Infrared spectroscopic determination method of bound acrylonitrile content in nitrile rubber

A measurement method, infrared spectroscopy technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems that the accuracy of standard samples is difficult to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1 test steps

[0049] (1) Preparation of sample solution

[0050] ① Extract the added oil and antioxidant in the nitrile rubber test sample with absolute ethanol, and then dry the extracted nitrile rubber test sample in a vacuum oven at 90°C.

[0051] ② Weigh 0.3g of the sample to be tested obtained in step ①, and put it into a 20mL sample bottle;

[0052] ③ Add 10mL of acetone to the sample bottle in step ②, shake the sample bottle to completely dissolve the nitrile rubber to be tested.

[0053] (2) Film preparation

[0054] Apply the sample solution obtained in step (1) evenly on the potassium bromide sheet, and evaporate the acetone on the potassium bromide sheet to prepare the sample membrane to be tested.

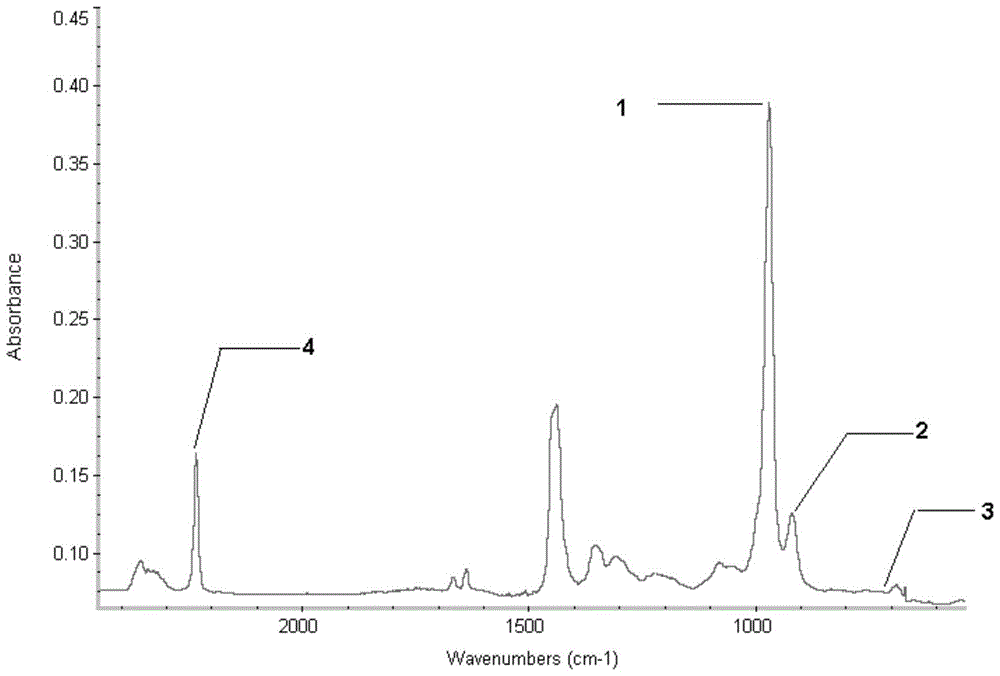

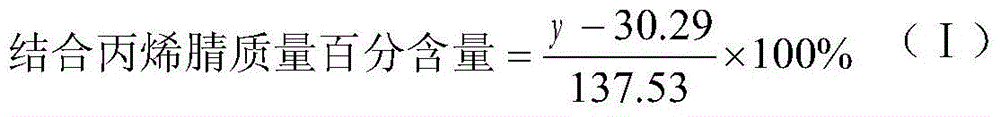

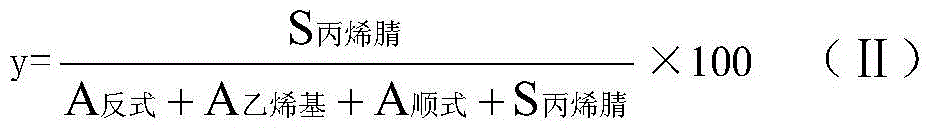

[0055] (3) Determination of infrared spectrum

[0056] ① Put the diaphragm obtained in step (2) into the infrared spectrometer;

[0057] ② The scanning parameters of the infrared spectrometer are set to 400cm -1 and 4000cm -1 , measure the background spec...

Embodiment 2

[0069] 1 test steps

[0070] (1) Preparation of sample solution

[0071] ①Use n-propanol to extract the added oil and antioxidant in the nitrile rubber test sample, and then dry the extracted nitrile rubber test sample in a vacuum oven at 105°C.

[0072] ②Weigh 0.1g of the sample to be tested obtained in step ①, and put it into a 20mL sample bottle;

[0073] ③ Add 20mL of acetone to the sample bottle in step ②, shake the sample bottle to completely dissolve the nitrile rubber to be tested.

[0074] (2) Film preparation

[0075] Apply the sample solution obtained in step (1) evenly on the potassium bromide sheet, and evaporate the acetone on the potassium bromide sheet to prepare the sample membrane to be tested.

[0076] (3) Determination of infrared spectrum

[0077] ① Put the diaphragm obtained in step (2) into the infrared spectrometer;

[0078] ② The scanning parameters of the infrared spectrometer are set to 600cm -1 and 2500cm -1 , measure the background spectrum ...

Embodiment 3

[0090] 1 test steps

[0091] (1) Preparation of sample solution

[0092] ① Extract the added oil and antioxidant in the nitrile rubber test sample with methanol, and then dry the extracted nitrile rubber test sample in a vacuum oven at 100°C.

[0093] ②Weigh 0.4g of the sample to be tested obtained in step ①, and put it into a 20mL sample bottle;

[0094] ③Add 15mL methyl ethyl ketone into the sample bottle in step ②, shake the sample bottle to completely dissolve the nitrile rubber to be tested.

[0095] (2) Film preparation

[0096] Apply the sample solution obtained in step (1) evenly on the potassium bromide sheet, evaporate the methyl ethyl ketone on the potassium bromide sheet, and prepare the sample membrane to be tested.

[0097] (3) Determination of infrared spectrum

[0098] ① Put the diaphragm obtained in step (2) into the infrared spectrometer;

[0099] ② The scanning parameters of the infrared spectrometer are set to 600cm -1 and 4000cm -1 , measure the bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com