Catalyst for chemical reinforcement of glass, and preparation method of reinforcement liquid thereof

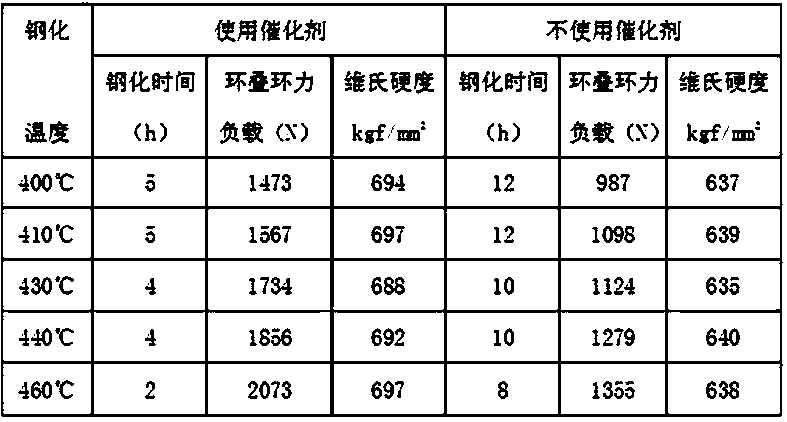

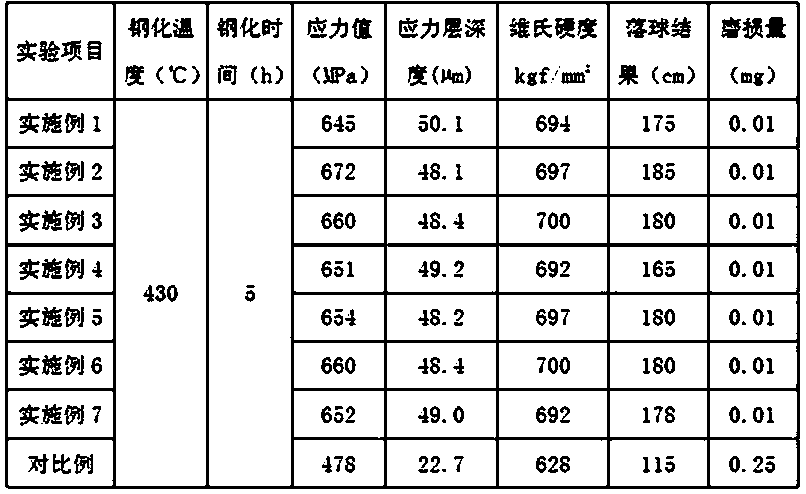

A glass strengthening and catalyst technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of long strengthening process, reduced production efficiency, low bending strength and scratch resistance of glass, and achieve The effects of balanced surface compressive stress distribution, increased strength, and shortened strengthening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] An embodiment will be described in detail below.

[0040] A method for preparing a glass strengthening liquid. The glass strengthening liquid is prepared by using a catalyst containing component A and component B. The steps of the method include:

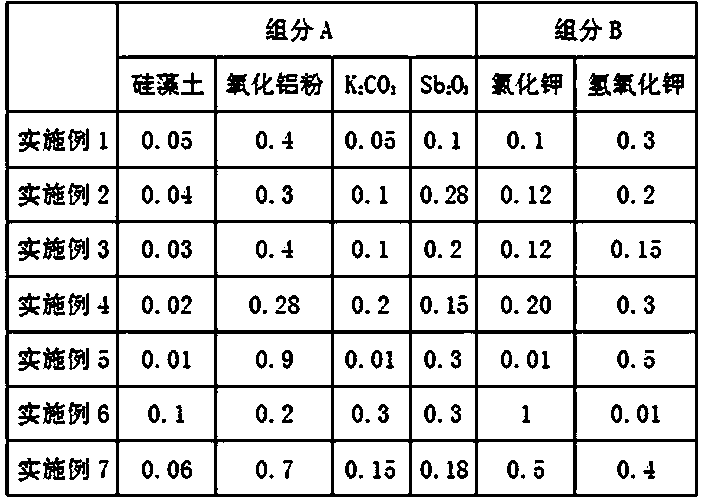

[0041] a. Prefabricated component A: Prepare and mix the following components in parts by weight:

[0042] Diatomaceous earth 1~10 parts,

[0043] Aluminum oxide powder 20~90 parts,

[0044] Potassium carbonate 1~30 parts,

[0045] Antimony trioxide 10~30 parts;

[0046] b. Add the mixed component A into the potassium salt and stir for 0.5-1 hour to form the first mixed salt; the potassium salt is potassium nitrate or a mixture of potassium nitrate and potassium nitrite, wherein the amount of component A added 0.5-1% of the amount of potassium salt;

[0047] c. Preparation of component B: Prepare and mix the following components in parts by weight:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com