminum alloy liquid flows in the liquid transfer chute and then flows into a casting device; and quantification precision of the mechanical pump is dynamically compensated through a liquid level heightdetected by the aluminum alloy liquid level detection device. By adopting the aluminum alloy casting furnace, a high-quality melt can be provided for aluminum alloy casting, the mechanical pump is high in quantification precision after compensation, and compared with an aluminum alloy atmospheric pressure casting furnace, the aluminum alloy casting furnace does not need to be sealed and is small in furnace body manufacturing difficulty, low in cost and applicable to large-scale application.

Owner:湖北启宏热工设备有限公司

System for supporting multi-language and method for inputting and reading multi-language data

ActiveCN100440143CSave spaceSave resourcesSpecific program execution arrangementsUser inputSoftware engineering

The invention is a system to support multiple languages, which comprises: server: which is used to store language information and data from clients; client: which includes construction module, data language input controller and communication module. The construction module includes variables to store interface language information and data language information respectively, which are used to construct the context of the conversation between client and server based on the choice of login interface language that users select; data language input controller consists of option sub module and record sub module; option sub module is used to provide with users the options of languages; record sub module is used to record user input data and the language used; mentioned communication module is used for the communication with server.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com