Patents

Literature

236results about How to "Remove obstacles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

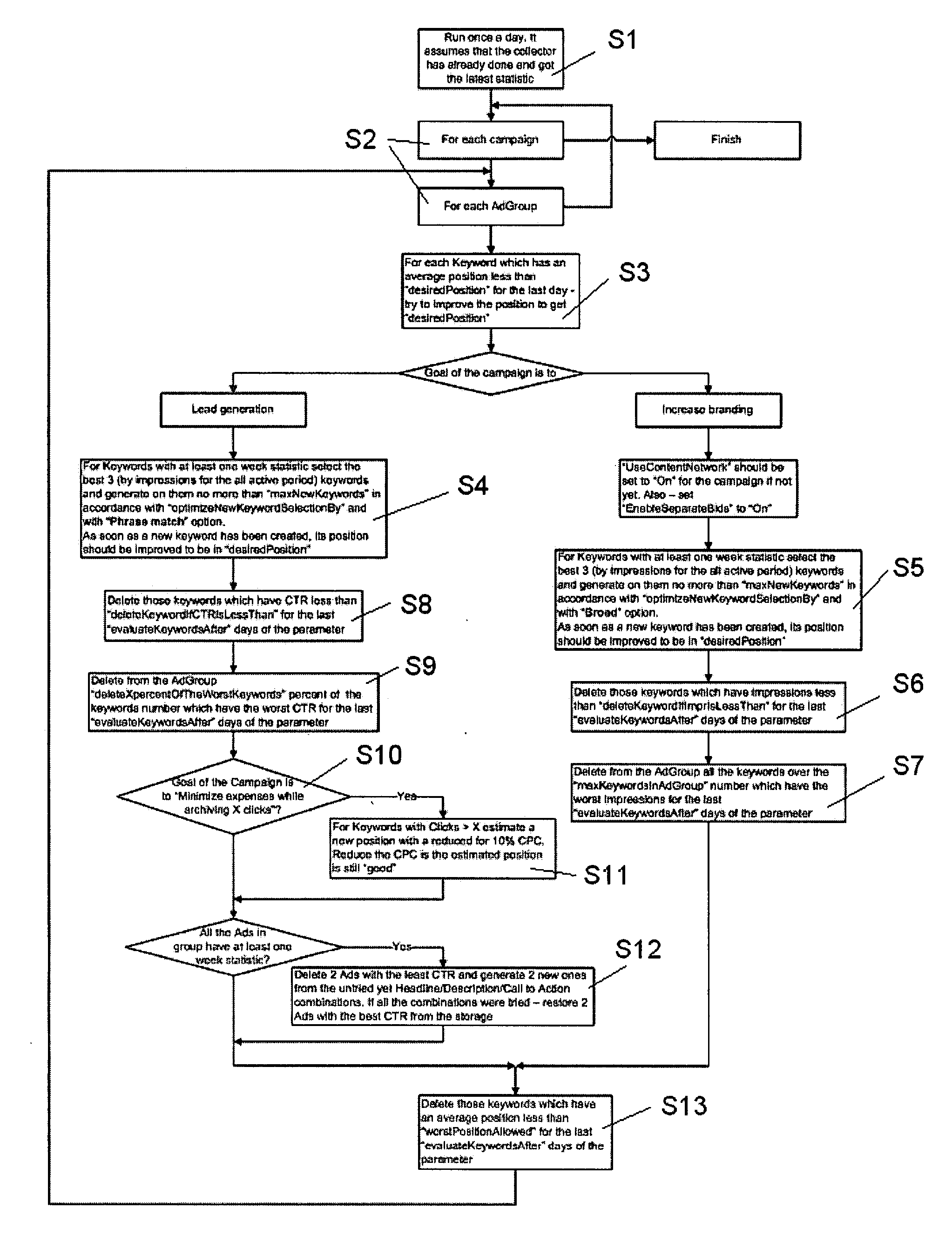

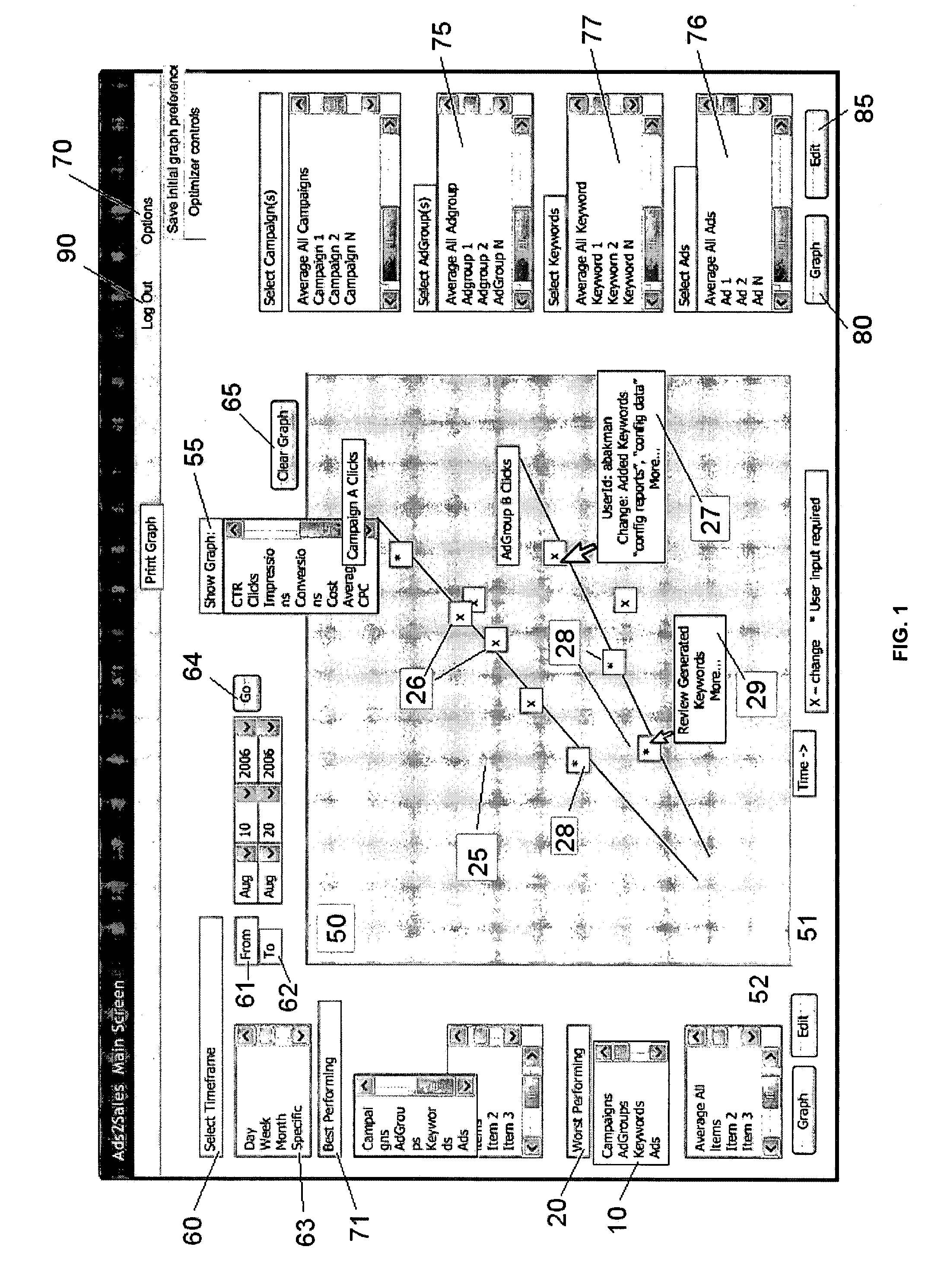

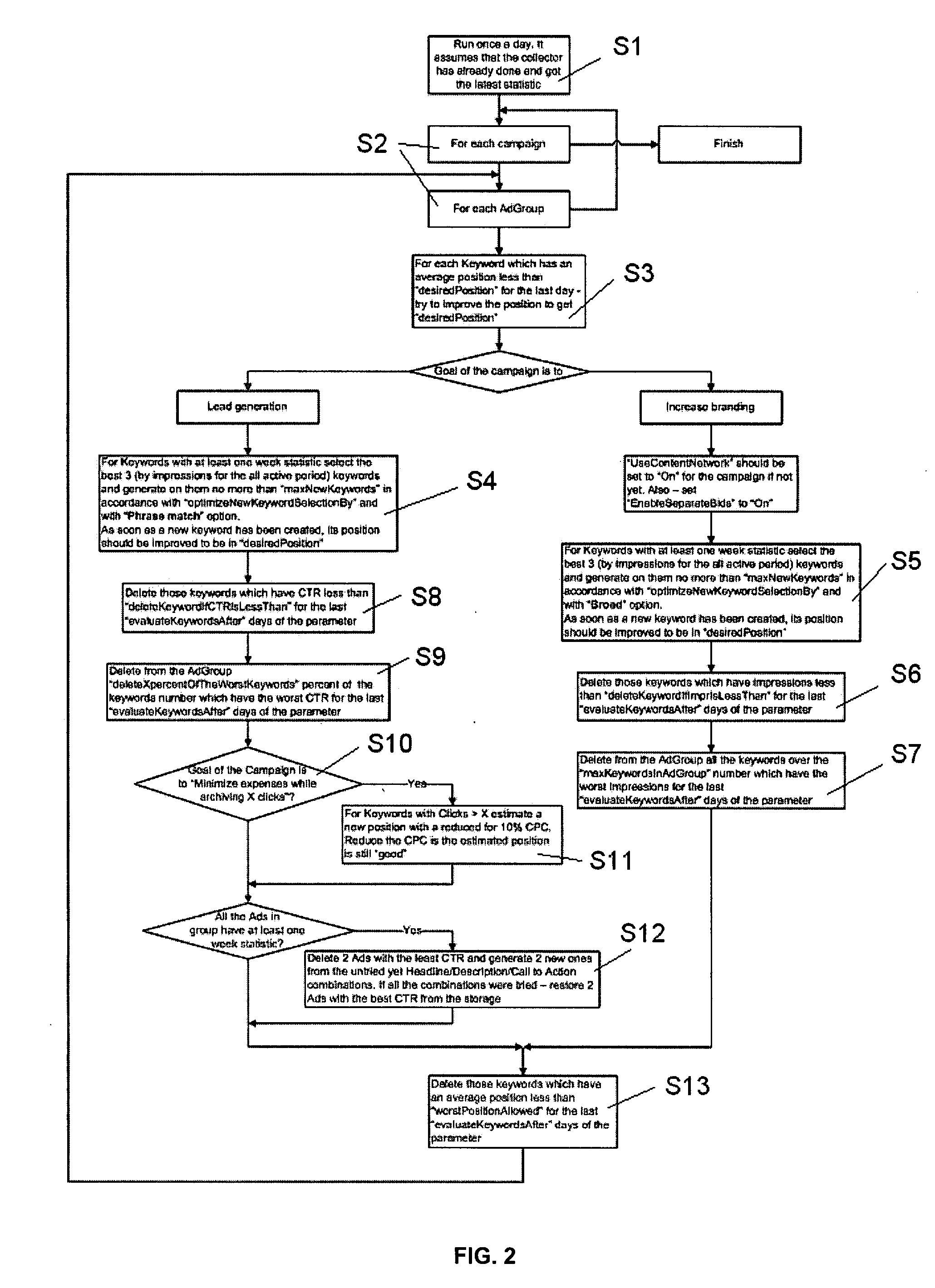

Automated advertising optimizer

InactiveUS20080065491A1Reduce in quantityPositive resultAdvertisementsInput/output processes for data processingWorld Wide WebTraffic volume

A method and system for automatically monitoring the performance level of various aspects of pay-per-click (PPC) and pay-per-action (PPA) advertising campaigns, and automatically revising the aspects to optimize performance levels, is provided. The advertiser is automatically notified if one or more particular aspects are resulting in less than desired click-through traffic. Further, the suspect aspects of the campaign are modified to ensure desired “click-through” regarding the advertisements and, thus, maximization of the advertiser's return on investment (ROI) with respect to the advertising campaign is achieved.

Owner:BAKMAN ALEXANDER

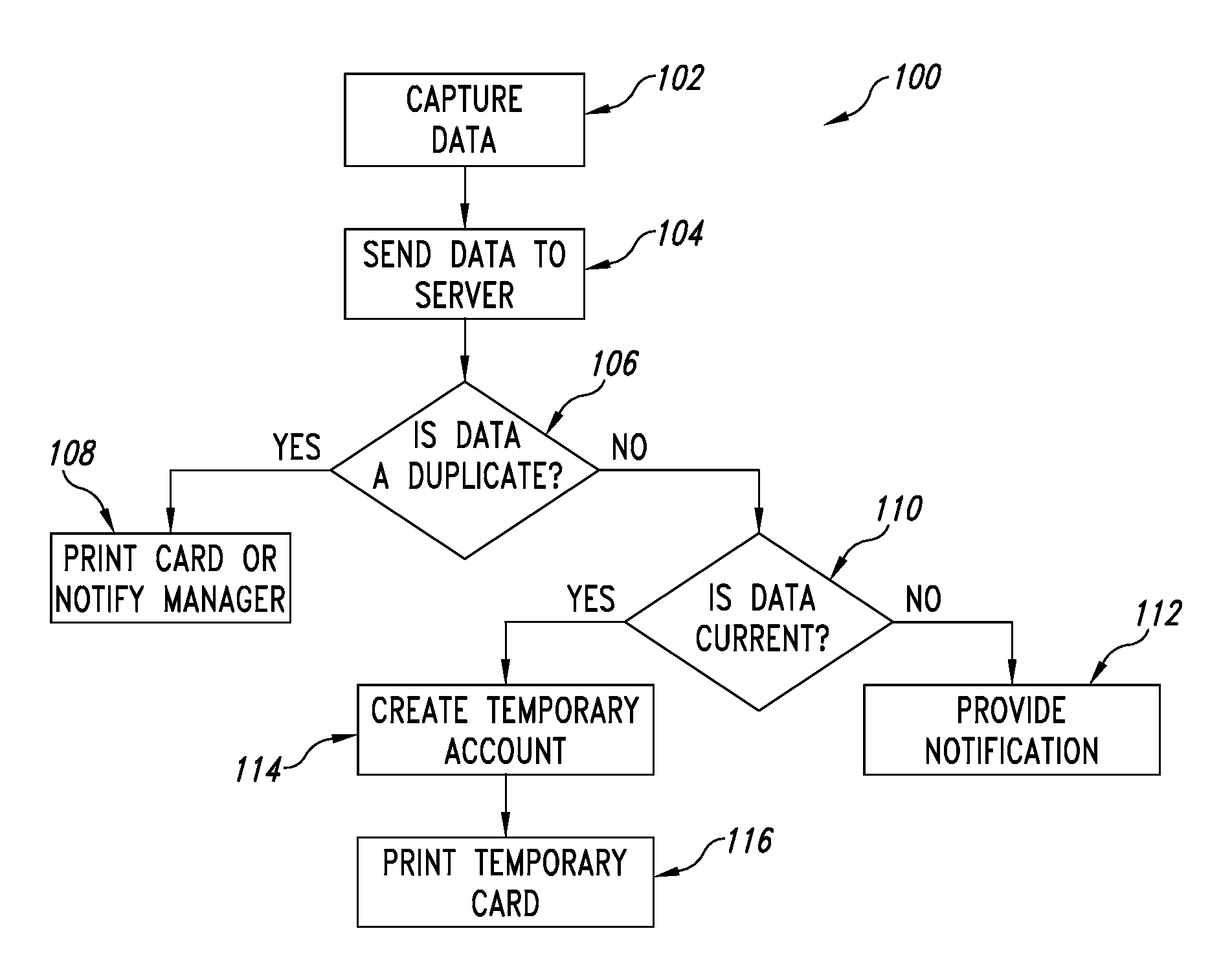

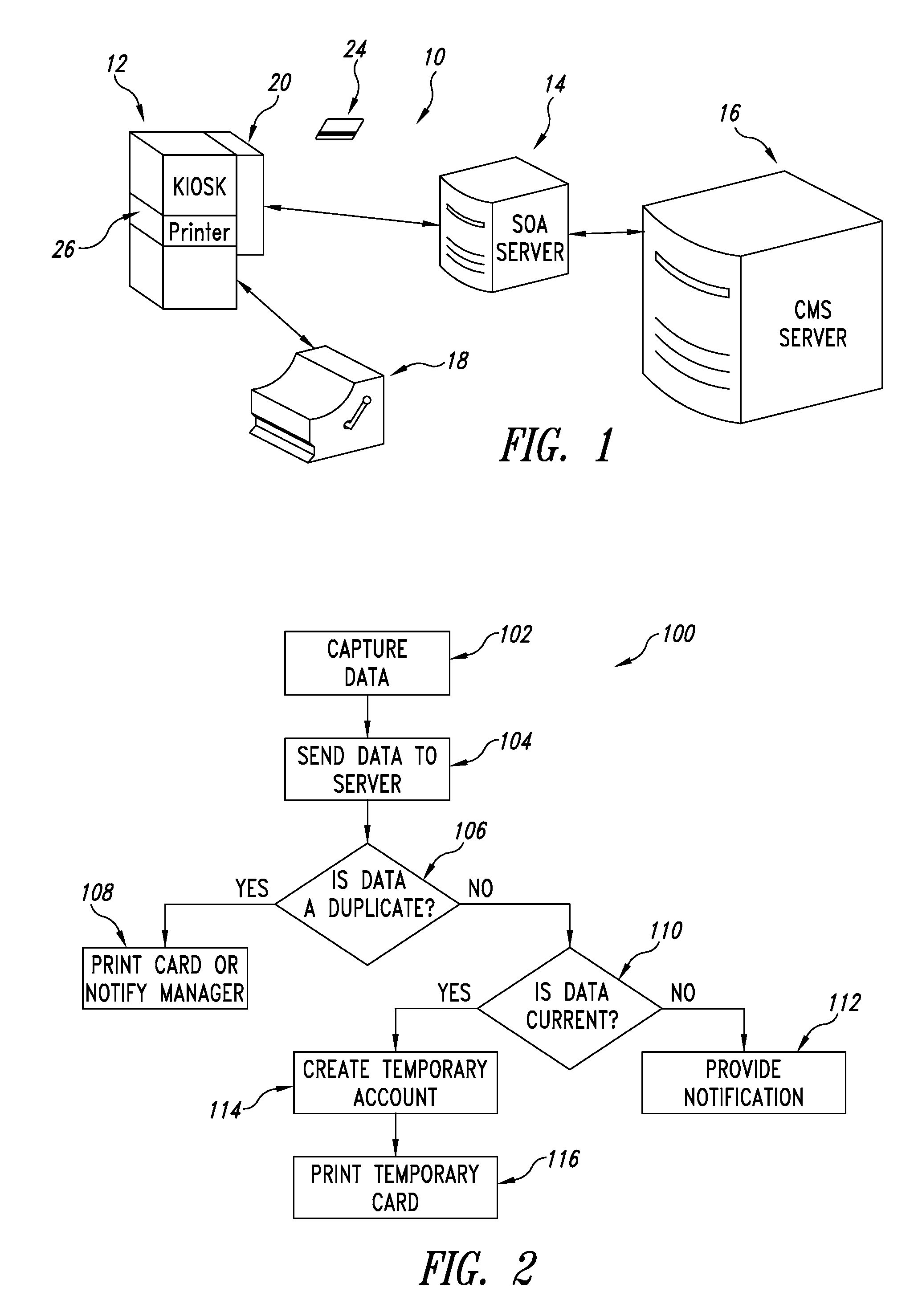

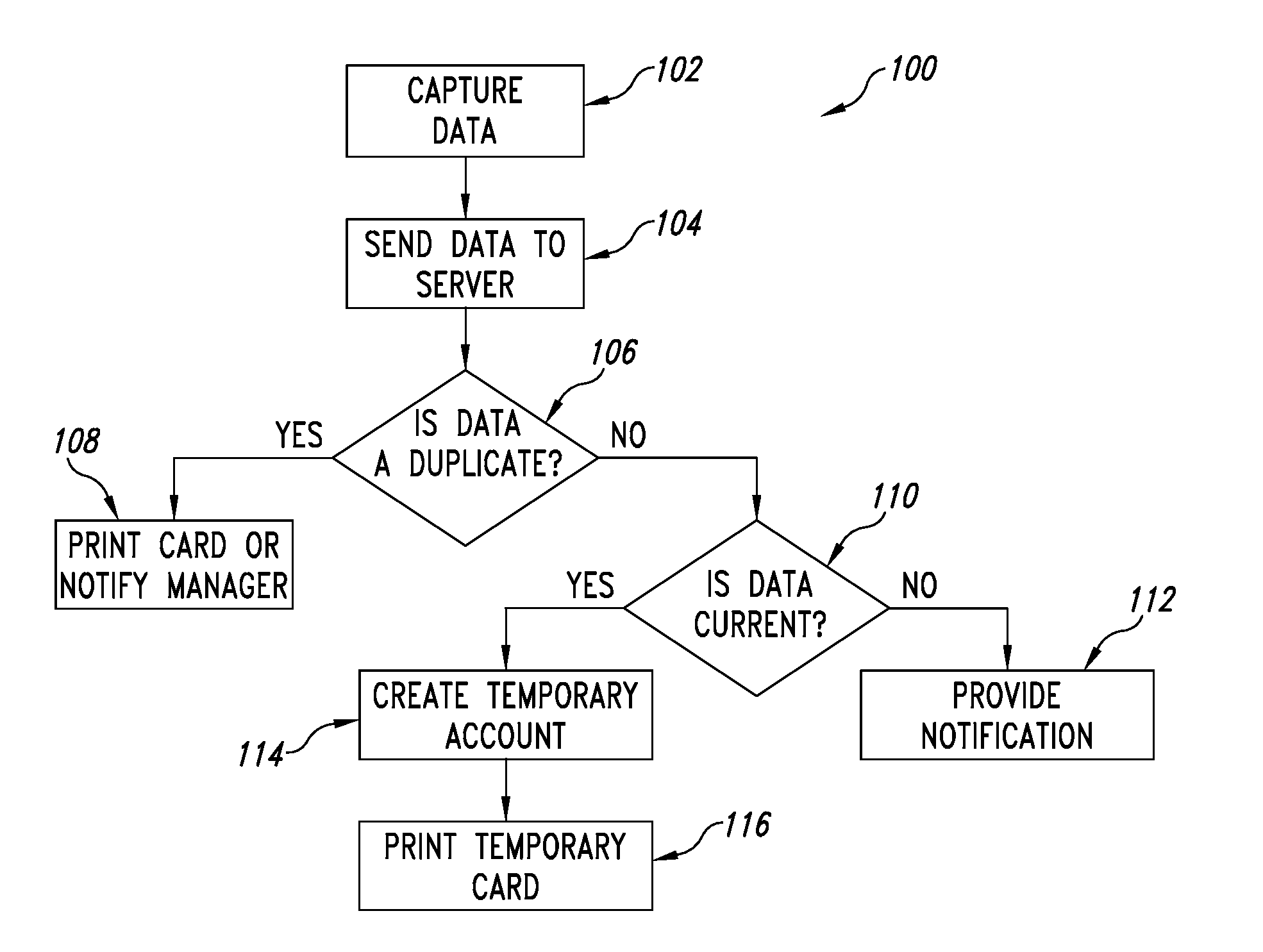

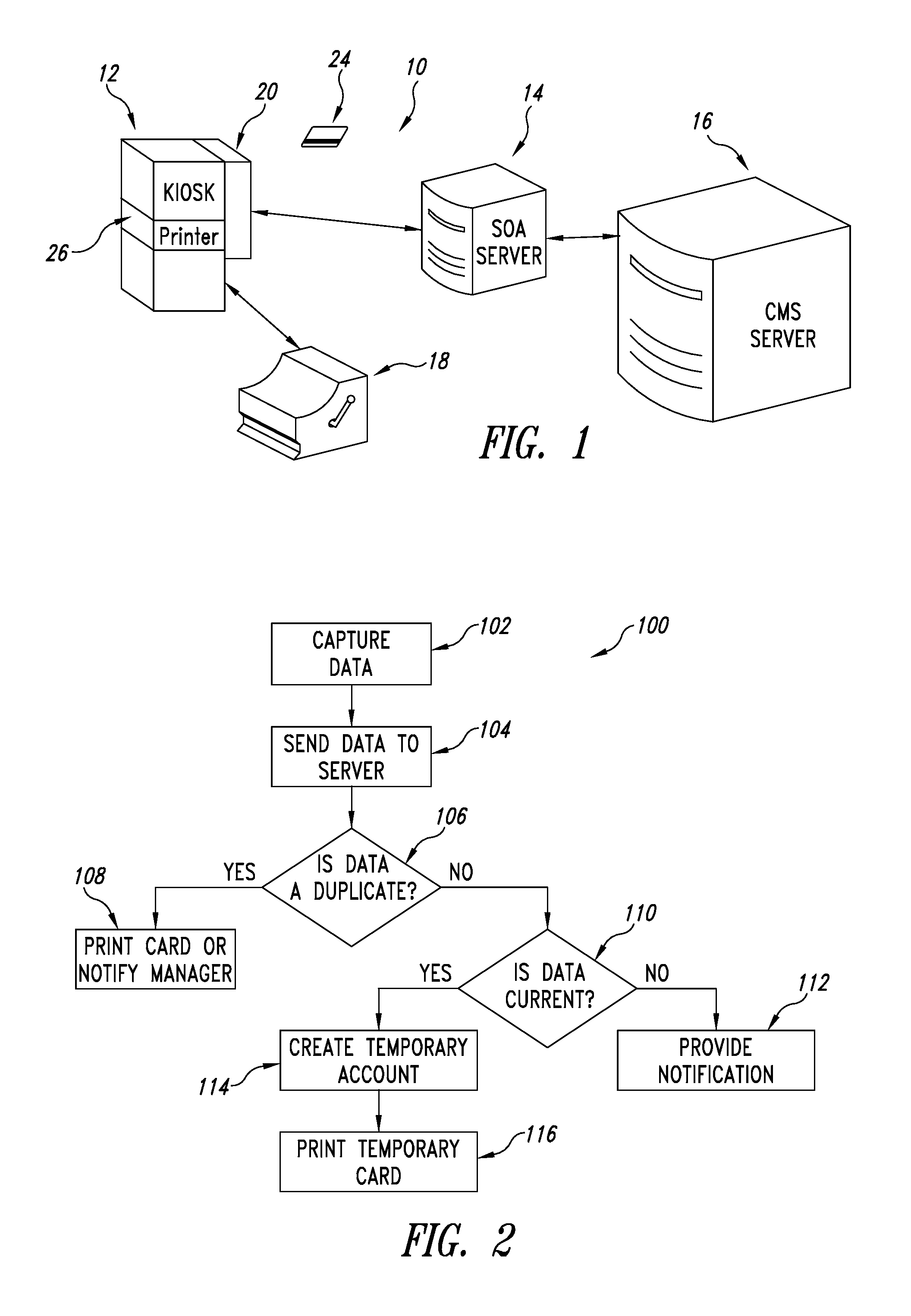

System and method for automated customer account creation and management

ActiveUS20090276341A1Remove obstaclesAvoid long linesComplete banking machinesFinanceDriver's licenseSelf-service

A method and system to automatically create and manage patron accounts using electronic data capture at an automated machine or kiosk, including electronically obtaining personal patron identification information from a patron identification source, such as a driver's license, determining if a patron account exists and if the identification source has expired and updating any existing patron account with the captured data. If the patron identification source is current and no account exists, a temporary account is created and a temporary patron account card supplied to the patron along with promotional offers. Patron activity is monitored at the location and used in creating a permanent patron account for providing additional offers, bonuses, and the like to the patron.

Owner:LNW GAMING INC

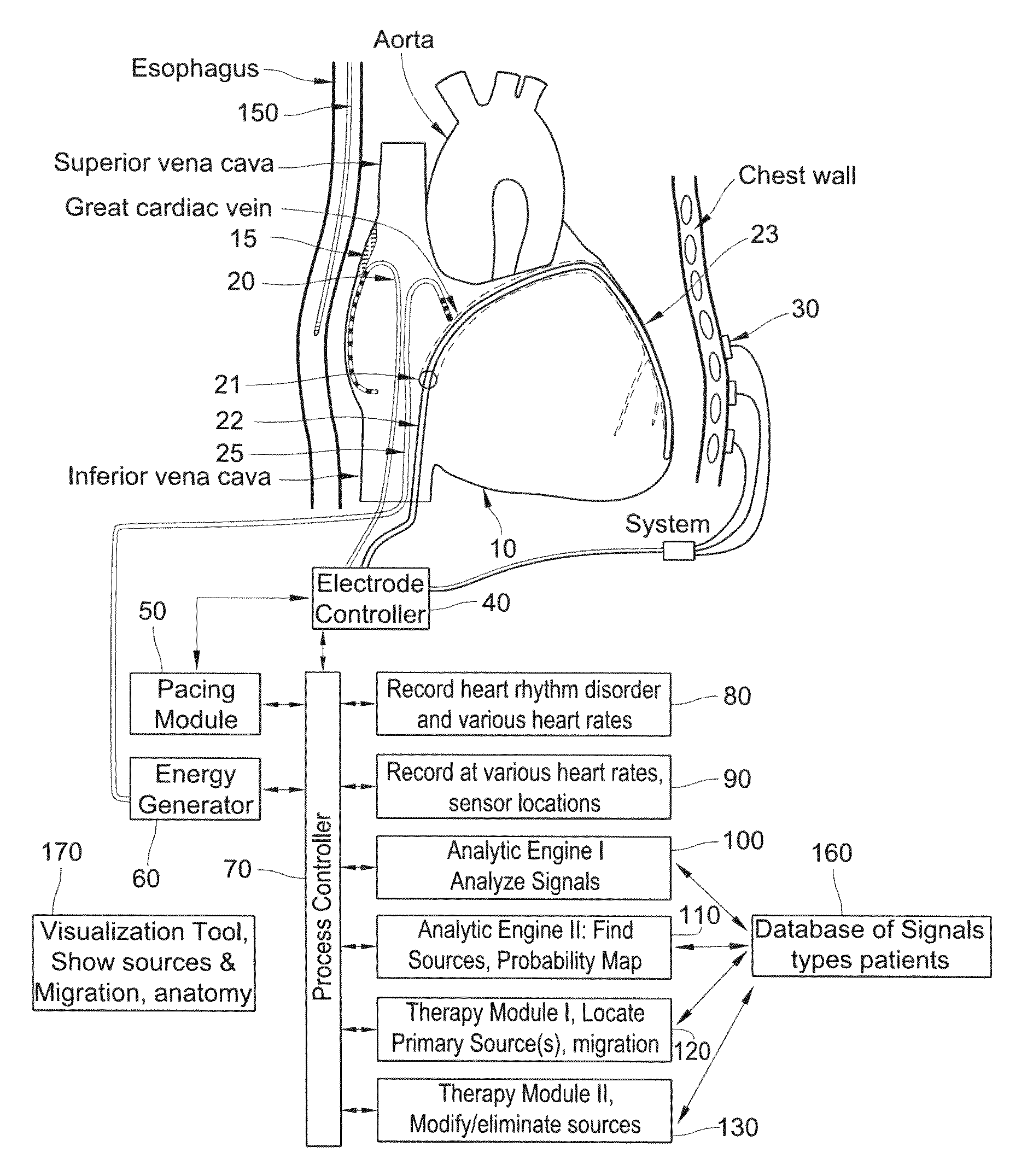

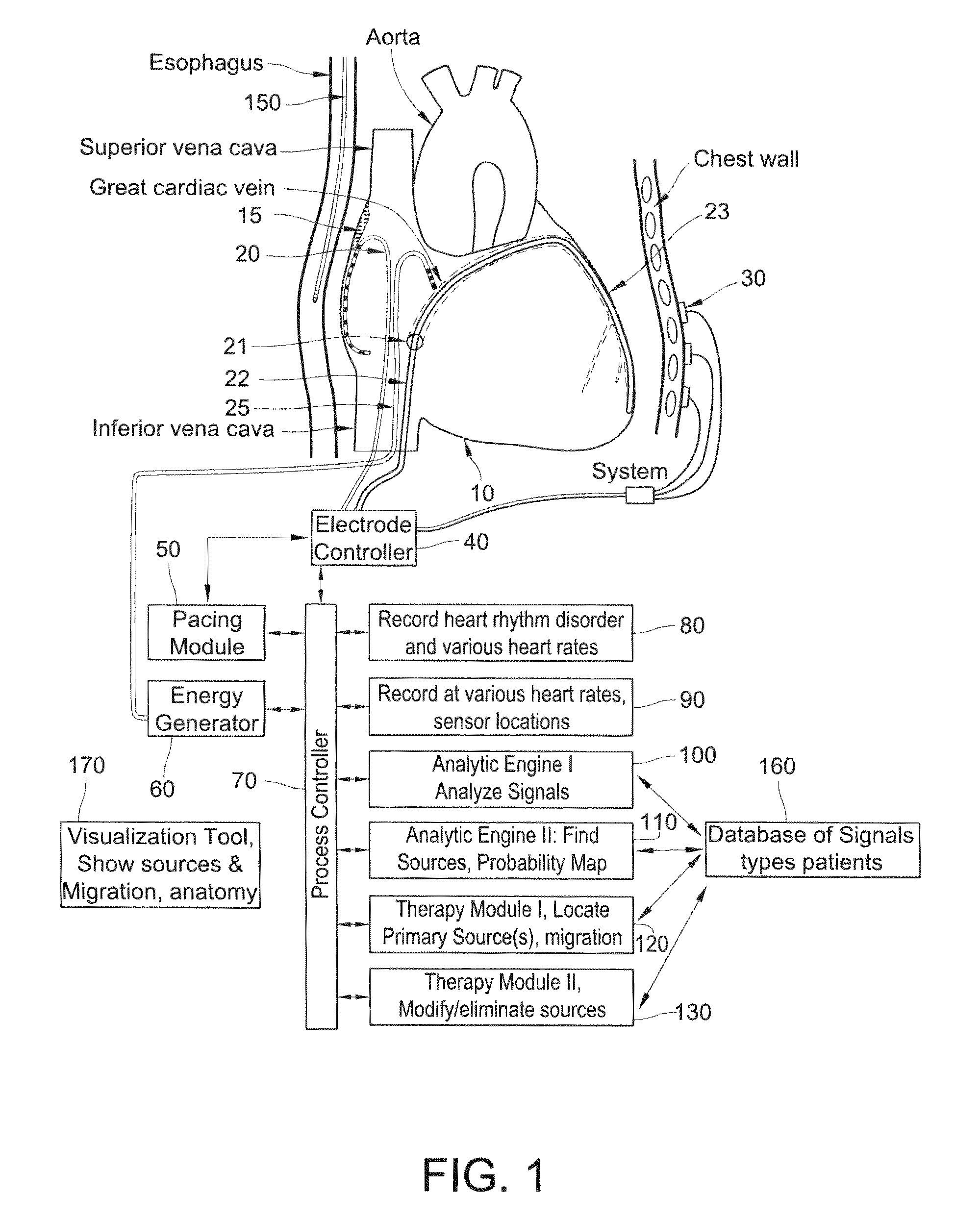

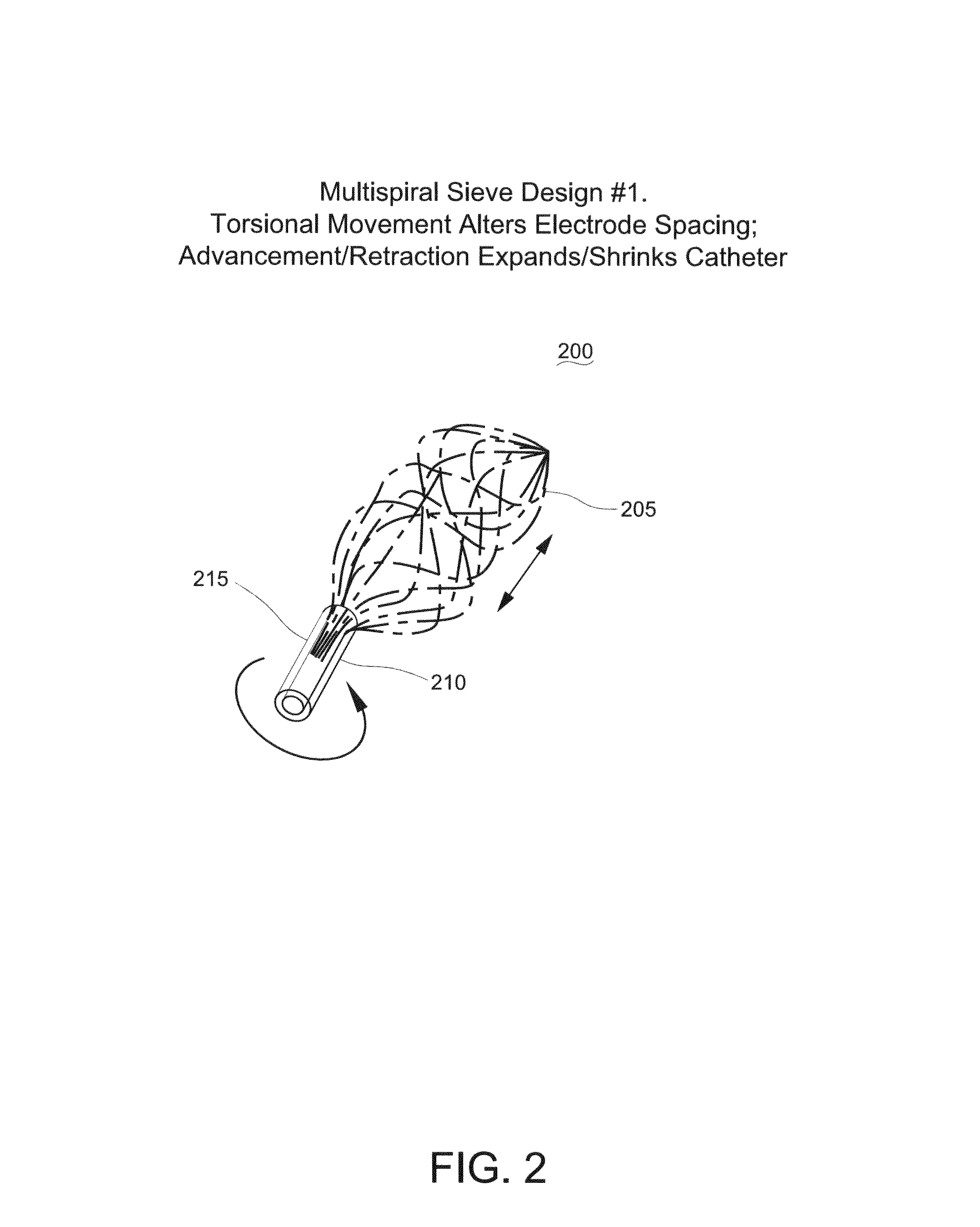

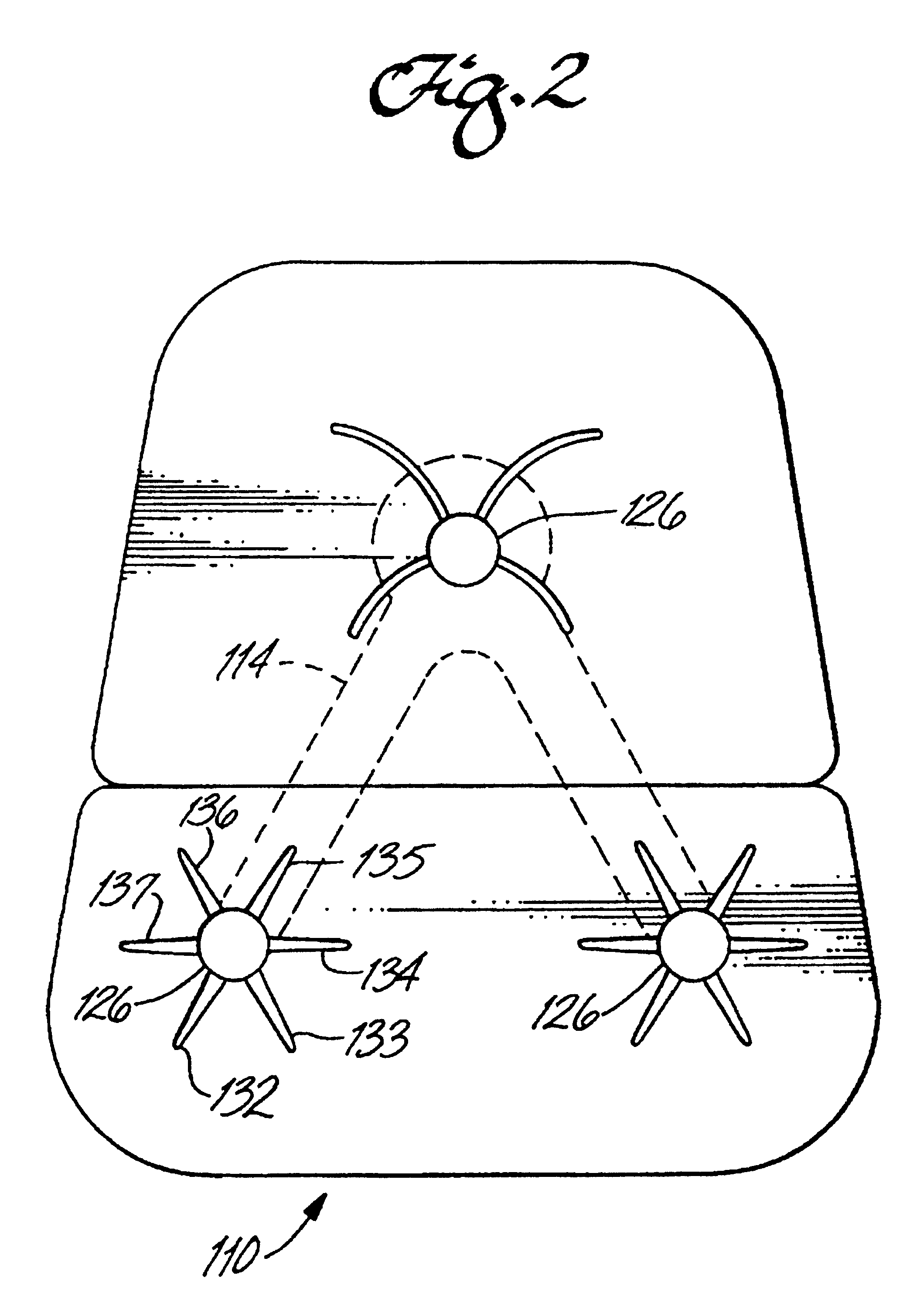

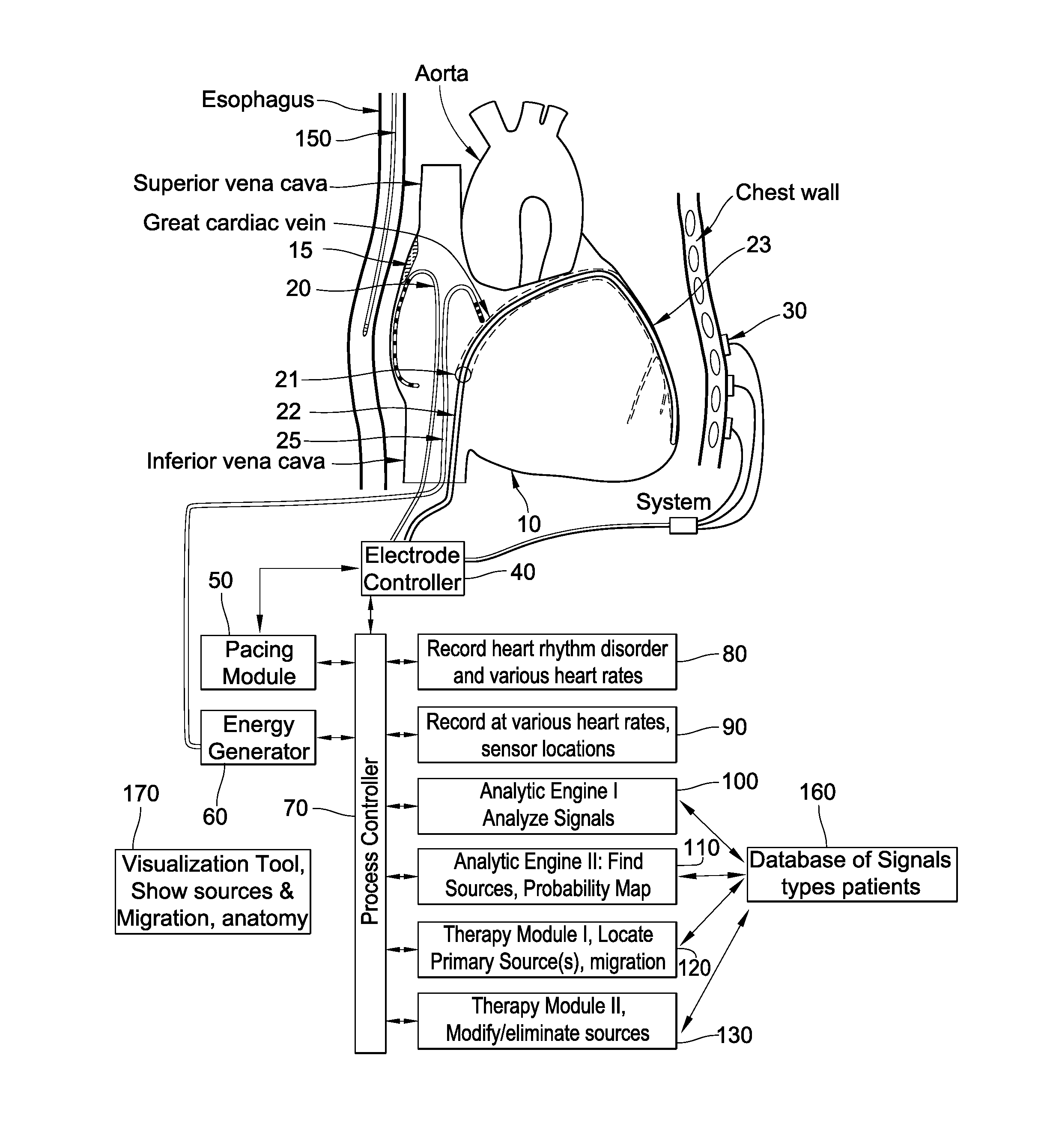

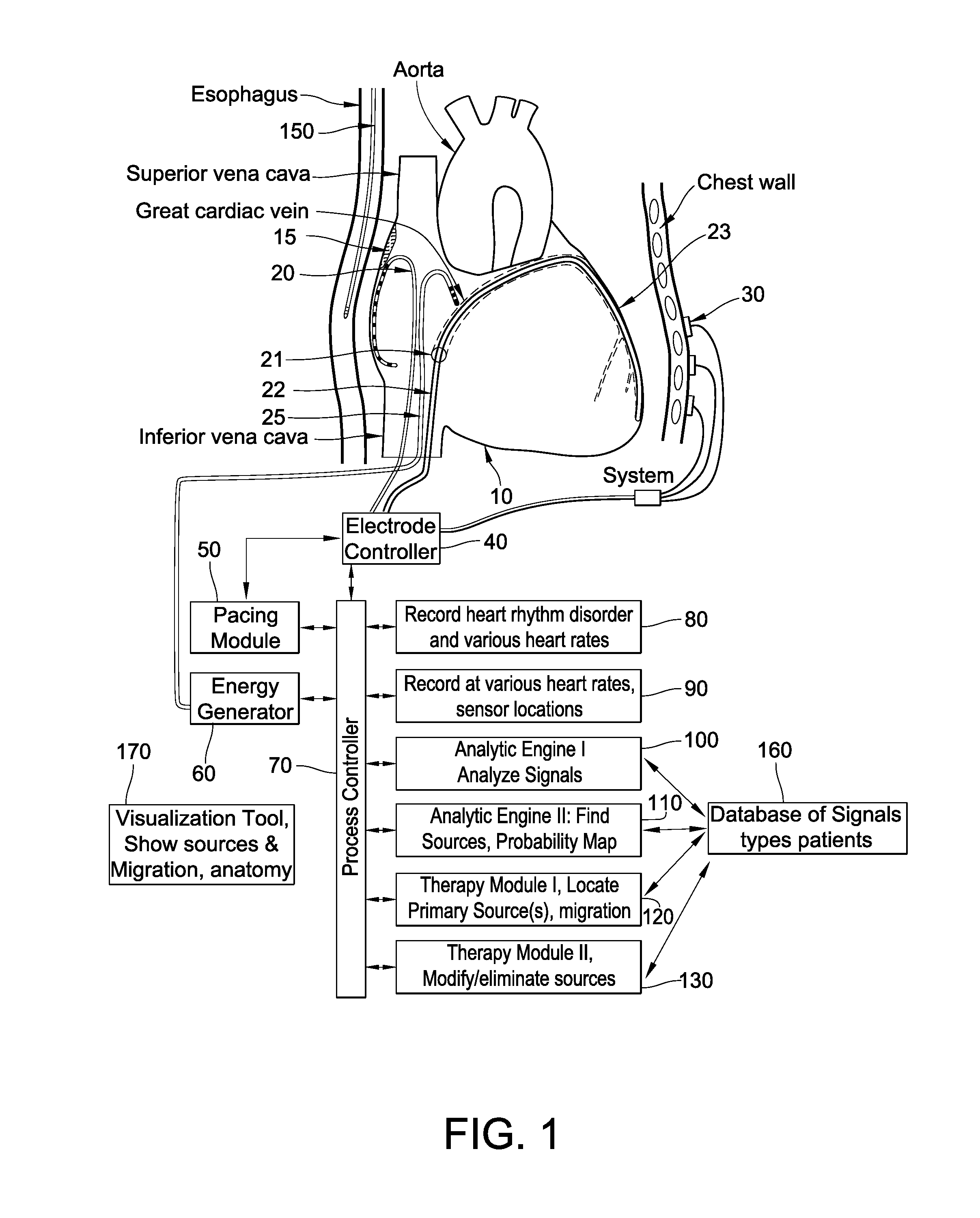

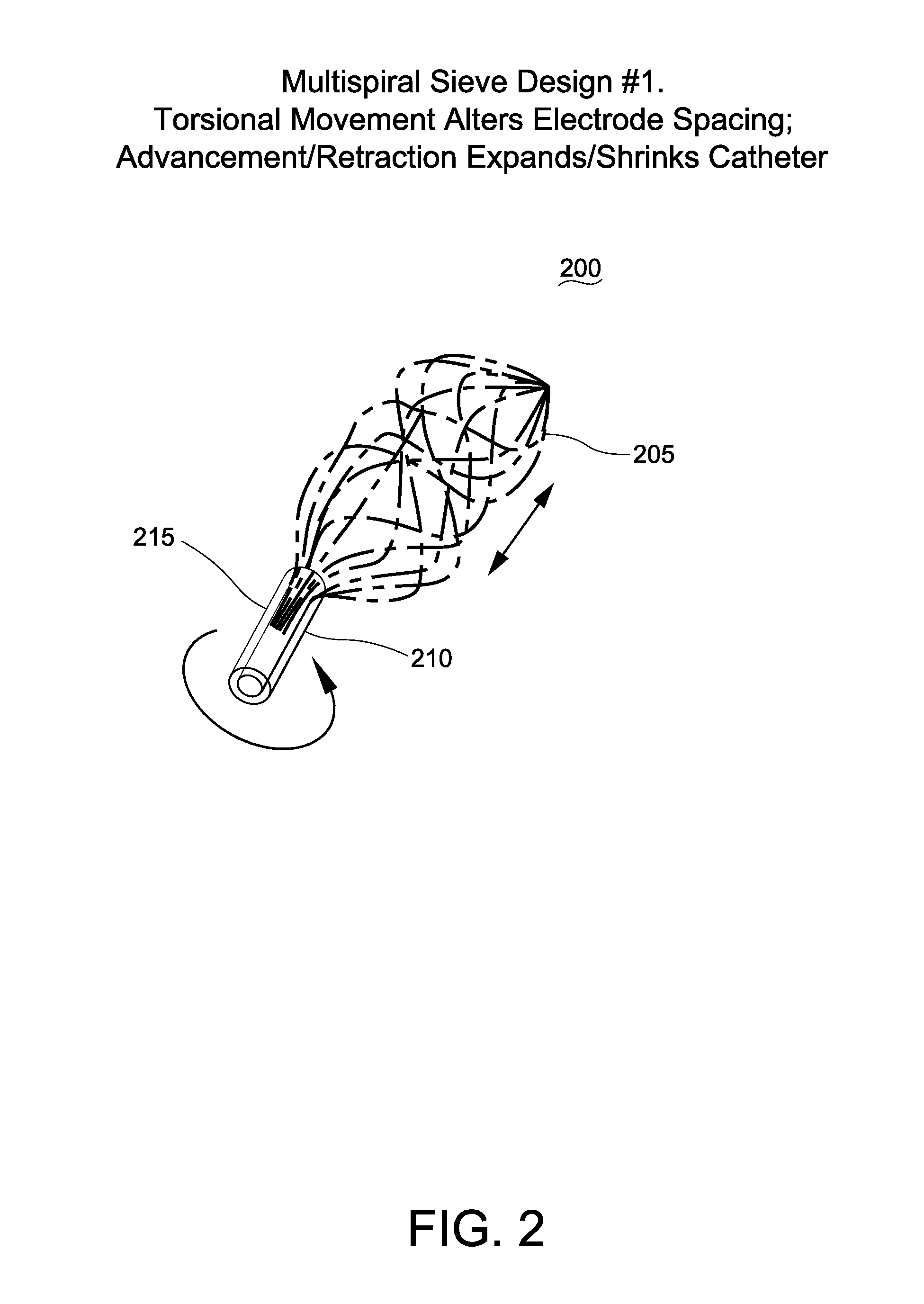

Methods for the detection and/or diagnosis of biological rhythm disorders

ActiveUS8521266B2Improve abilitiesRemove obstaclesUltrasonic/sonic/infrasonic diagnosticsElectrocardiographyMedicineRhythm

Method, system and apparatus to detect, diagnose and treat biological rhythm disorders. In preferred particularly desirable embodiment relating to the real-time detection of heart rhythm disorders, this invention identifies localized sources for complex rhythms including atrial fibrillation to guide the localized application of energy to modify the source and treat the rhythm disorder.

Owner:THE US REPRESENTED BY THE DEPT OF VETERANS AFFAIRS OFFICE OF THE GENERAL COUNSEL 024 +1

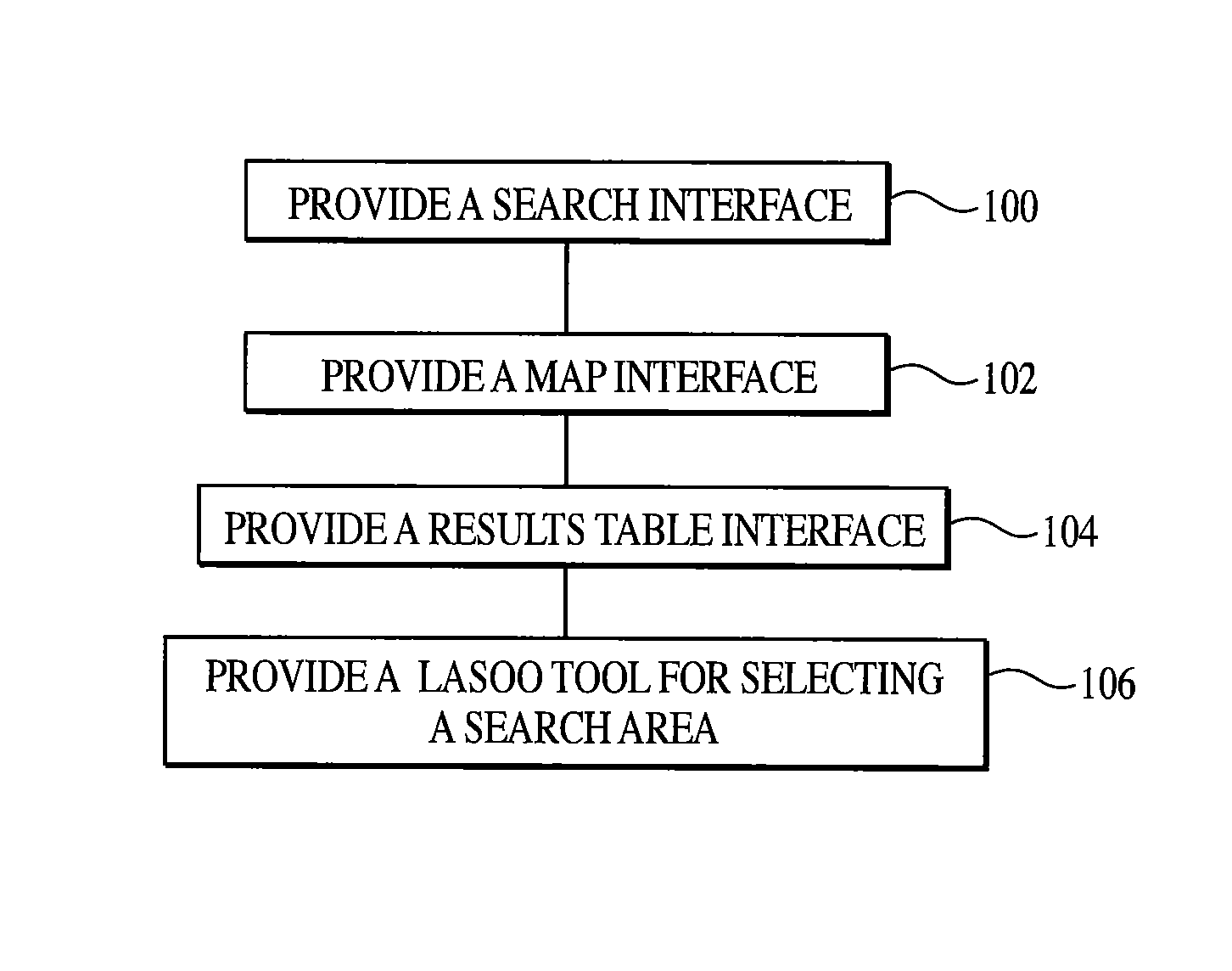

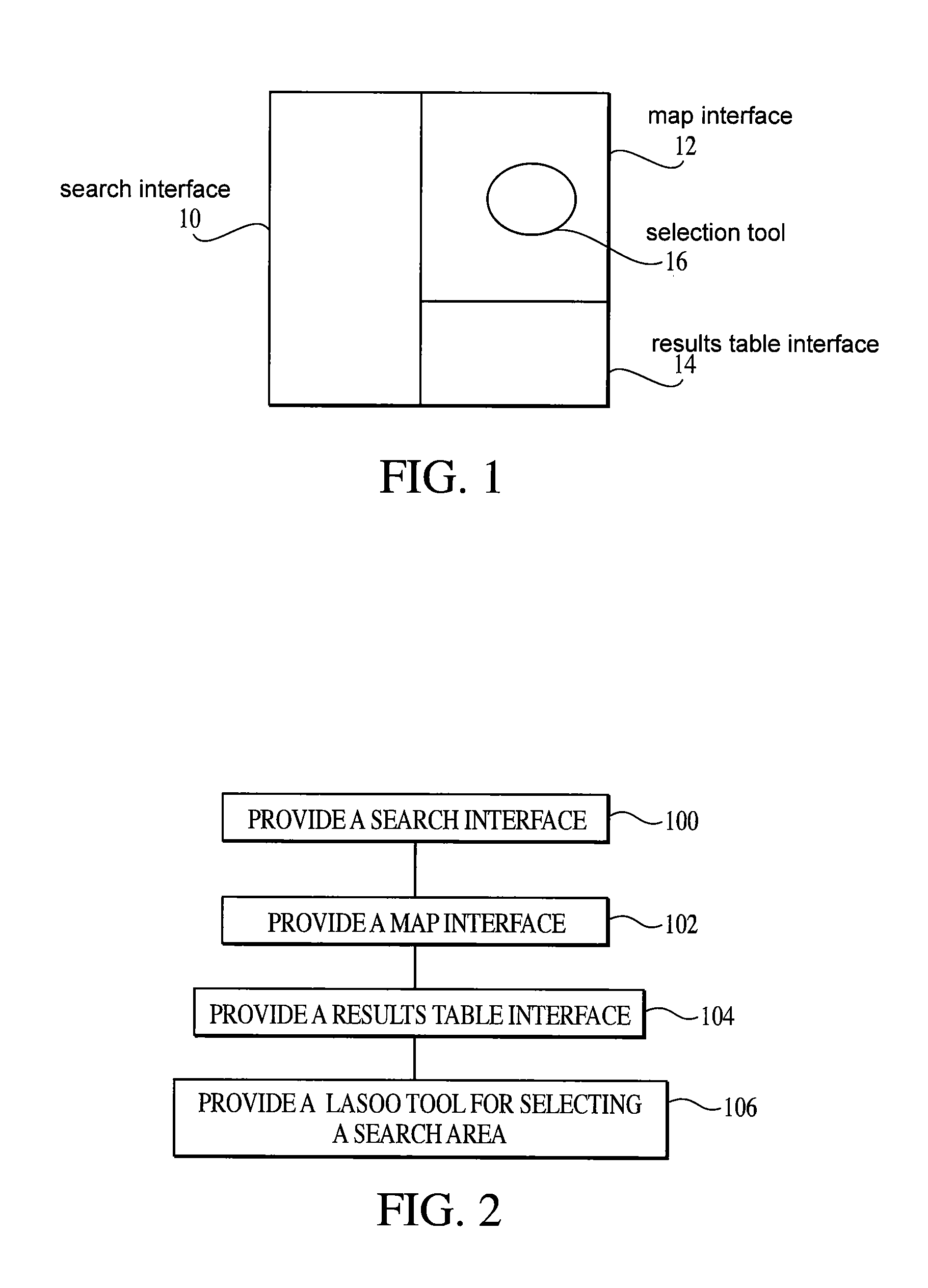

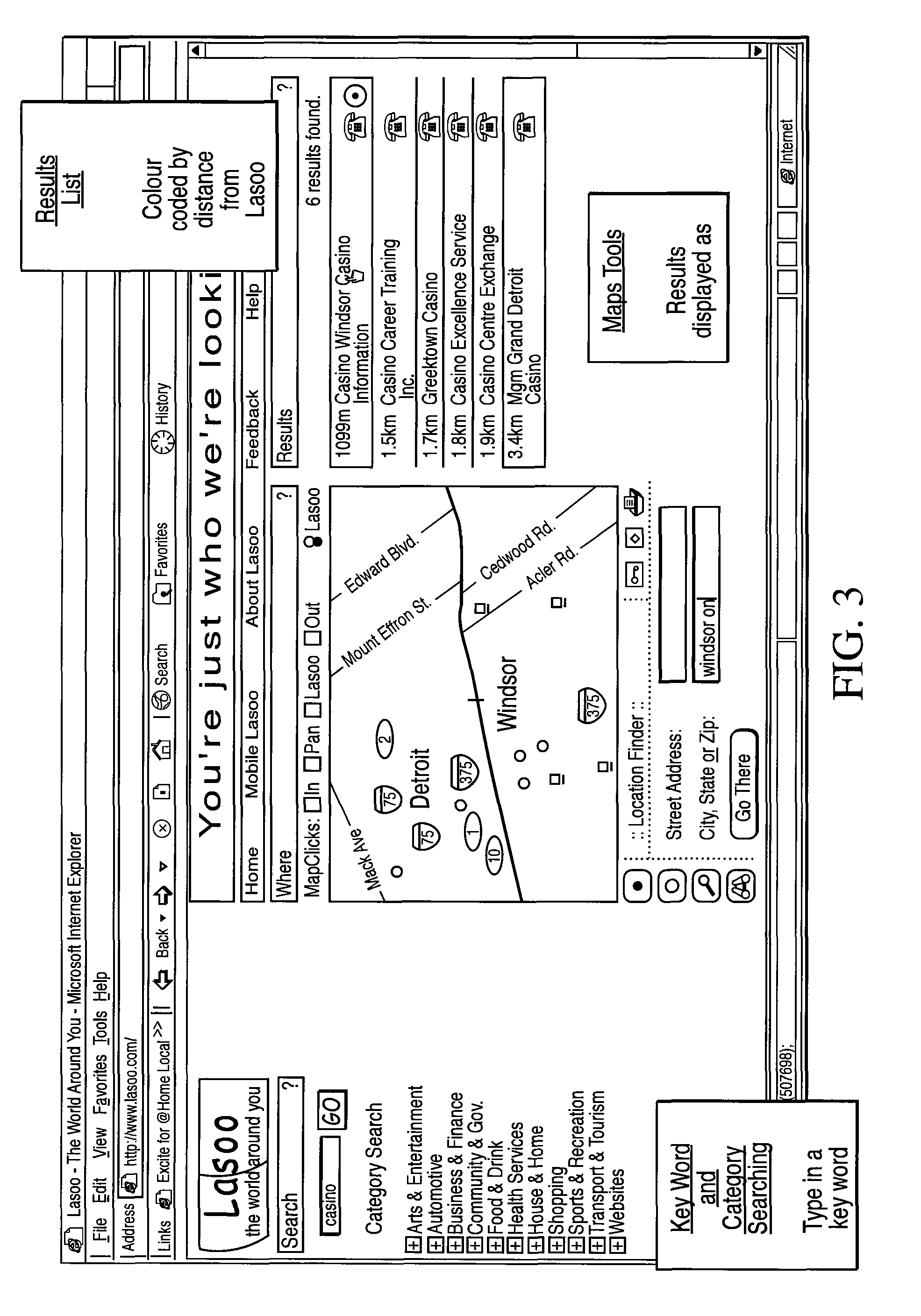

Information retrieval system and method employing spatially selective features

ActiveUS7707140B2Remove obstaclesDigital data processing detailsGeographical information databasesComputer scienceInformation retrieval

Owner:R2 SOLUTIONS

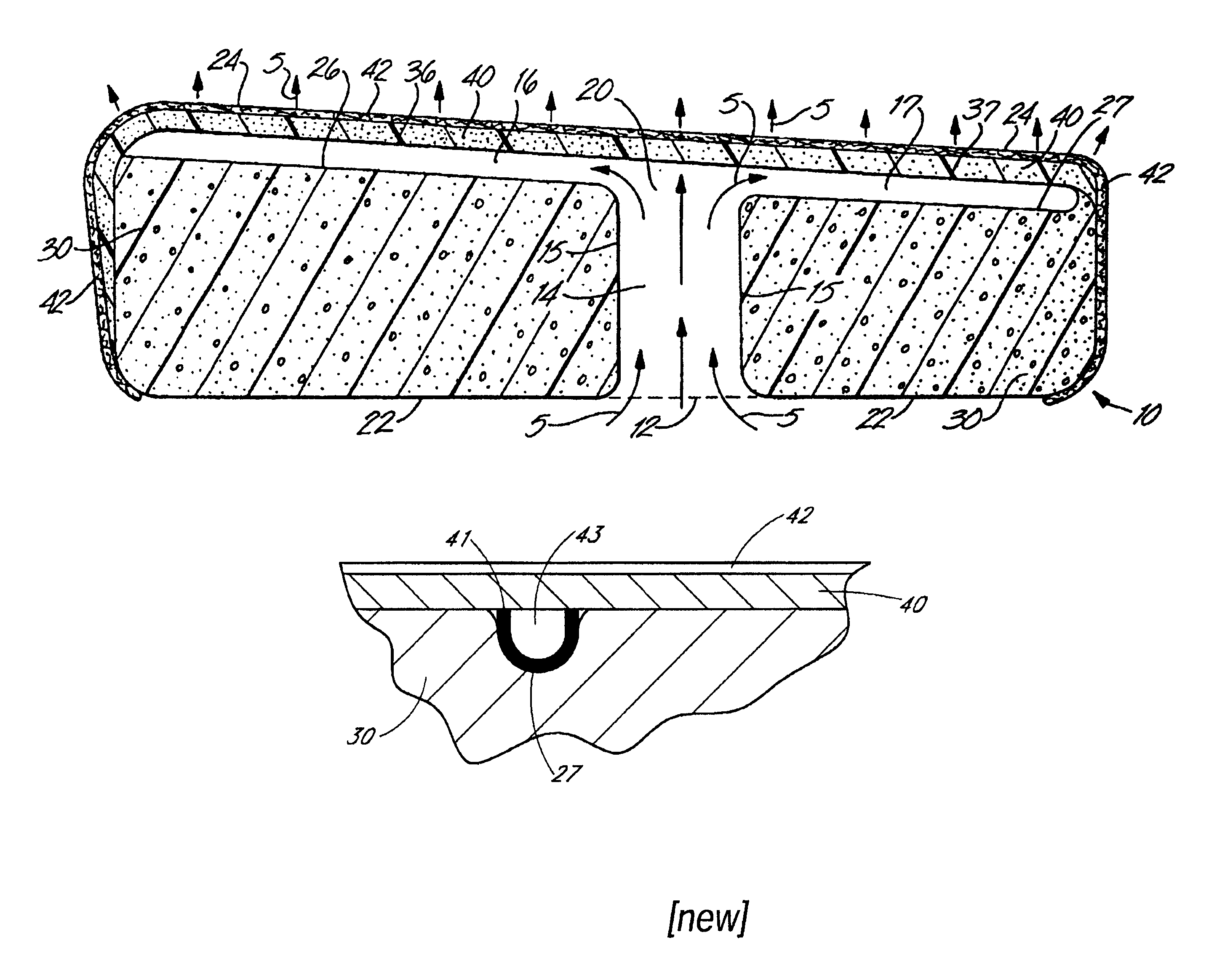

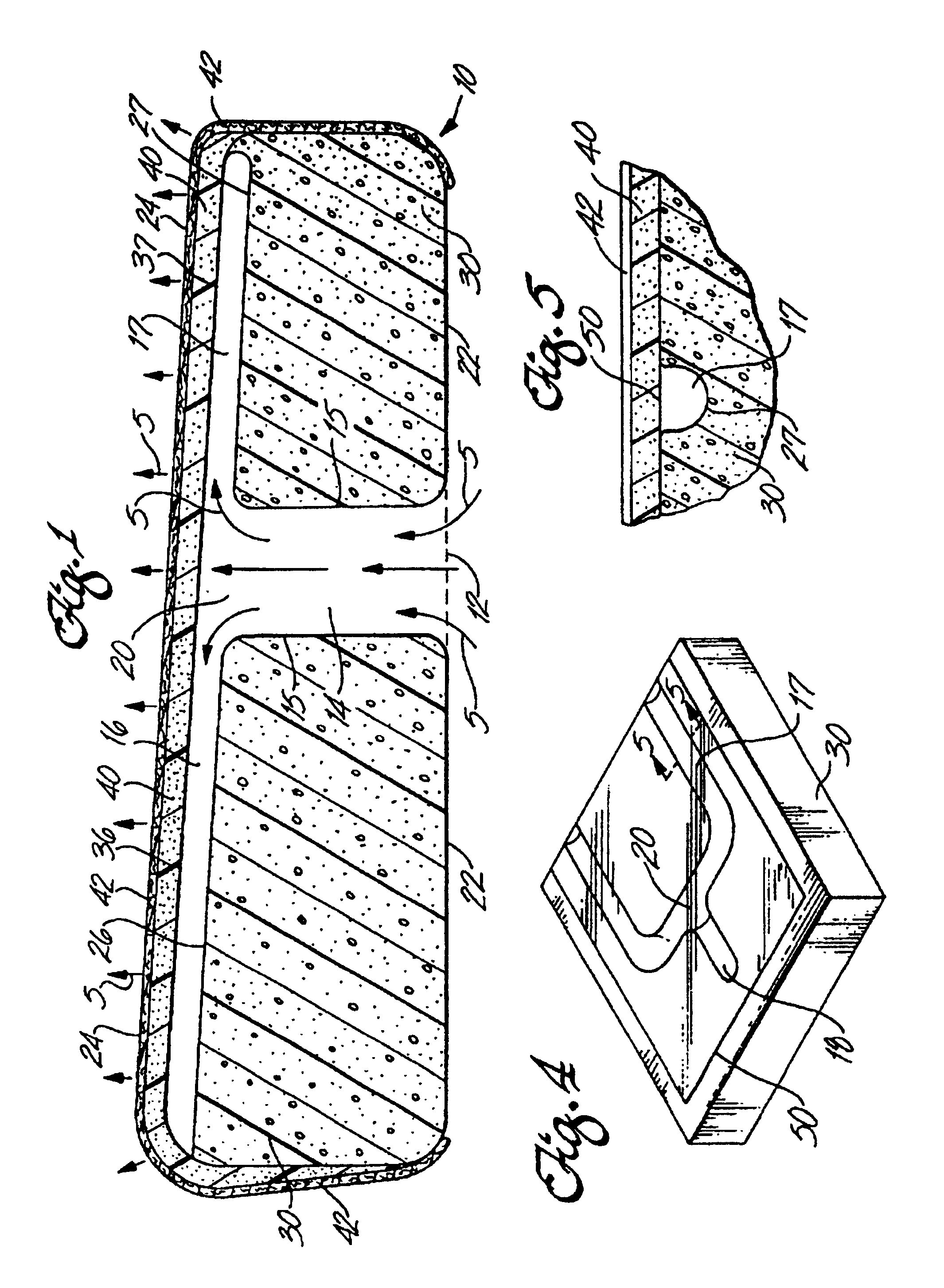

Variable temperature seat

A seating construction with a plurality of plenums into which is received temperature conditioned air. The air passes through the seat via a plurality of channels formed in the foam of the seat cushion. The air then migrates through a reticulated foam layer that is itself covered with an air permeable layer of material. The reticulated foam and stitching of the seat fabric facilitate diffusion of the air from the foam channel conduits. The air then convectively circulates against and near the occupant of the seat to facilitate climate control around the occupant.

Owner:GENTHERM INC

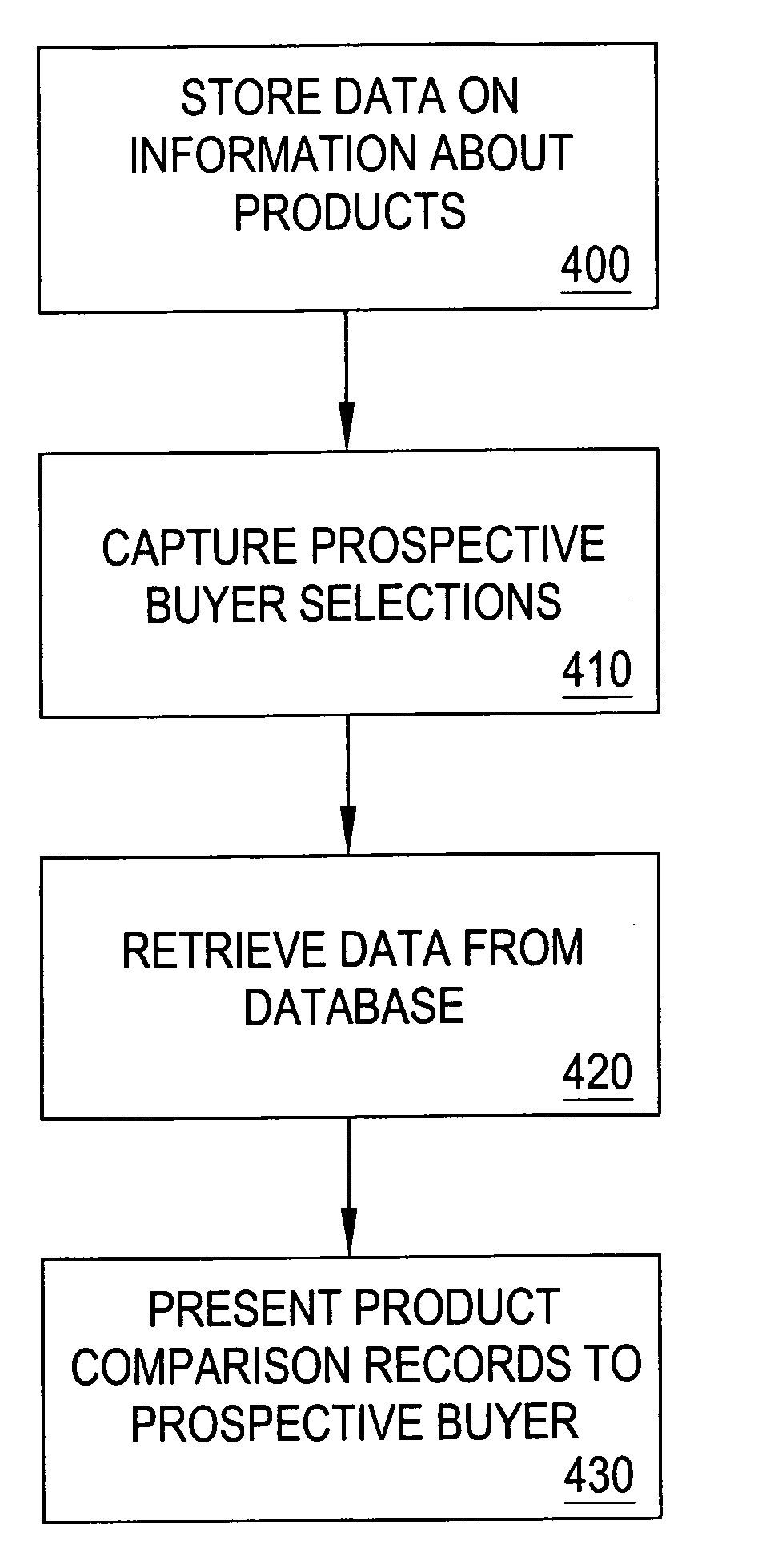

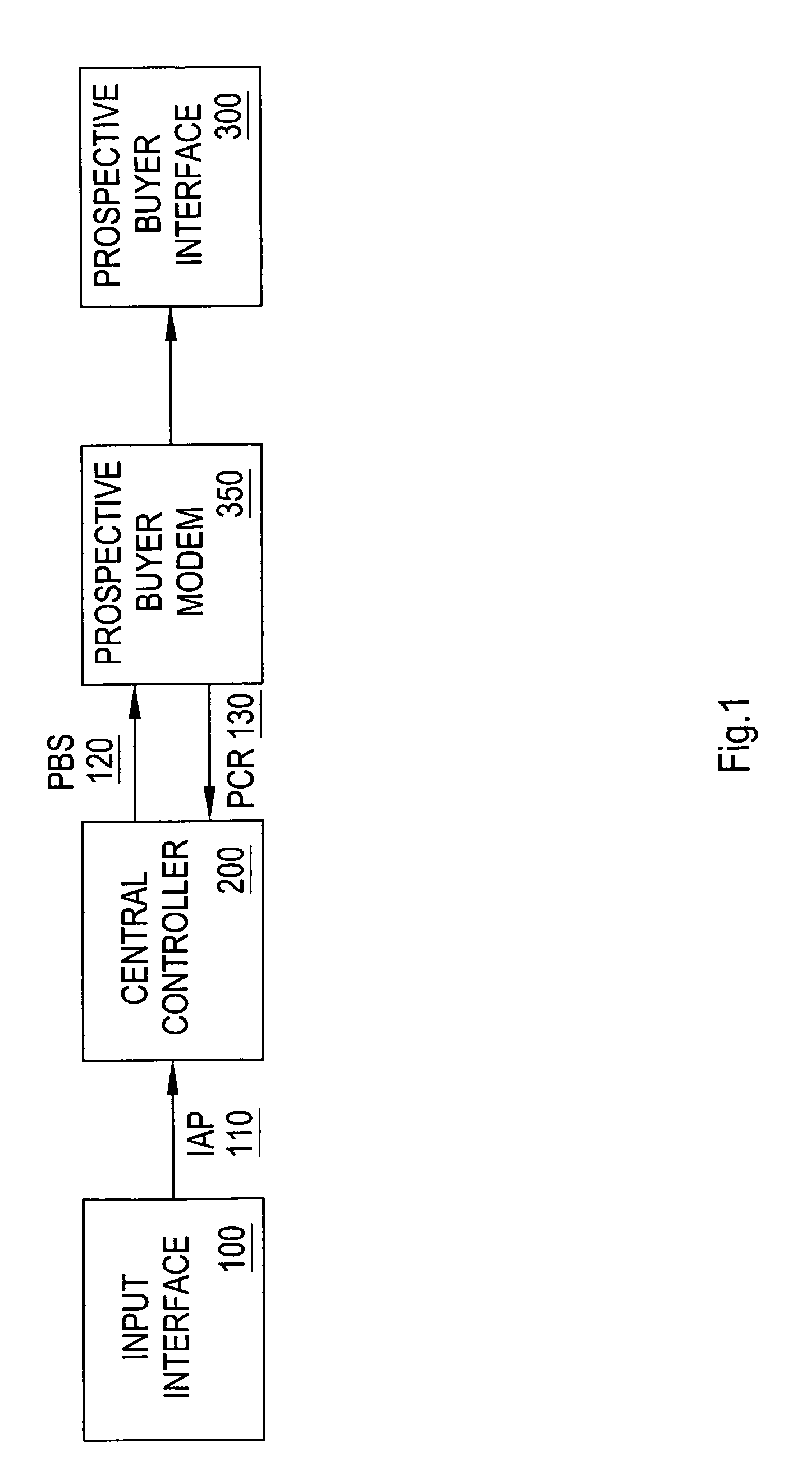

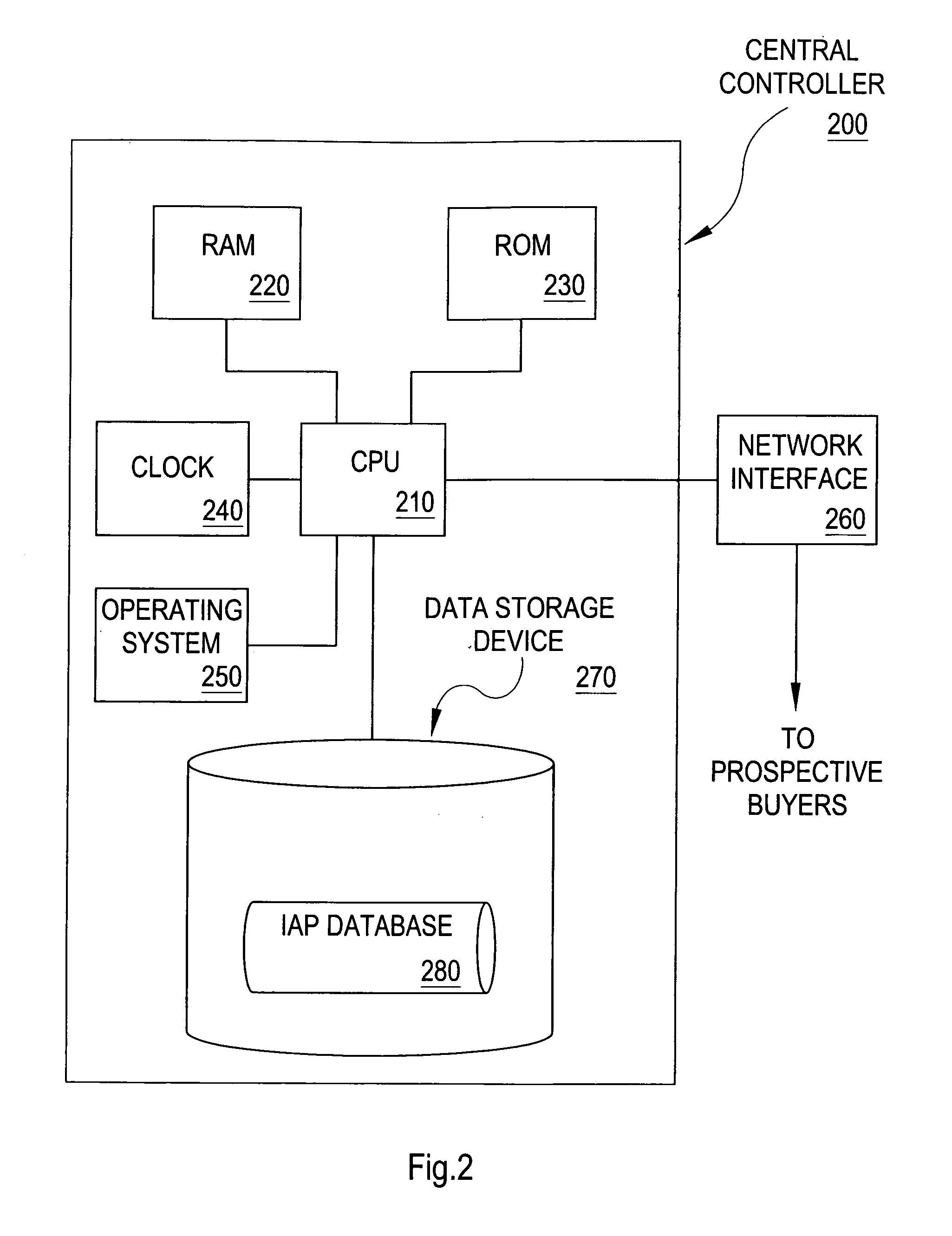

Method and apparatus for presenting price comparison to prospective buyers

InactiveUS6976006B1Remove obstaclesCommerceSpecial data processing applicationsCommunications systemComputerized system

A method and apparatus designed to facilitate price comparison for products, offered by a plurality of merchants, that are stocked by the merchants in stores that the prospective buyers may personally visit to see and / or touch and / or feel the products. The data from various merchants, comprising details on products including price, is collected into a computer system. A subset of the data is retrieved and organized to present a comparison to the prospective buyers. The method and apparatus of the present invention have applications on the World Wide Web as well as conventional communications systems such as voice telephony.

Owner:VERMA CHHEDI LAL +1

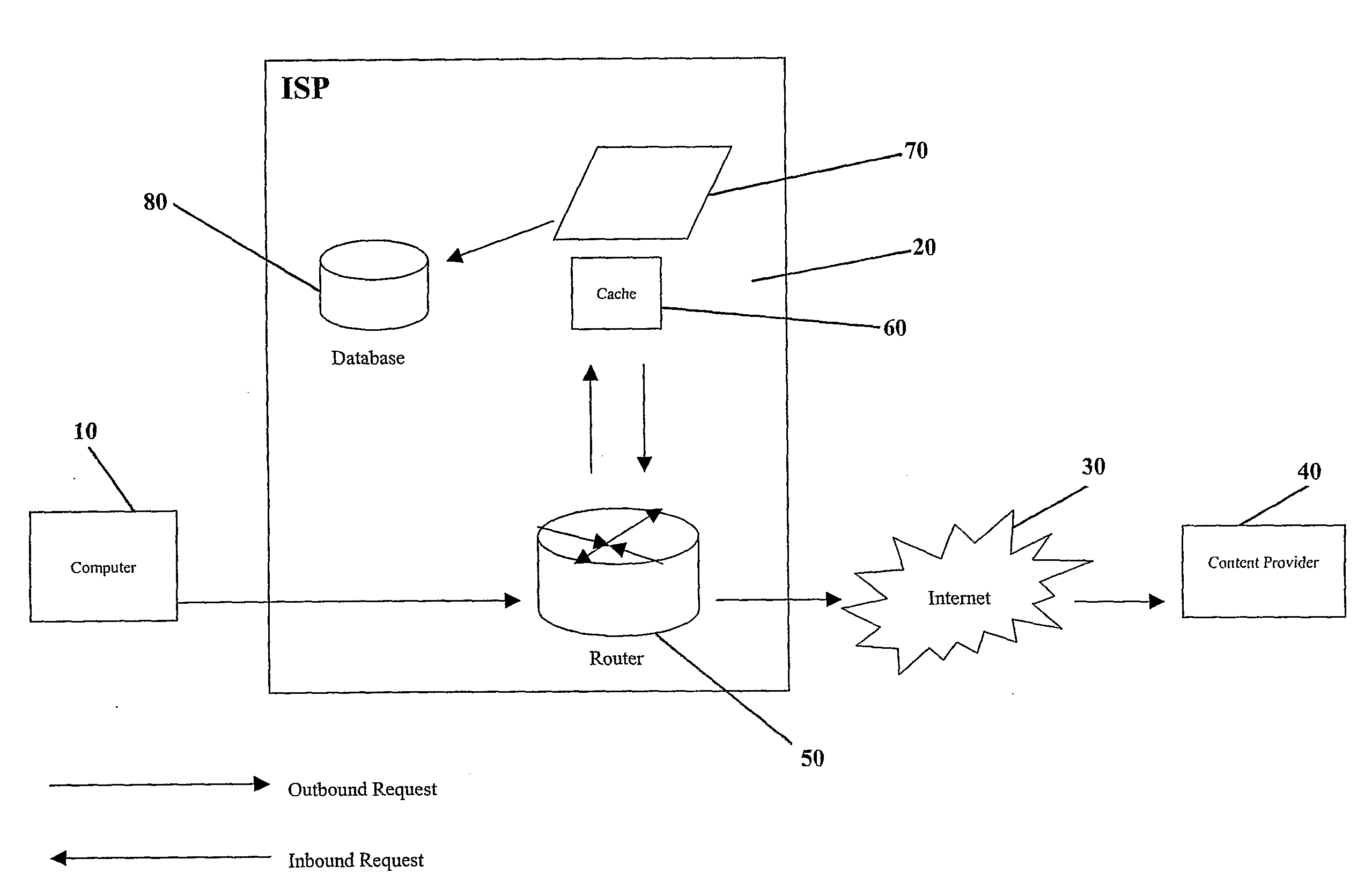

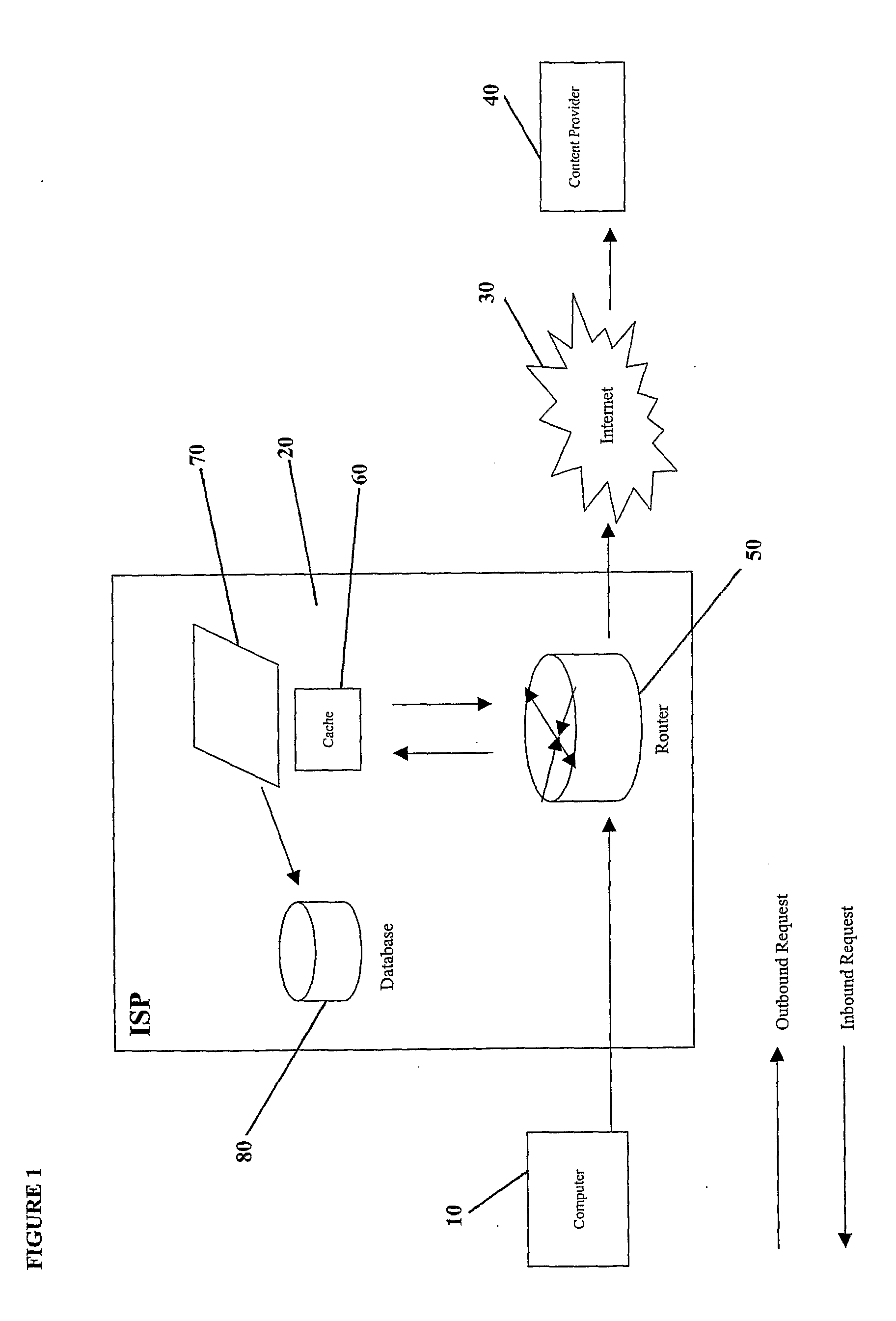

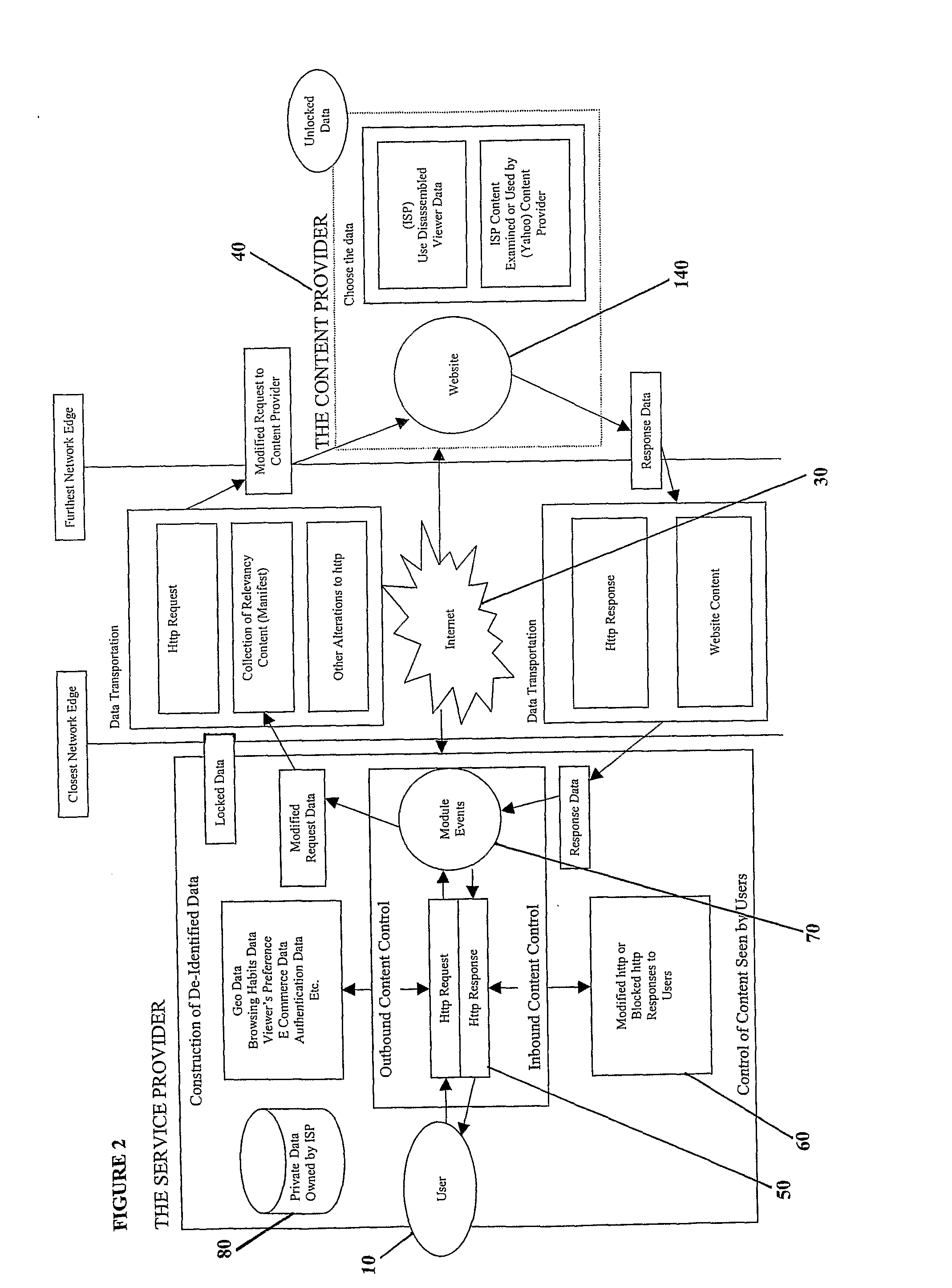

Method and System of Targeting Content

InactiveUS20080270417A1Improve customer experienceGenerating new sourceAdvertisementsTransmissionService provisionNetwork packet

A network device is placed on the edge of a service provider's network to intercept incoming and outgoing packets from a computer within the service provider's network. On interception of such a packets, the network device uses personal information about the user of the computer stored in a database in the service provider's network, to determine if such packet should be altered, and if deeming it appropriate alters such packet before sending the packet to its destination. This allows users of the service provider's network to provide personal preferences to the service provider, which will be used by the network device to alter packets according to such preferences.

Owner:ADZILLA INC

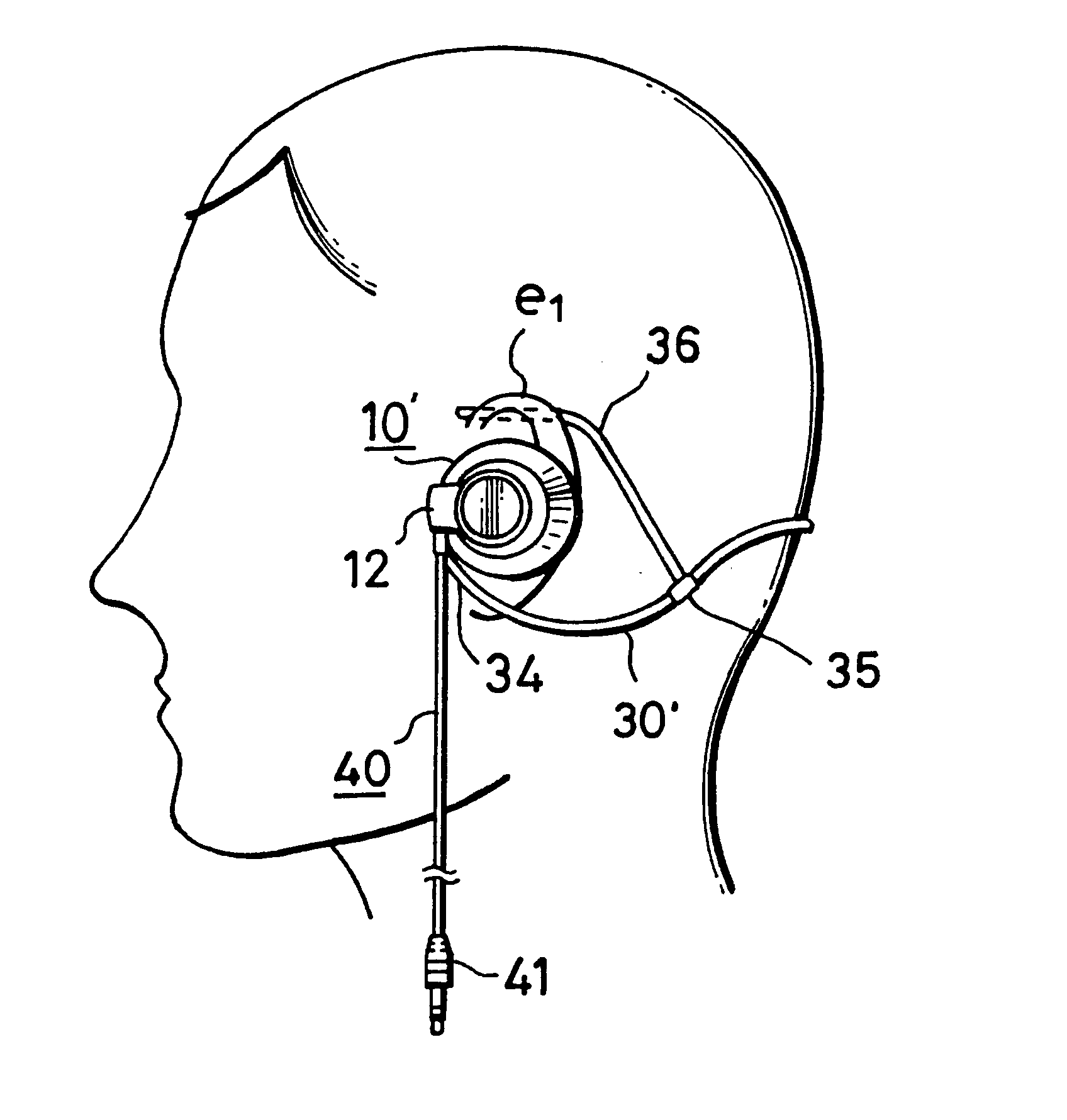

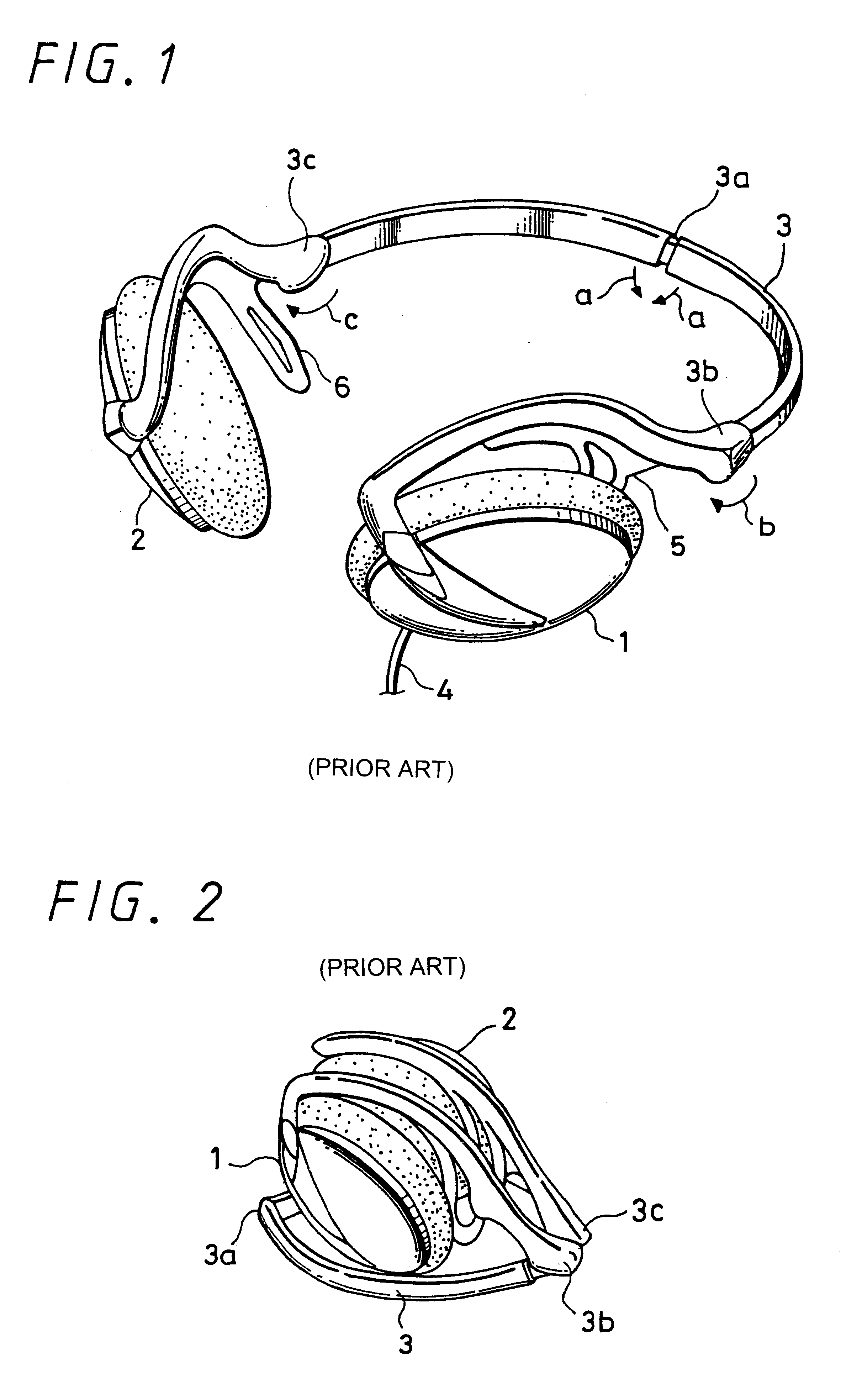

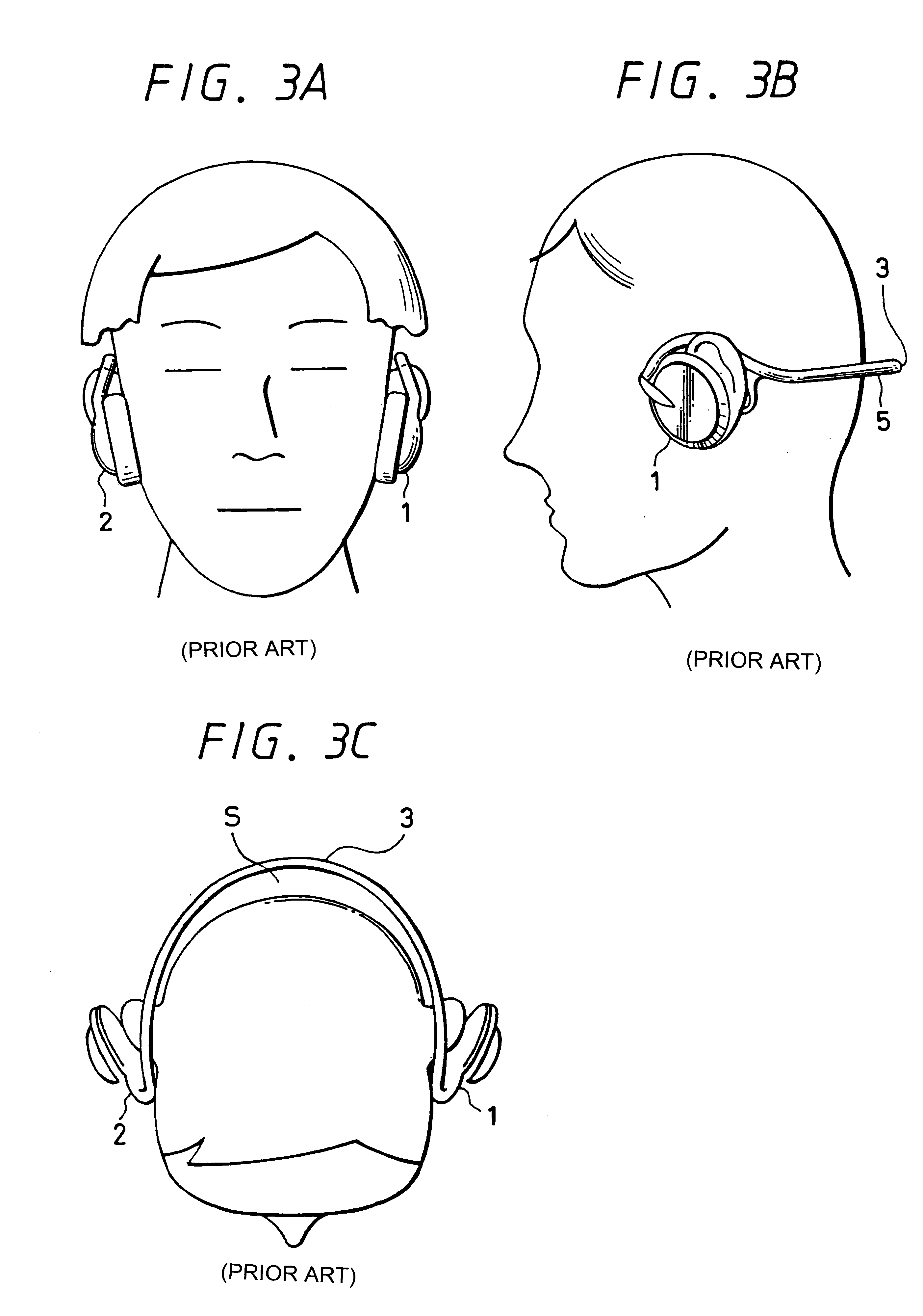

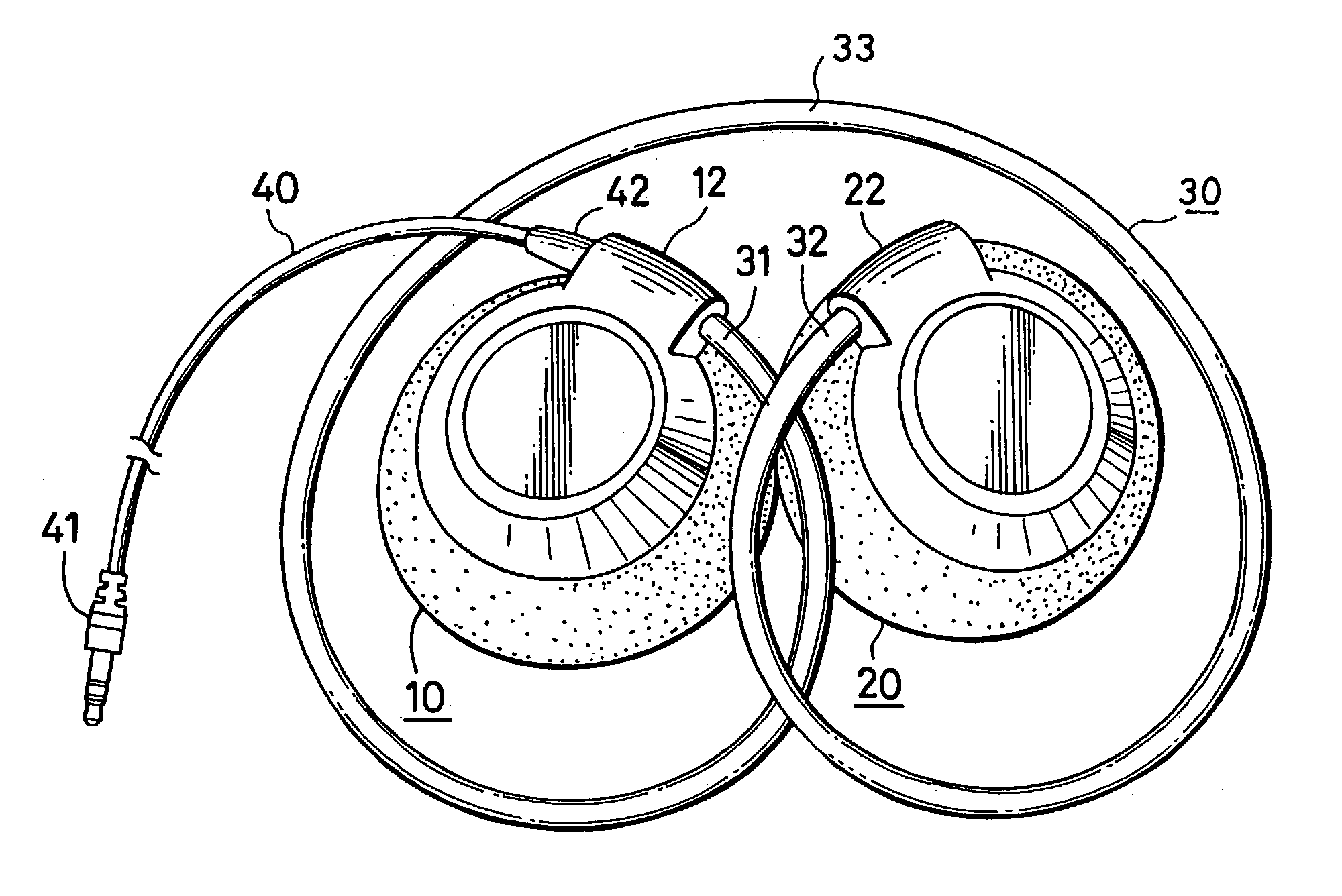

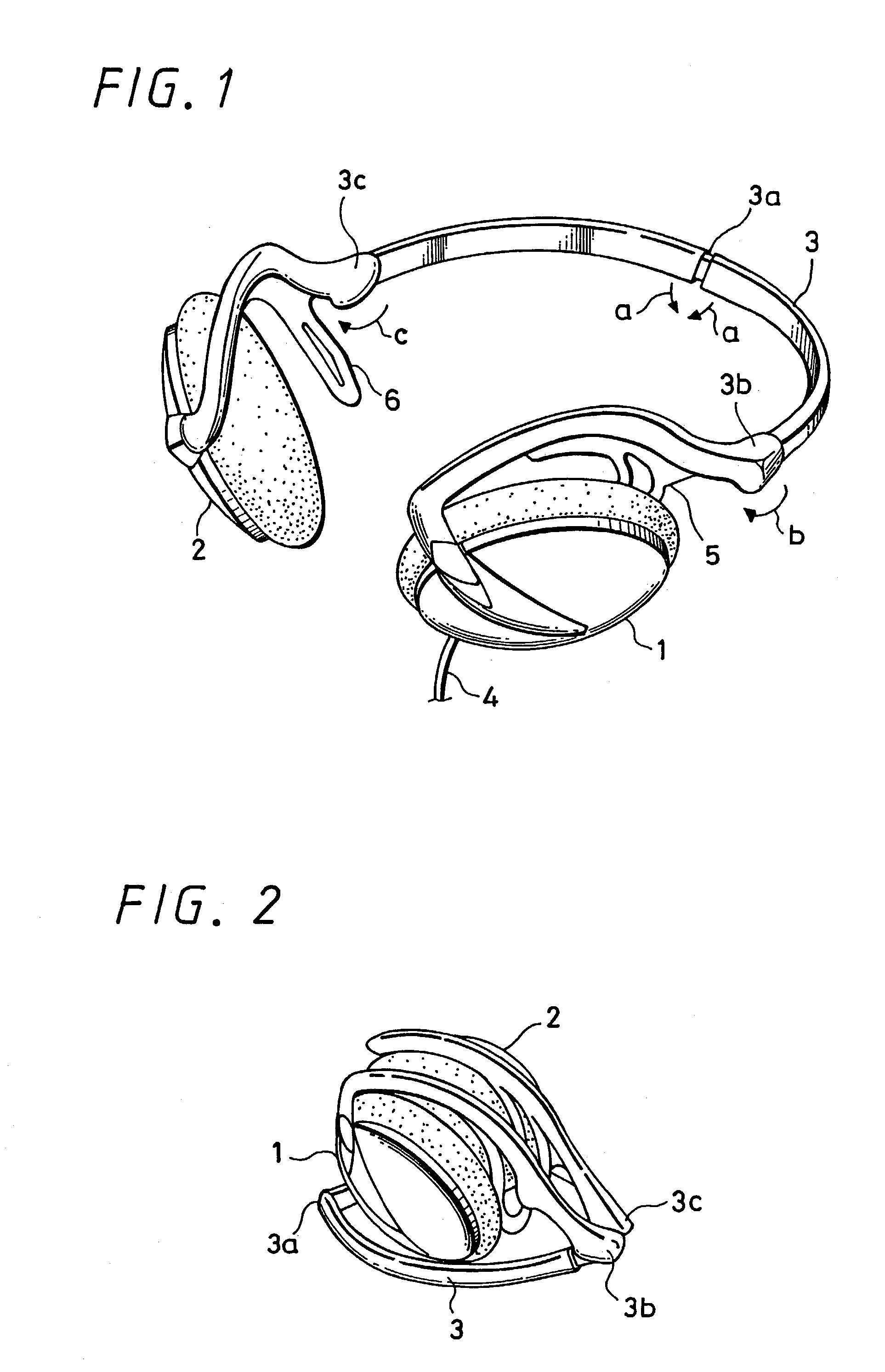

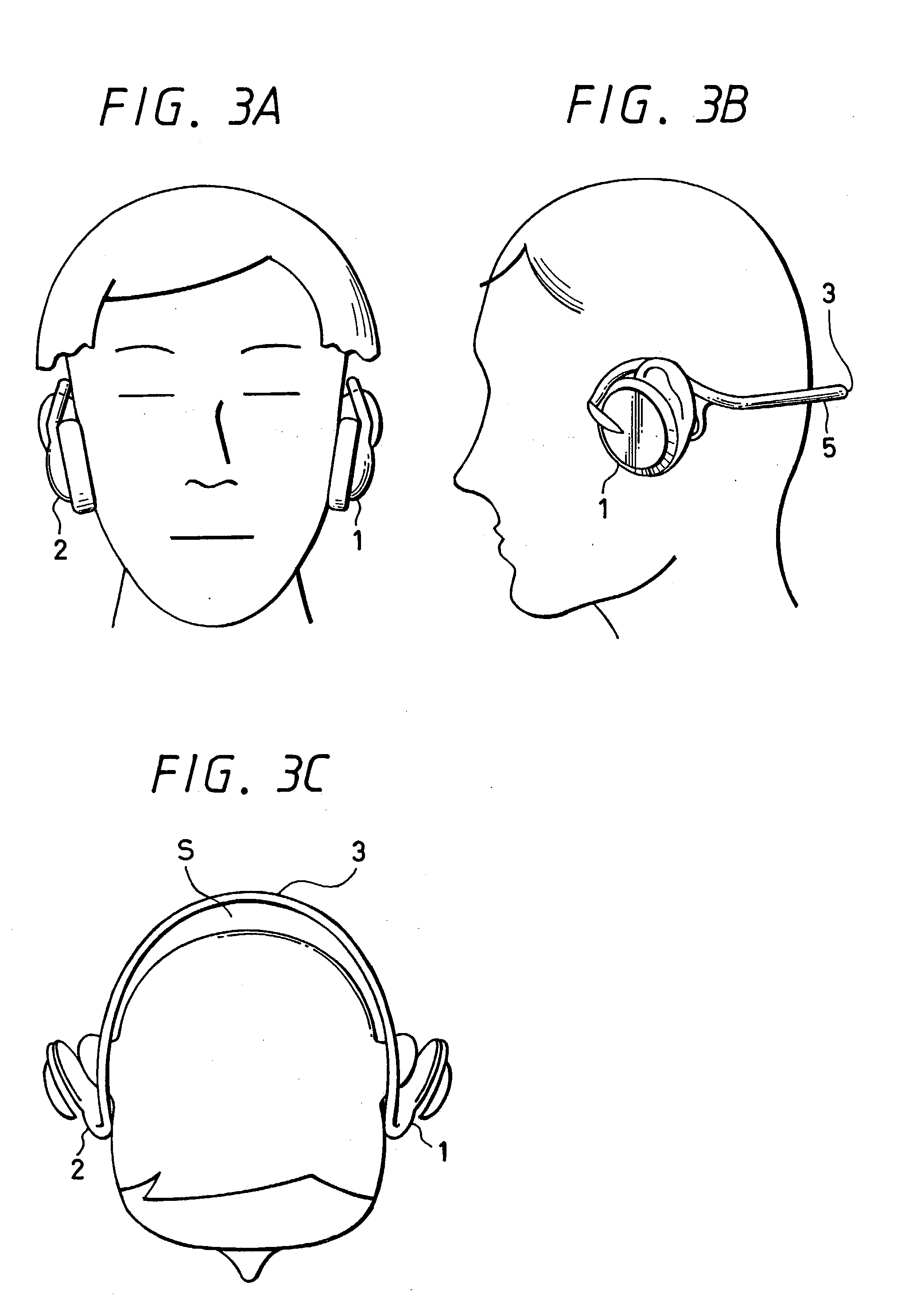

Headphone

InactiveUS6744901B2Simple compositionEasy to carryHeadphones for stereophonic communicationSupra/circum aural earpiecesEngineeringHeadphones

Owner:SONY CORP

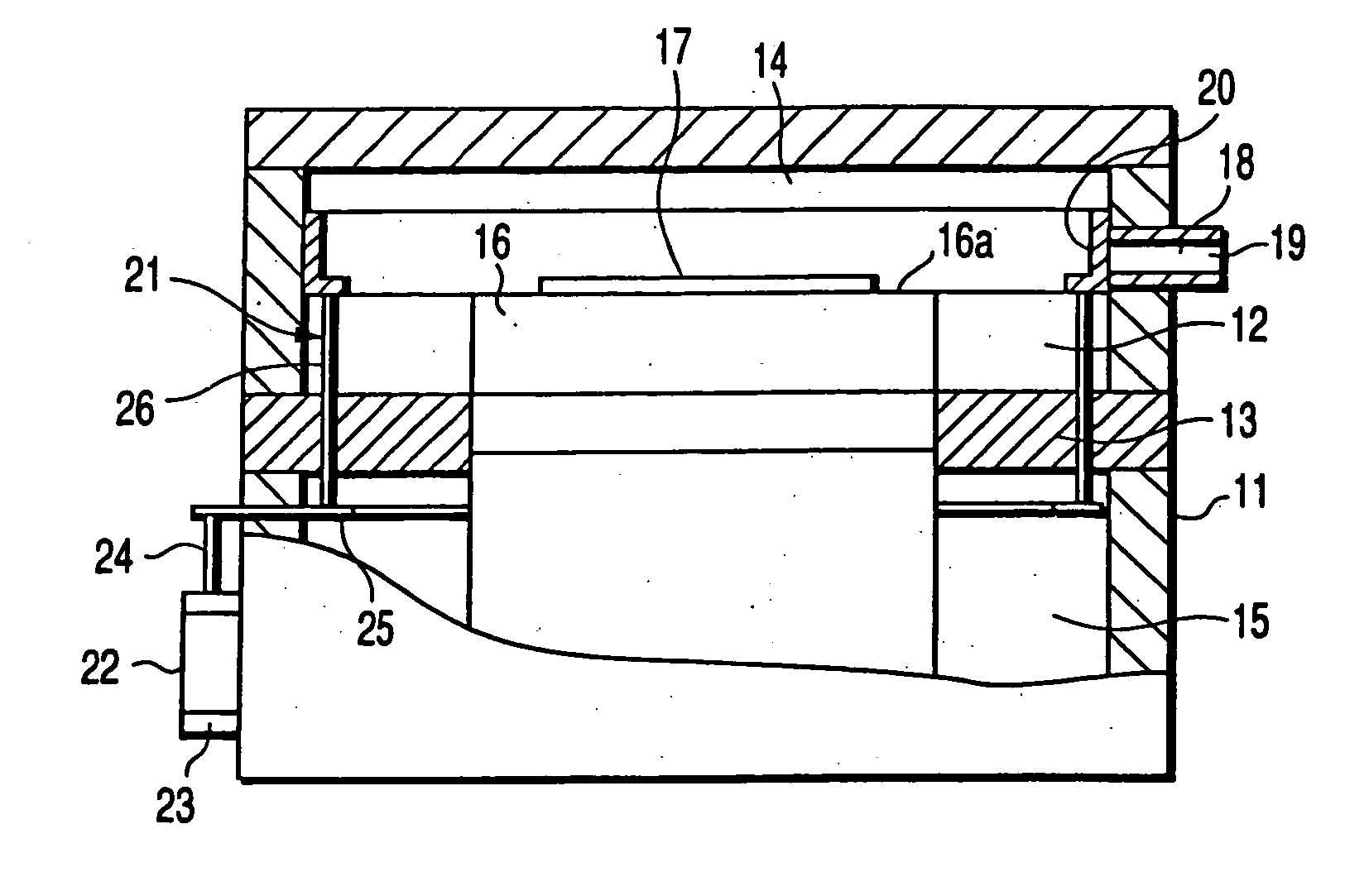

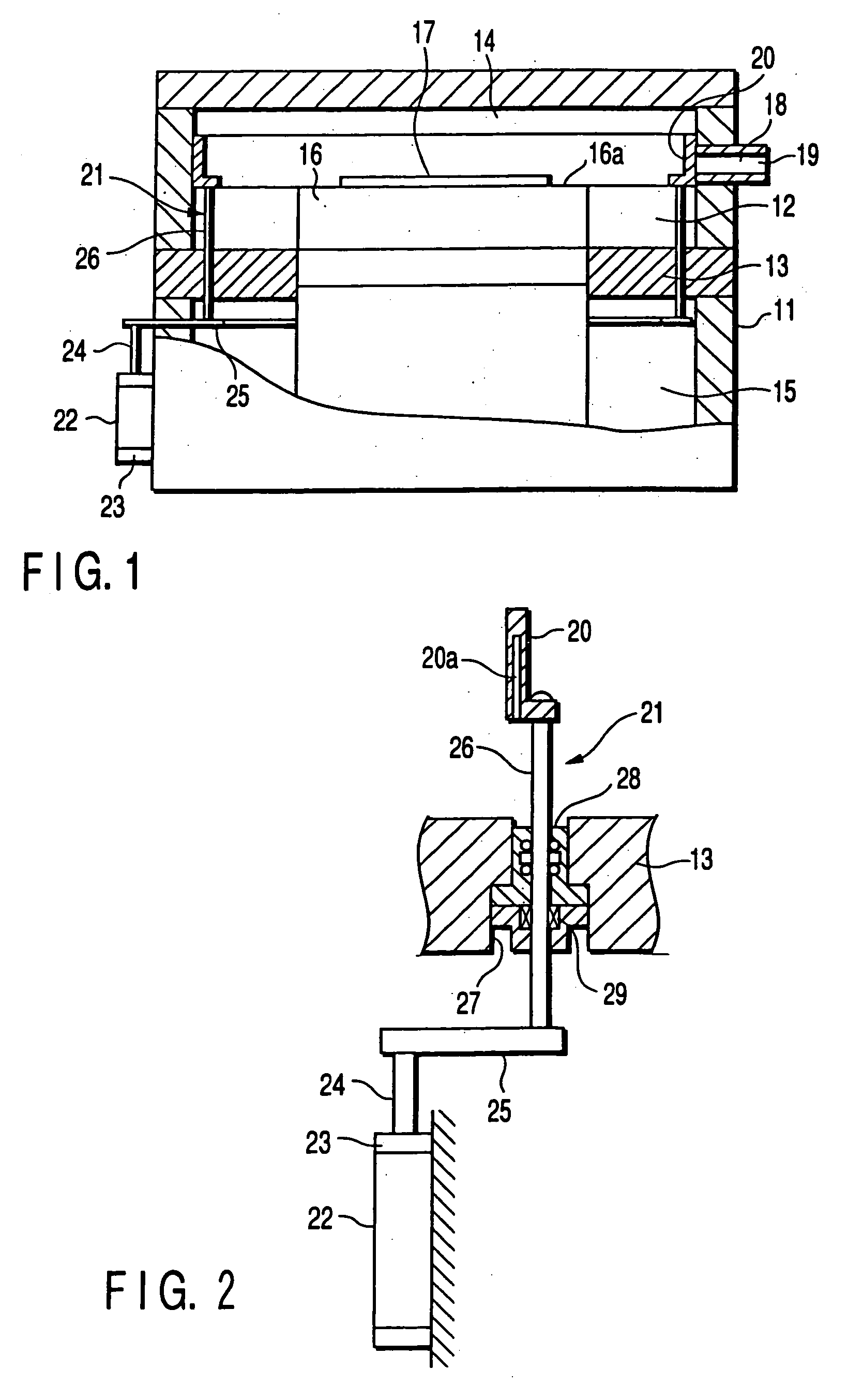

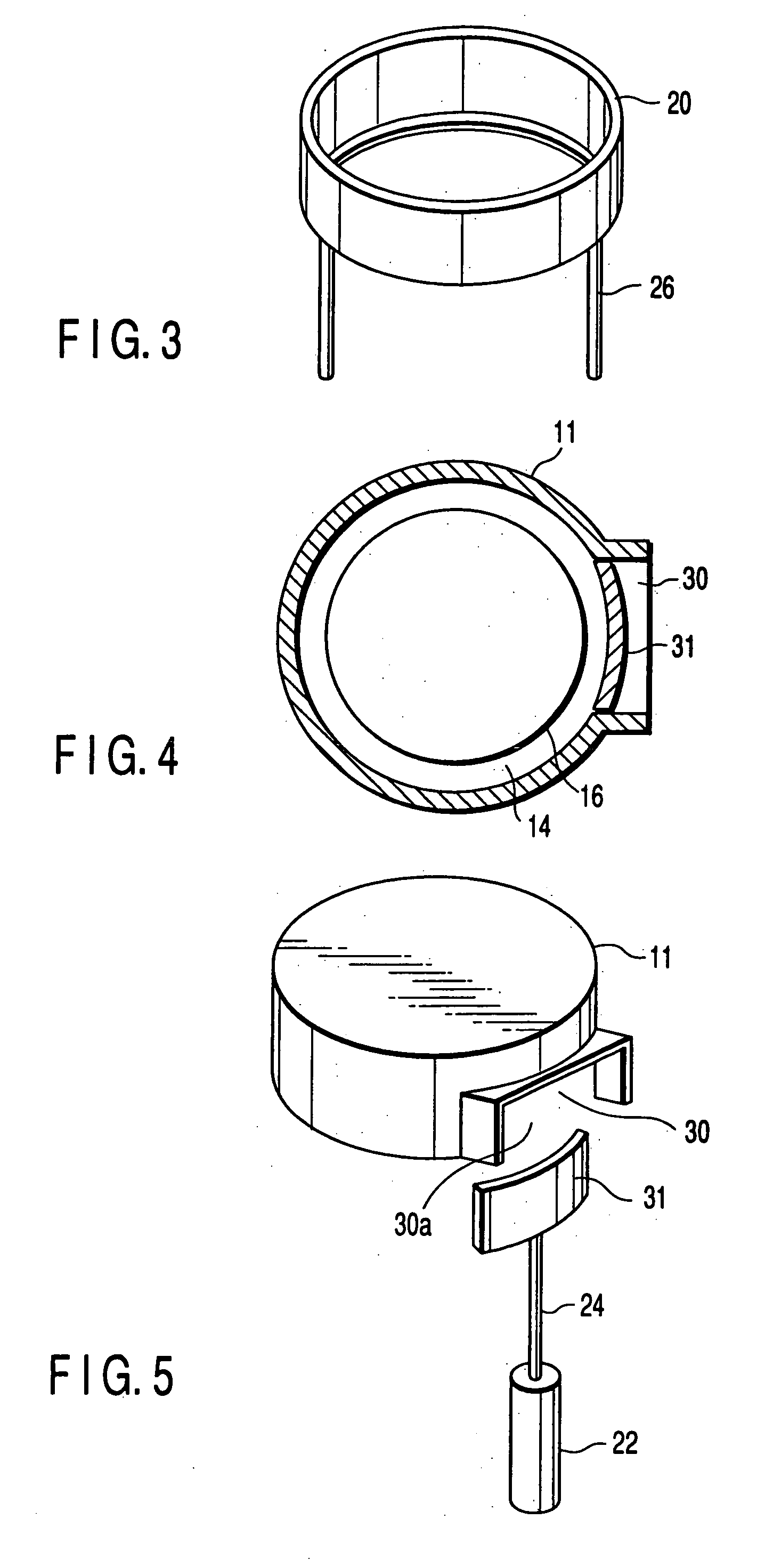

Vacuum processing apparatus

InactiveUS20040149214A1Remove obstaclesSimple structureLiquid surface applicatorsElectric discharge tubesProcess regionEngineering

This invention is a vacuum processing apparatus comprising of a vacuum processing area (14) having a stage (16) on which a substrate to be processed (17) is mounted, and a carrier port (18) provided on a periapheral wall of a processing chamber (11) forming the vacuum processing area (14) and carrying the substrate (17) onto and off the stage (16), for generating plasma in the vacuum processing area (14) and subjecting the substrate (17) on the stage (16) to a plasma processing, wherein a shutter (20) closing the carrier port (18) to prevent the plasma from being disordered when the plasma is generated in the vacuum processing chamber is provided.

Owner:TOKYO ELECTRON LTD

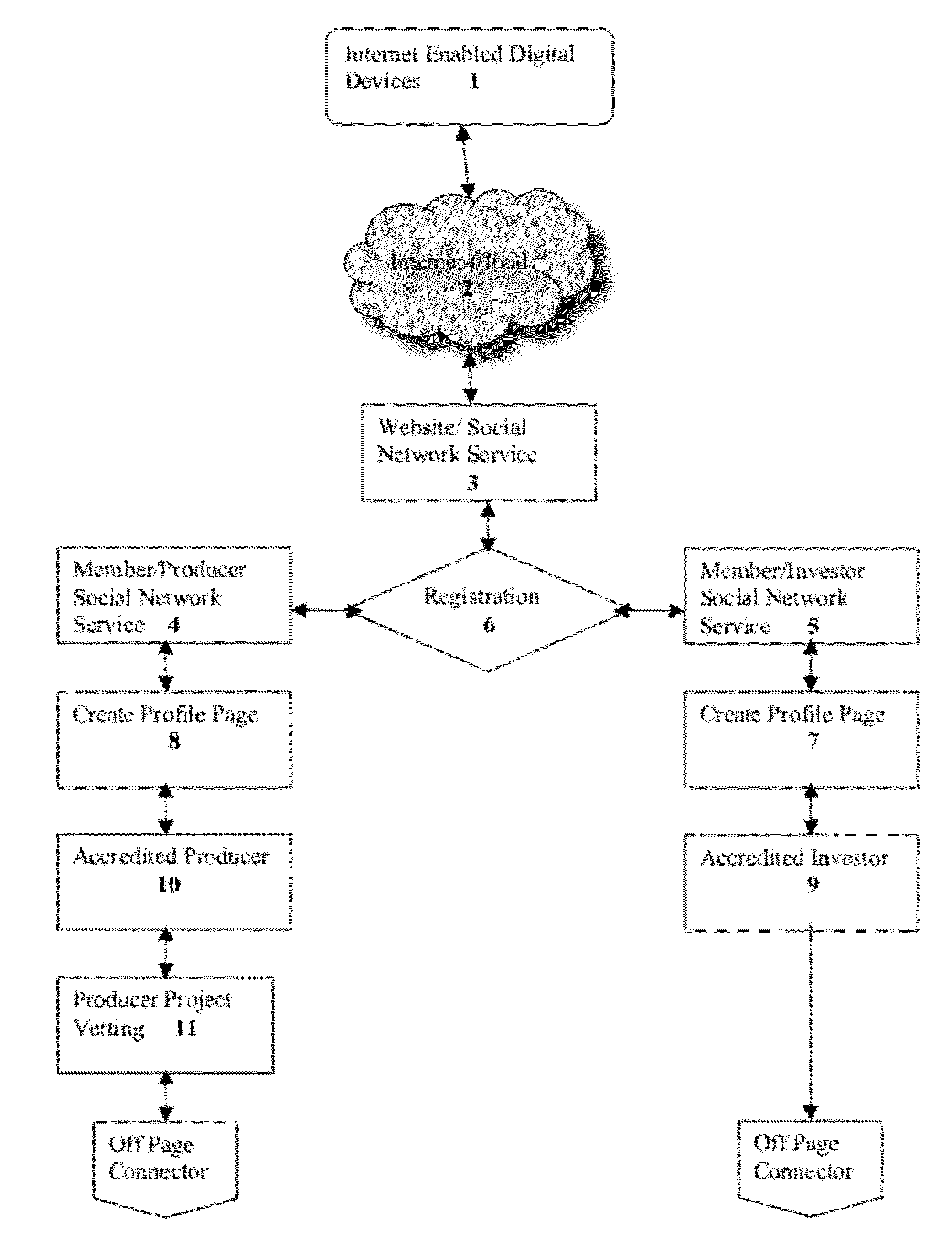

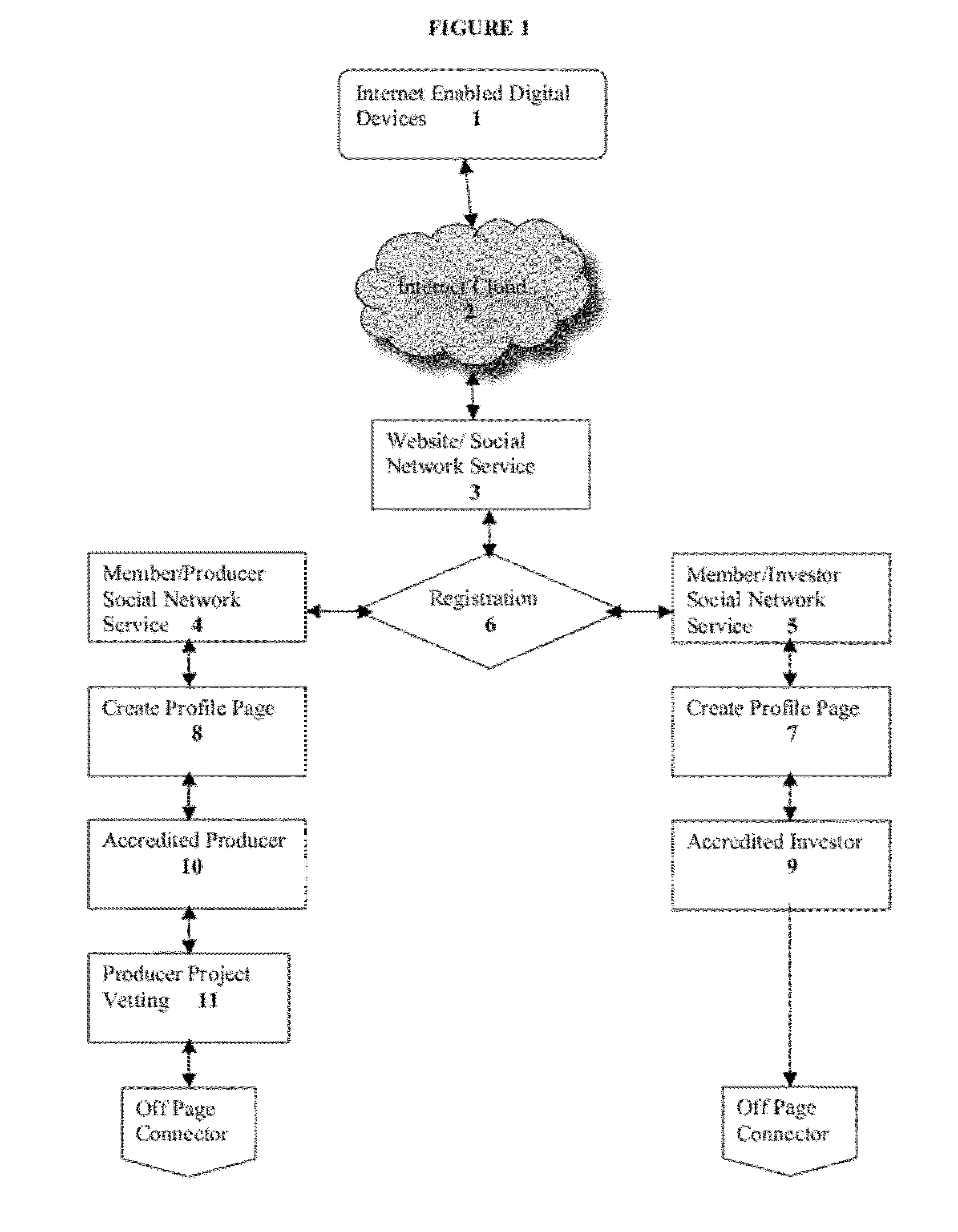

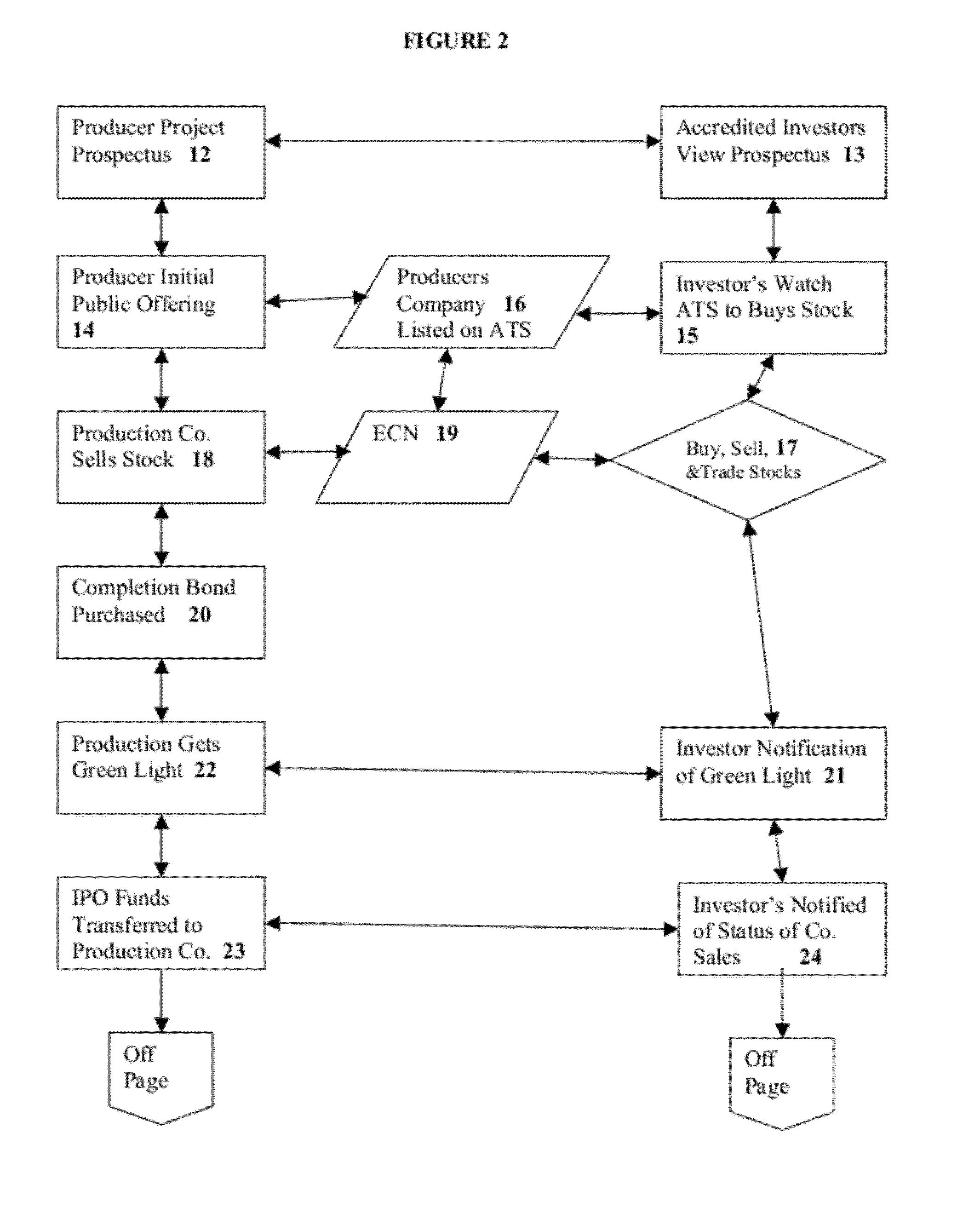

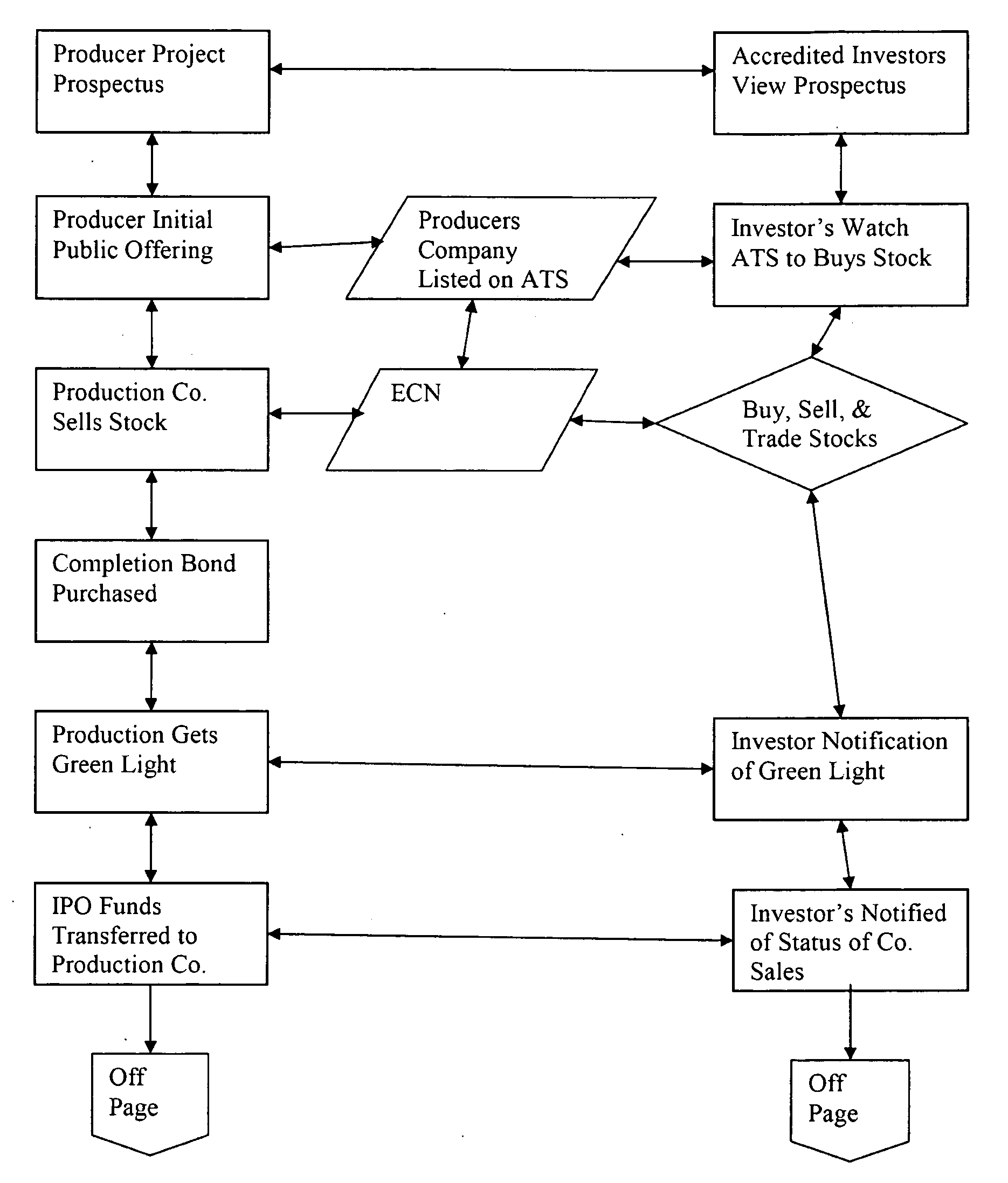

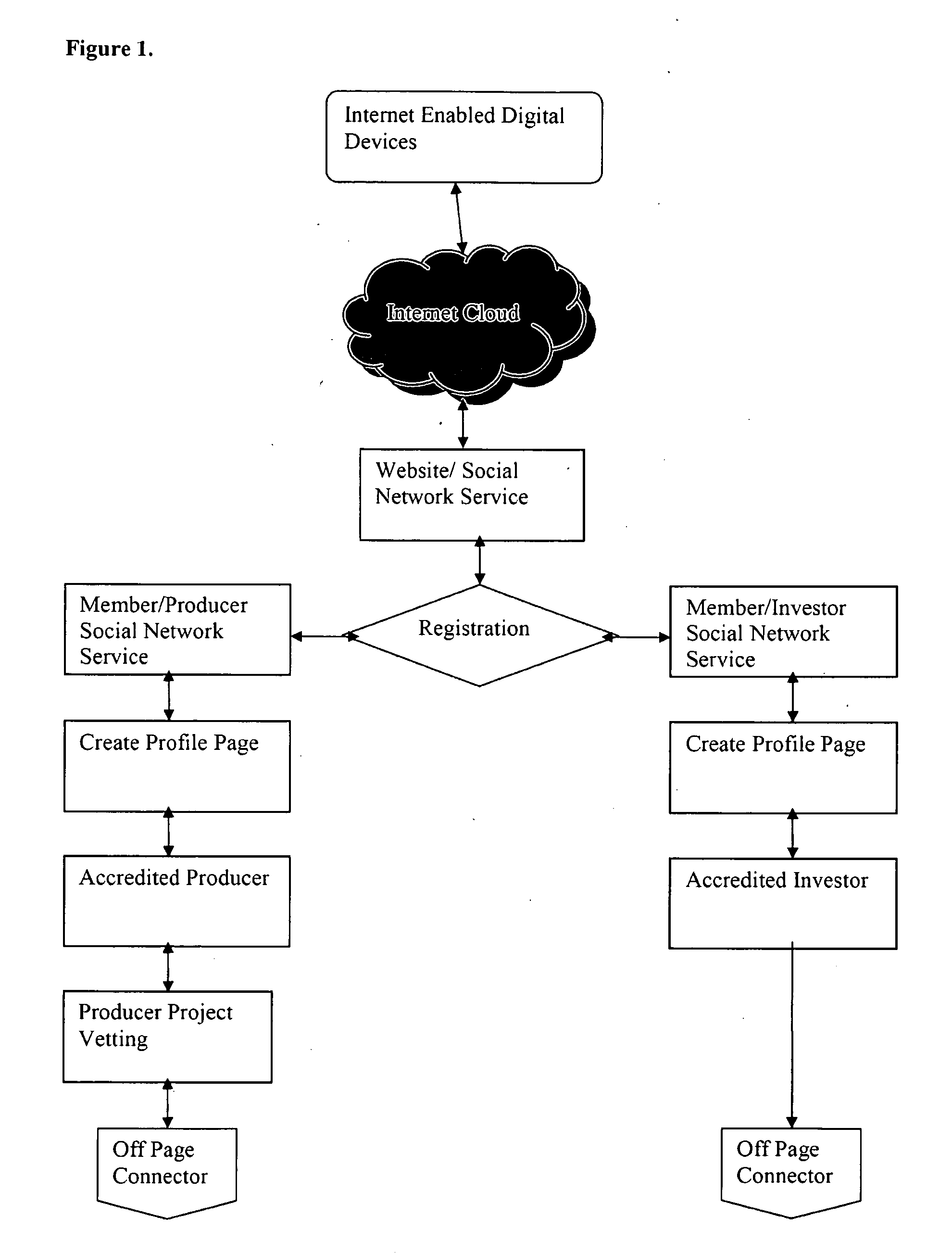

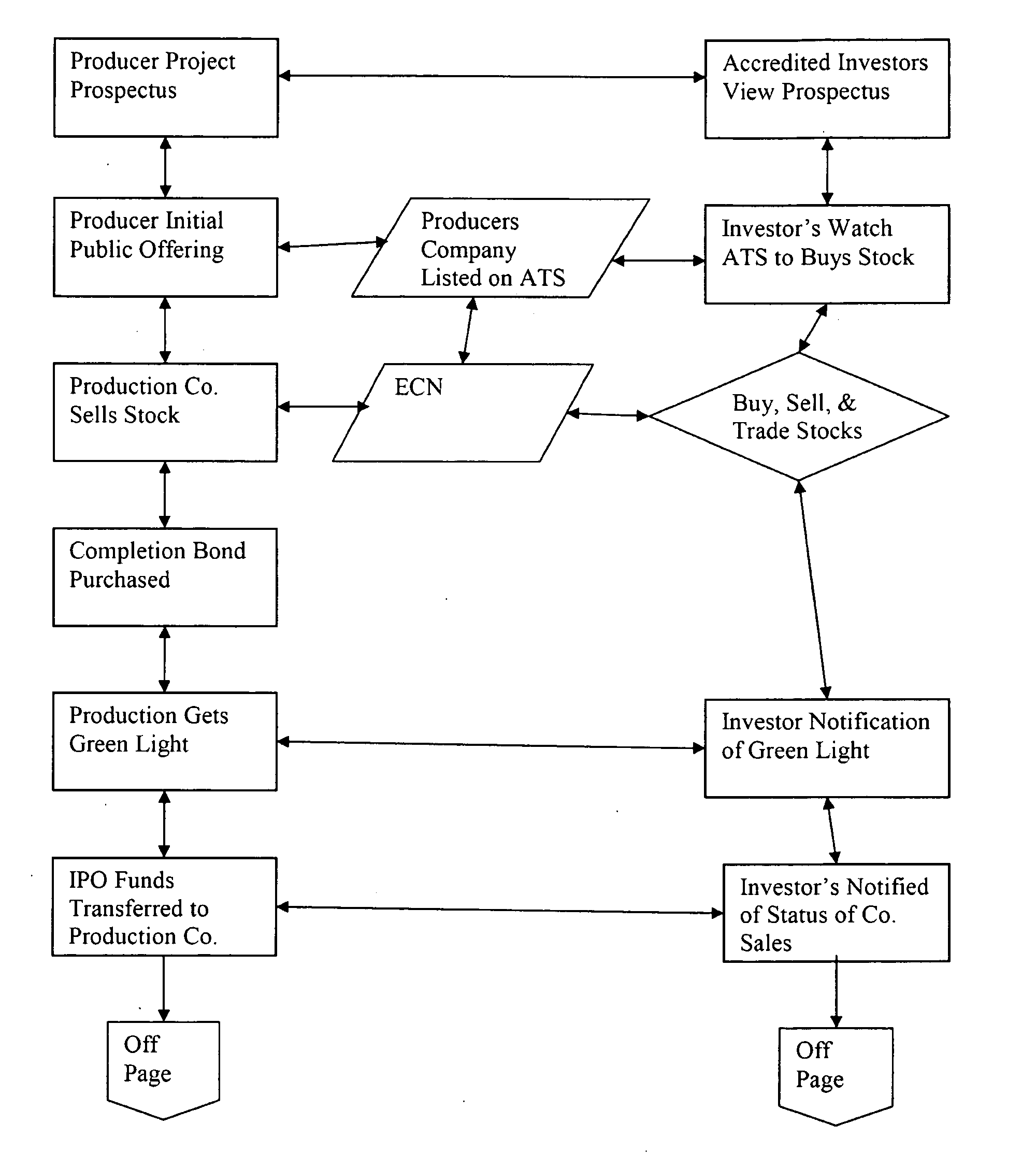

Method and system for financing and producing entertainment media

InactiveUS20120226595A1Barrier to entry into the media industry has been removedRemove obstaclesFinanceSocial network serviceCorrelation method

A web-based financing system for financing entertainment media production companies implemented by a computer or personal digital assistant, comprising a member database for storing registration information wherein the user has access to a social network service and registers as member-producers or as member-investors to form communities; an alternative trading system in communication with said member database, enabling said member-producers and said member-investors to list, quote, buy, sell and trade in initial public offerings or secondary trading of equity shares of said entertainment media companies, and an electronic communications network in communication with said alternative trading system, that matches buy and sell orders of said entertainment media companies selling equity stocks with member-investors purchasing said stocks; and related methods of producing entertainment media and selling and investing in entertainment media companies using an alternative trading system.

Owner:TORRES ADAM

Method and System combining a Social Network Service with an Alternative Trading System and Electronic Communication Network to produce entertainment media

InactiveUS20100250424A1Barrier to entry into the media industry has been removedRemove obstaclesFinanceSocial network serviceApplication software

A Method and System combining a Social Network Service with an Alternative Trading System and Electronic Communications Network to produce entertainment media. The application can be used in a myriad of ways, from a social point of view and a financial one, to assist in the creation of the independent producer's art.

Owner:TORRES ADAM

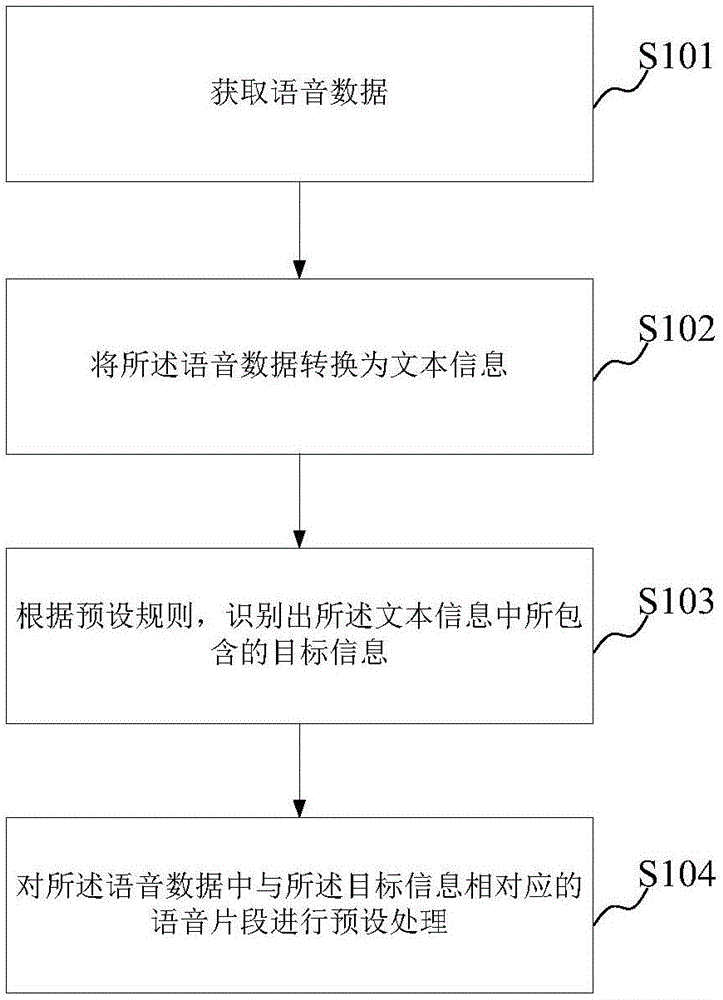

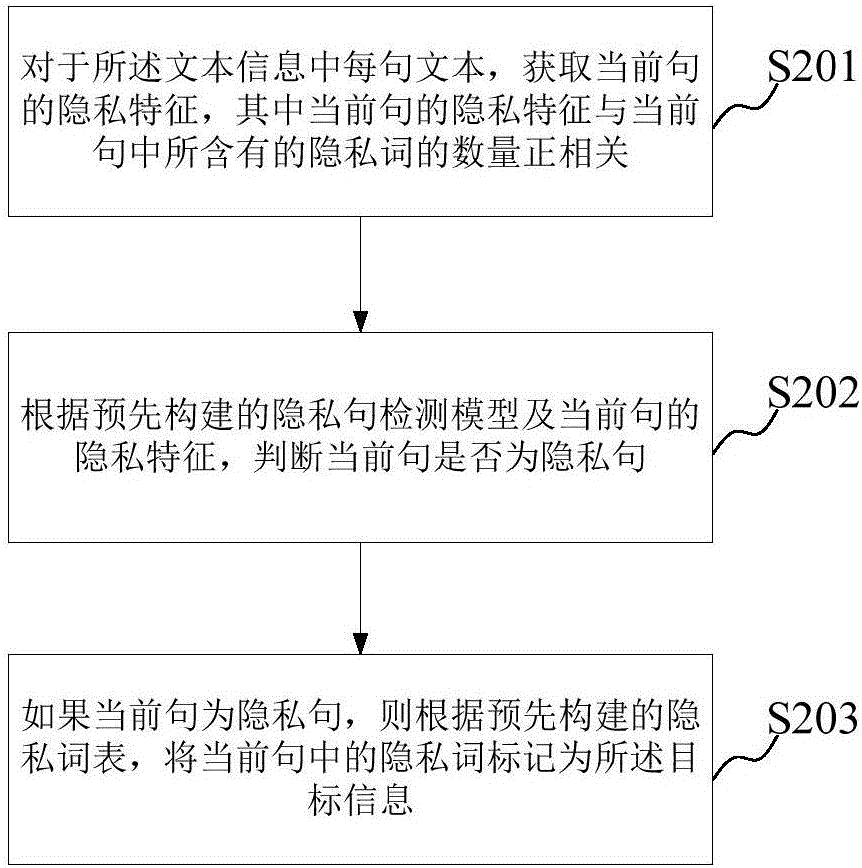

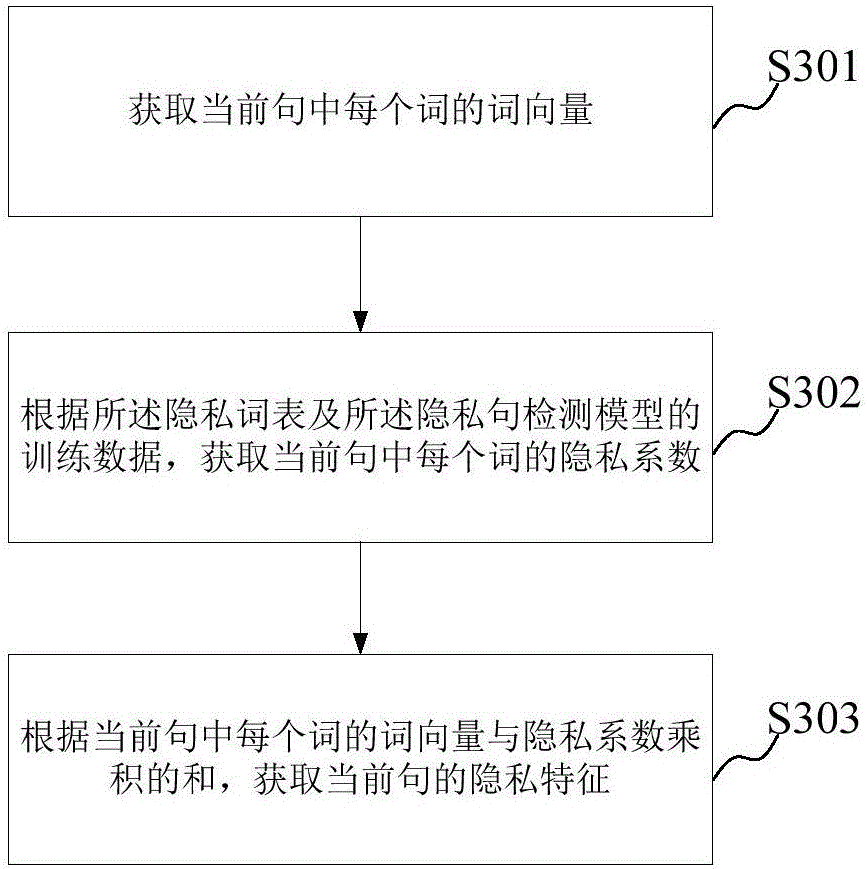

Voice processing method and device

ActiveCN106504744AEliminate concernsRemove obstaclesSpeech recognitionSpeech synthesisPrivacy protectionSpeech sound

The embodiment of the invention provides a voice processing method and device. The method comprises: obtaining voice data, converting the voice data into text information; according to a preset rule, identifying target information included by the text information; and carrying out pretreatment on a voice segment corresponding to the target information in the voice data. According to the embodiment of the invention, after conversion from the voice data into the text information, the target information including privacy of a speaker in the text information is identified based on the preset rule; and then the pretreatment is carried out on the voice segment corresponding to the target information in the voice data, wherein the pretreatment includes deleting the voice segment. Therefore, the content of the target information like privacy of the speaker can not be obtained by others and thus the rights of the speaker are protected, thereby eliminating the consideration and obstacle of the voice data during the transmission process and realizing privacy protection and voice transmission simultaneously.

Owner:IFLYTEK CO LTD

Selective barrier slurry for chemical mechanical polishing

ActiveUS20060068589A1Remove obstaclesOther chemical processesDecorative surface effectsNonferrous metalCompound (substance)

The polishing solution is useful for removing a barrier from a semiconductor substrate. The solution contains by weight percent 0.001 to 25 oxidizer, 0.0001 to 5 anionic surfactant, 0 to 15 inhibitor for a nonferrous metal, 0 to 40 abrasive, 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 barrier removal agent selected from imine derivative compounds, hydrazine derivative compounds and mixtures thereof, and water; and the solution has an acidic pH.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

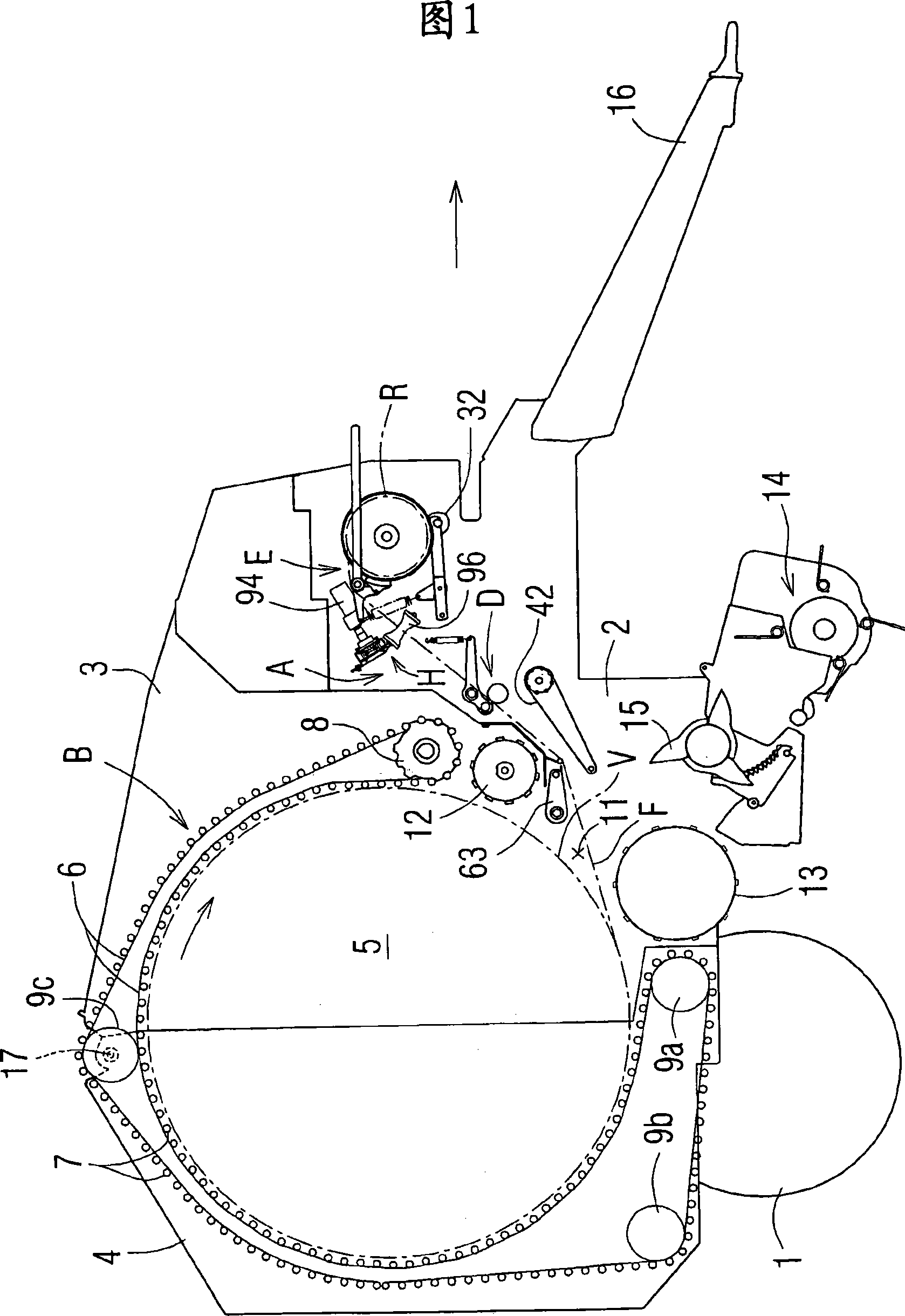

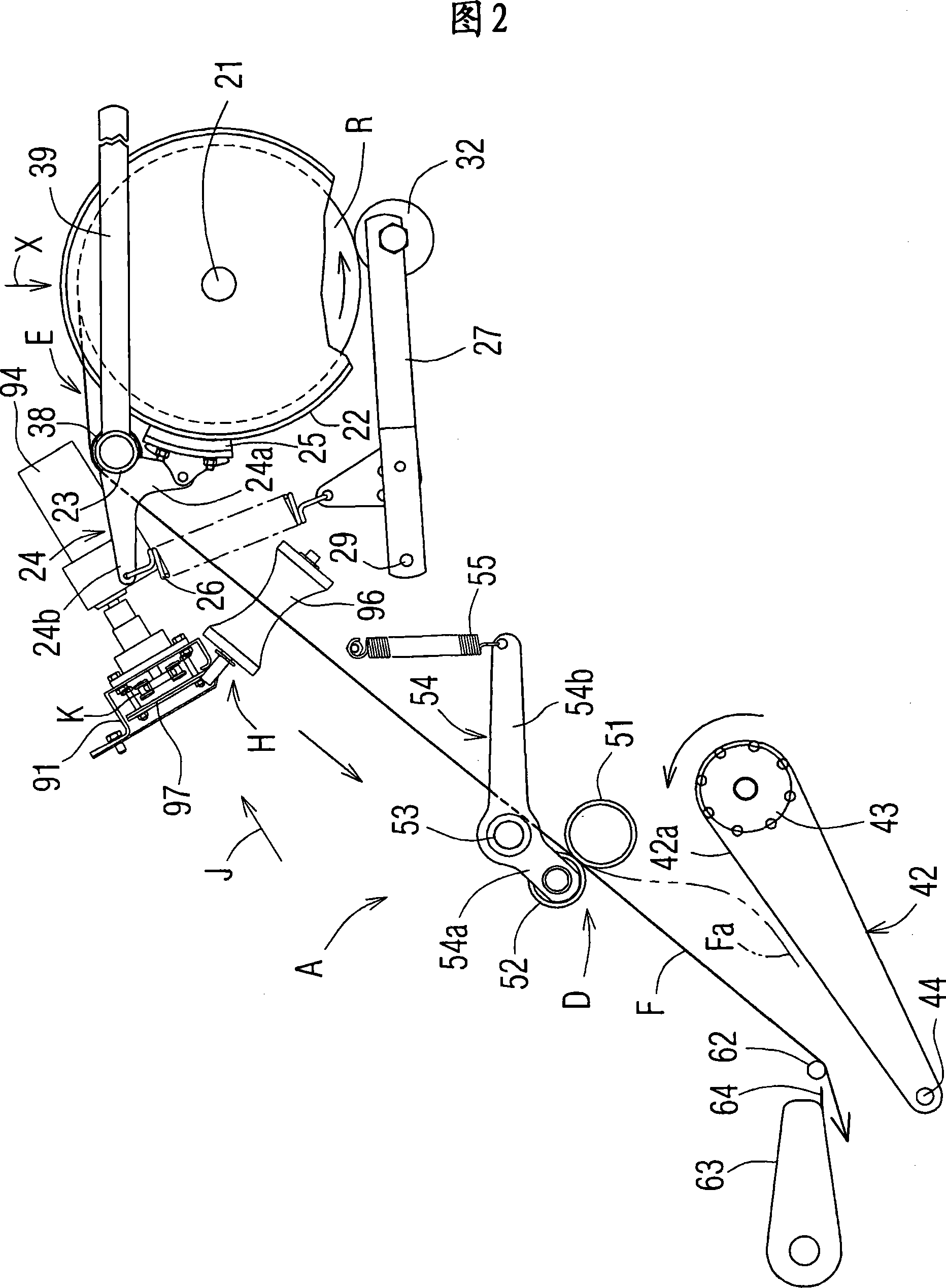

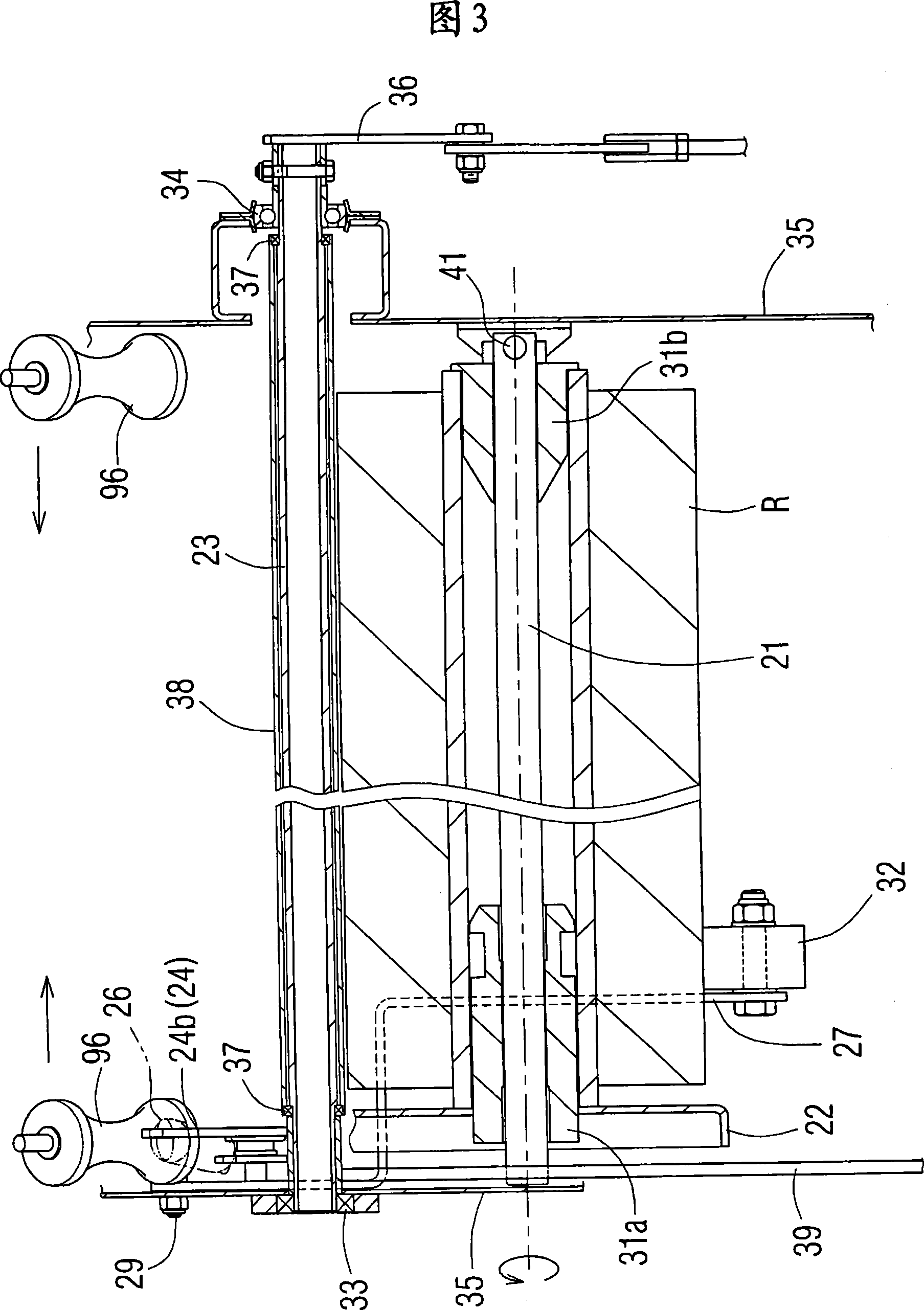

Film letting-off device for roll baler, and method for winding film on rolled bale

ActiveCN101096228ANo damageEliminate damageWrapping material feeding apparatusBalingEngineeringMechanical engineering

Owner:德佳达有限公司

Methods for detecting biological rhythm disorders

ActiveUS20130331718A1Improve abilitiesRemove obstaclesUltrasonic/sonic/infrasonic diagnosticsElectrocardiographyStart timeMedicine

A method of detecting a cause of a heart rhythm disorder includes collecting data corresponding to activation onset time of each heart activation at multiple locations of the heart and generating an activation trail based on the sequential order of activation onset times. The activation trail is indicative of the cause of the heart rhythm disorder.

Owner:THE US REPRESENTED BY THE DEPT OF VETERANS AFFAIRS OFFICE OF THE GENERAL COUNSEL 024 +1

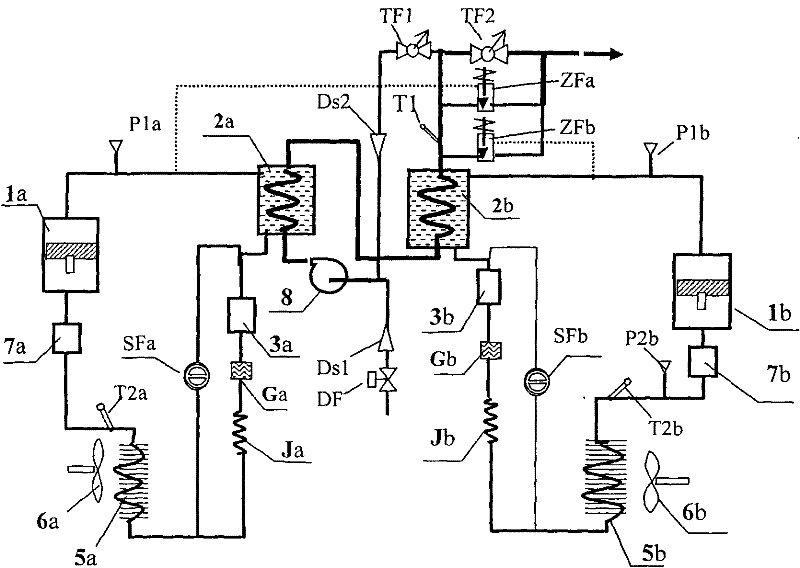

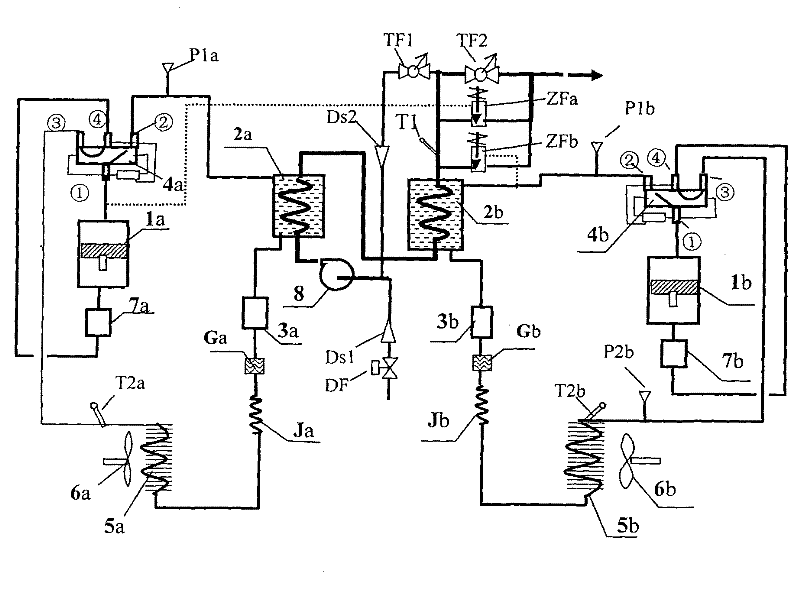

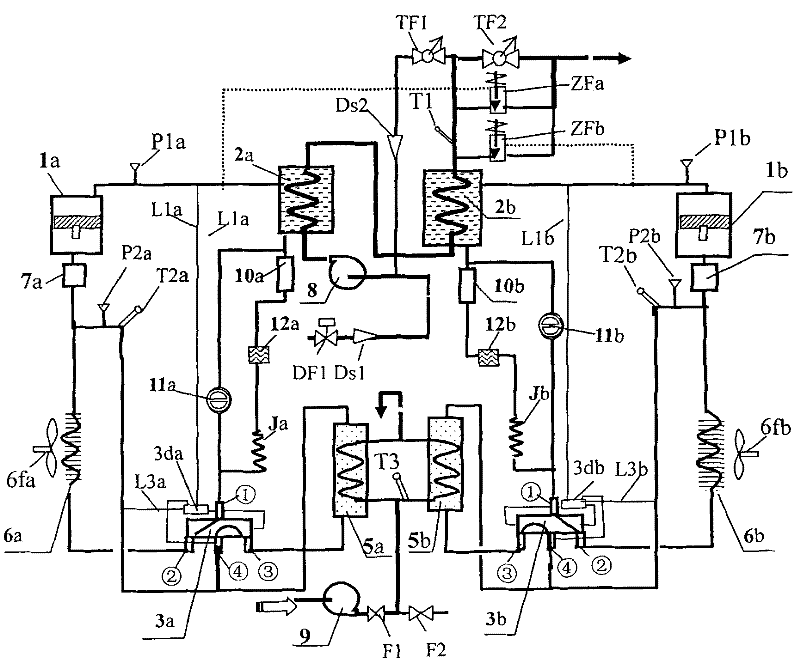

Mutual defrosting method for air source heat pump water heater and five-cycle dual heat source heat pump water heater

ActiveCN102297548ASolve the defrosting problemGuaranteed uptimeFluid heatersCorrosion preventionFour-way valvePlate heat exchanger

The invention discloses a mutual defrosting method for an air source heat pump water heater and a technical scheme of a five-cycle double-heat-source heat pump water heater. The mutual defrosting method is characterized in that: a unit is provided with at least two refrigerant loop systems; hot water heat exchangers of all systems are partitioned into two groups; water paths of the two groups are connected in series; a hot water inner cycle uniform hot water heat exchange system connected with a circulating water pump and the like is arranged between a water outlet interface and a water inlet interface; each system is defrosted in sequence in batches; and defrosted and normal cycle systems exchange heat through the uniform hot water heat exchange system, and are defrosted mutually. The five-cycle double-heat-source heat pump water heater comprises a compressor, a hot water heat exchanger, a water source, water source and wind source evaporators, a throttling device and the like, and is characterized by further comprising two four-way valves and a defrosting valve, wherein the water source and wind source evaporators are connected between the outlet of the throttling device and the air suction port of the compressor by using a double-four-way-valve switching mechanism; the defrosting valve is connected between the refrigerant outlet of the hot water heat exchanger and the inlet of the wind source evaporator; and the five cycles include a wind source cycle, a water source cycle, serial wind source and water source cycle, a serial water source and wind source cycle and a defrosting cycle.

Owner:江苏恒信诺金科技股份有限公司

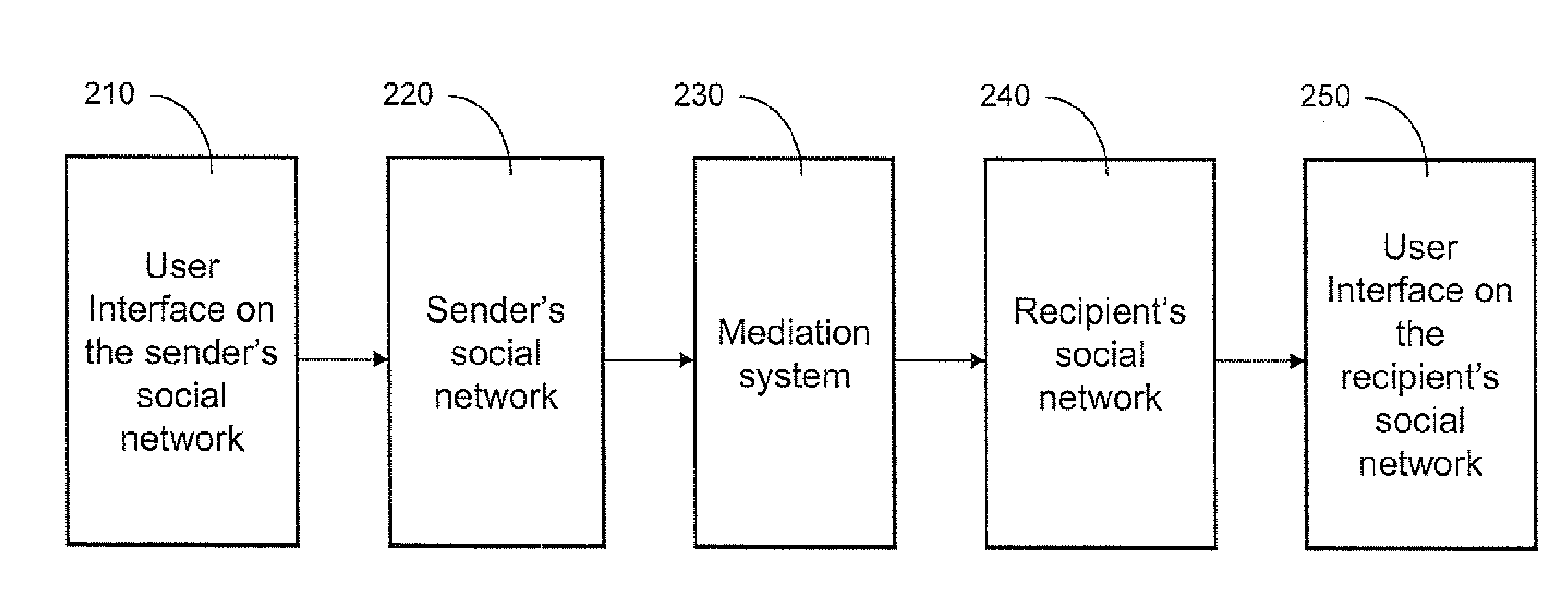

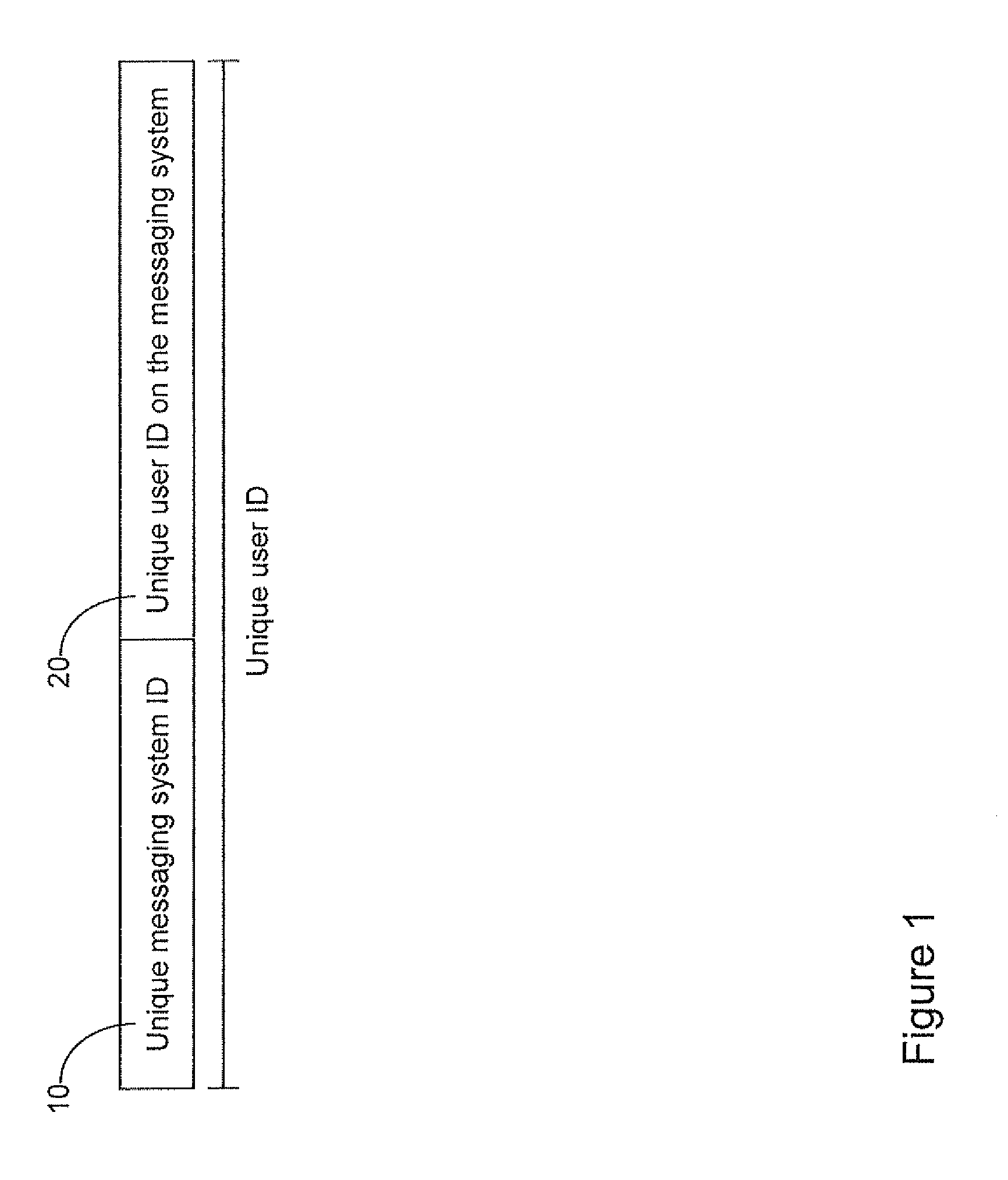

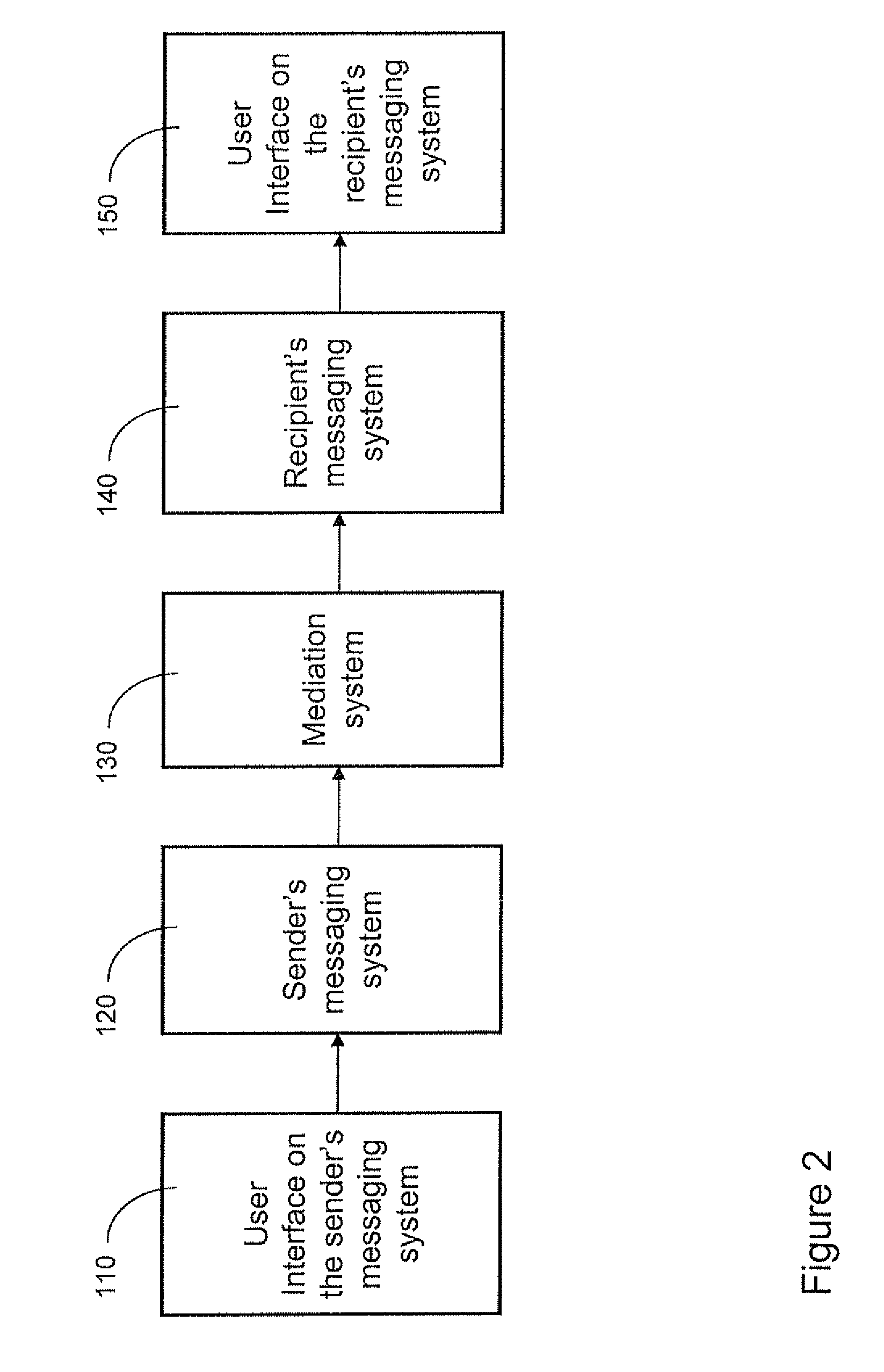

Method and apparatus for enabling messaging between users of different social networks and between users of social networks and users of other communication systems

InactiveUS20100077045A1Remove obstaclesMultiple digital computer combinationsTransmissionCommunications systemSocial network

A method for enabling messaging between users of different social networks is disclosed. Additionally, a method for enabling messaging between users of social networks and users of other communication systems which are not social networks is displosed. This is done by providing an identification mechanism to allocate unique user IDs guaranteeing user ID uniqueness across the different social networks and the other communication systems and by a mediation system comprised of social network specific and communication system specific interfaces and a mediation server connected to these interfaces.

Owner:SEND M

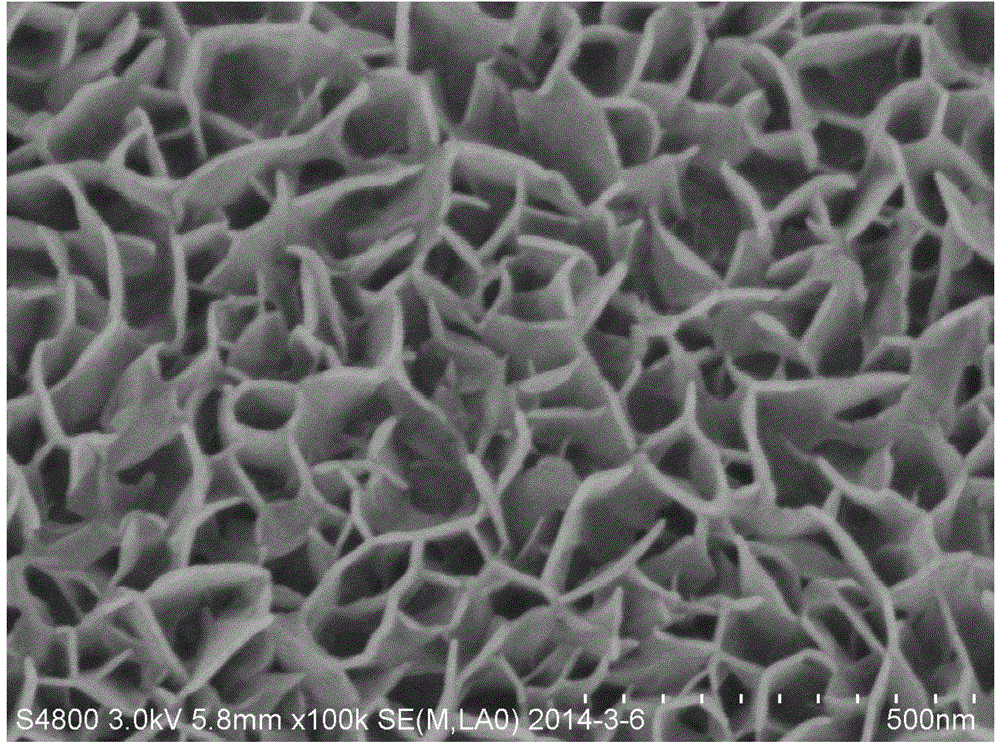

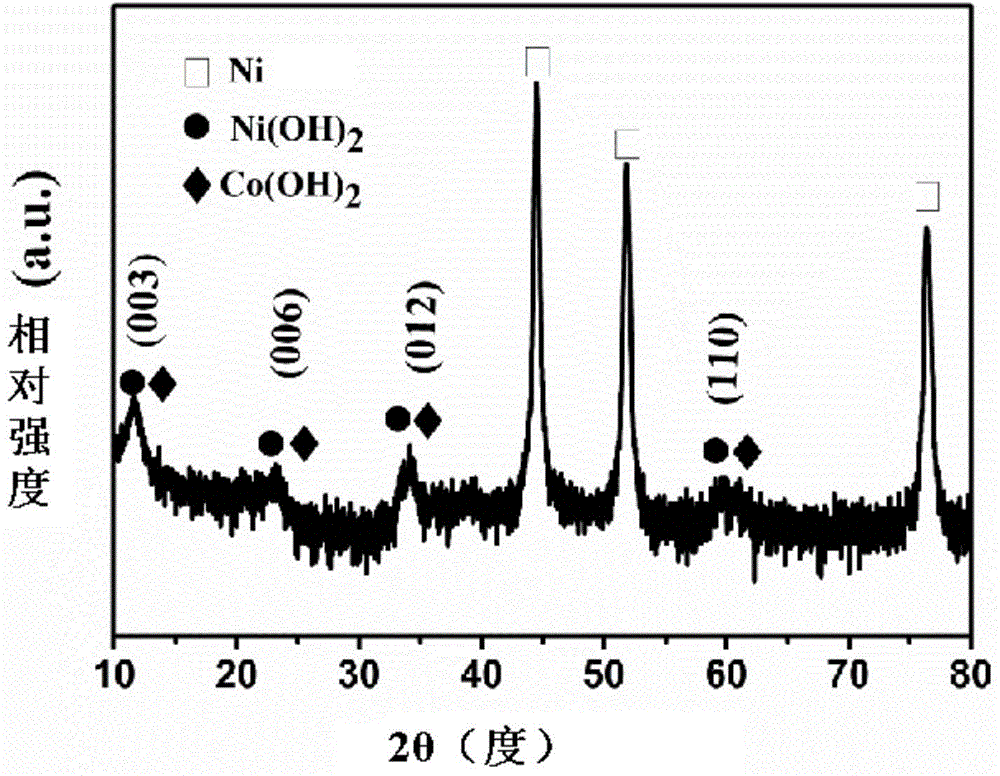

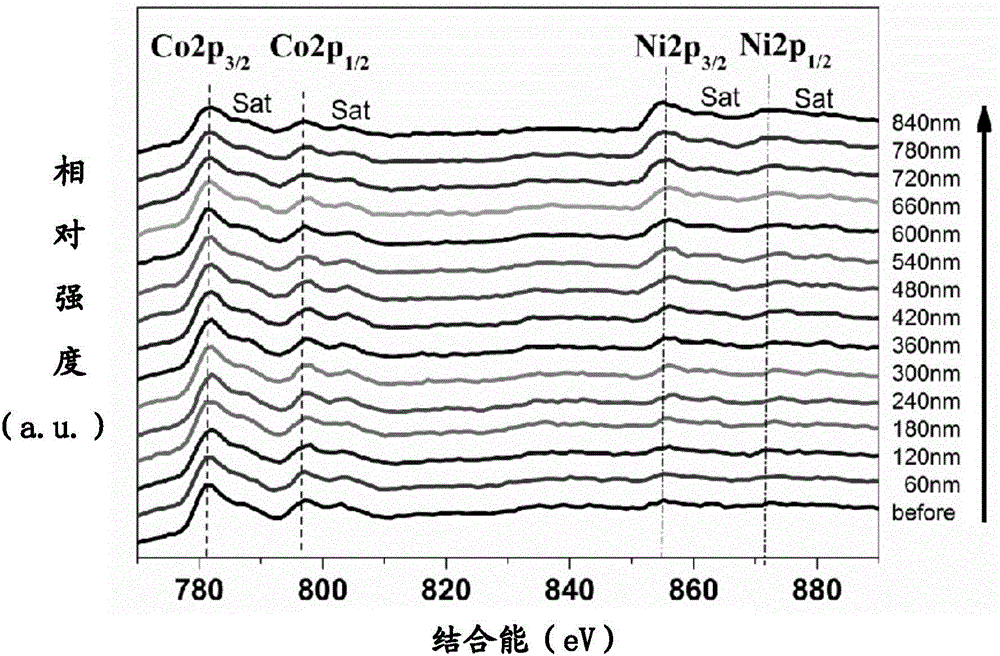

Three dimensional gradient metal hydroxide/oxide electrode material and manufacture method and application thereof

ActiveCN104134788AElectrodeposition method is simpleThe electrodeposition method is convenientMaterial nanotechnologyElectrode manufacturing processesIonElectrode material

The invention provides a three dimensional gradient metal hydroxide / oxide electrode material and a manufacturing method and application thereof. The three dimensional gradient metal hydroxide / oxide electrode material consists of a conductive substrate and a metal compound layer, wherein the metal compound layer is arranged or formed on the surface of the conductive substrate, and the metal compound layer is made of metal hydroxide or oxide; the metal is transition metal, and the content of the metal ions in the metal compound layer decreases or increases in a gradient manner towards the conductive substrate. The three dimensional gradient metal hydroxide / oxide electrode material has the advantages of good cycling performance and good rate capability. The method for manufacturing the three-dimensional gradient metal hydroxide / oxide electrode material is easy and convenient, and the three dimensional gradient metal hydroxide / oxide electrode material can be used for manufacturing electrodes and batteries directly and shows good electrochemical activity.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

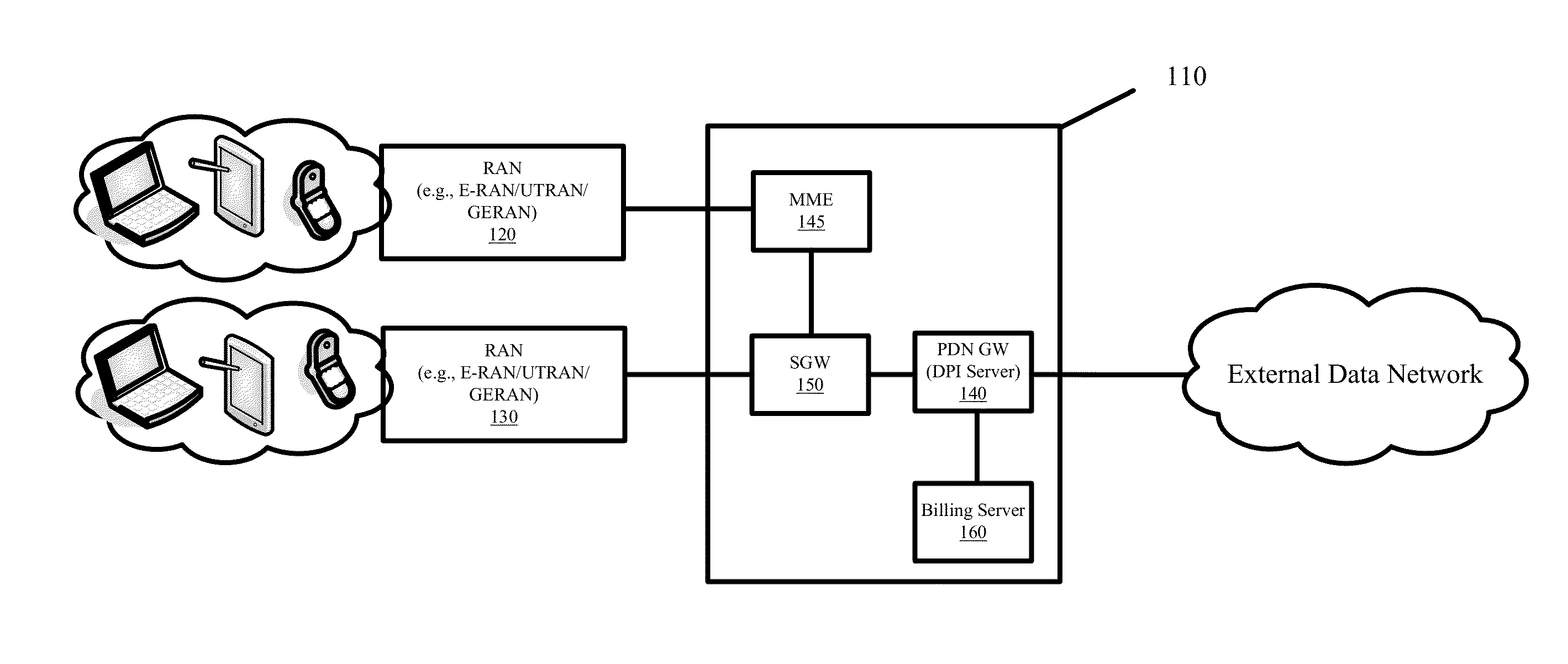

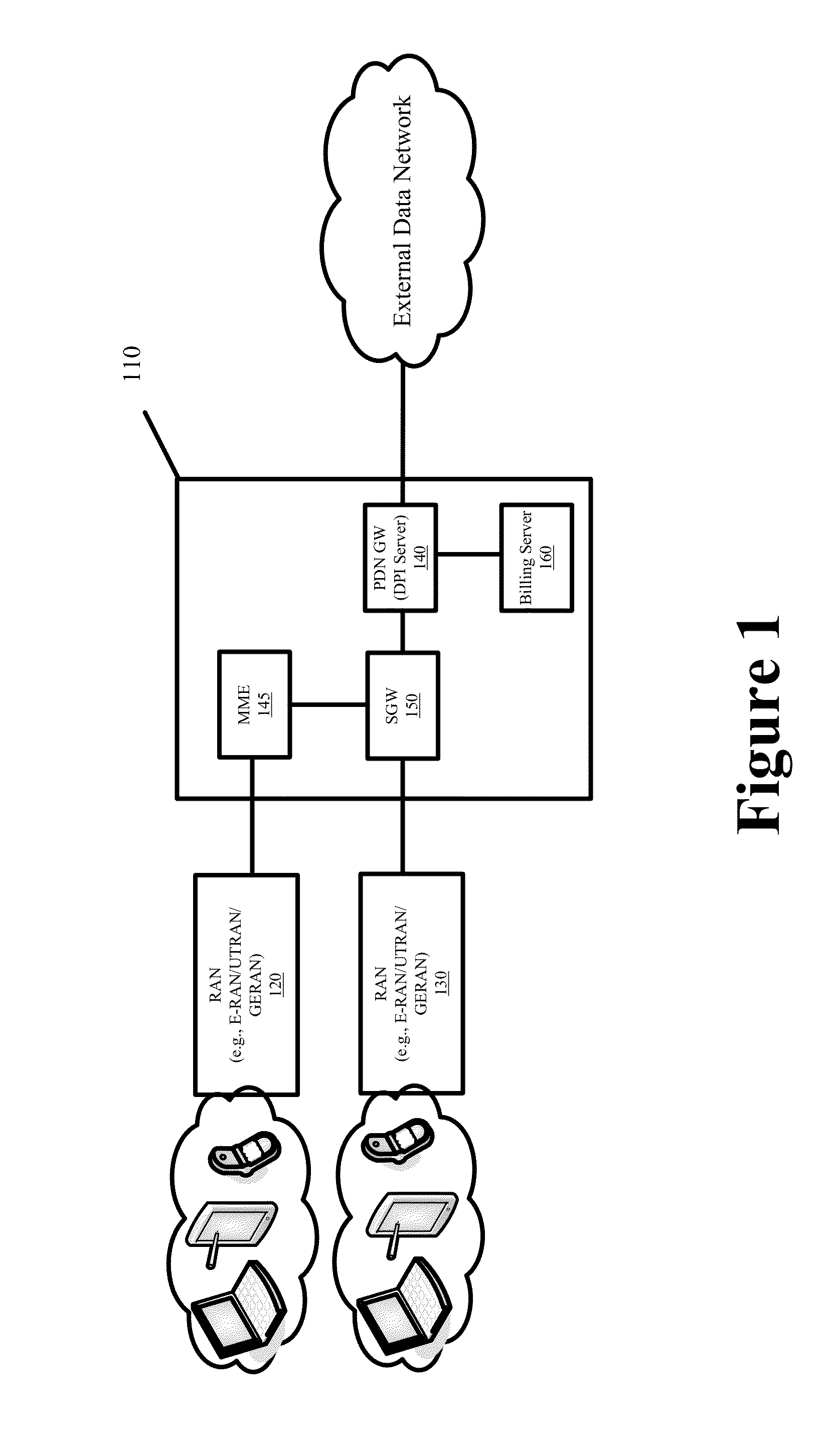

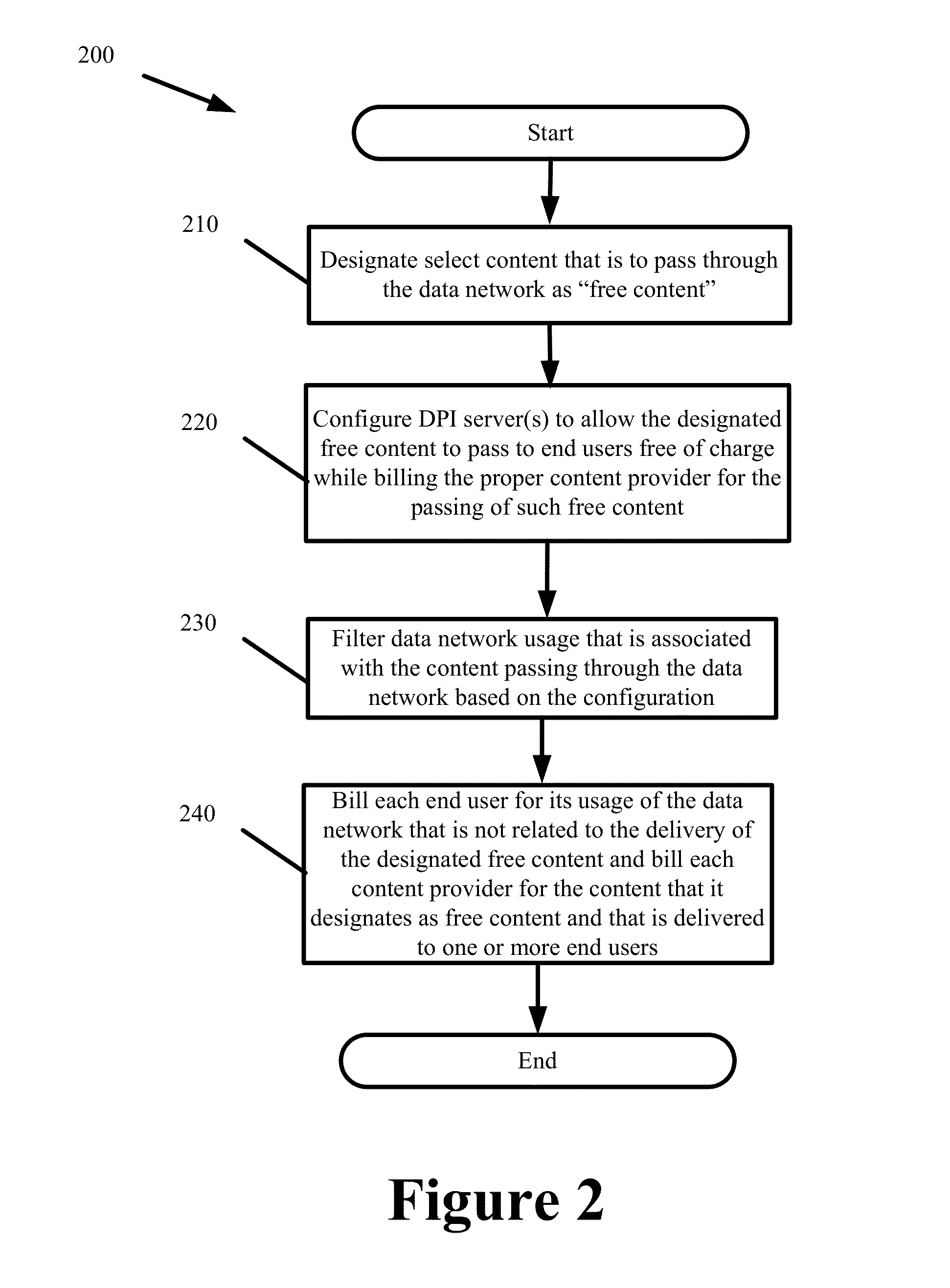

Systems and Methods for Billing Content Providers for Designated Content Delivered Over a Data Network

ActiveUS20130238473A1Generate revenueWithout costComplete banking machinesTelephonic communicationComputer scienceEnd user

Some embodiments provide multi-tenant billing systems and methods whereby data network usage fees that are associated with delivering select content of different content providers over a data network are passed to the content provider that originates or is the source for that select content instead of the end users that request and receive the select content. A deep packet inspection server or a billing server may be configured with a list of identifiers to distinguish between the network usage that is related to the delivery of the designated free content from the network usage that is not related to the delivery of the designated free content. The network usage can be distinguished by filtering or processing usage logs that track the network usage using the configured list of identifiers. Such filtering or processing can be done in real-time or in a delayed manner in a standalone or integrated system.

Owner:EDGIO INC

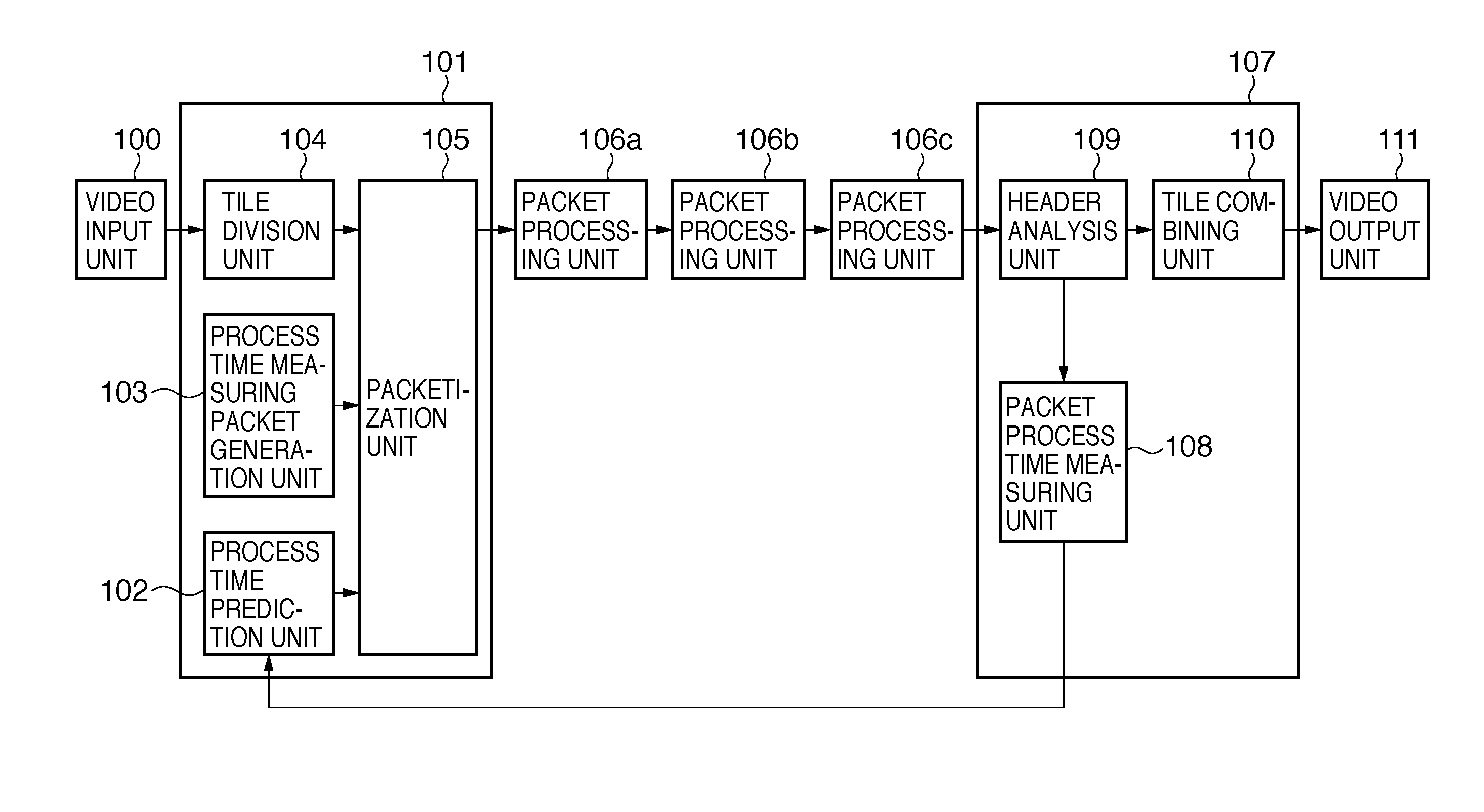

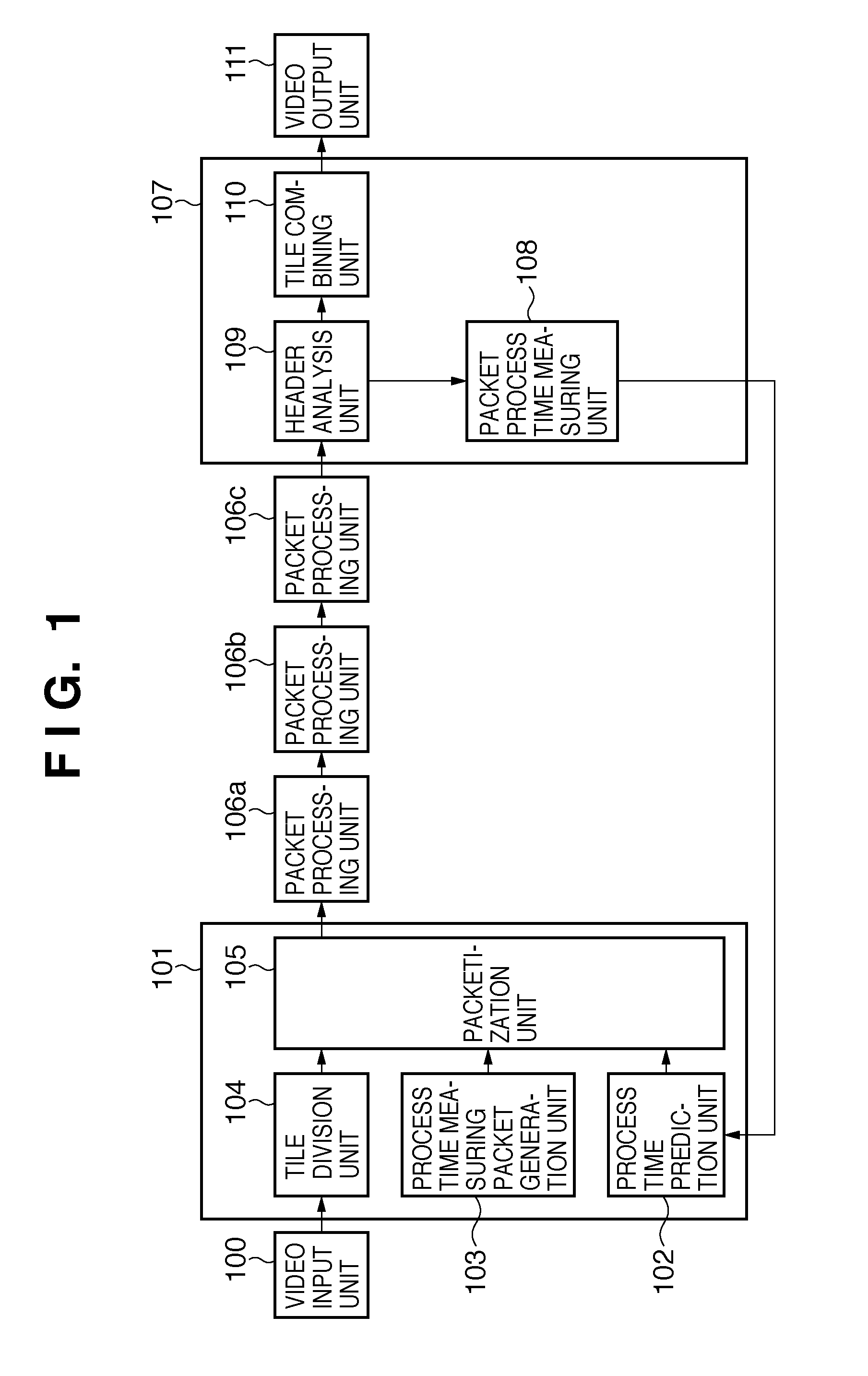

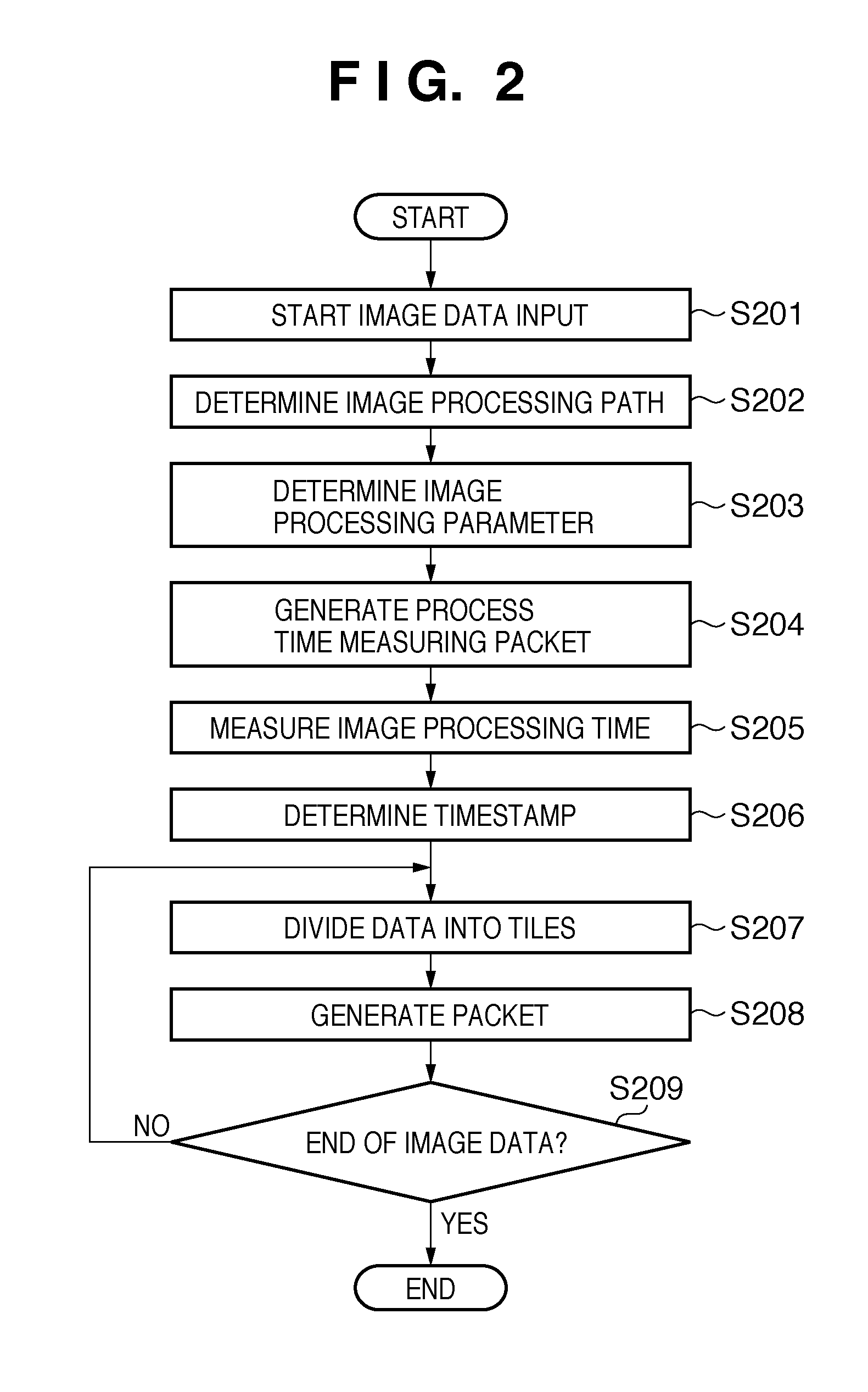

Information processing system, information processing apparatus, information processing method, and program

InactiveUS20090310670A1Remove obstaclesReduce capacityPulse modulation television signal transmissionError preventionInformation processingTimestamp

An information processing system for performing processing of dividing a moving image into tiles and packetizing and outputting information corresponding to each tile includes a process time measuring packet generation unit adapted to generate and transmit a process time measuring packet in which a packet sending time is set to measure a packet process time, a packet process time measuring unit adapted to measure, based on the packet sending time set in the process time measuring packet and the reception time of the process time measuring packet, the packet process time necessary for processing a packet, a determination unit adapted to determine, based on the packet process time, the timestamp of the moving image divided into the tiles, and a packetization unit adapted to execute processing of packetizing and outputting the timestamp and the information of the moving image divided into the tiles.

Owner:CANON KK

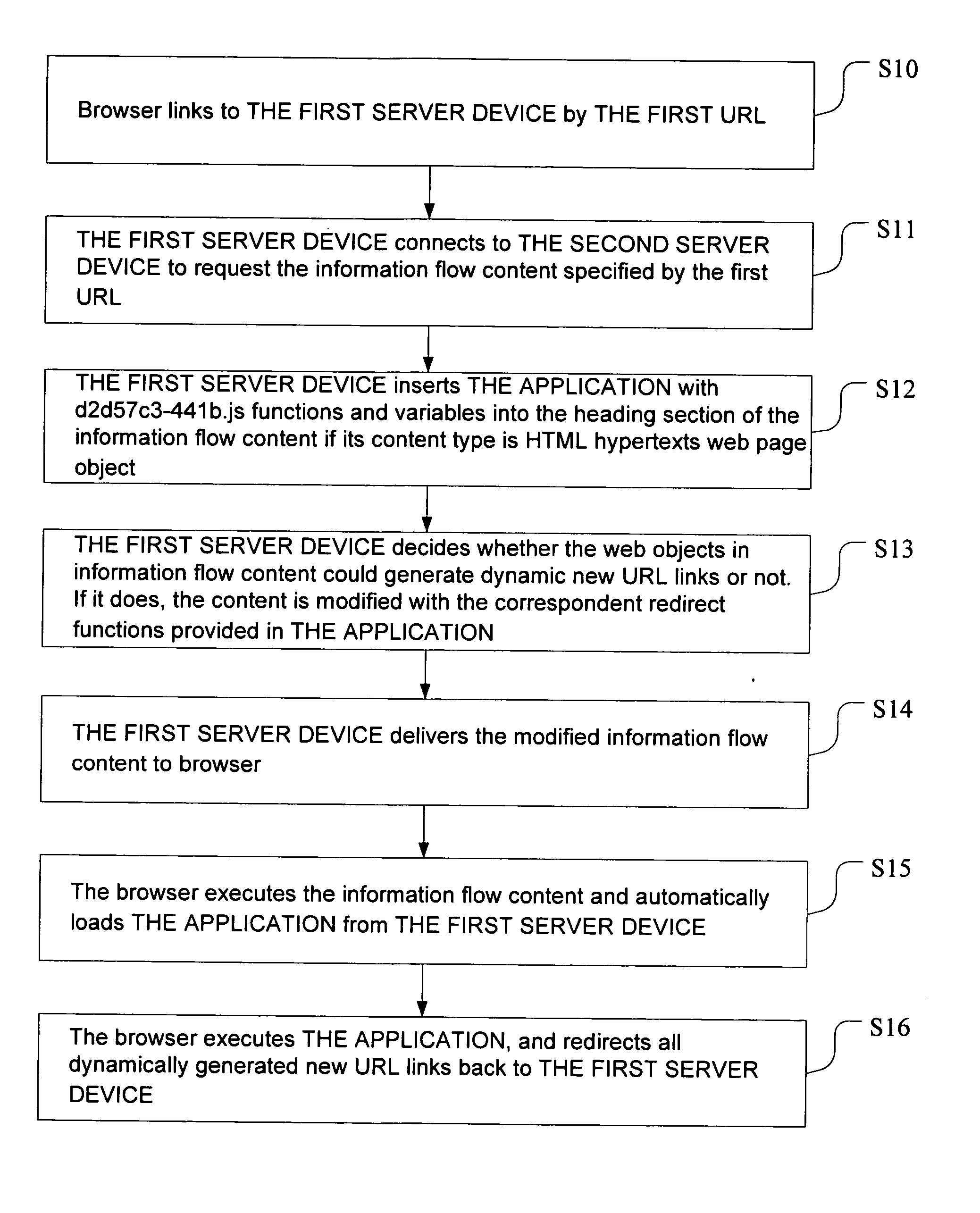

Architecture and methodology of redirection for dynamic new URL links

InactiveUS20060059416A1Remove obstaclesReduce loadNatural language translationDigital data information retrievalUniform resource locatorServer appliance

An architecture and methodology of redirection for dynamic new URL Links uses a first server device to get information flow content from a second server device. By inserting an application into the information flow content retrieved from the second server device, the first server device replaces the web objects, which may generate dynamic new URL links, with the redirect functions in the code and sends the content to the browser. The browser will execute the code automatically. Whenever the browser generates new dynamic new URL links, it would call the provided redirect functions, and thus redirect them and retrace back to the first server device.

Owner:LIN JIMMY JONG YUAN

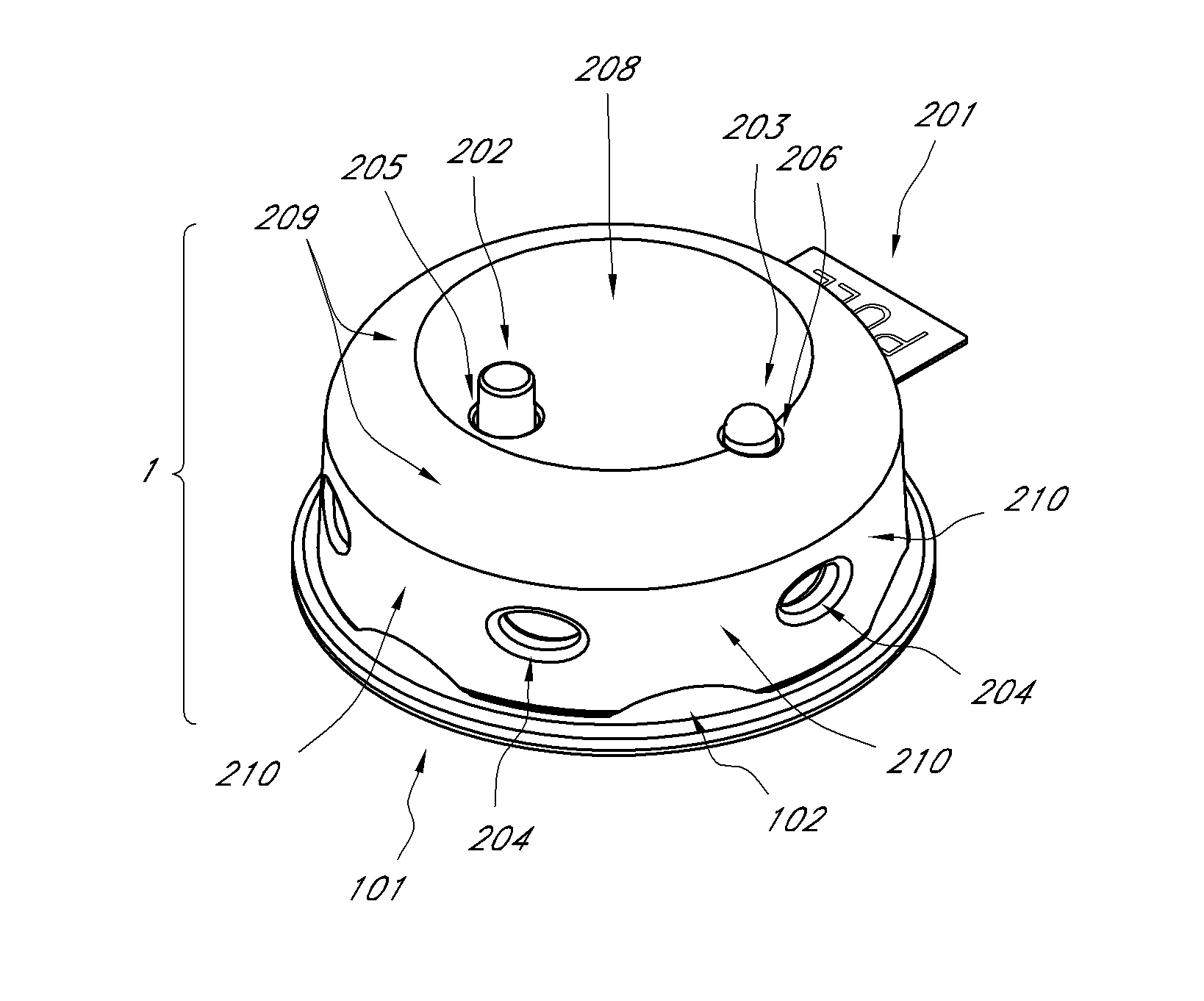

Indicative chest seal

InactiveUS20110054340A1Remove obstaclesPromote activationMedical devicesRespiratory organ evaluationGas passingWireless signal

A wound dressing can include an adhesive dressing with a diaphragm vent that allows the passage of gas out of a patient's body but restricts the flow of gas into the body. A sensor device is positioned so as to be able to sample gas passing through the vent and measure one or more gas characteristics, such as temperature, humidity, and / or pressure. If the data from the sensor device exceeds certain parameters suggestive of a pneumothorax, a processing device can activate an alert system, such as an indicator light, audible alarm, and / or wireless signal, to alert the care provider.

Owner:COMBAT MEDICAL SYST

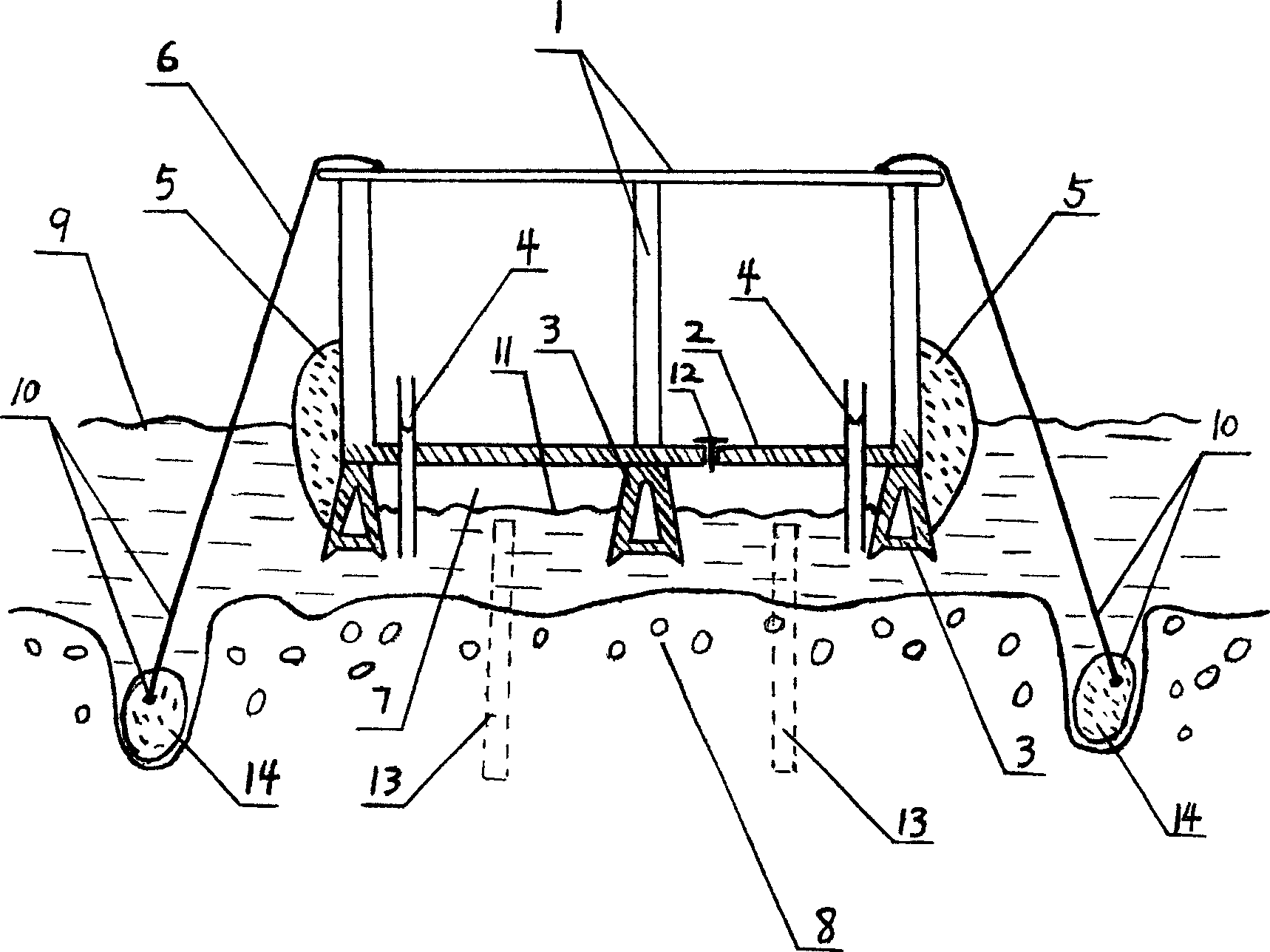

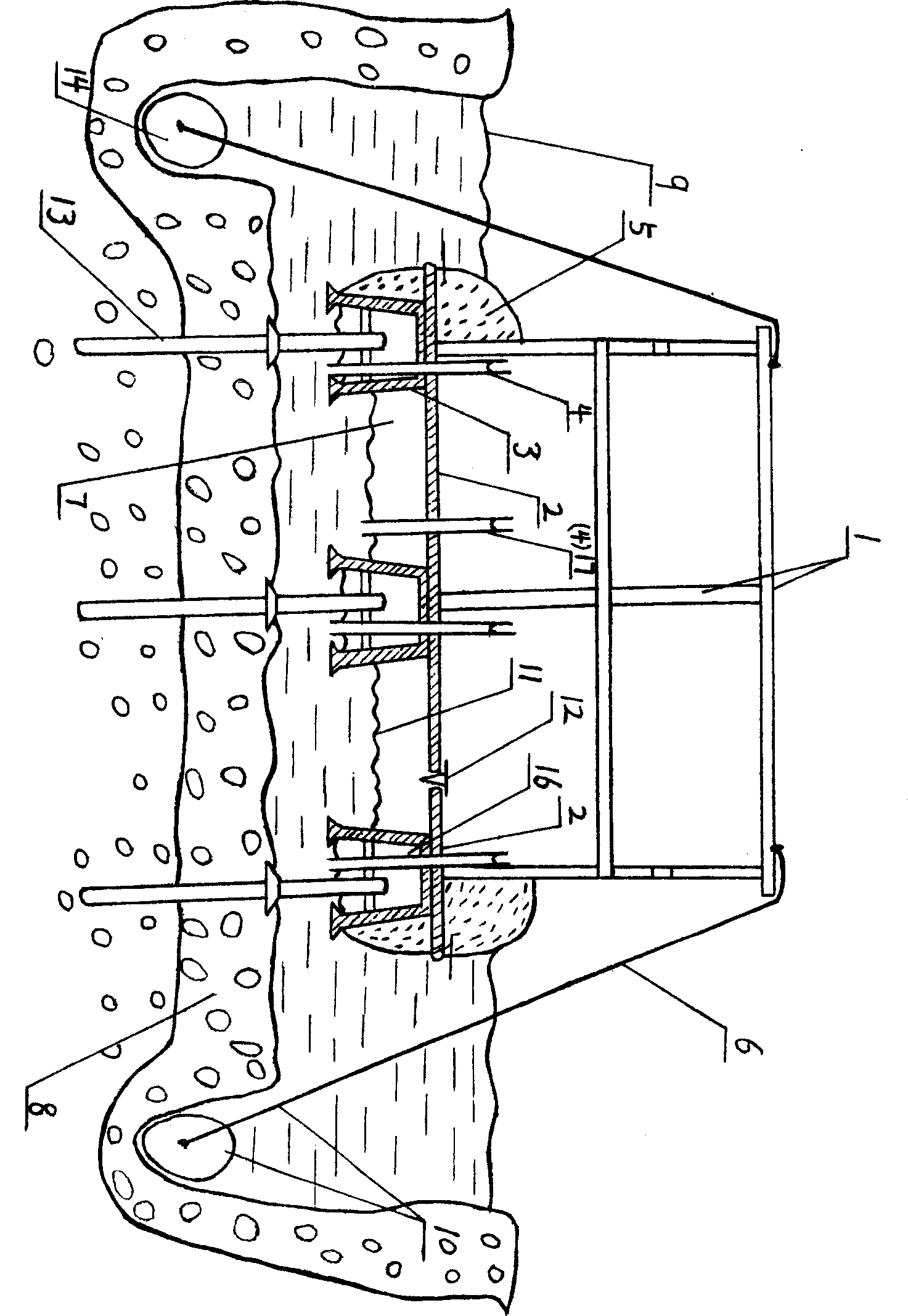

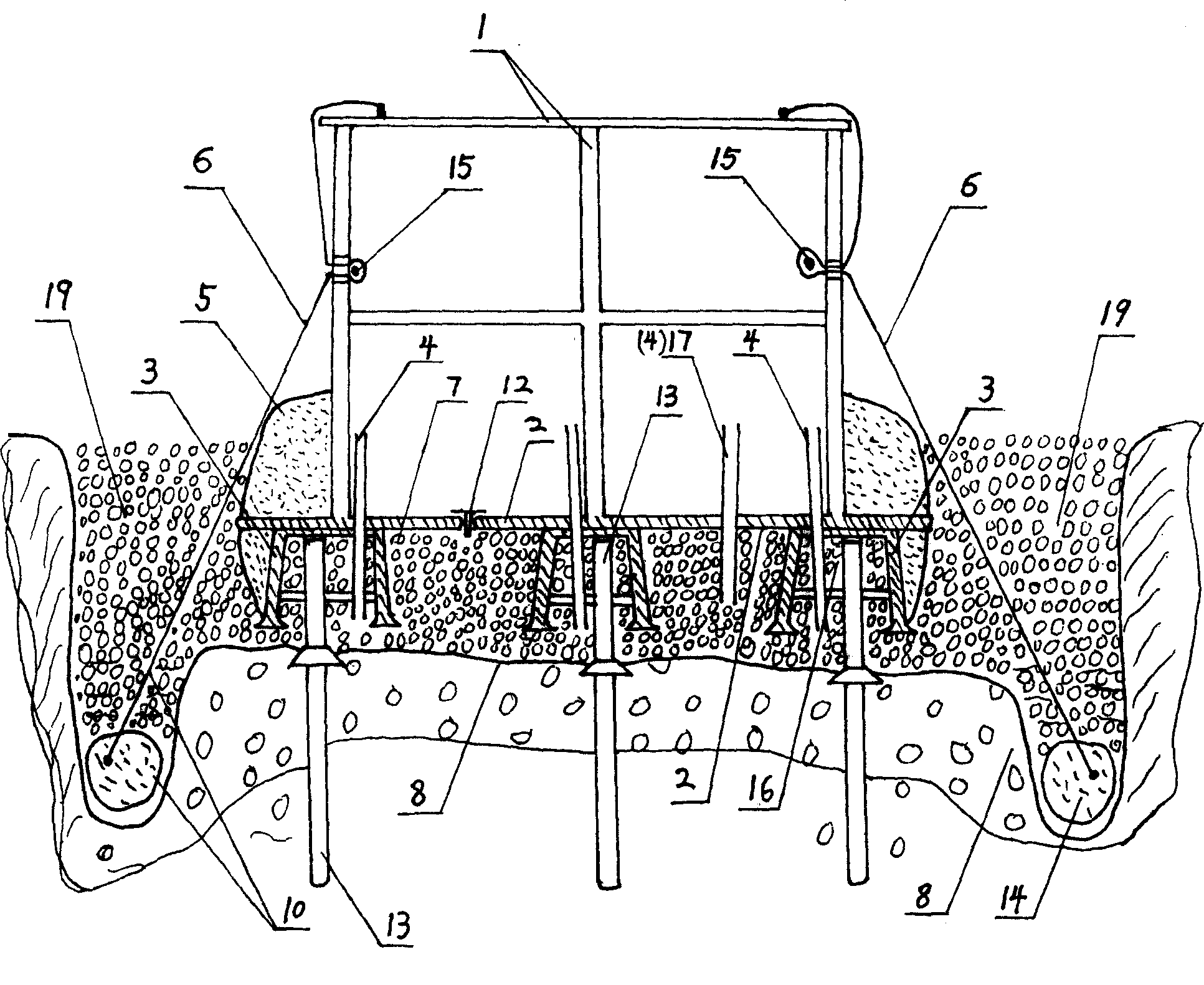

Water-based or land-based or semi-floating house and variable damping method thereof

InactiveCN101519920AChange performanceReduce weightClimate change adaptationProtective buildings/sheltersWater basedNatural disaster

The invention relates to a water-based or land-based or semi-floating common low-rise house and a floating vessel thereof, also relates to houses used for preventing natural disasters, comprising fire preventing houses, flood control and debris flow prevention houses, houses for drought resistance by reservoirs, water air conditioner houses for preventing global warming, and displacing houses, in particular to damping common low-rise houses. As a footing supports the house, the accidental inclination or sinking of the house can be limited in 0.7 or 0.3m, thus ensuring the personal safety. Also, other reasons are as follows: the weight of the house is light, the structural strength is high, the floating force is large and the stability is good. The importance of the case is variable damping function of the house, and the case is a damping machine which is realized by water, soil and wood and aims at challenging maximum earthquake, and how to lead the environment of the damping machine to be restored to environmental layout of the common house is described in the following.

Owner:刘吉彬

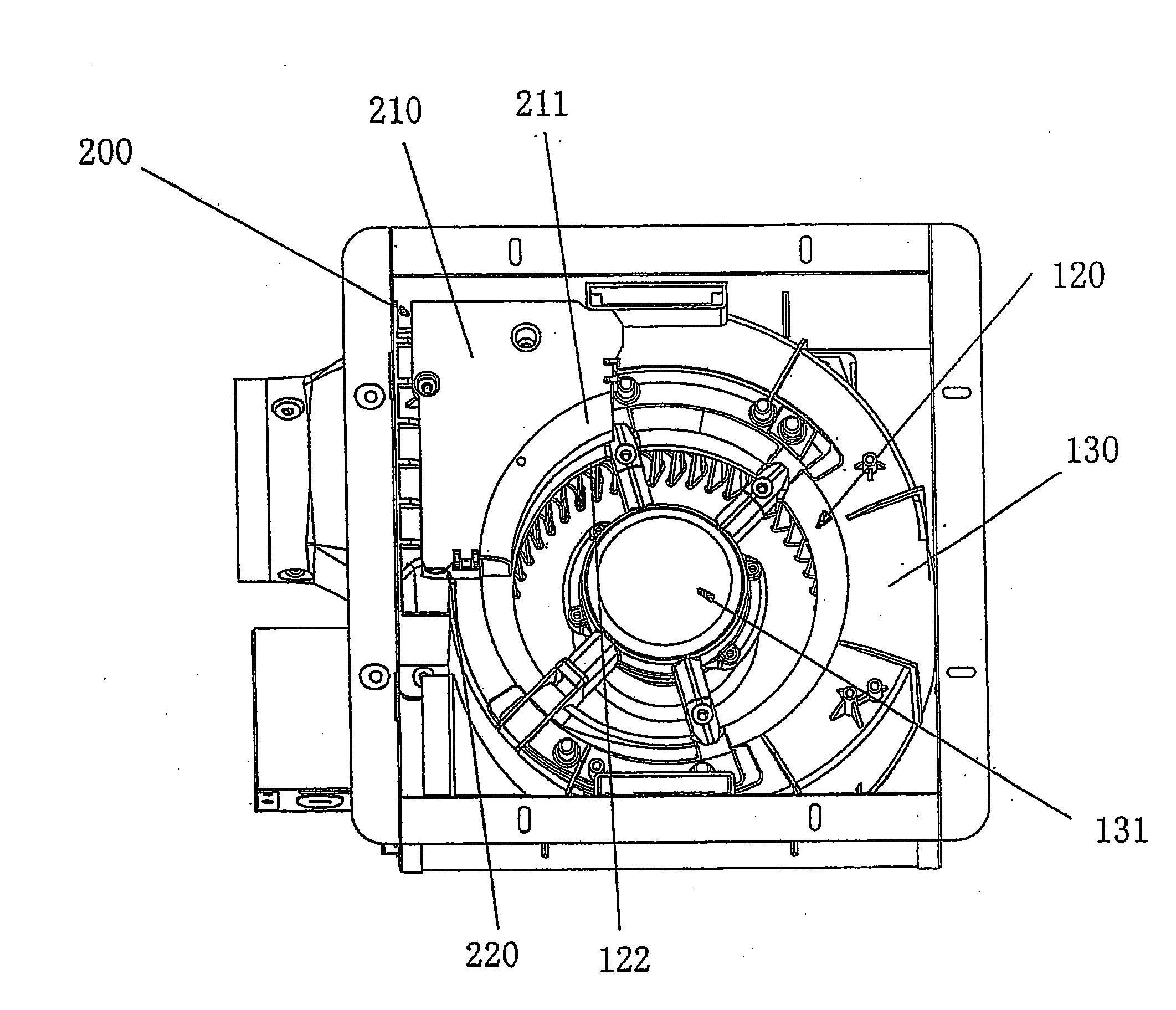

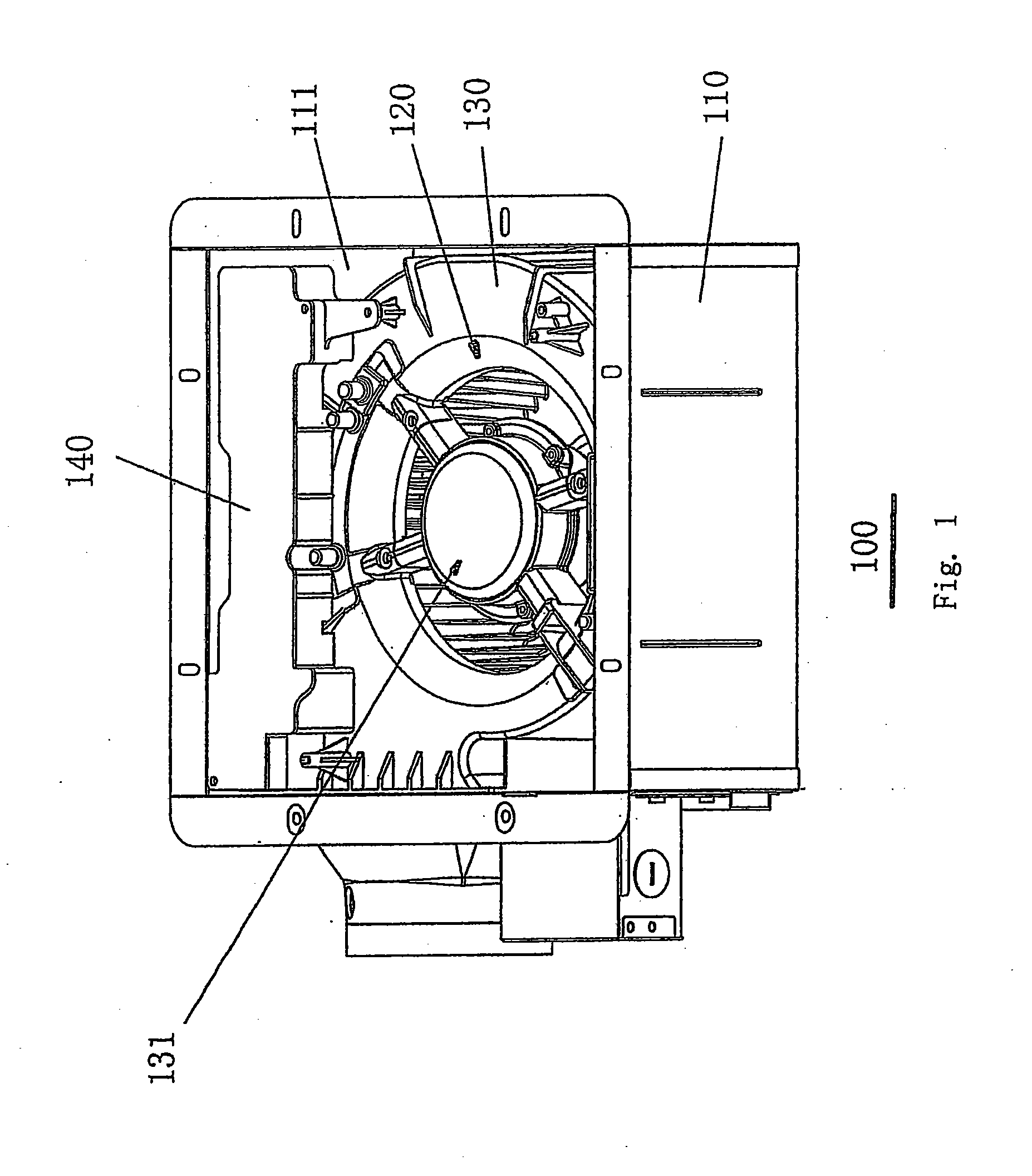

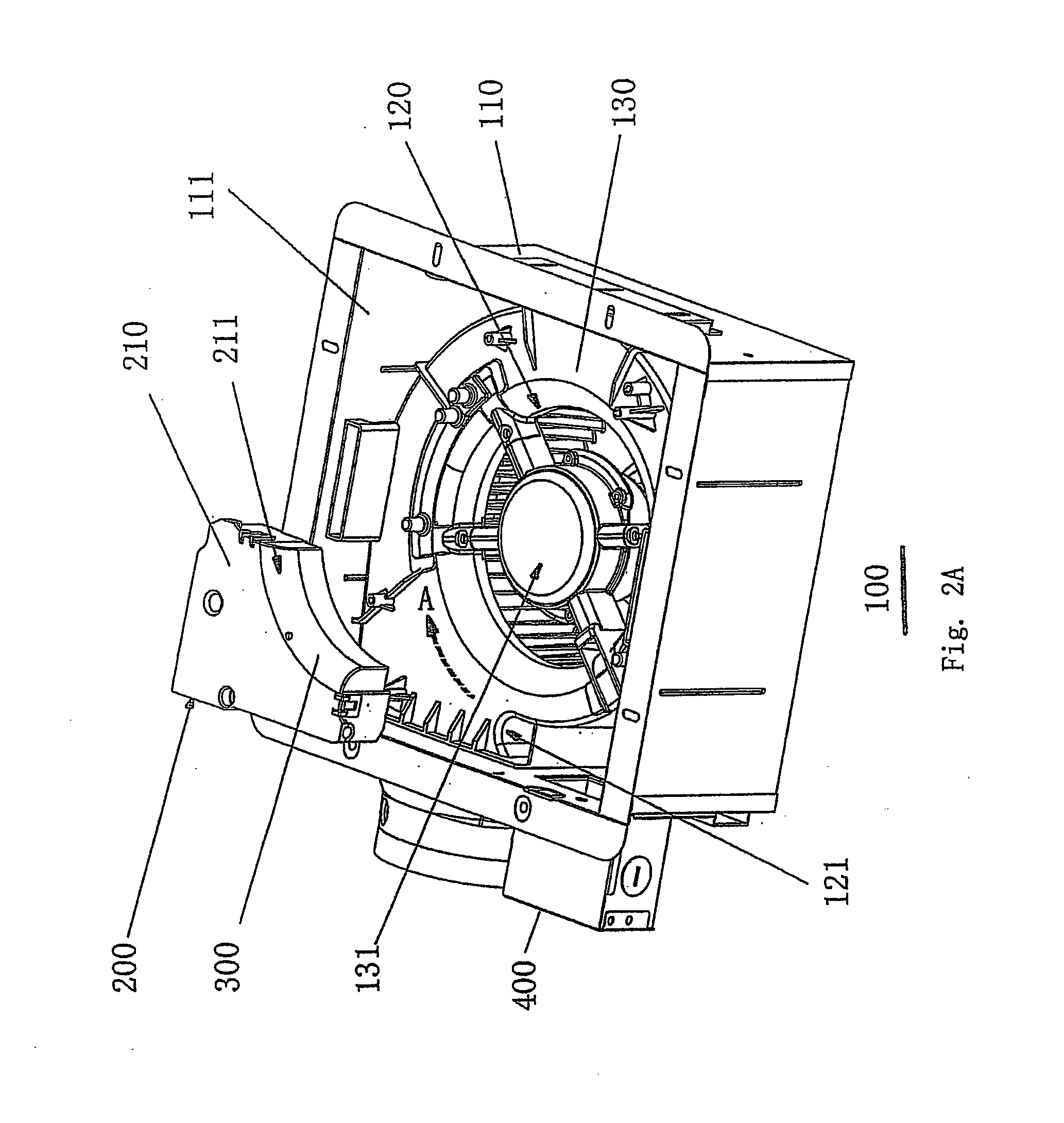

Air exchange fan and circuit board box therefor

ActiveUS20120107096A1Reduce noiseImprove securityPump componentsBlade accessoriesEngineeringAir blower

An air exchange fan comprises: a frame with an opening, a helicoid housing with an air suction inlet disposed in the frame, an air blower disposed in the housing, and, an elongated circuit board box mounted at the air suction inlet side of the housing; a silencing plate is mounted above the outer peripheral of the inlet, and has a streamlining structure formed by outwardly expanding from the inlet in an axial direction of a rotation axis of the air blower, the rotation axis of which being served as the center, within a range that is from a tongue of the housing to a location with a 90 degrees angled from the tongue in a direction opposing to the rotation direction, and has a curved chamfered shape which mates with the peripheral shape of the inlet. A circuit board box for such air exchange fan is also disclosed.

Owner:PANASONIC ECOLOGY SYSTEMS GUANGDONG CO LTD +1

System and method for automated customer account creation and management

ActiveUS9563898B2Remove obstaclesAvoid long linesComplete banking machinesFinanceDriver's licenseData mining

A method and system to automatically create and manage patron accounts using electronic data capture at an automated machine or kiosk, including electronically obtaining personal patron identification information from a patron identification source, such as a driver's license, determining if a patron account exists and if the identification source has expired and updating any existing patron account with the captured data. If the patron identification source is current and no account exists, a temporary account is created and a temporary patron account card supplied to the patron along with promotional offers. Patron activity is monitored at the location and used in creating a permanent patron account for providing additional offers, bonuses, and the like to the patron.

Owner:LNW GAMING INC

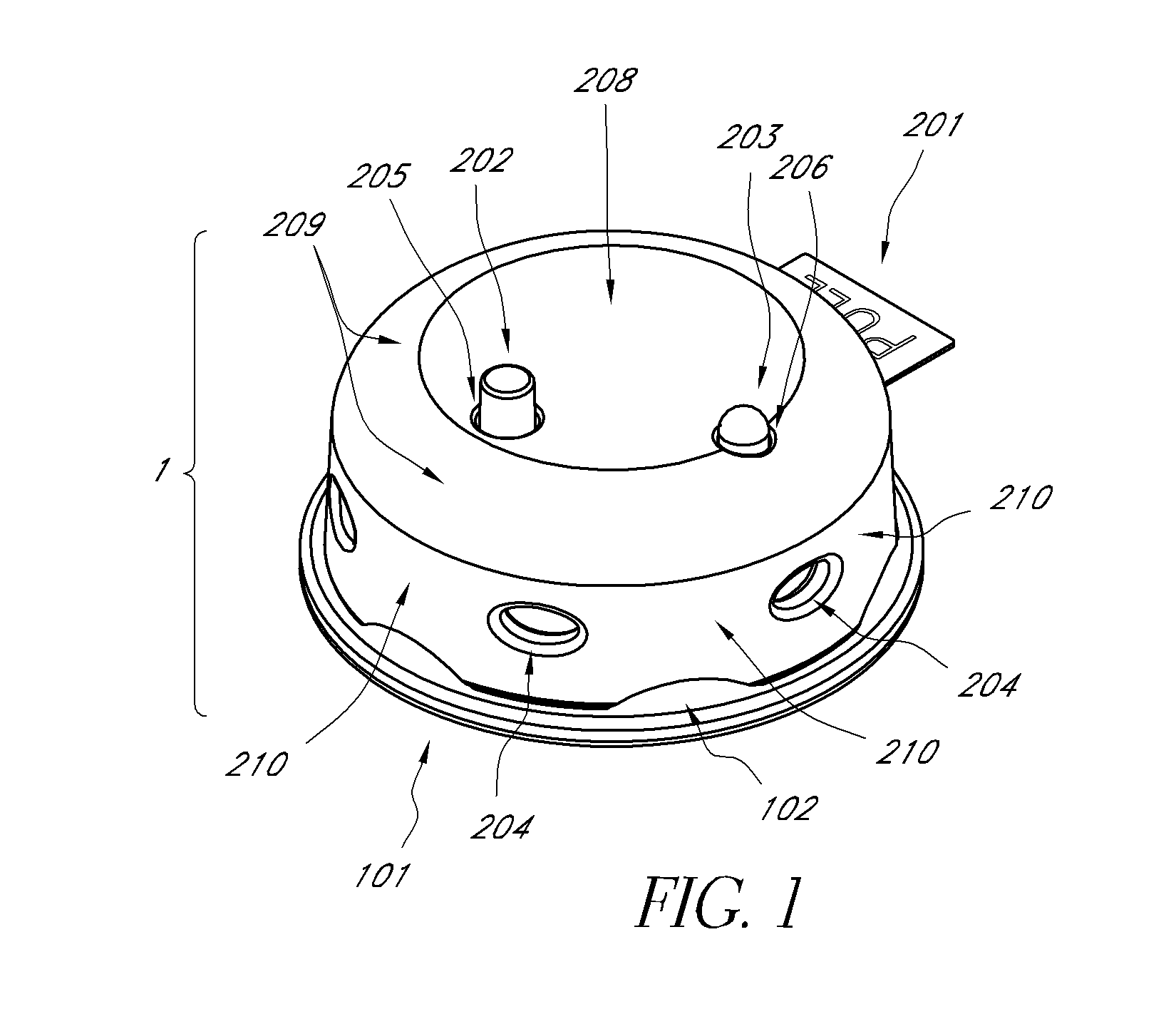

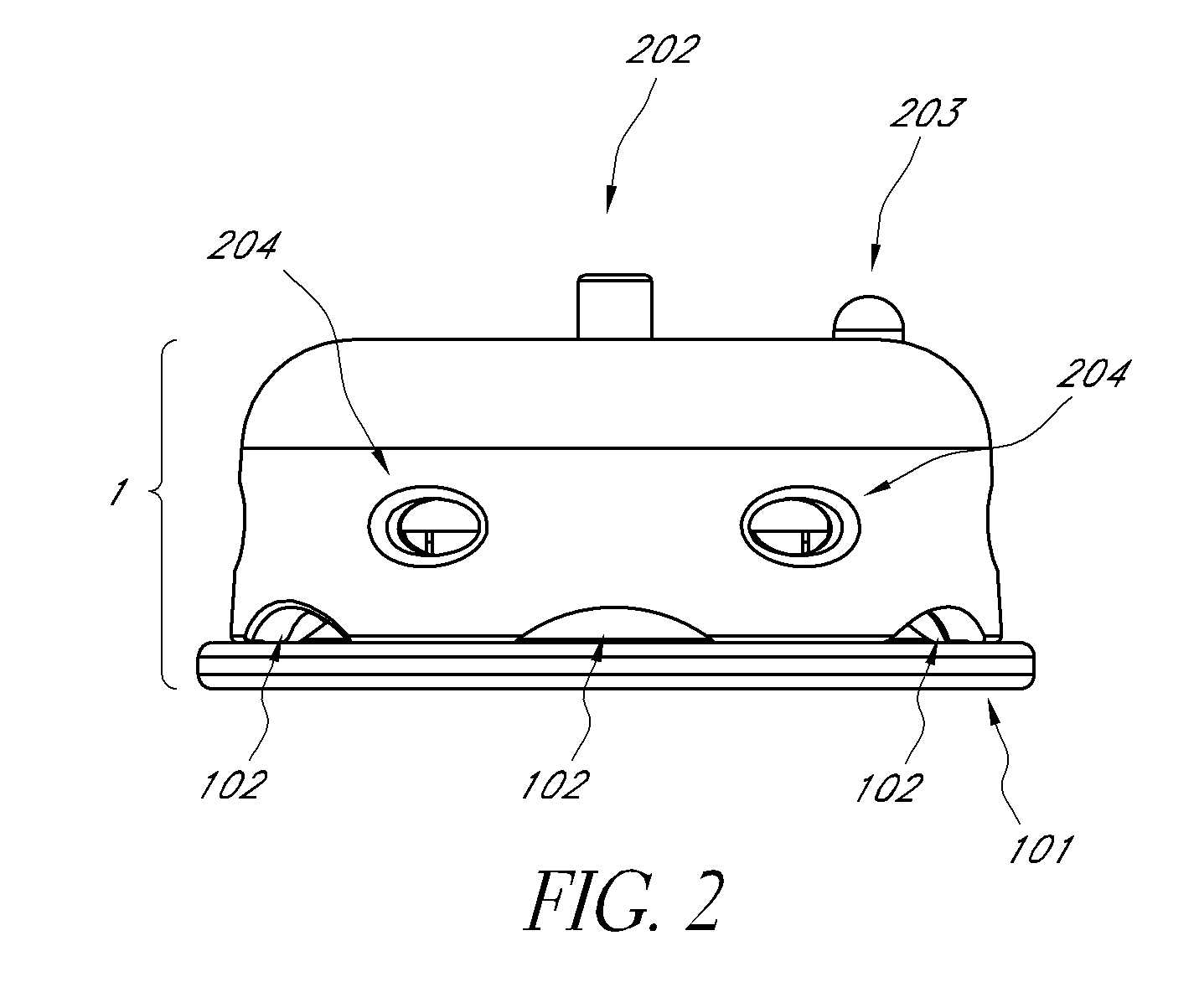

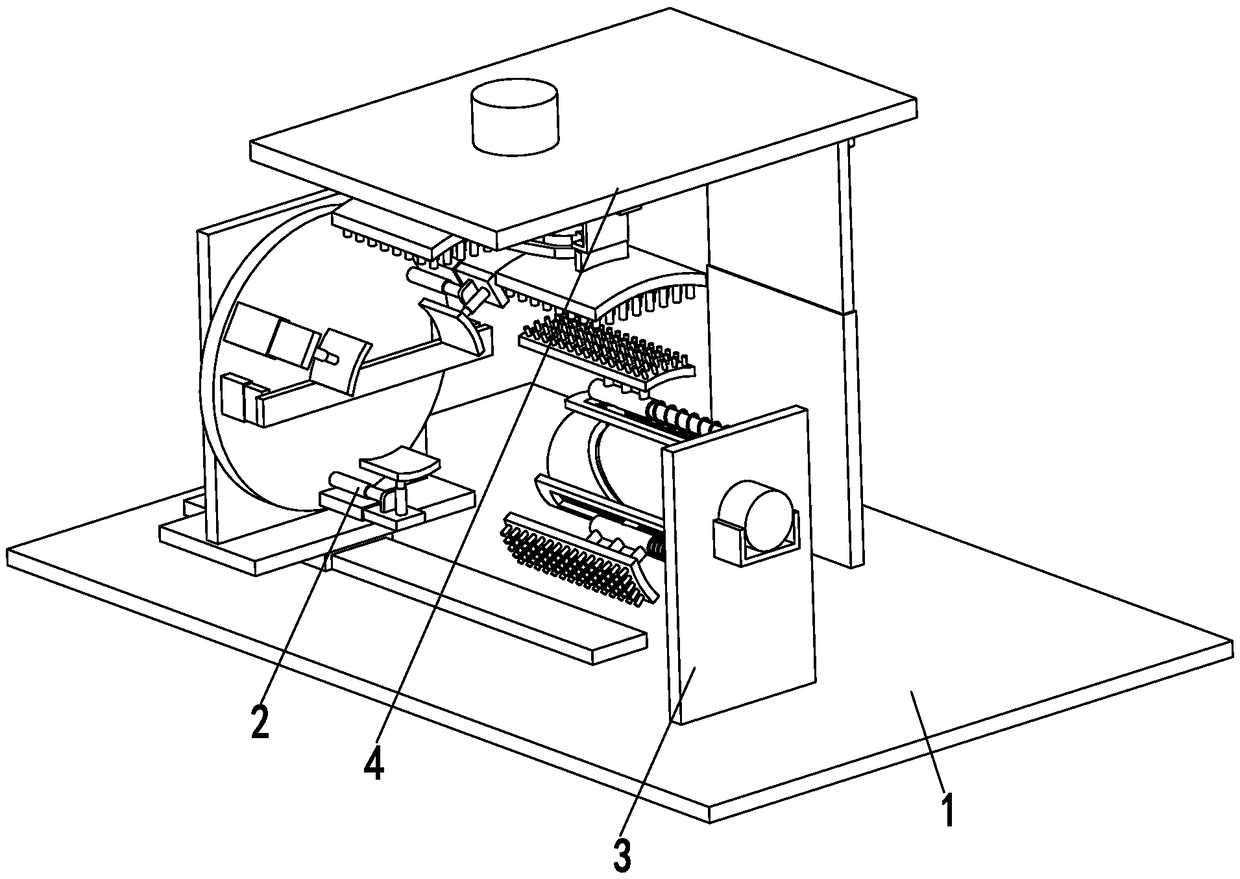

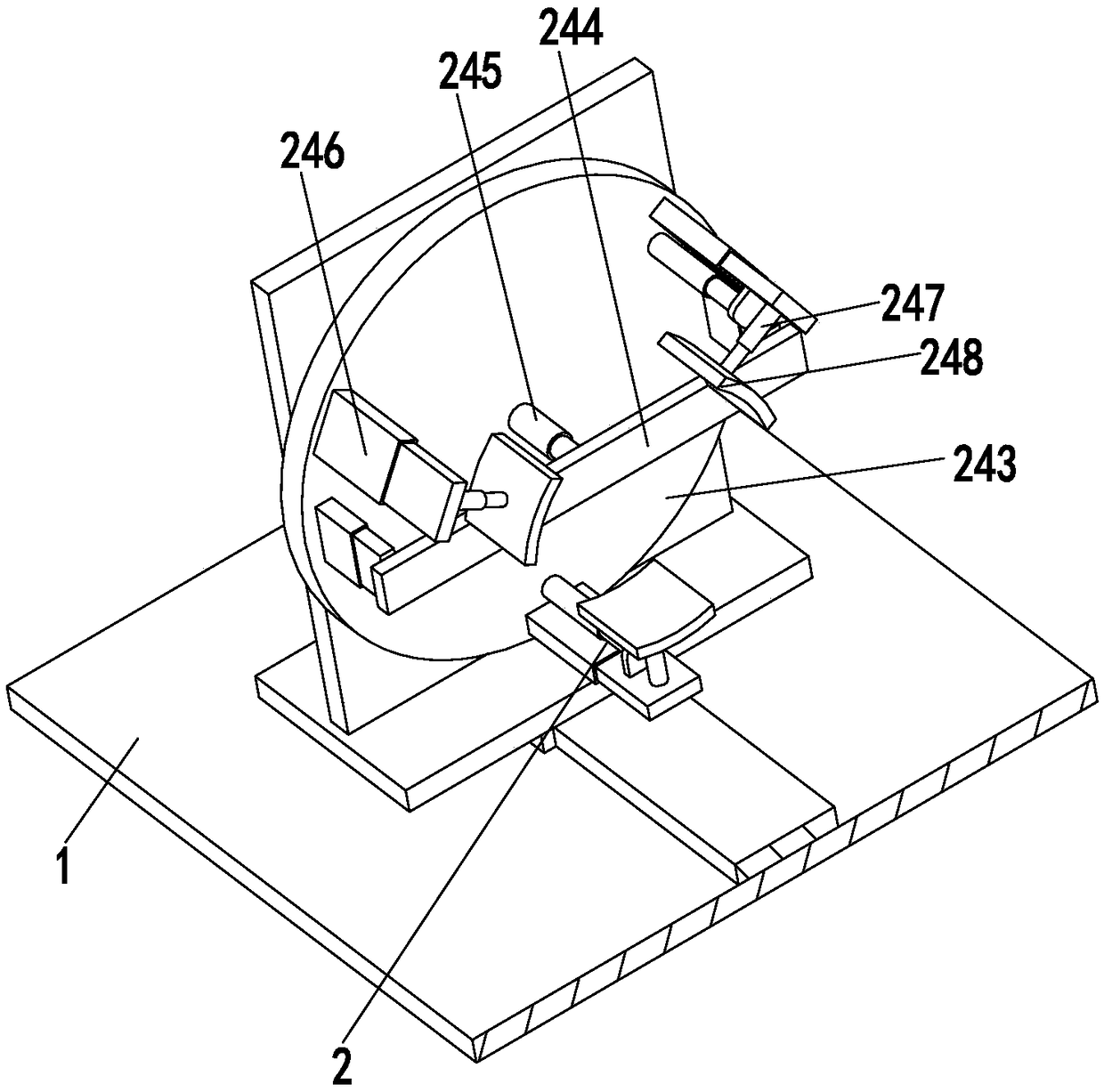

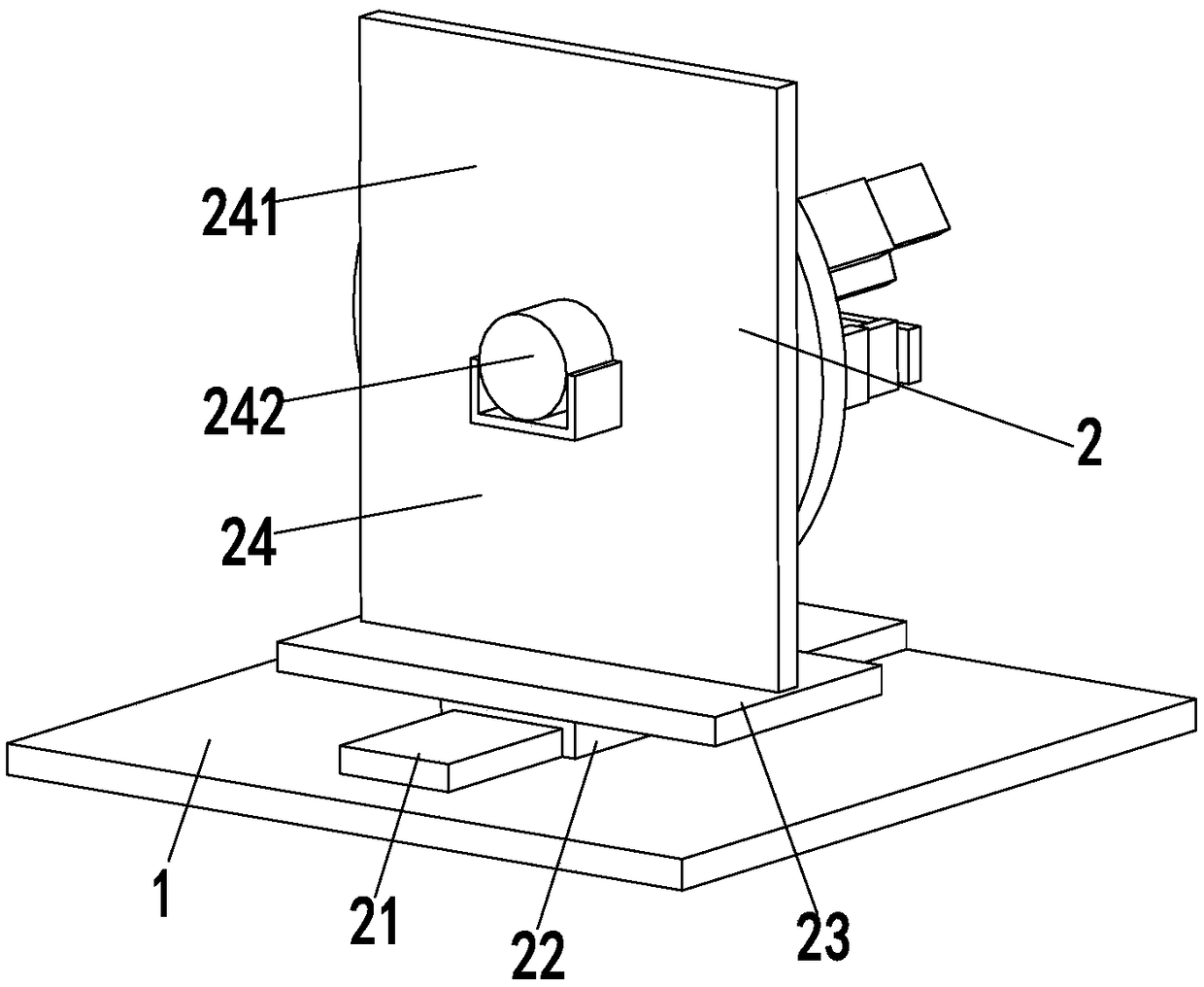

Workpiece grinding machine of numerical-control electric spark machine tool

InactiveCN108789046ASolve the costSolve labor intensityGrinding carriagesGrinding drivesNumerical controlEngineering

The invention relates to a workpiece grinding machine of a numerical-control electric spark machine tool. The workpiece grinding machine of the numerical-control electric spark machine tool comprisesa base plate, a fixing device, an inner wall grinding device and an outer wall grinding device. The fixing device and the inner wall grinding device are sequentially installed on the base plate from left to right. The outer wall grinding device is installed on the back side of the base plate. The inner wall grinding device comprises a fixing plate, a rotating motor, a rotating column, sliding blocks, limiting frames, telescopic rods, springs, adjusting air cylinders and first steel wire brushes. The outer wall polishing device comprises a lifting frame, a rotating motor, a rotating column, a cam, connection sliding blocks, connection frames, guide rails and second steel wire brushes. The workpiece grinding machine of the numerical-control electric spark machine tool can solve the problemsthat in an existing annular workpiece grinding process, the labor cost is high, the labor intensity is high, the work efficiency is low, the grinding difficulty is large, and the adjustability is poor; the automatic grinding function on the annular workpiece can be achieved; and the workpiece grinding machine of the numerical-control electric spark machine tool has the advantages of being low in labor cost, low in labor intensity, high in work efficiency, small in polishing difficulty, good in adjustability and the like.

Owner:浙江芊荷科技有限公司 +1

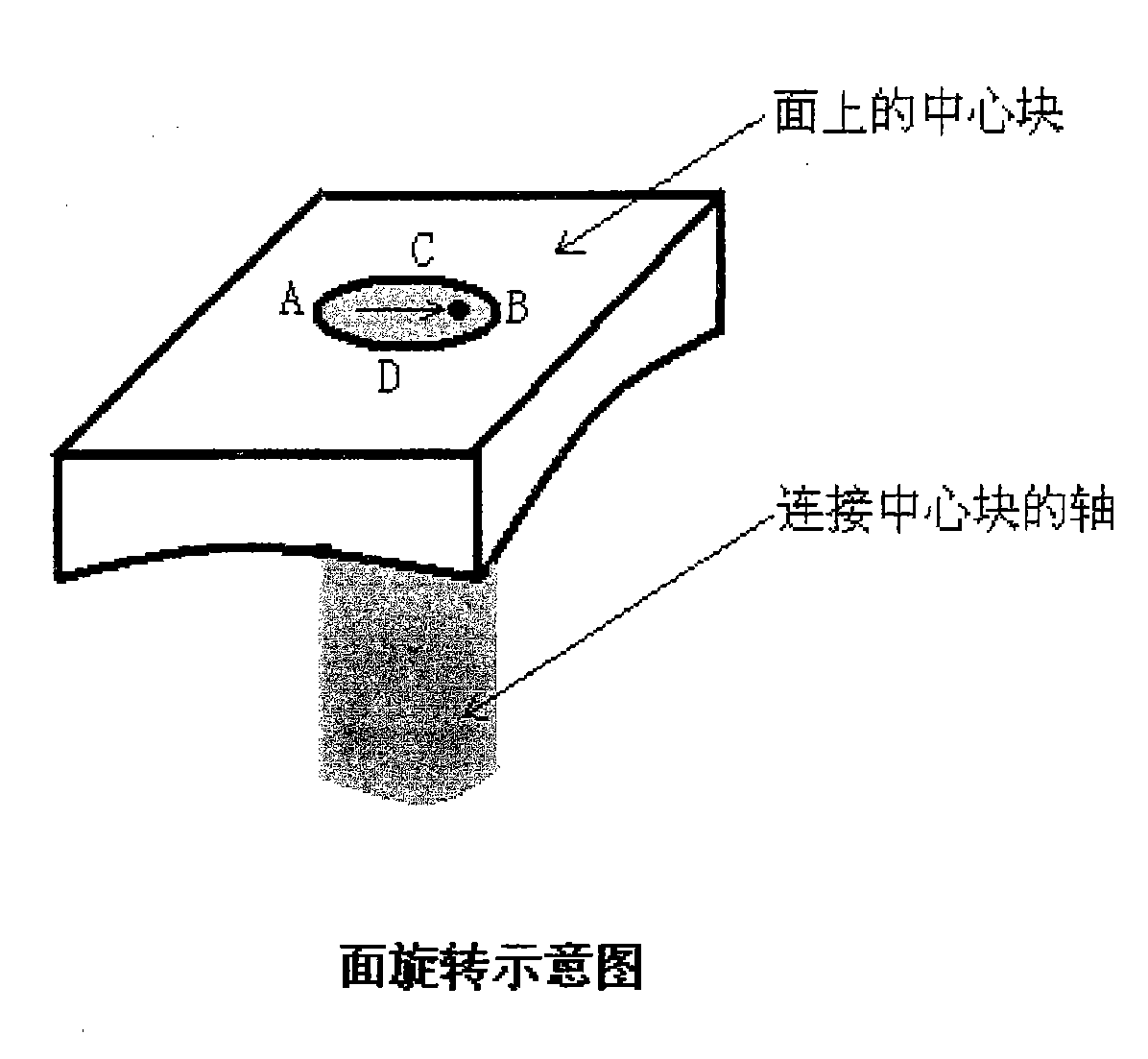

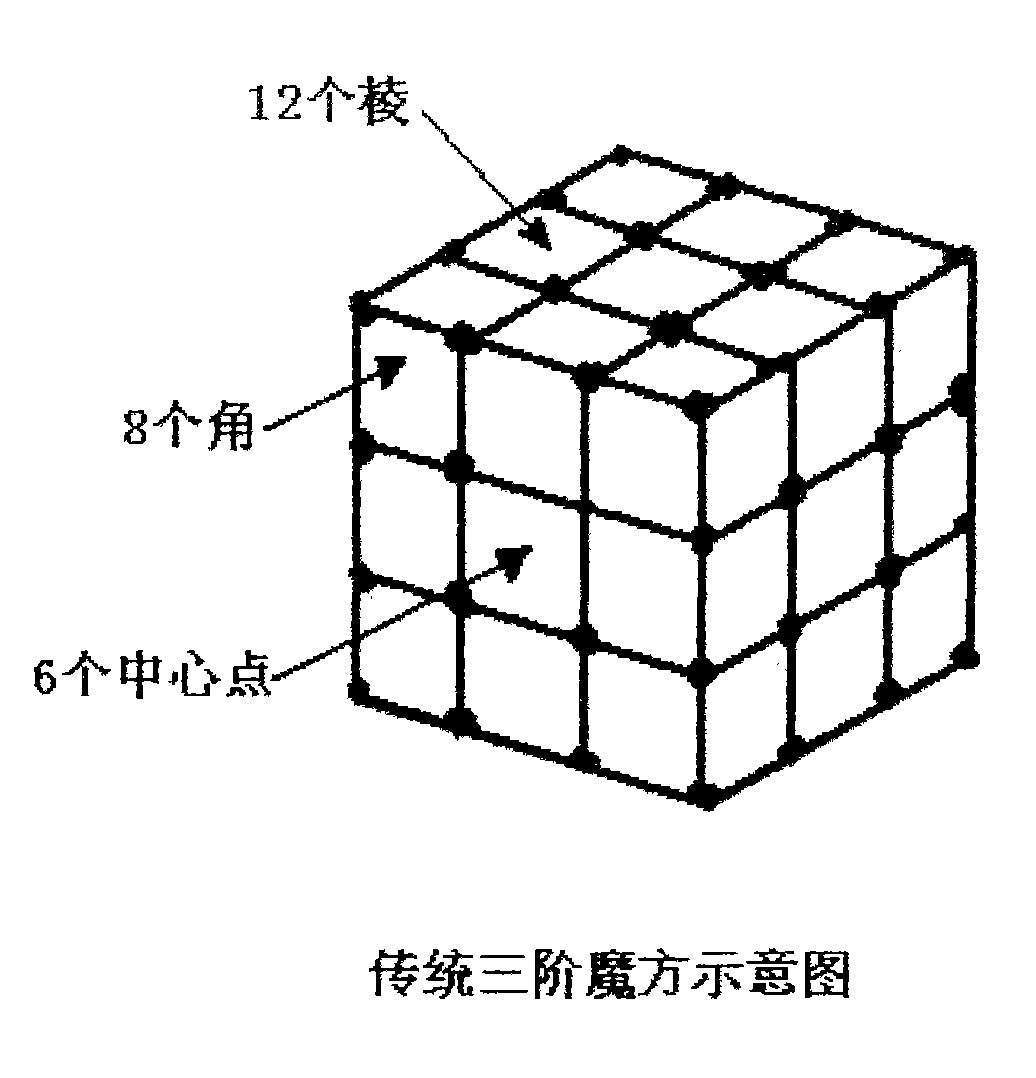

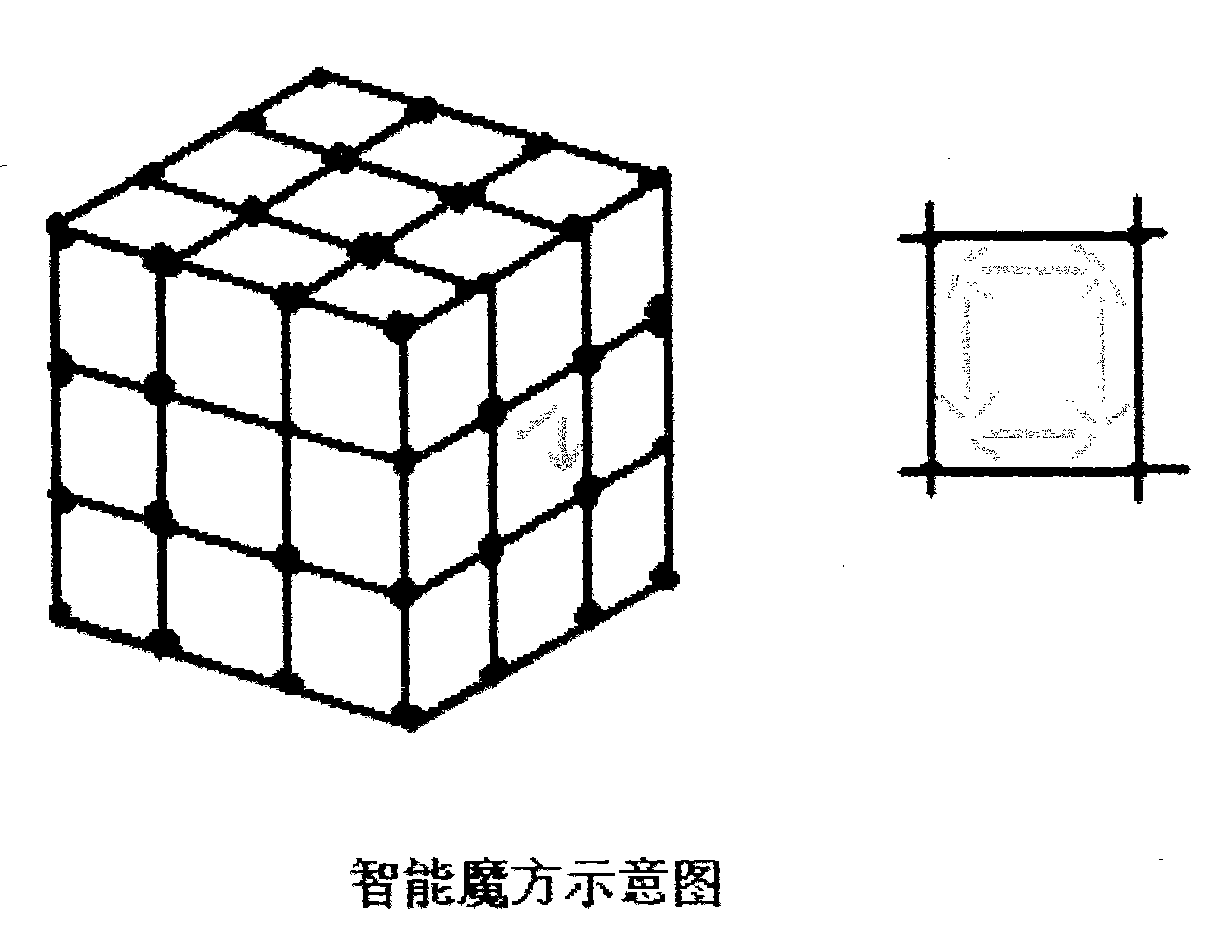

Intelligent magic cube

The invention discloses a novel magic cube with a memory function, which can direct users to finish the recovery of the magic cube so as to greatly simplify the obstacle of the magic cube to beginners and improve the enjoyment of the magic cube, and is particularly suitable for teenagers and children to improve intelligence and hands-on capability when the enjoyment is obtained. At the same time, internal electronic equipment can provide the functions such as information, background music and light effect when users use the novel magic cube so as to greatly increase the charm of the magic cube and the enjoyment of the playing of the magic cube.

Owner:刘辉

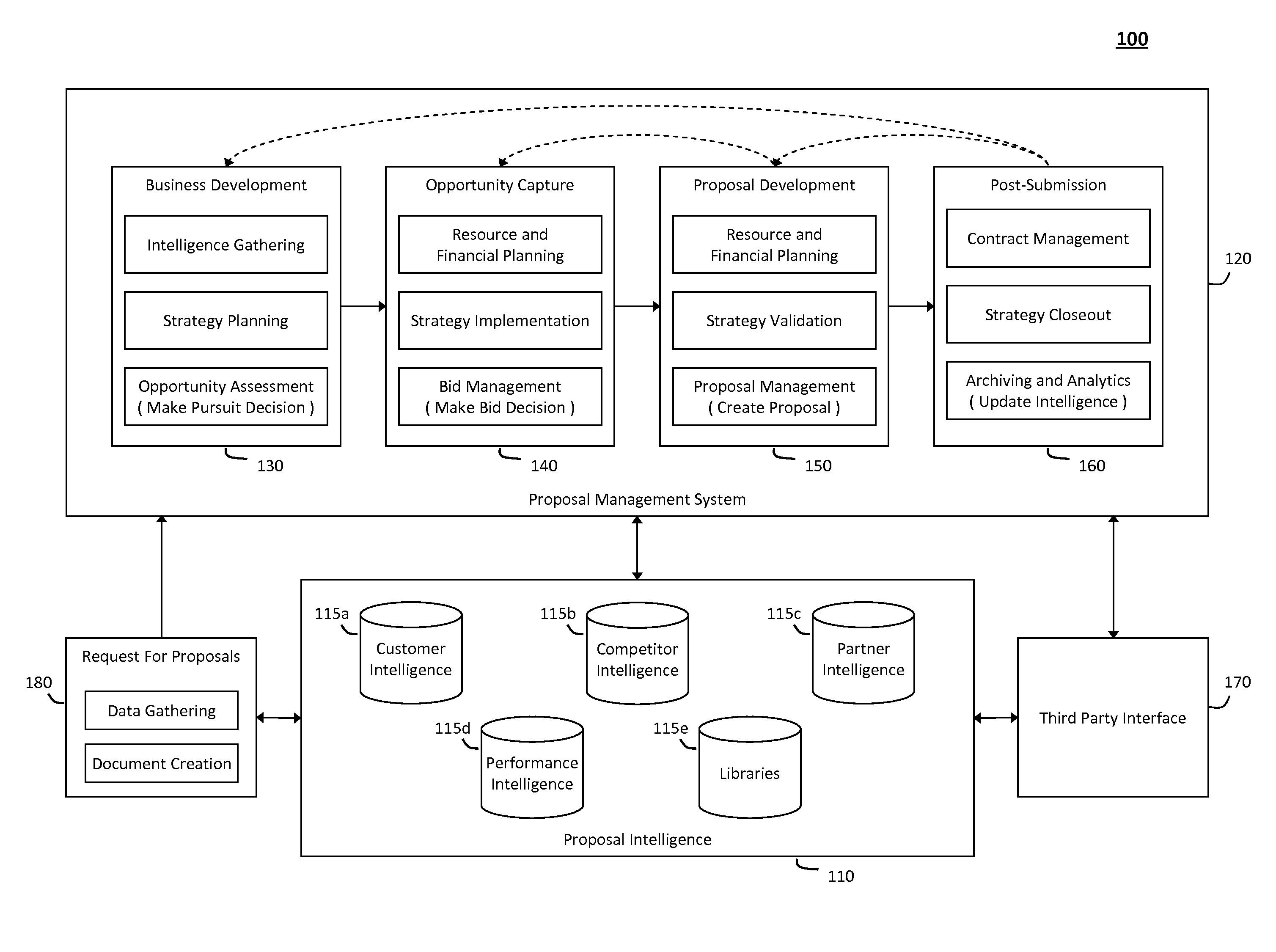

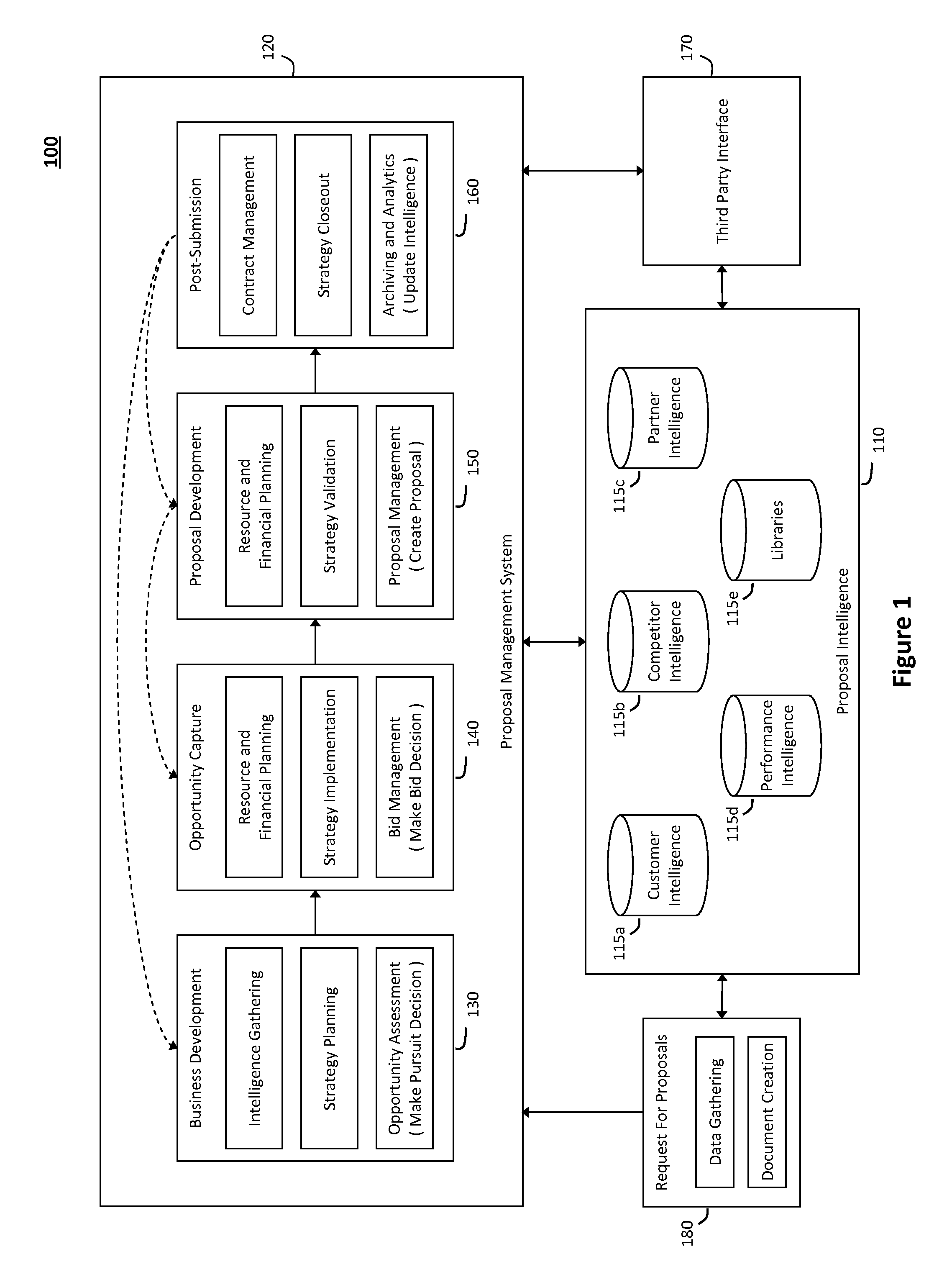

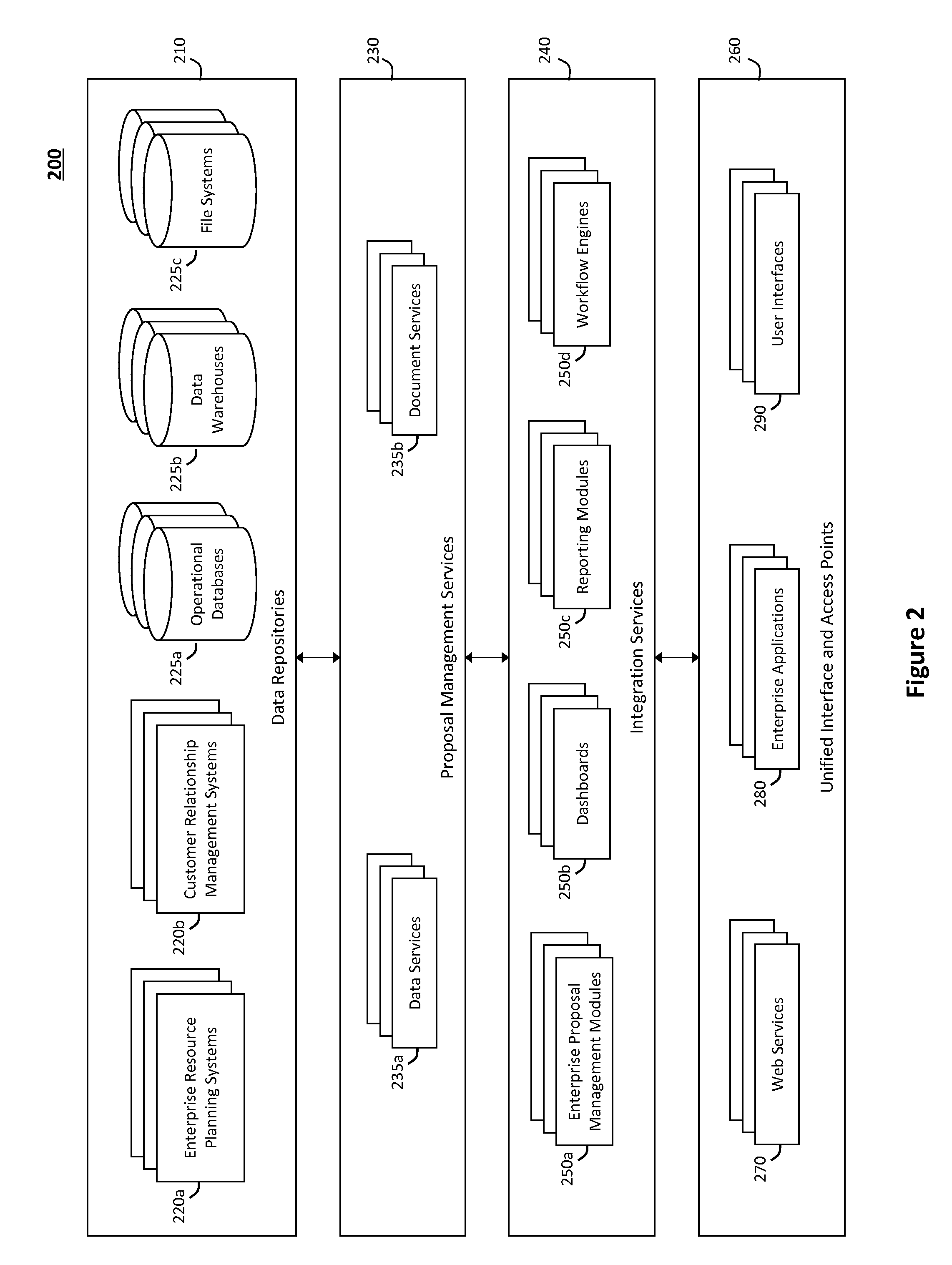

System and method for creating documents to manage a proposal lifecycle

The system and method described herein may integrate an enterprise proposal management system with various enterprise systems, applications, data sources, and other resources to provide a comprehensive solution to manage and coordinate a proposal lifecycle and data associated therewith. In particular, the system and method described herein may integrate and use business information stored in various data sources to execute repeatable and effective strategies to manage business development and proposal efforts, reduce the time that proposal authors spend to search, retrieve, and use content from past proposals to create proposals likely to win new business, coordinate collaboration across organizational teams involved in managing proposal, reliably track capture and proposal pipelines, and preserve documents, data, and other information relevant to the proposal lifecycle, thereby providing real business value in day-to-day proposal management operations.

Owner:I3SOLUTIONS

Headphone

InactiveUS20030091209A1Simple compositionEasy to carryHeadphones for stereophonic communicationSupra/circum aural earpiecesLoudspeakerEngineering

Owner:SONY CORP

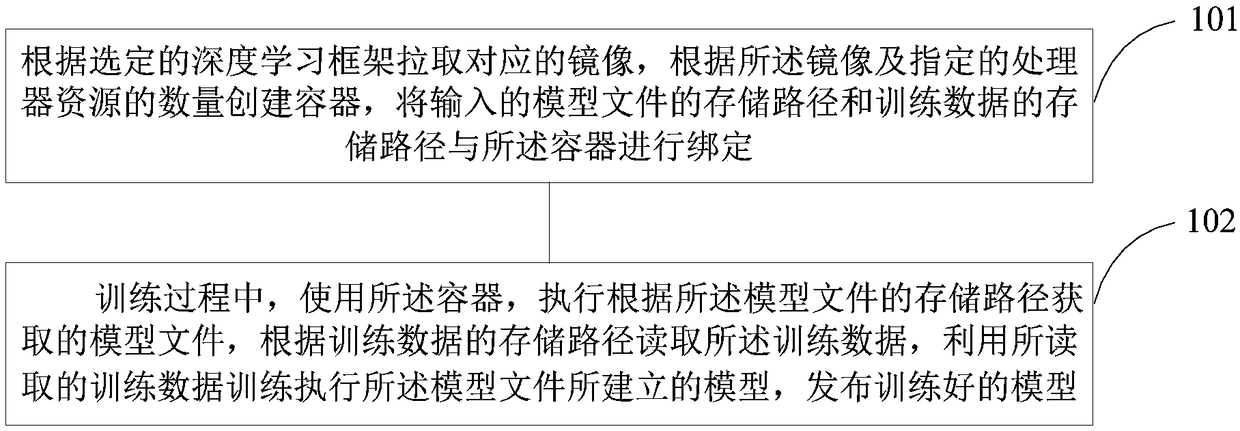

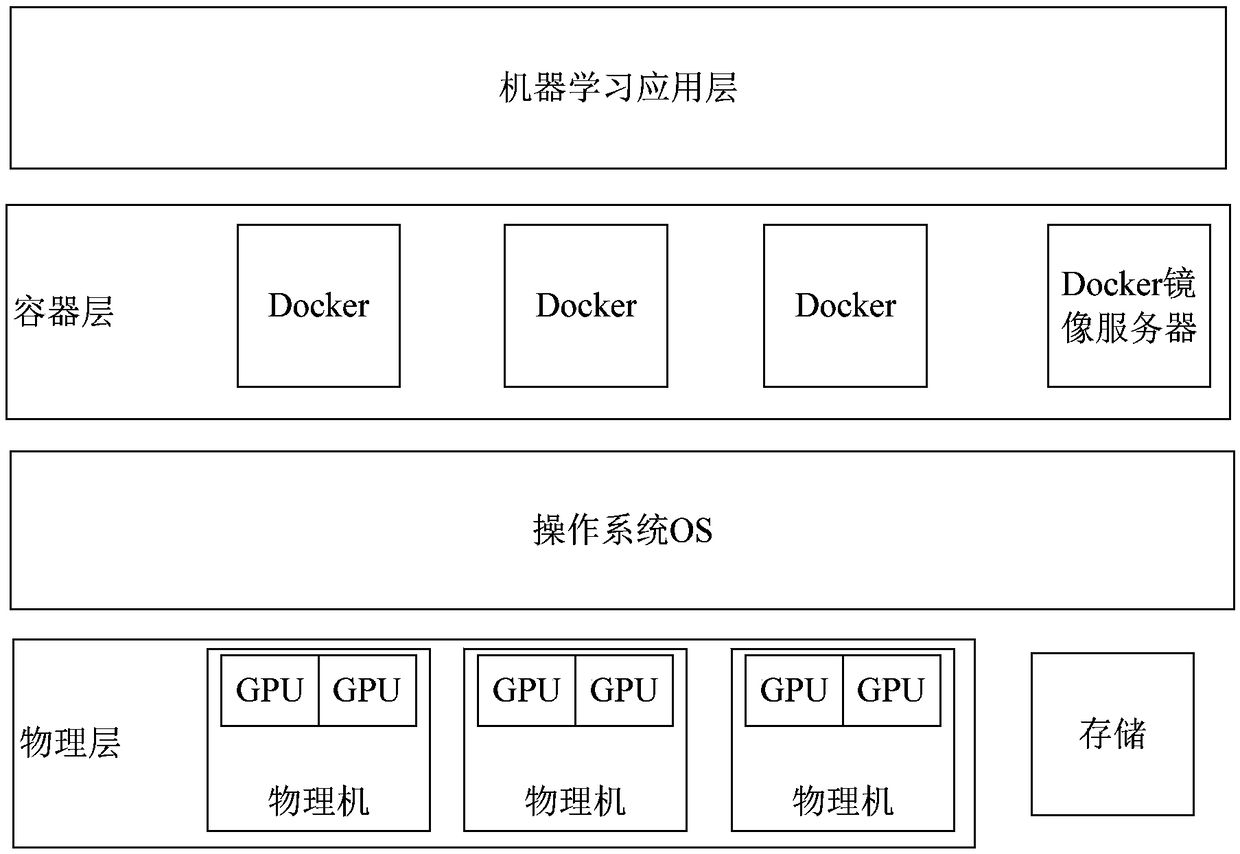

A method and apparatus for machine learning based on cloud computing

A machine learning method based on cloud computing includes pulling corresponding images according to a selected depth learning framework, creating containers according to the images and configurationinformation including a specified number of processor resources, and binding a storage path of an input model file and a storage path of training data with the containers; in the training process, the container is used to execute the model file obtained according to the storage path of the model file, the training data is read according to the storage path of the training data, the model established by the model file is trained and executed by the read training data, and the trained model is published. A device for machine learning based on cloud computing is also disclosed. The scheme can eliminate the complexity in the process of machine learning and reduce the threshold of learning and using.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com