Belt tearing detection device for belt conveyor

A belt conveyor and detection device technology, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of complicated installation, high cost, low reuse rate, etc., to reduce construction difficulty, installation and debugging. The effect of convenient and convenient maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

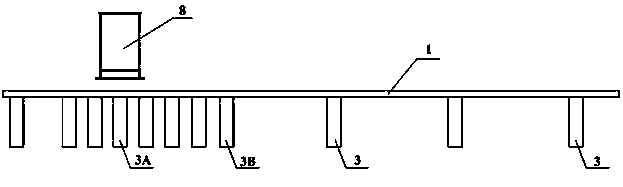

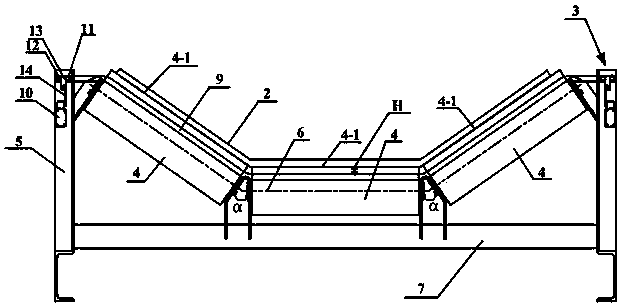

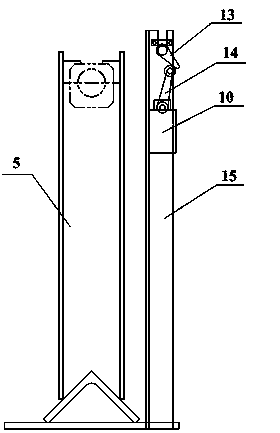

[0025] Embodiment 1, the existing belt conveyor is mainly composed of a frame 1, a belt 2 for conveying dispersed materials, a motor for driving the belt 2 to run, and a load bearing that supports the belt 2 during the operation of the belt 2. The idler unit consists of 3, combining figure 1 , figure 2 shown. Wherein, the carrying roller unit 3 mainly includes two parts of the roller 4 and the roller frame, see figure 2 As shown, the idler frame is used to support the idler 4, including the main components such as the column 5, the rotating shaft 6 and the bottom beam 7. Among them, the idler 4 is set on the rotating shaft 6, and the two ends of the rotating shaft 6 are fixed on the column 5, and are supported by the bottom beam 7; the column 5 can be erected on the ground, or can be hung on the frame 1 of the conveyor, see Figure 4 shown.

[0026] When loading and unloading materials, the materials shoveled by the reclaimer are transferred to the belt 2 of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com