Variable temperature seat

a seat and variable temperature technology, applied in the field of variable temperature seats, can solve the problems of seat occupants' back and other pressure points sweating, vehicle seats being very hot and uncomfortable for a long time, and achieving the effect of optimal operation without, reducing the number of parts and complexity, and reducing the cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

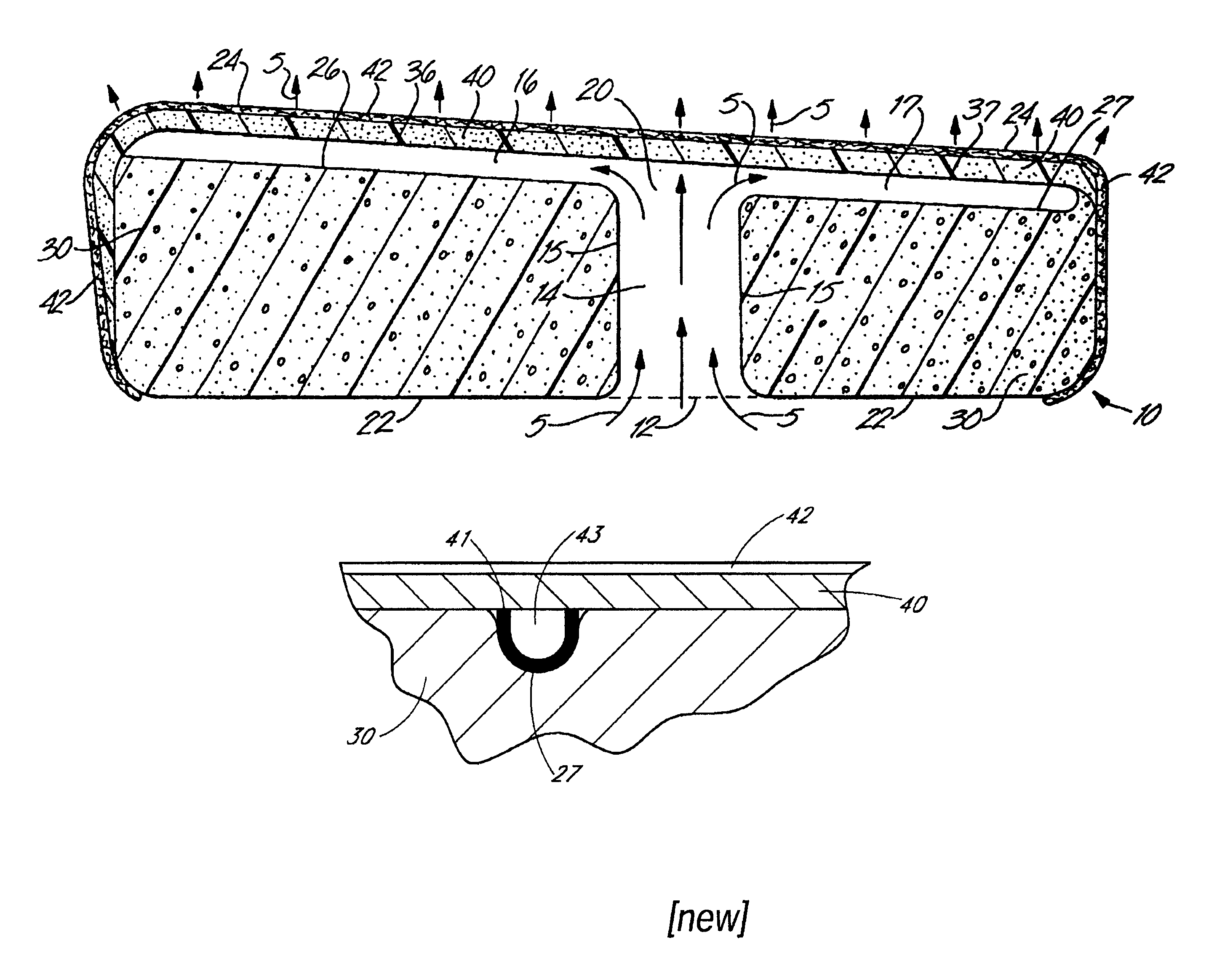

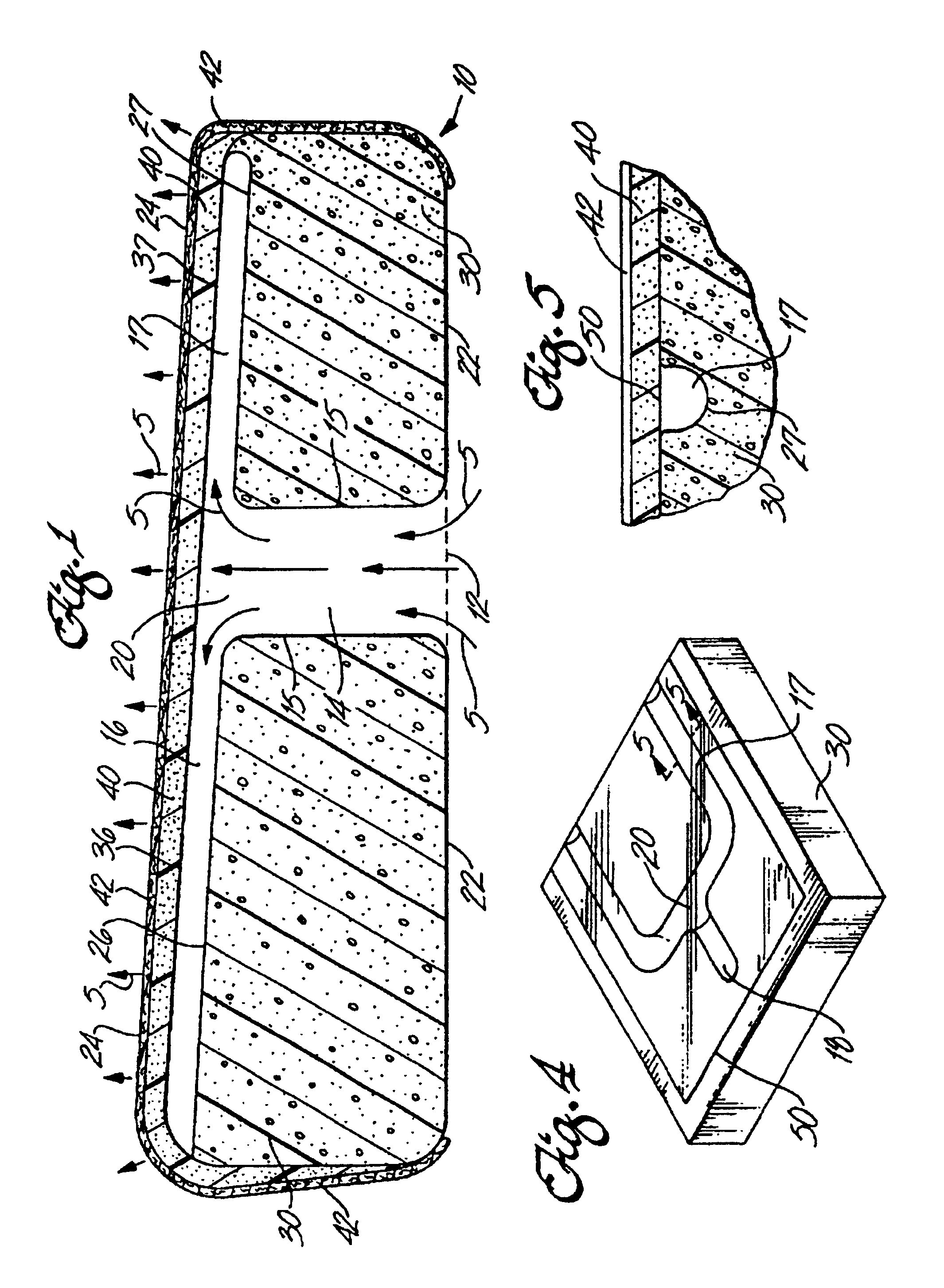

[0032]In a first embodiment of the invention, conditioned air 5, represented by arrows, is supplied to the air inlet 12 of an automotive seat cushion 10 as shown in FIG. 1. The conditioned air 5 passes through the main channel 14 and is divided via the manifold 20 into subchannels 16, 17, as shown in FIG. 1. The air inlet 12 is located on the entrance side 22, and is opposite the occupant side 24 of the seat cushion 10. The air inlet 12, the channel walls 15, and a portion of the subchannel walls 26, 27 are substantially formed by standard automotive seat cushion foam material 30. The subchannel walls 36, 37 nearest the occupant side 24 of the seat cushion 10 preferably are formed by reticulated foam 40. The reticulated foam is encapsulated by a layer of automotive upholstery 42 that is preferably air permeable.

[0033]The conditioned air 5 passes from the subchannel regions into the reticulated foam layer 40. Within the reticulated foam, the conditioned air is free to move both verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com