Film letting-off device for roll baler, and method for winding film on rolled bale

A wrapping machine and film technology, which is applied in the field of film output devices, can solve the problems of film stretching, excessive sliding resistance, and being wound, and achieve the effects of eliminating film damage and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

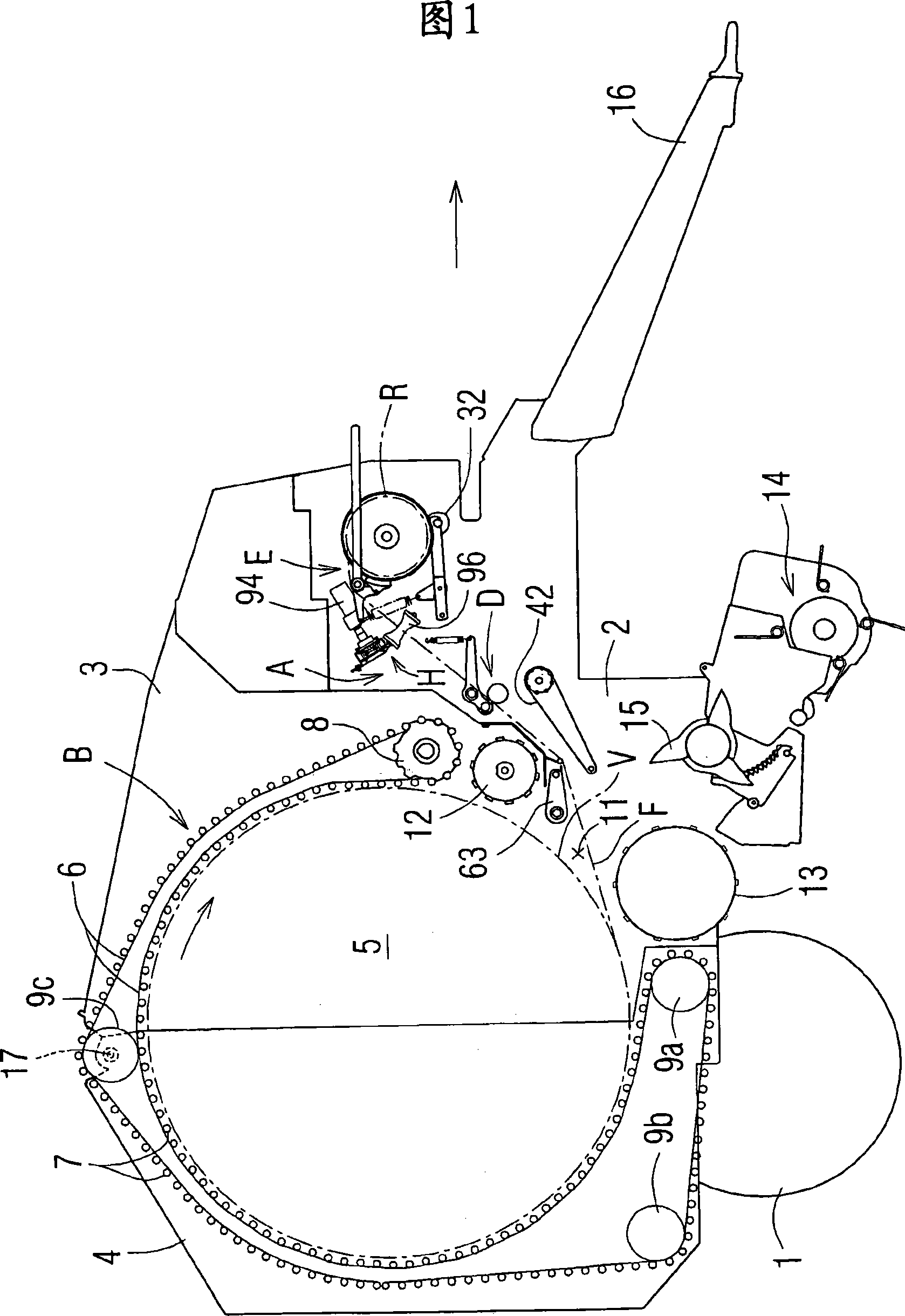

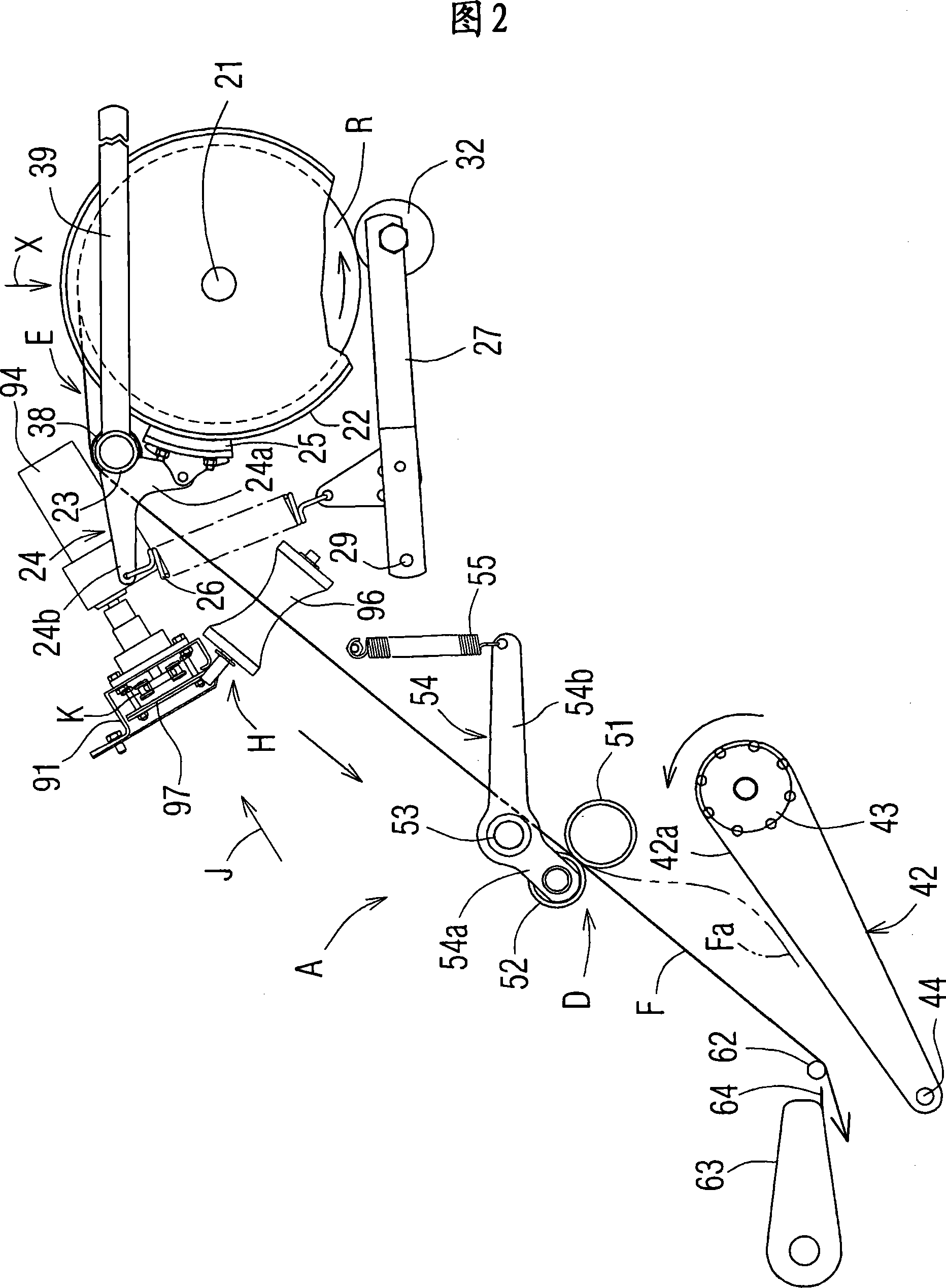

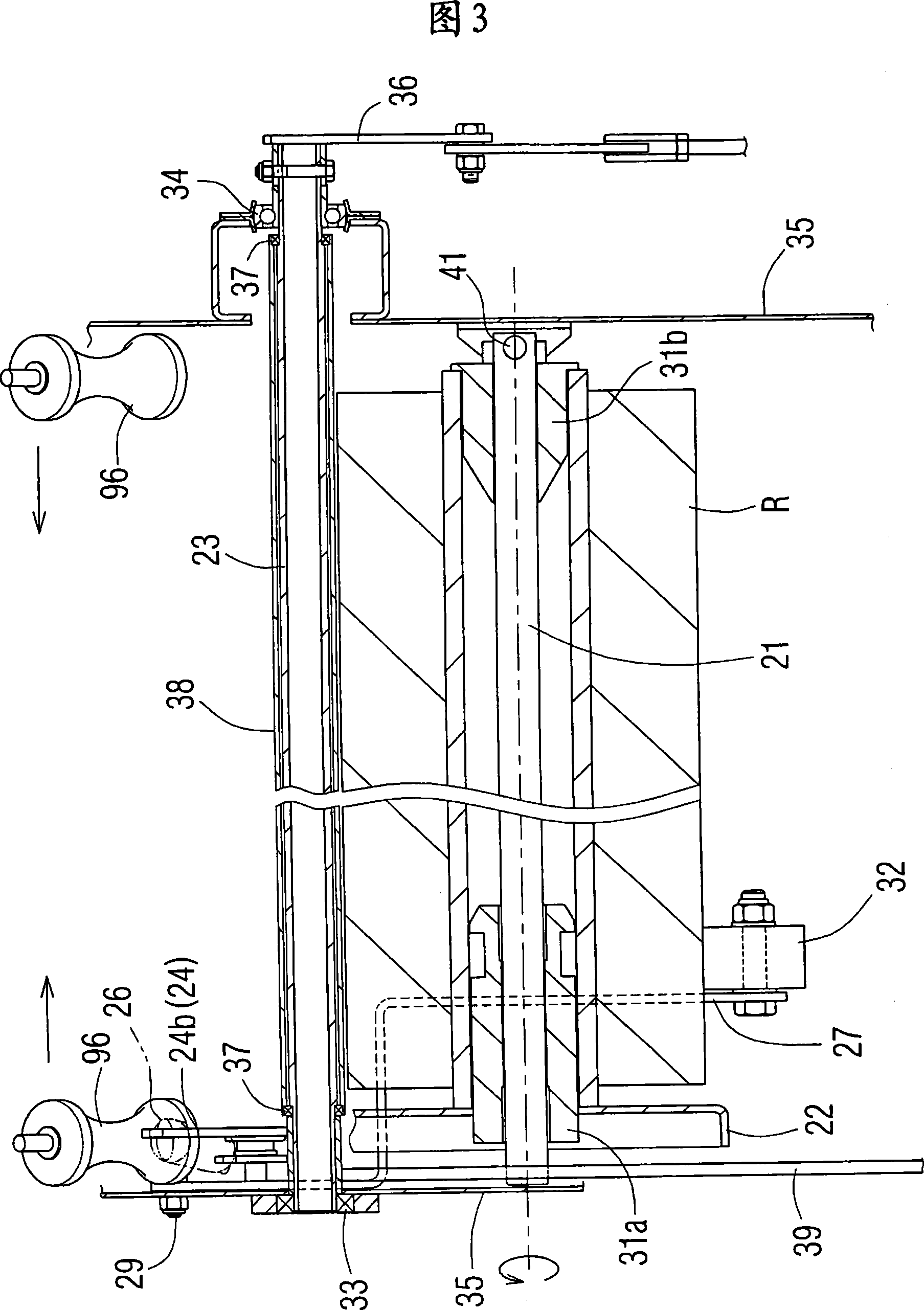

[0176] Hereinafter, the present invention will be explained in more detail by listing preferred embodiments. First, referring to FIGS. 1 to 4, the film discharge device A of the present invention will be described. Fig. 1 is an overall view of a roll bundle provided with a film discharge device A of the present invention. Fig. 2 is an enlarged view of the film discharge device A. 3 is a cross-sectional view taken along the line X of FIG. 2 (a top cross-sectional view of the roll film drum device E). 4 is a partial perspective view of the brake shoe 25 side of the roll film drum device E. In the description of the film discharging device A, the same or equivalent parts as the existing net discharging device A" use the same reference numerals and refer to the above description, and only the parts specific to the film discharging device A of the present invention are used. A detailed description will be given. First, the overall general structure of the winder will be briefly describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com