Non-phosphorus solid slow-release corrosion inhibitor

A corrosion inhibitor and slow-release technology, which is applied in the field of solid phosphorus-free slow-release corrosion inhibitors, can solve the problems of unsustainable effect and large dosage, and achieve convenient transportation and on-site dosage, slow corrosion, The effect of reducing the corrosion rate

Active Publication Date: 2016-10-12

BEIJING NORMAL UNIVERSITY

View PDF9 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, the corrosion inhibitors currently used are mainly liquid, and the dosage is large, and the effect of the agent is not long-lasting after one dosage, so frequent dosage is required to control the corrosion of pipelines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

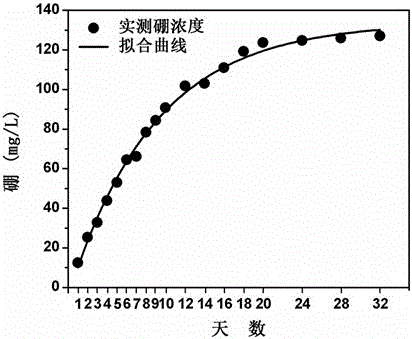

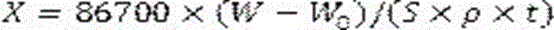

The invention provides a non-phosphorus solid slow-release corrosion inhibitor. The non-phosphorus solid slow-release corrosion inhibitor comprises 20%-30% of boric acid, 25%-35% of borax, 10%-20% of Na2O, 15%-25% of SiO2, 5% of Na2SO4 and 5% of (NH4)6Mo7O24. The corrosion inhibitor provided by the invention is the non-phosphorus corrosion inhibitor, the content of phosphate in water is decreased beneficially, and the eutrophication risk of receiving water is reduced; aiming at the acidic water quality (pH is larger than or equal to three), the medium-high-salinity water quality (the content of Cl- is smaller than or equal to 0.5mol / L) and the medium-high-alkalinity water quality (the content of CaCO3 is smaller than or equal to 250mg / L), the corrosion inhibitor is researched and developed, and corrosion of carbon steel materials in the acidic water quality environment, the medium-high-salinity water quality environment and the medium-high-alkalinity water quality environment can be effectively inhibited; and the corrosion inhibitor belongs to a slow-release medicament, and the corrosion inhibition effect of the medicament lasts for 30 days or more.

Description

technical field [0001] The invention relates to a phosphorus-free solid slow-release corrosion inhibitor, in particular to a corrosion inhibitor applicable to natural conditions, acidic conditions (pH: ≥ 3), salinity conditions (with Cl - meter: ≤0.5 mol / L) and alkalinity conditions (as CaCO 3 Calculation: ≤250 mg / L) solid phosphorus-free slow-release corrosion inhibitor. Background technique [0002] Circulating water system is an effective water-saving measure and is widely used in industrial production. However, with the continuous operation of the circulating water system, the circulating water is continuously reused, and the concentration of corrosion factors in the water increases exponentially, causing corrosion of pipelines and equipment, causing direct economic losses to enterprises. At present, in industrial production, the method of adding corrosion inhibitors is often used to control pipeline corrosion. The commonly used corrosion inhibitors are chromate serie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F11/00C23F11/04C23F11/06C23F11/18

CPCC23F11/00C23F11/04C23F11/06C23F11/187

Inventor 裴元生崔骏李萌史蕊蕊

Owner BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com