Splitting-preventing cap pressing device of capsule filling machine

A technology for filling machines and capsules, applied in capsule delivery, drug delivery, pharmaceutical formulations, etc., to achieve the effects of reducing skin insertion, improving production efficiency, and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

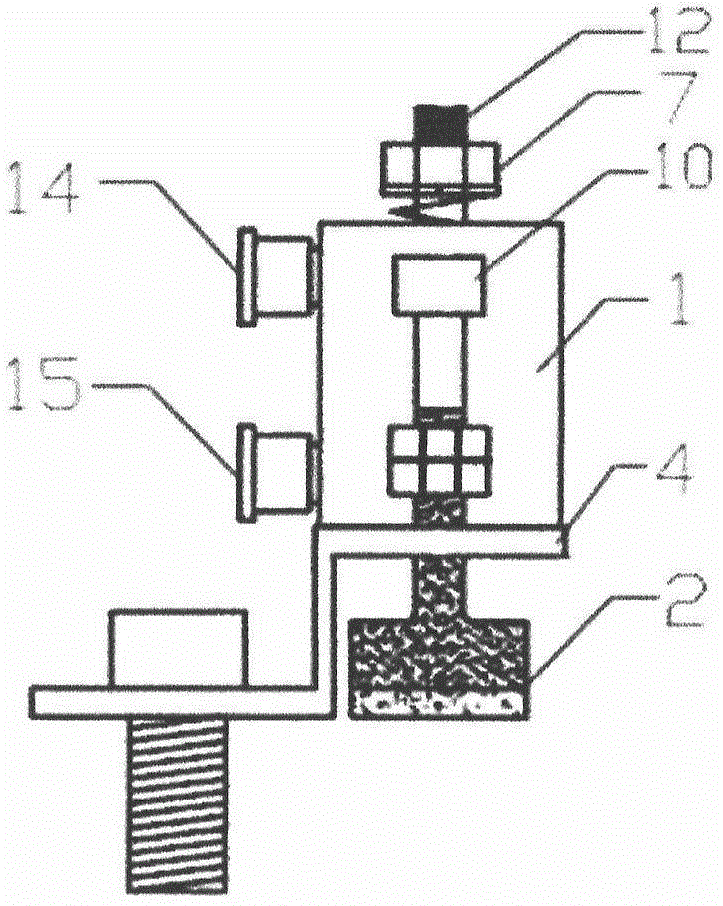

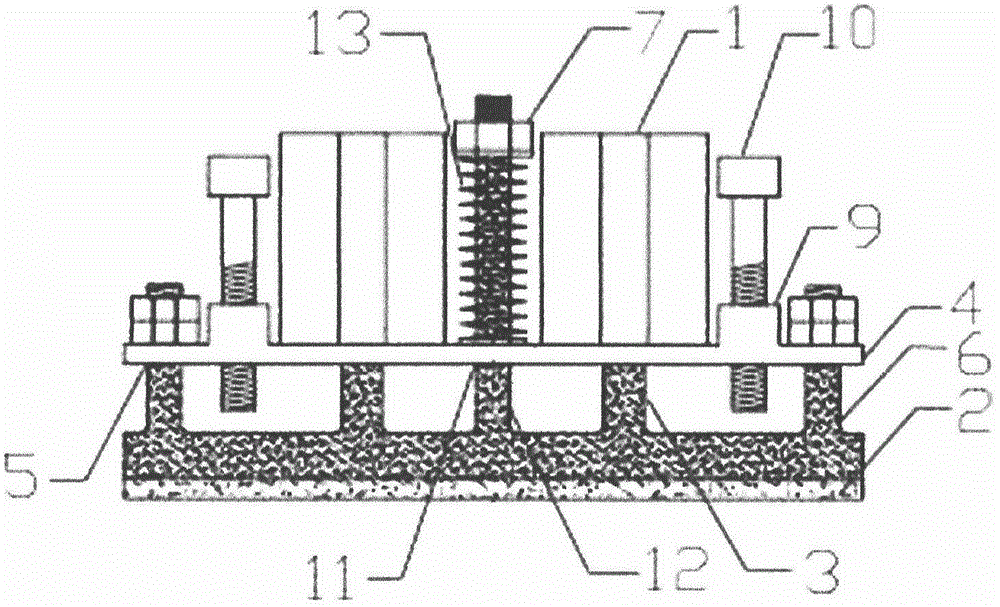

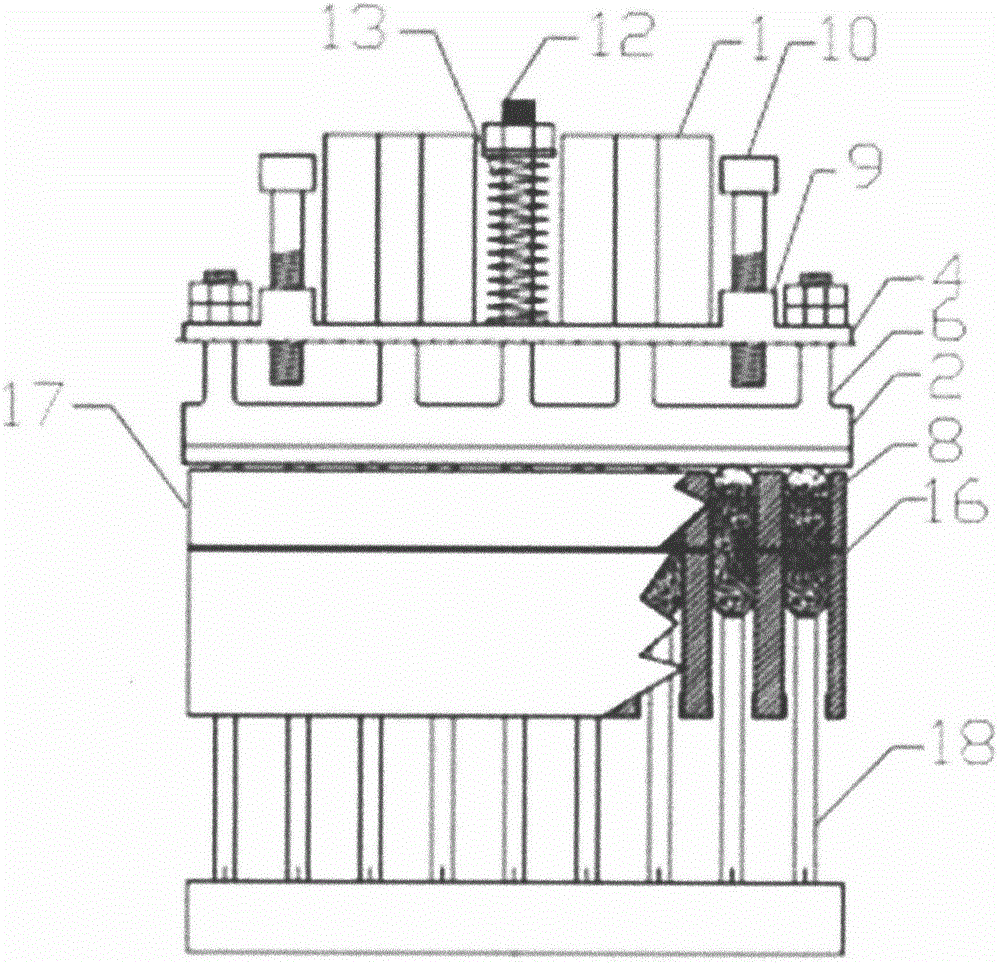

[0020] The invention provides an anti-insertion skin capping device for a capsule filling machine, which includes a driving device, the driving device adopts two cylinders 1, and the cylinders 1 are connected to the bottom plate 4 through the piston cylinder 3 on the cap pressing module 2, and the bottom plate 4 is two The end is provided with an end face through hole 5, and the end face cylinder 6 of the corresponding pressure cap module is inserted into the end face through hole 5. The top of the end face cylinder 6 is provided with a thread, and a nut 7 is matched on the thread, and the end face cylinder 6 and the nut 7 are pressed against each other. When the cap module 2 runs downward, the limit adjustment is performed to prevent the stroke from being too large, resulting in a large impact force and downward force, which will cause extrusion deformation and frictional impact on the capsule cap 8 and the capsule shell module. The two end faces of the bottom plate 4 have thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com