Method for backfilling goaf and supporting roof

A technology for gobs and roofs, which is applied to fillings, mining equipment, earthwork drilling and mining, etc. It can solve the problems of unavoidable roof collapse, lack of support strength, waste of water resources, etc., and protect groundwater resources and land resources. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

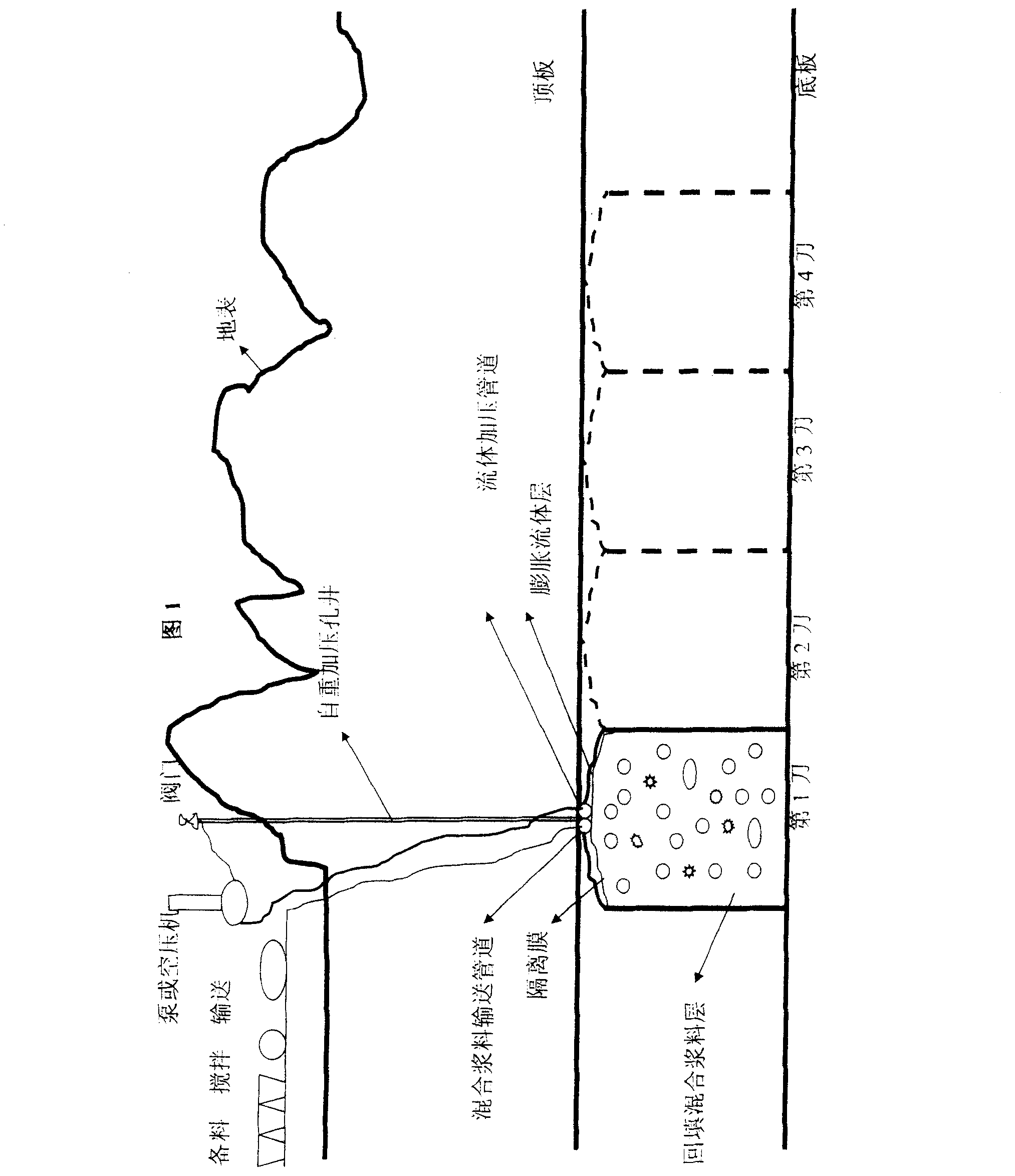

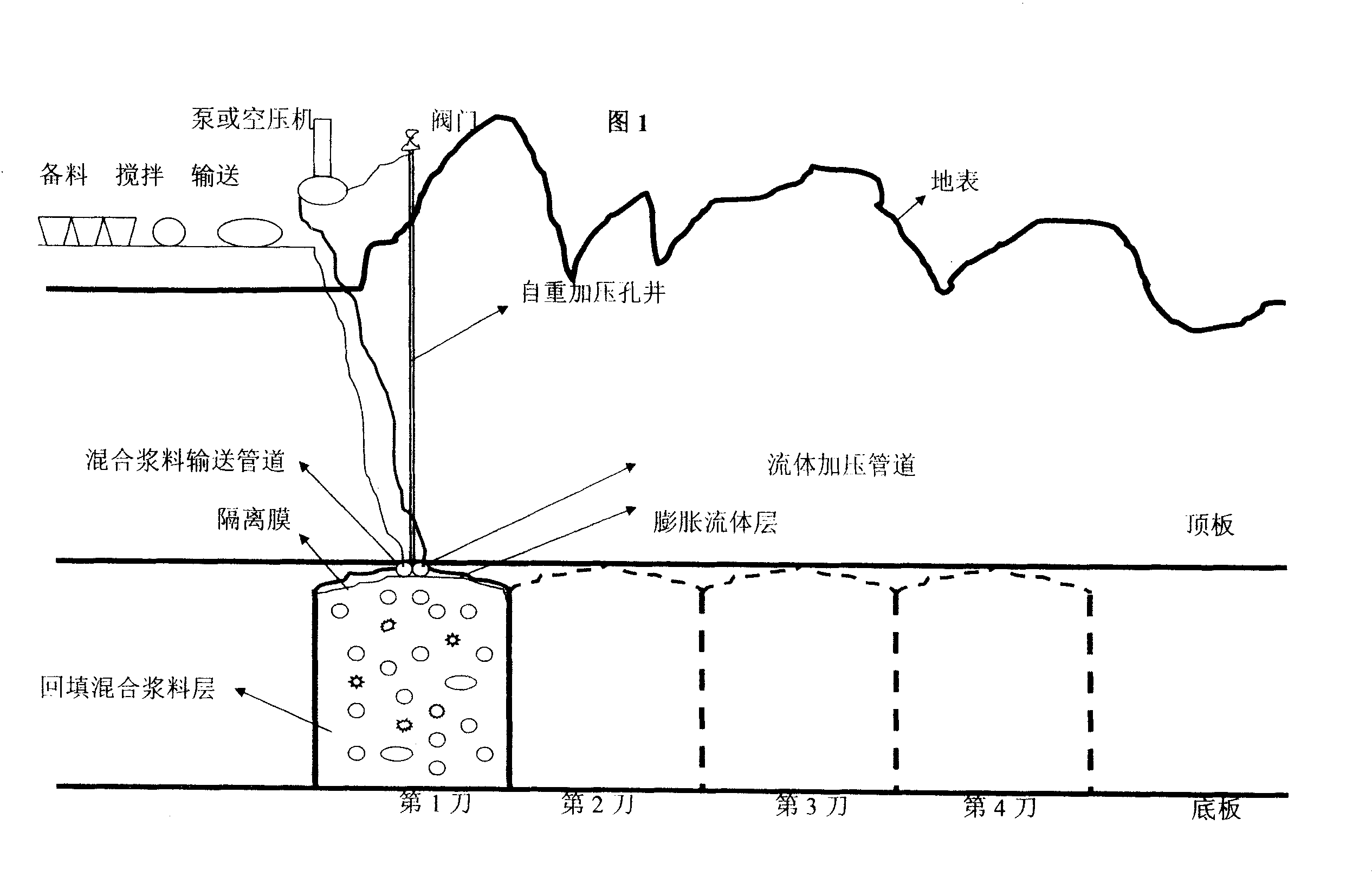

[0026] Embodiment 1: A method for backfilling gobs and supporting the roof, which includes the following steps in turn: (1): preparation stage: (a), drilling a well from the ground to the roadway, and inserting a Self-weight pressurized pipe, install a valve on the part of the pipe exposed on the ground, and close the gap between the well wall and the pipe: First, drill an 8 cm well from the ground to the middle top of the backfill area, and insert a 1 meter long well into the well Install valves on the part of the pipeline exposed to the ground, and close the gap between the well wall and the pipeline.

[0027] (b) Lay the pressurized fluid delivery pipeline on the top of the roadway, and then install the isolation film from the arc-shaped top of the roadway: hang the pressurized fluid delivery pipeline with a diameter of 2 cm on the top of the roadway, and then glue or glue it from the arc-shaped top of the roadway. Iron nails to the isolation film. The isolation film is an...

Embodiment 2

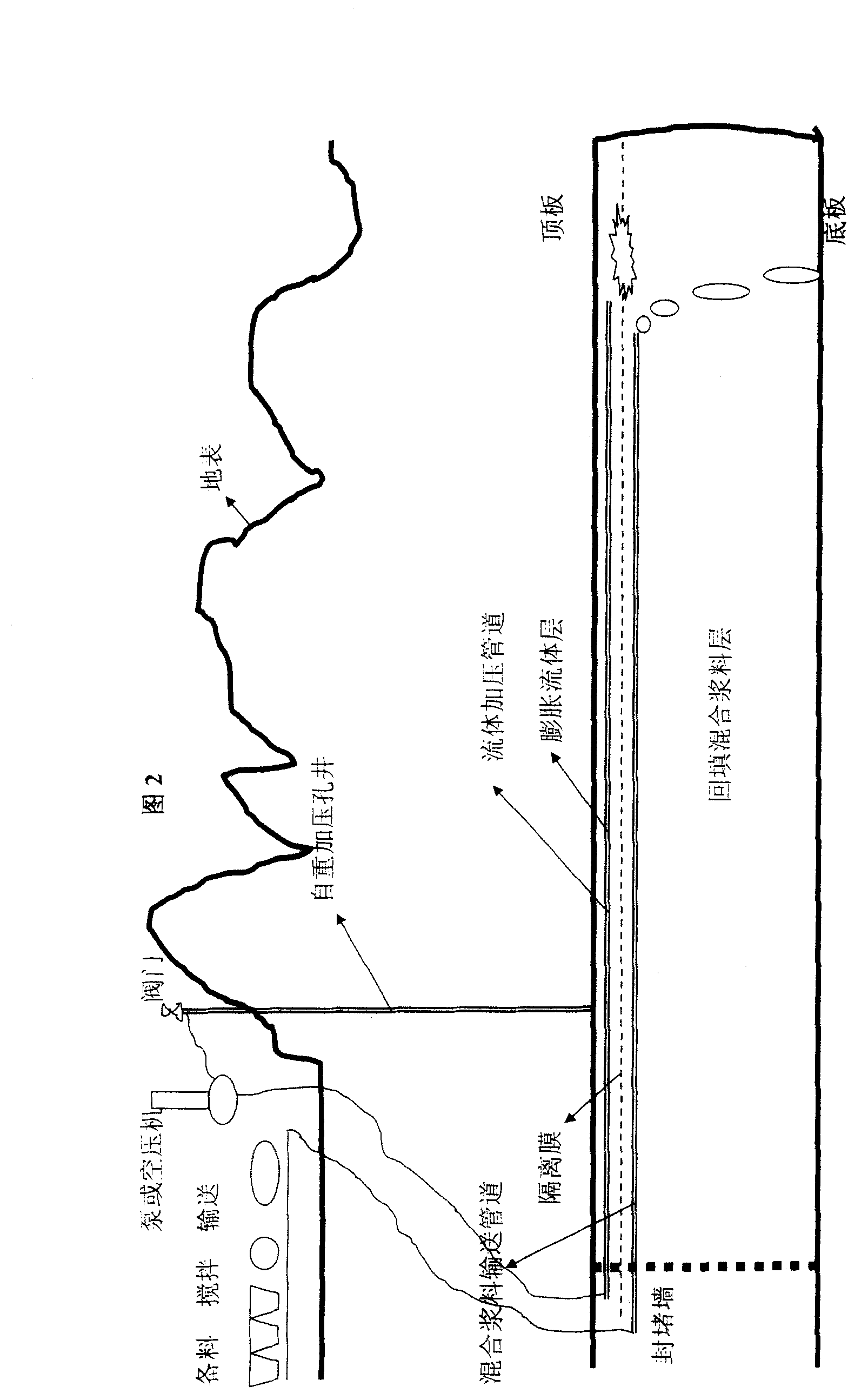

[0040] Embodiment 2: A method for backfilling gobs and supporting the roof, which includes the following steps in turn: (1): preparation stage: (a), drilling a well from the ground to the roadway, and inserting a Self-weight pressurized pipe, install a valve on the part of the pipe exposed on the ground, and close the gap between the well wall and the pipe: First, drill a 40-centimeter well from the ground to the middle top of the backfill area, and insert a 30-meter-long well into the well Install valves on the part of the pipeline exposed to the ground, and close the gap between the well wall and the pipeline.

[0041] (b) Lay the pressurized fluid delivery pipeline on the top of the roadway, and then install the isolation film from the arc-shaped top of the roadway: Hang the pressurized fluid delivery pipeline with a diameter of 20 cm on the top of the roadway, and then glue or glue it from the top of the roadway arc. Iron nails to the isolation film. The isolation film is...

Embodiment 3

[0054] Embodiment 3: A method for backfilling gobs and supporting the roof, which includes the following steps in turn: (1): preparation stage: (a), drilling a well from the ground to the roadway, and inserting a Self-weight pressurized pipe, install a valve on the part of the pipe exposed on the ground, and close the gap between the well wall and the pipe: First, drill a 24 cm well from the ground to the middle top of the backfill area, and insert a 15-meter-long well into the well Install valves on the part of the pipeline exposed to the ground, and close the gap between the well wall and the pipeline.

[0055] (b) Lay the pressurized fluid delivery pipe on the top of the roadway, and then install the isolation film from the arc-shaped top of the roadway: hang the pressurized fluid delivery pipe with a diameter of 10 cm on the top of the roadway, and then glue or glue it from the arc-shaped top of the roadway. Iron nails to the isolation film. The isolation film is any one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com