Anti-aging anti-corrosion paint used for road lamp

An anti-corrosion and anti-aging technology, applied in the field of paint materials, can solve problems such as brittleness, cracking, and yellowing of the paint film, and achieve the effects of increasing flame retardancy, safety performance, and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

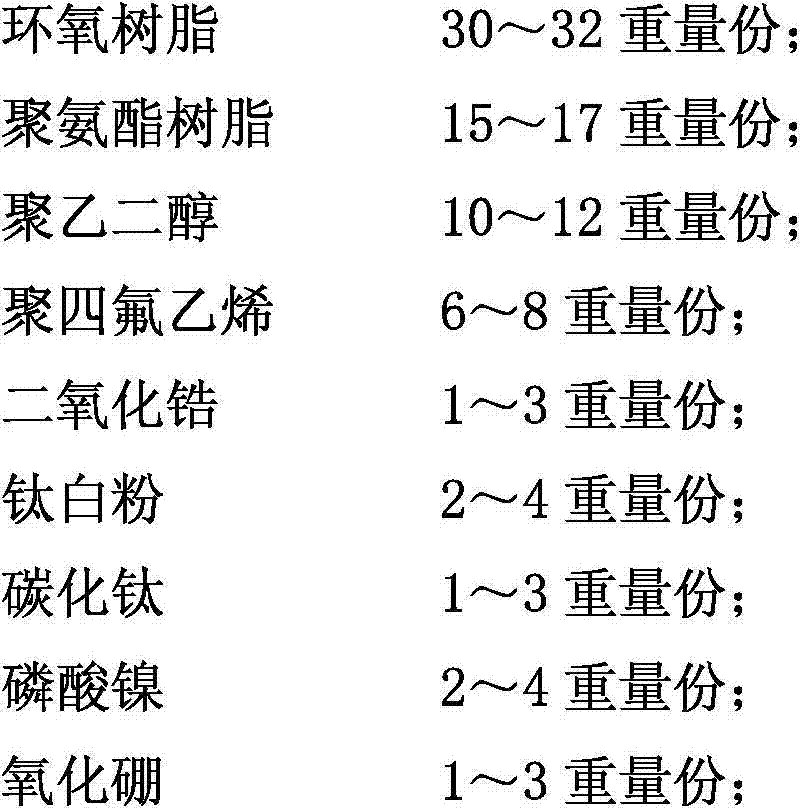

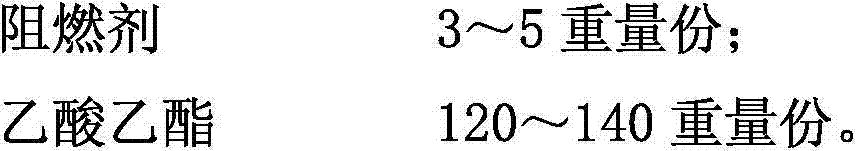

[0017] This case proposes an anti-aging and anti-corrosion street lamp paint with low production cost, which is made by mixing the following materials in parts by weight:

[0018]

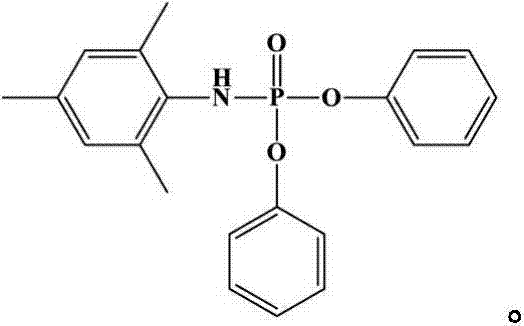

[0019] Among them, epoxy resin is the main component of the paint, and its number average molecular weight should be limited, preferably 10000-14000 g / mol. Epoxy resin has good temperature physical and chemical properties, strong adhesion to metal surfaces, good dielectric properties, strong toughness, excellent weather resistance, alkaline solvents and most organic solvents, and the epoxy resin used in this case does not need to be cured . Polyurethane resin has the characteristics of high strength, tear resistance and wear resistance. It is radiation-proof. After being exposed to sunlight and ultravio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com