Aluminum alloy casting furnace

An aluminum alloy and side furnace technology, which is applied in the field of high-quality aluminum alloy melt and aluminum alloy machine side furnace, achieves the effects of low cost, easy purchase and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

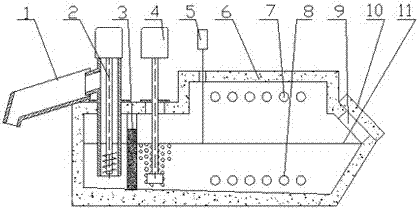

[0018] Take the mechanical pump thermal insulation pouring furnace as an example. figure 1 The schematic diagram of an aluminum alloy machine side furnace is shown for further explanation:

[0019] When an aluminum alloy machine side furnace is produced, open the material door (10), manually or mechanically add aluminum water or aluminum ingots from the charging port into the furnace body (6), the top heating device (7) or the bottom heating device (8) ) Heat and adjust the temperature of the aluminum melt. When the required pouring temperature is reached, the aluminum alloy melt flows through the refining and degassing device (5) for hydrogen removal and ceramic filter plate (3) for slag removal, and the aluminum liquid level is detected The device (5) inputs the detected height value of the liquid level line (11) to the control system. The control system calculates the quantitative pouring parameters of the mechanical pump and controls the mechanical pump (2) to lift the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com