Patents

Literature

37results about How to "Low processing environment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

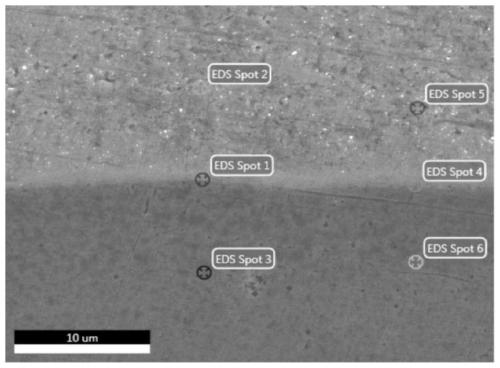

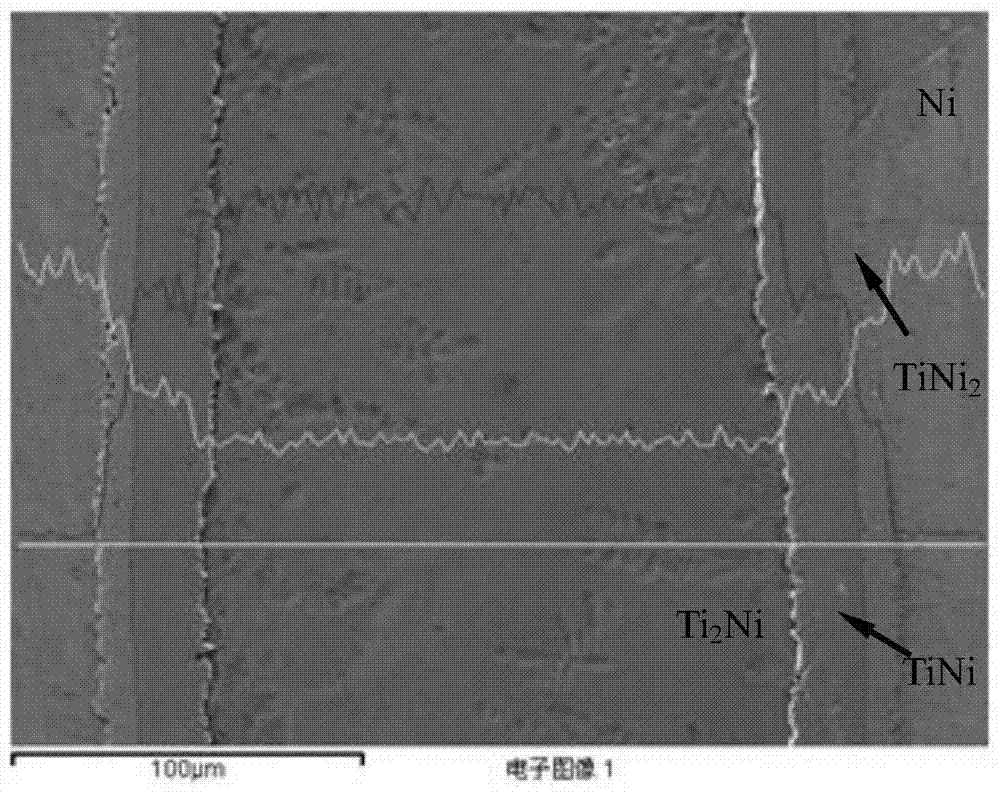

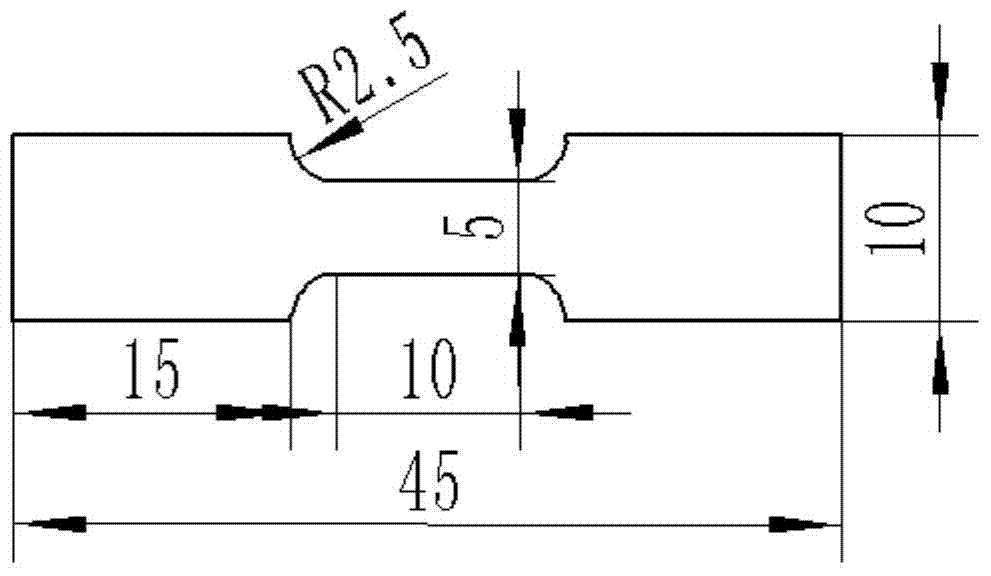

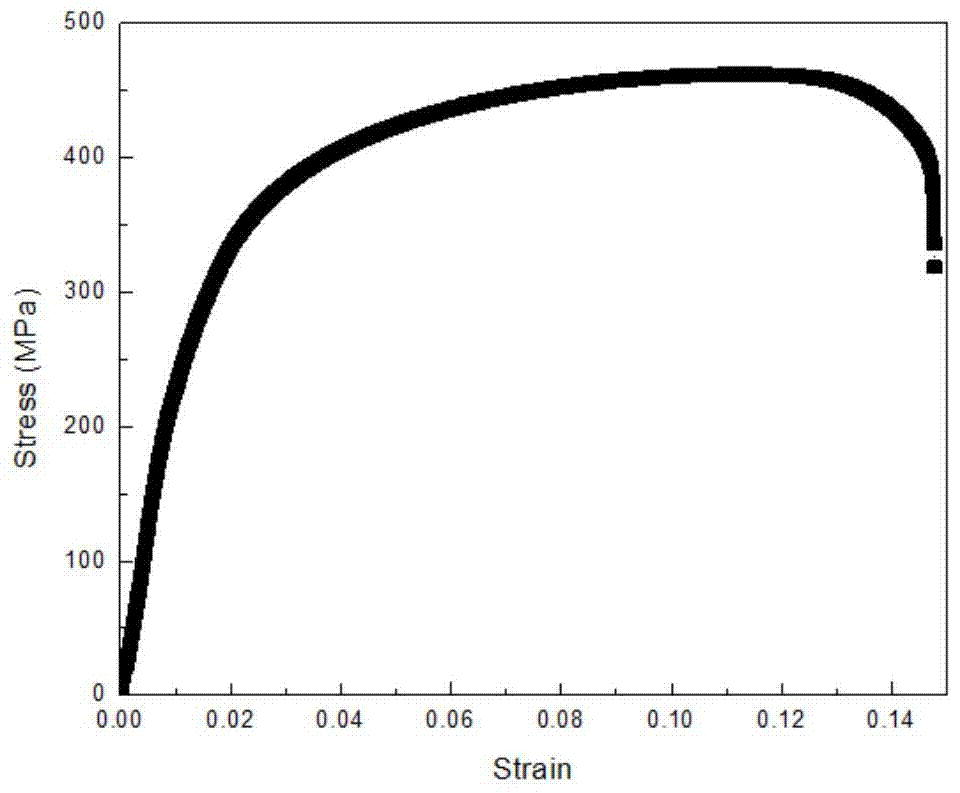

Layered Ti-Ni shape memory composite material and preparation method thereof

ActiveCN105058914AHigh specific strengthImprove toughness and plasticityMetal rolling arrangementsMetal layered productsBiocompatibility TestingTitanium

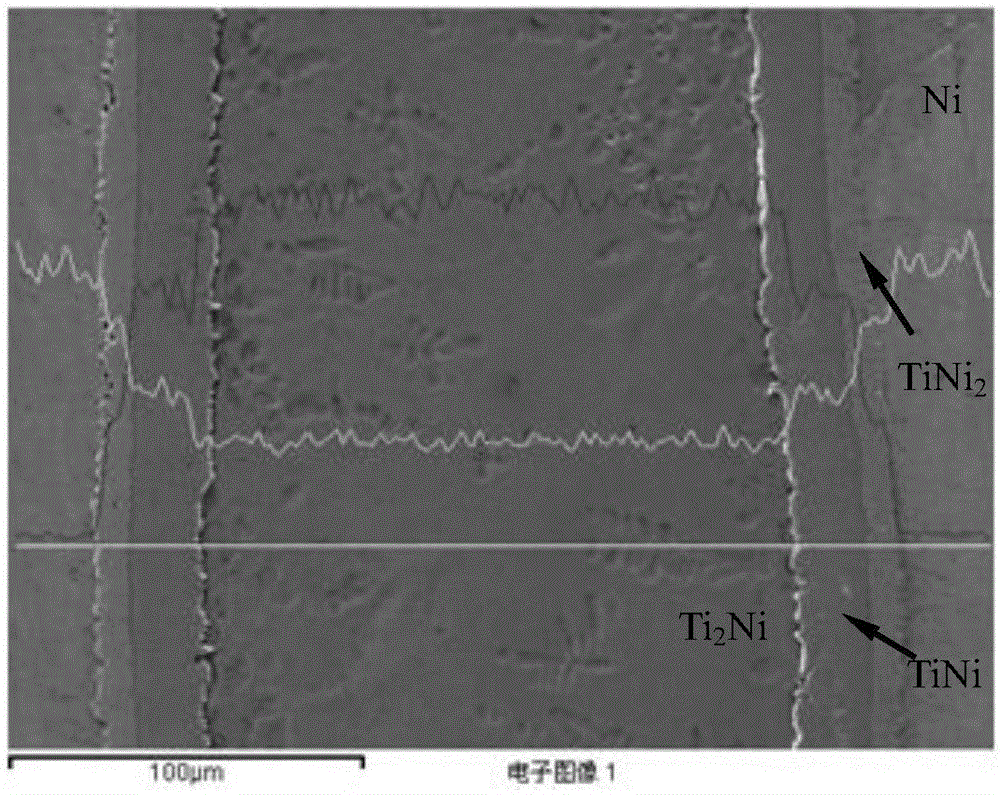

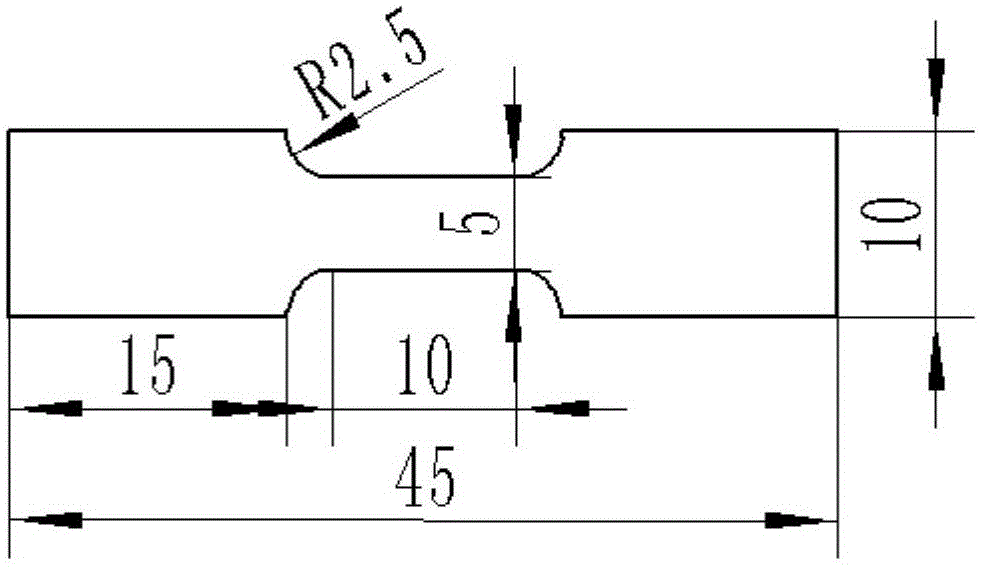

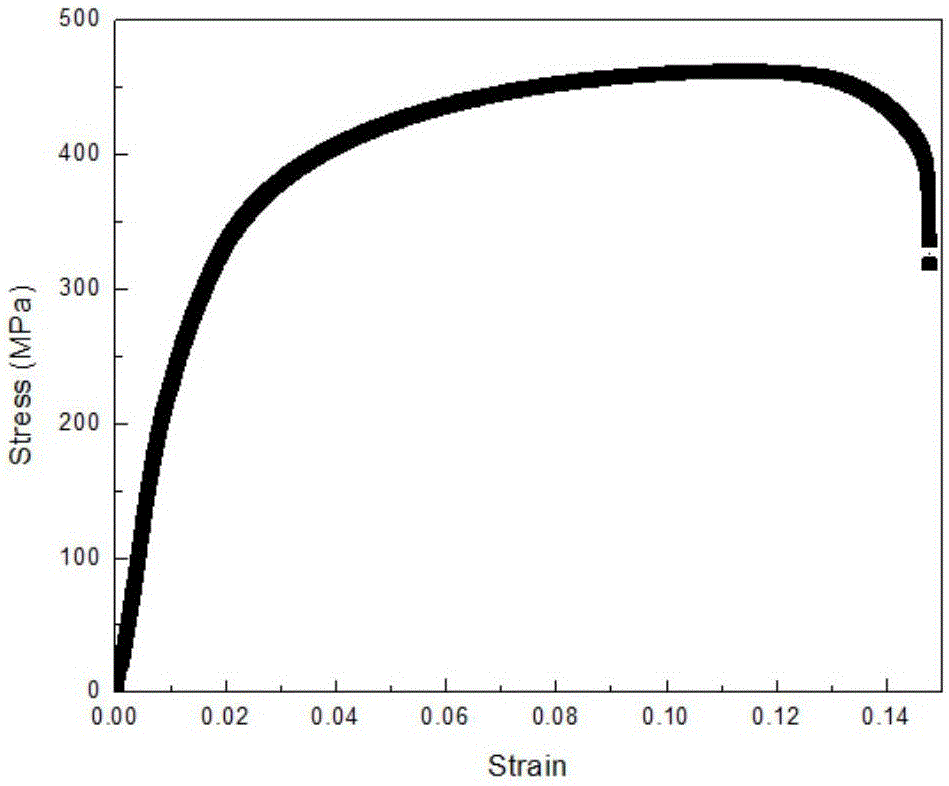

The invention discloses a layered Ti-Ni shape memory composite material and a preparation method thereof and belongs to the technical field of preparation of functional composite materials. Pure titanium and pure nickel are used as initial raw materials, a titanium plate and a nickel plate are subjected to surface pretreatment, accumulative composite rolling and diffusion annealing, controlled cooling is adopted, and the multi-phase and multi-layer structure shape memory composite material with a Ti layer serving as the outmost layer and a Ti-Ni layer and an Ni layer coated with the Ti layer is prepared. The shape memory composite material prepared with the method has the characteristics that the material is high in specific strength, good in plasticity and toughness, high in fatigue strength, high in interface bonding, excellent in conductivity, free of magnesium and toxicity, high in corrosion resistance, good in biocompatibility and the like. The preparation method has the advantages of simple process and convenience in operation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

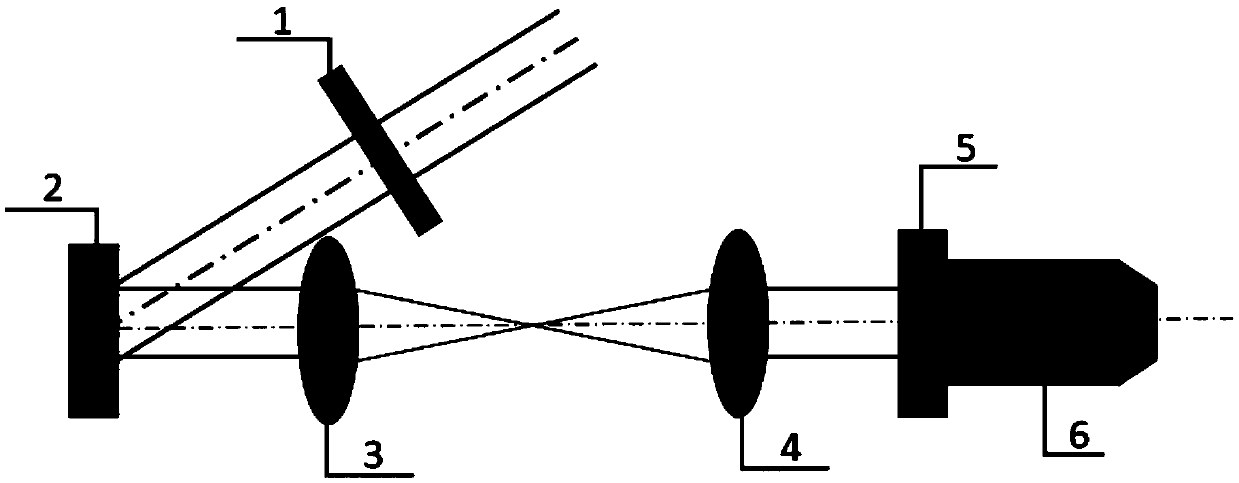

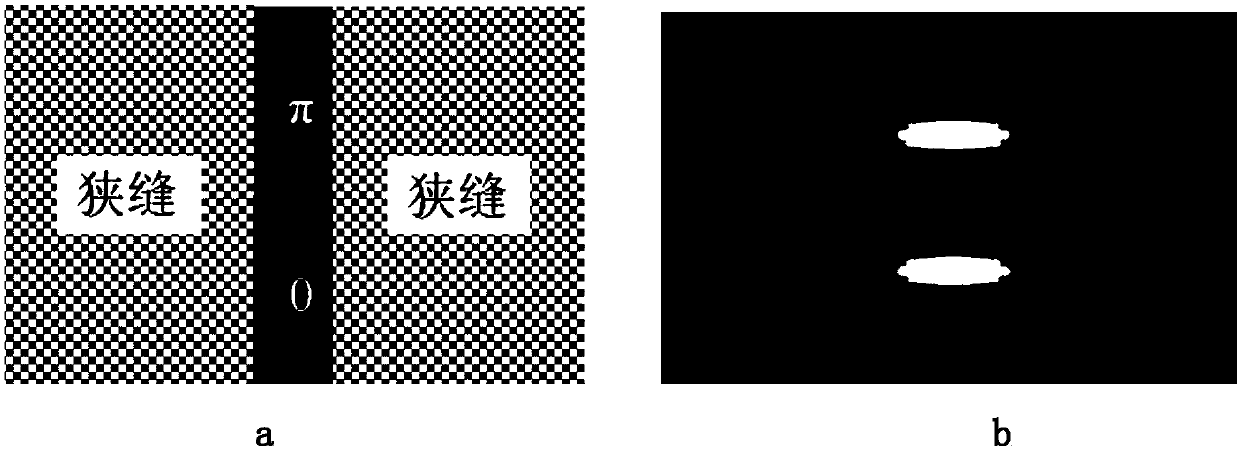

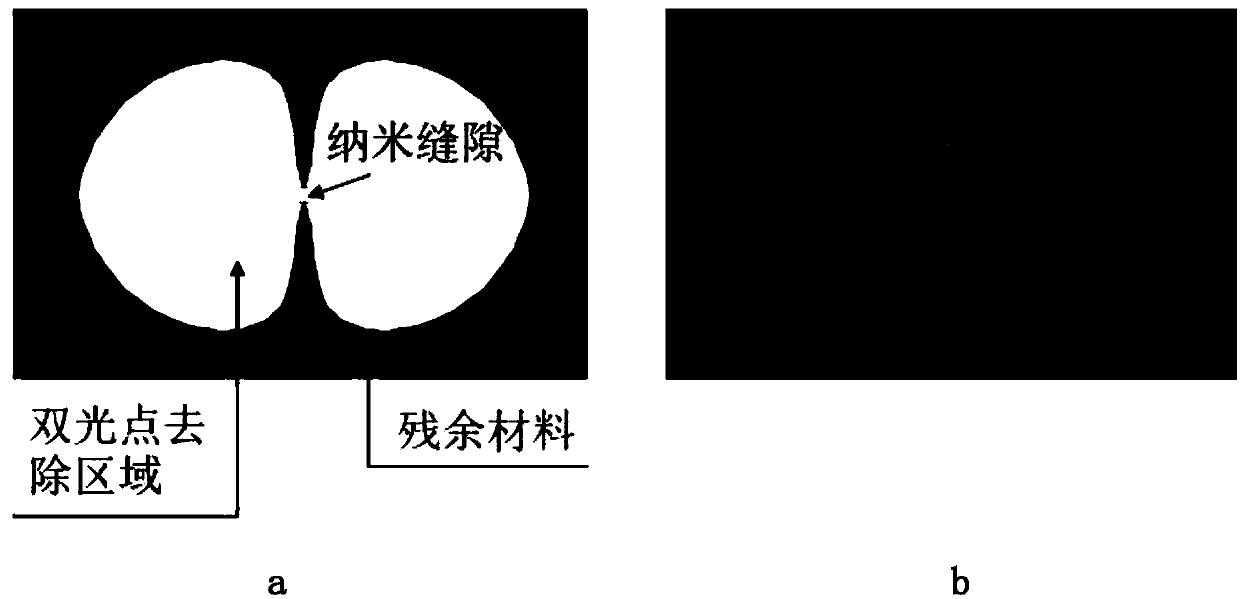

Method for machining butterfly-shaped nanometer gap through coordinative shaping of femtosecond laser phase position amplitude

ActiveCN109590606AAchieve removalReduce widthLaser beam welding apparatusPoint lightMaterial removal

The invention relates to a method for machining a butterfly-shaped nanometer gap through coordinative shaping of femtosecond laser phase position amplitude and belongs to the technical field of laserapplication. A reflecting type phase position type liquid crystal spatial light modulator can carry out phase position modulation on incident light, thus reflected light has designated phase positiondistribution on space, meanwhile, a narrow gap is utilized for carrying out amplitude shaping on light beams obtained after phase position shaping, and thus coordinative shaping of the phase positionand the amplitude of the initial light beams is achieved. The light beams obtained after coordinative shaping pass through a focusing objective lens to be focused, and multi-light-point light beams with different structure parameters are formed. The generated multi-light-point light beams are utilized for machining a designated material, material removal can be achieved in the area with strong light intensity, the material is kept in the area with the weak light intensity, and thus the butterfly-shaped nanometer gap can be obtained. According to the method, a light path needing to be set up issimple, use is convenient, a mask and vacuum environment are not needed, the machining cost is low, the machining efficiency is high, and the method plays an important role in the machining field oflaser micro nanometer structures.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

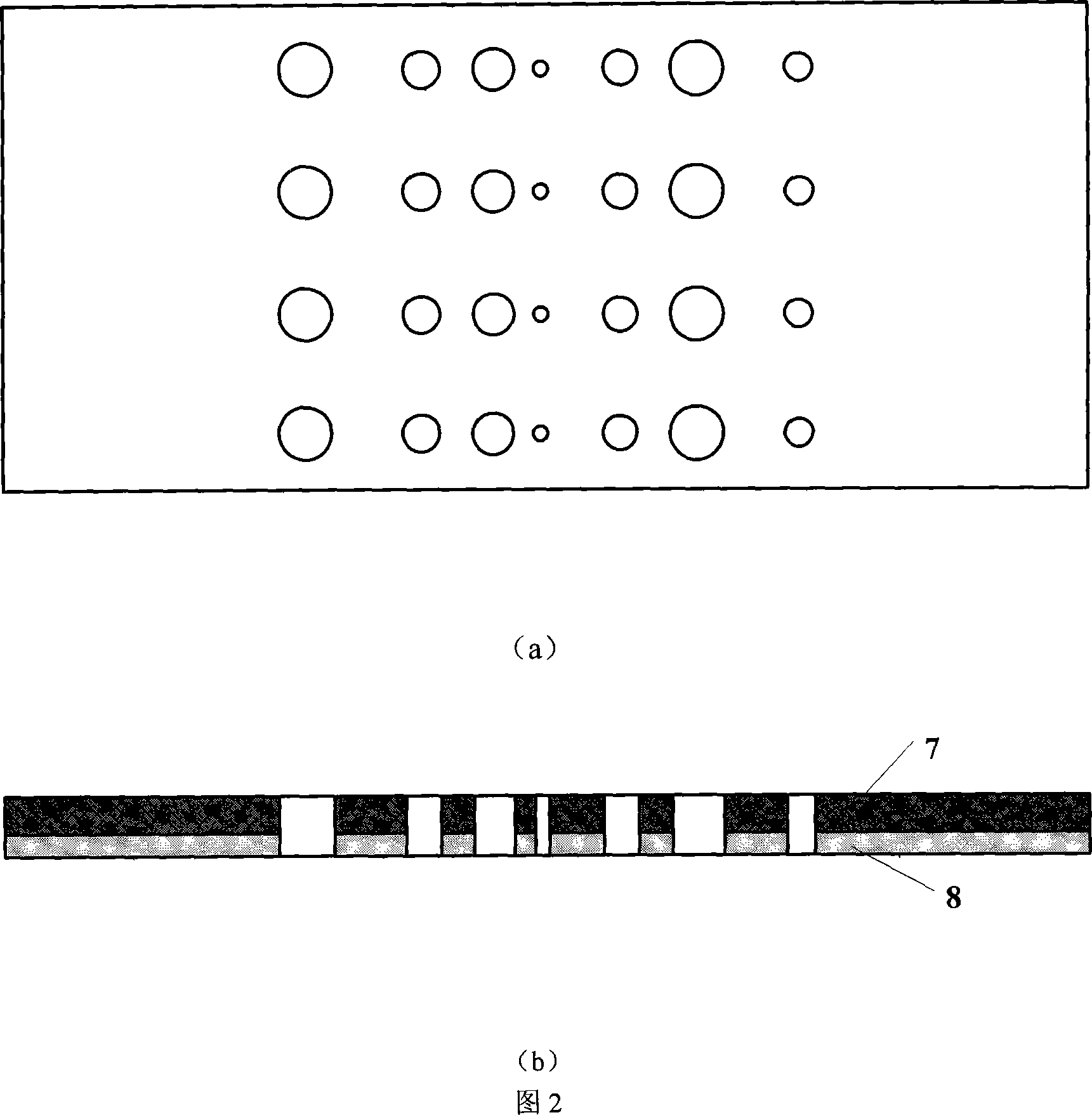

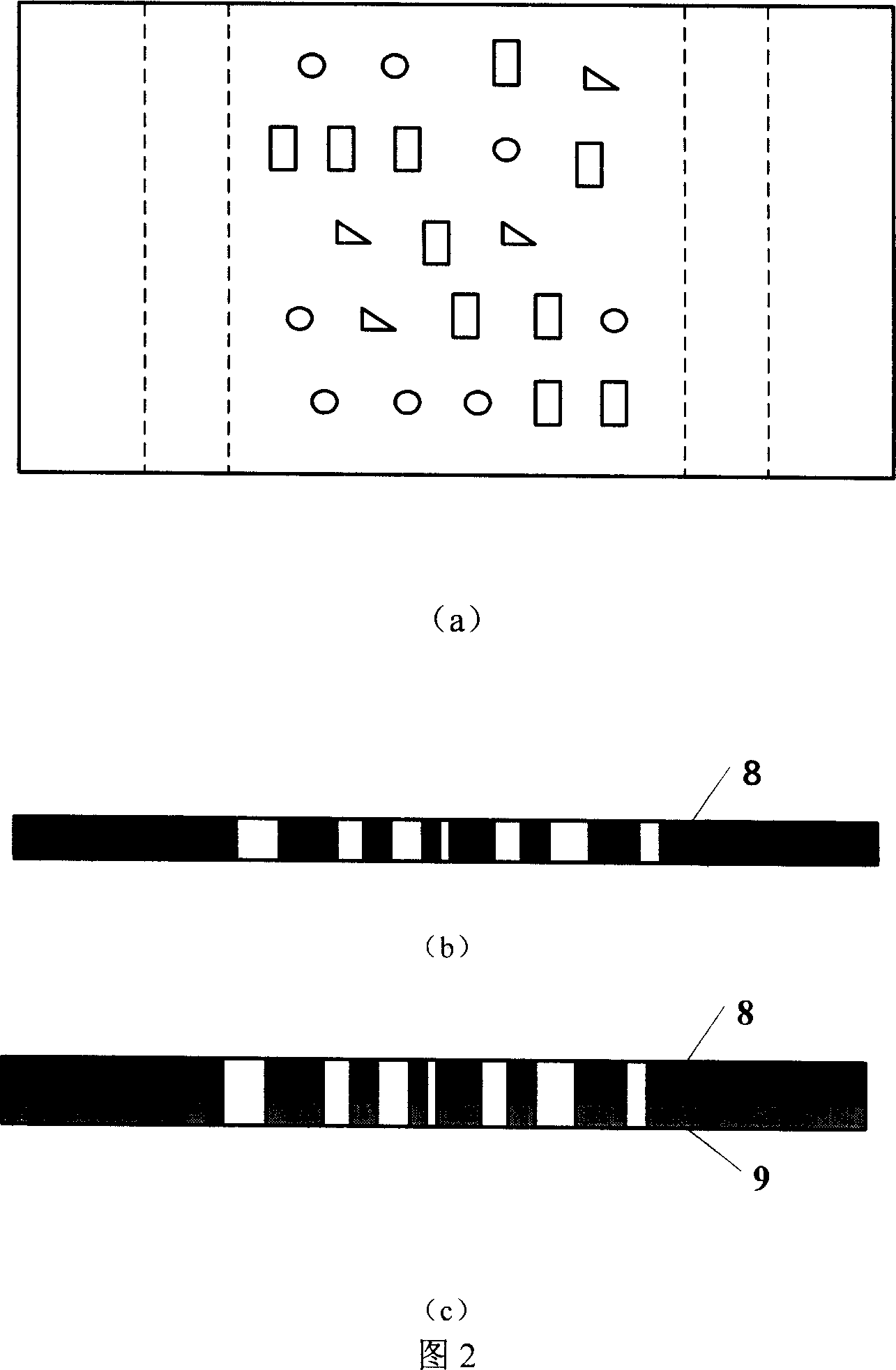

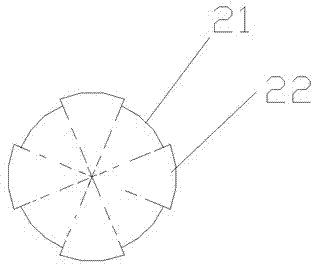

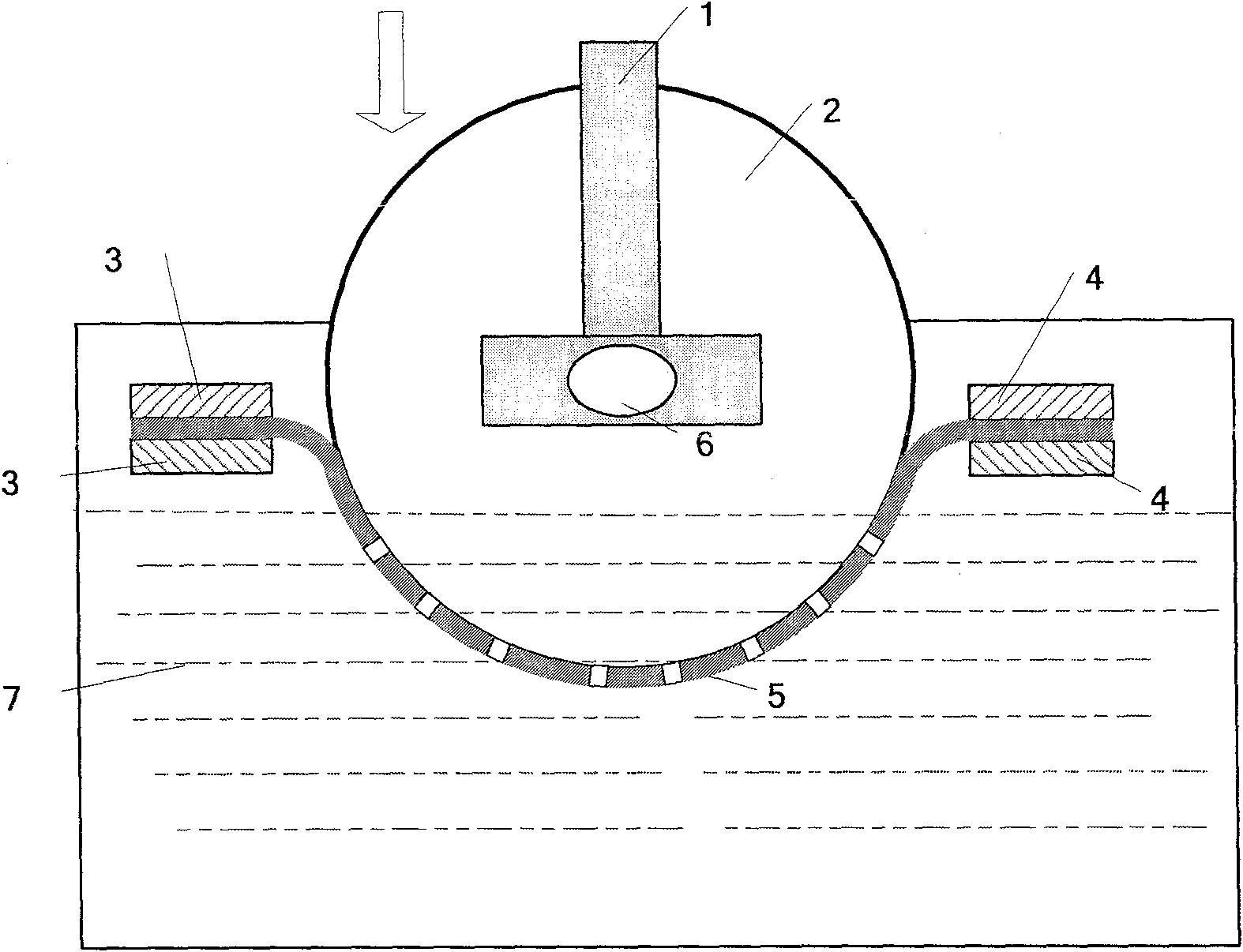

Column-shape revolving-body element external-surface micro-tissue electrolysic processing method

ActiveCN101070605AReduce processing costsImprove efficiencyElectrochemical machining apparatusElectrolysisMechanical engineering

The invention provides a method of electrochemical machining to minuteness texture of column aspect tumbling body part exteriority, which belongs to electrochemical machining domain. The characteristic of the method is that it adopts machinery extrusion method to closely fit column aspect tumbling body part and flexible screened film which has the structure of micro hiatus. Electrolyze with the part as anode, and minuteness texture will be formed in the exteriority of column aspect tumbling body part. Simultaneously if uses double layer flexible electrolytic screened film which contents insulating layer and metallic layer, its metallic layer can be directly utilized as the electrolysis cathode. If uses the electrochemical machining method of this invention, minuteness texture can be formed in the exteriority of column aspect tumbling body part. It has the characteristics of manufacture precision high, the speed quick and the cost low and so on.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

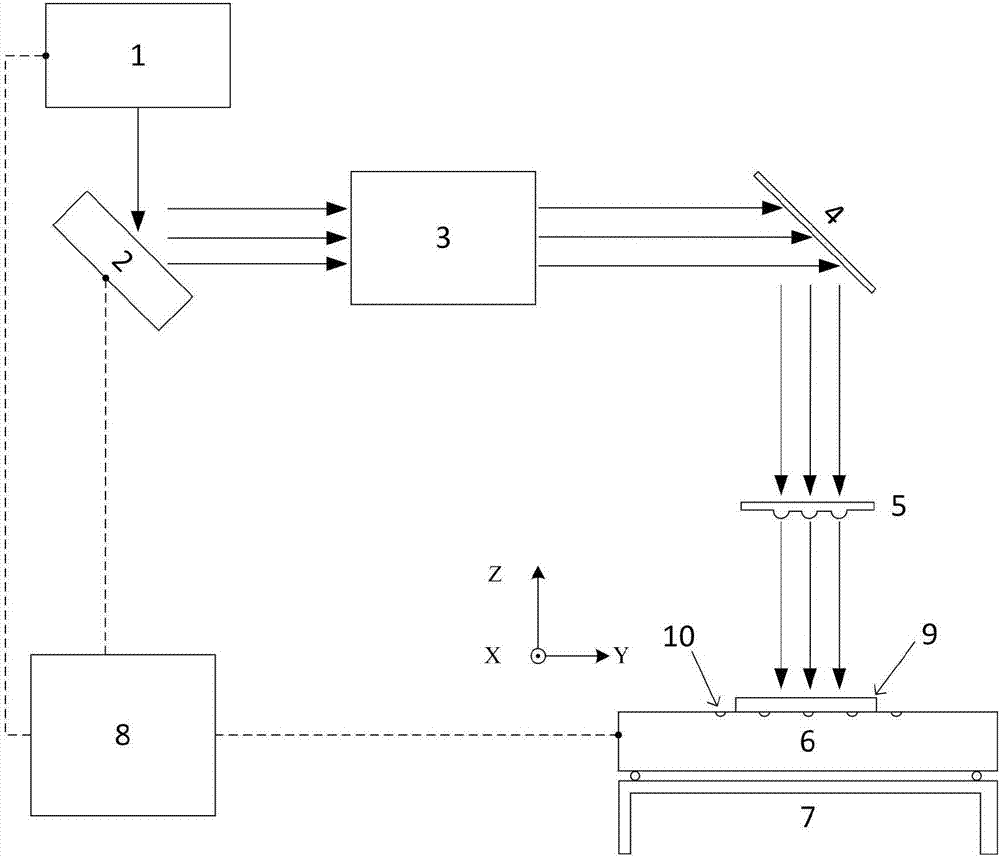

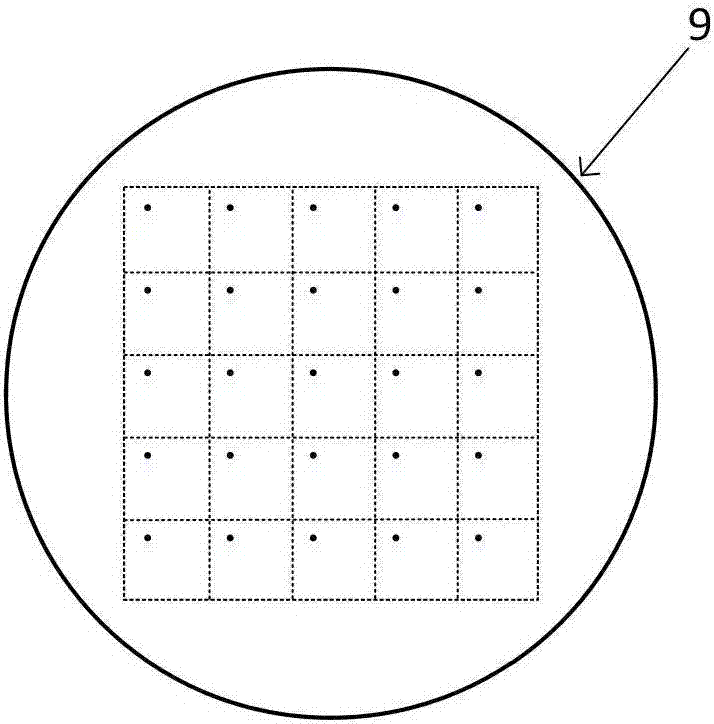

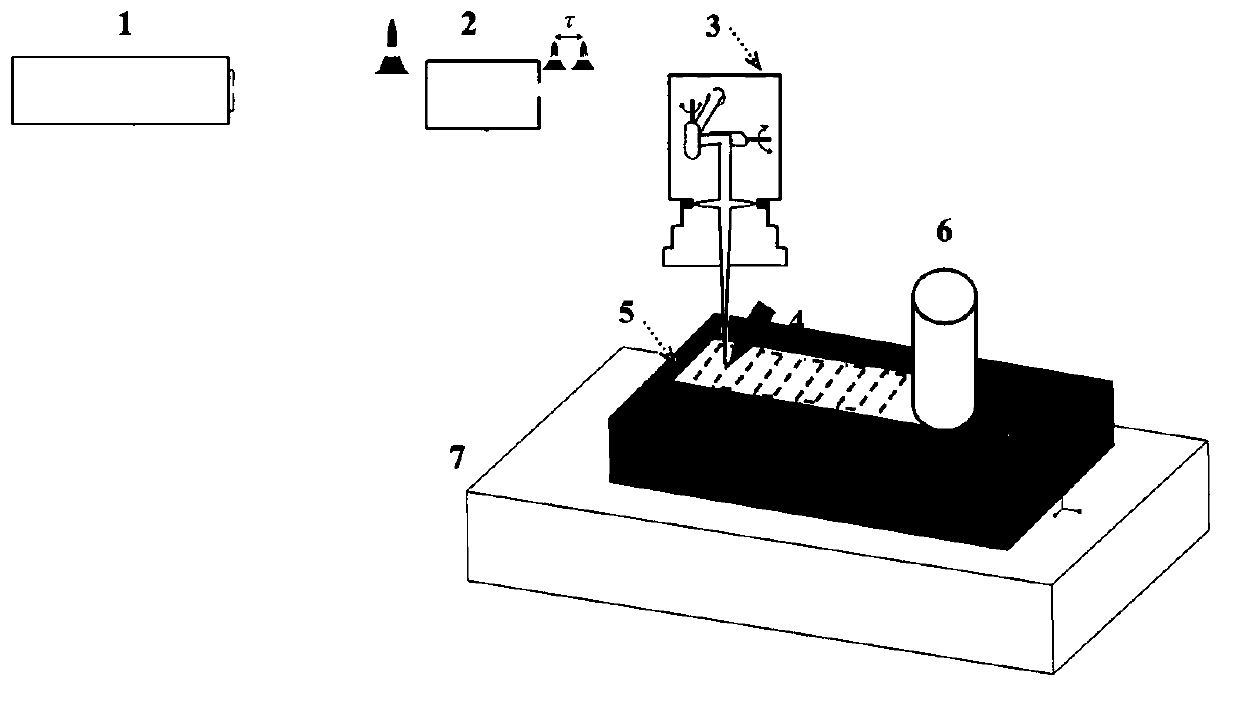

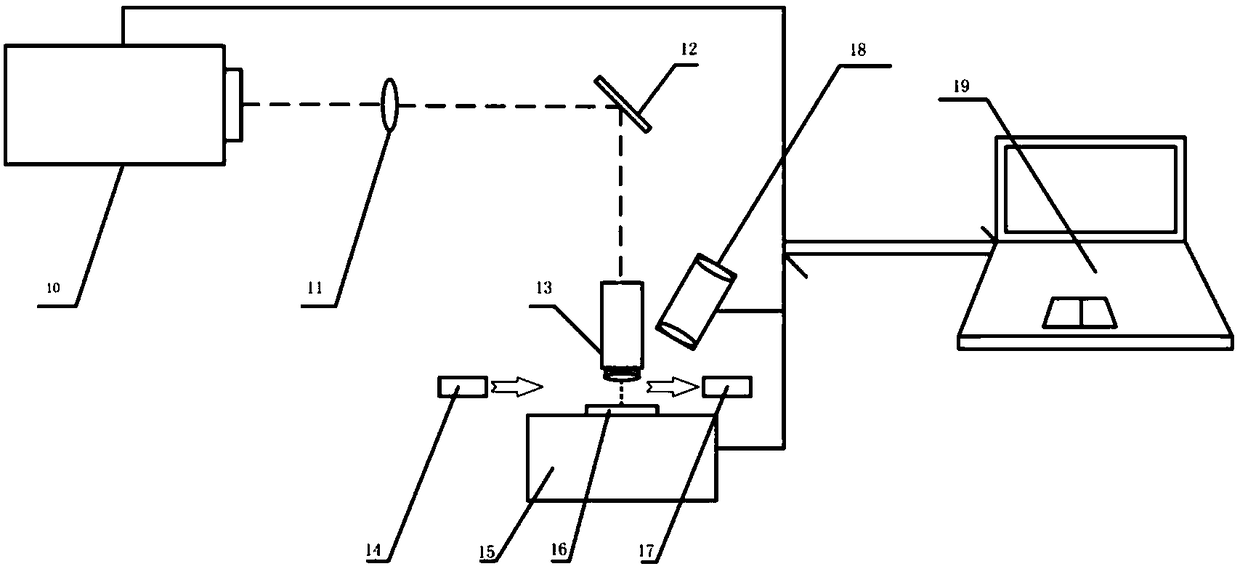

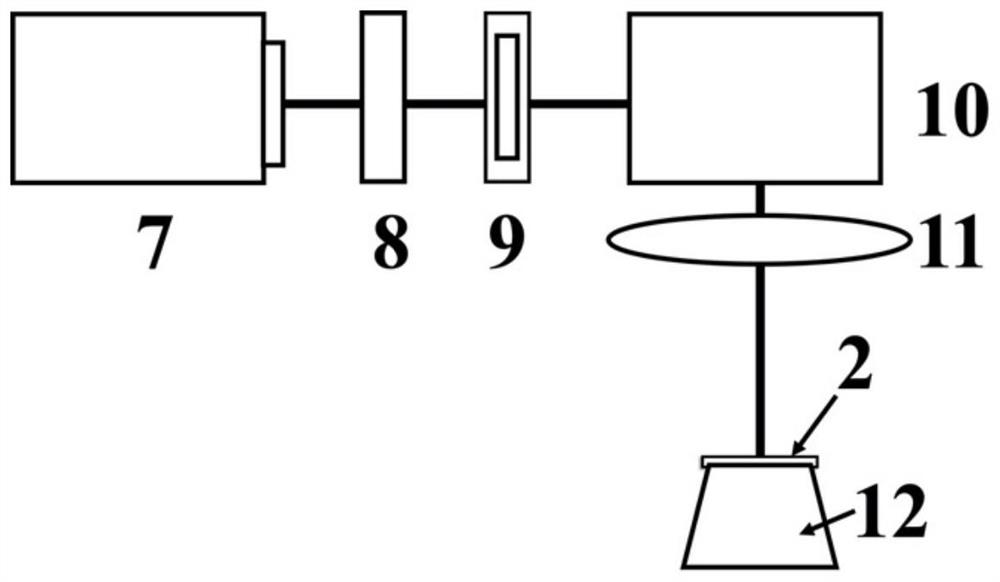

Ultrafast-laser optical chip array processing system and method

InactiveCN107199404AImprove processing efficiencyImprove quality consistencyLaser beam welding apparatusMicro nanoBeam expander

The invention discloses an ultrafast-laser optical chip array processing system and method, and belongs to the technical field of micro-nano processing of optical chips. The system comprises a laser light source, a spatial light modulator, a beam expander, a reflector, a micro-lens array and a six-dimensional working platform, and the system further comprises an air-floating platform and a central-control computer, wherein the central-control computer is connected with the laser light source, the spatial light modulator and the six-dimensional working platform and used for control of the whole system, and the air-floating platform is arranged under the six-dimensional working platform and used for bearing the six-dimensional working platform. According to the ultrafast-laser optical chip array processing system and method, a laser array processing method is adopted, dozens of optical chips can be obtained in one-time processing process, the processing efficiency is high, and quality consistency is good; in addition, the laser processing method is adopted, processing equipment is simple, the requirement on the processing environment is low, and therefore the production cost is greatly reduced.

Owner:HUBEI UNIV OF TECH

Electromoulding processing method for micro-structure on external surface of cylindrical revolving body element

InactiveCN101012568AReduce processing costsImprove efficiencyElectroforming processesMicro structureMetallic materials

The invention discloses a trace structural electric-cast manufacturing method on the external surface of column-shaped rotary bulk element in the electric cast manufacturing domain, which is characterized by the following: making flexible electric-cast screen film with micro-hole structure; attaching column-shaped rotary bulk element and flexible electric-cast screen film through mechanic squeezing pattern; casting element as cathode; forming trace projecting structure on the external surface of column-shaped rotary bulk element; making electric-cast screen film through insulating material; adding a layer of electrochemical insoluble metal material (platinum or titanium) to make the insulating material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for processing aluminum alloy cap

InactiveCN103522020AReduce processing burdenGuaranteed connection qualityThread cutting machinesClosure capsMetallurgyMaterials science

Disclosed is a method for processing an aluminum alloy cap. The method includes a vertical rib processing step and an inner thread processing step. The vertical rib processing step includes extruding an extruding head into a cap blank slowly from the opening of the cap blank, accordingly extruding a concave part and a convex part on the inner side of the cylindrical side wall of the cap blank, and acquiring the cap blank with the concave part and the convex part. The inner thread processing step includes assembling an executing component on the inner side of the cylindrical side wall of the cap blank with the concave part and the convex part, starting a hydraulic lifting device and a rotary motor, forming a thread on the convex part accordingly, and obtaining the aluminum alloy cap.

Owner:青岛亚华制盖有限公司

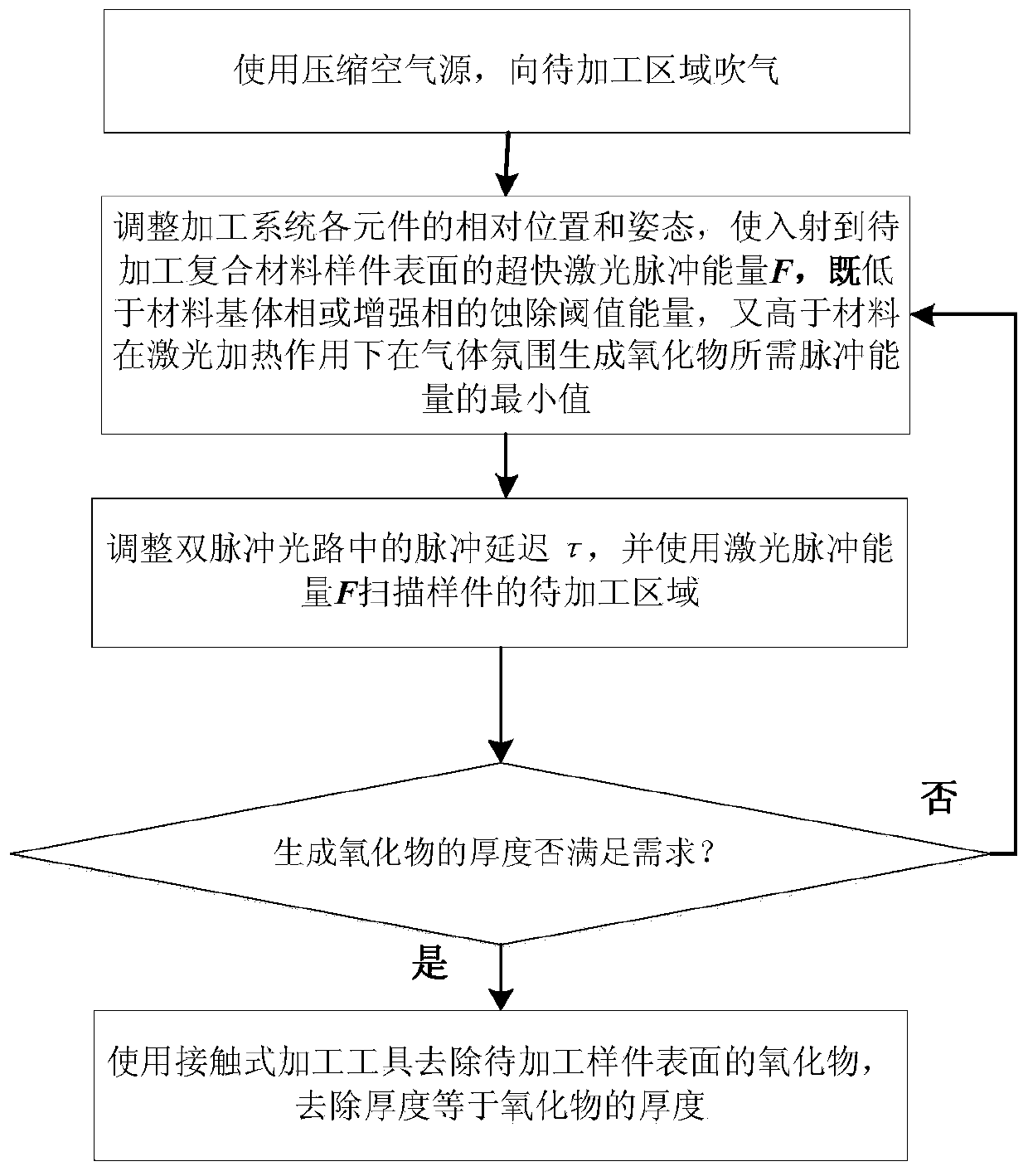

Efficient and precise machining method for composite material

ActiveCN111037101AReduce wearImprove continuous processing abilityOther manufacturing equipments/toolsLaser beam welding apparatusMachinabilityHeat effect

The invention discloses an efficient and precise machining method for a composite material. The thickness and the heated degree of a heated area of the composite material are regulated accurately through time domain shaping ultrafast lasers; the thickness of easily-machined loose oxide generated in the manner that a matrix phase and a reinforced phase of the material are subjected to a chemical reaction through gas assisting under the heat effect is controlled; conditions are created for achieving precise machining by directly removing a loose oxide layer subsequently through cutting / grindingmachining; and machinability of the material is greatly improved.

Owner:BEIJING SATELLITE MFG FACTORY

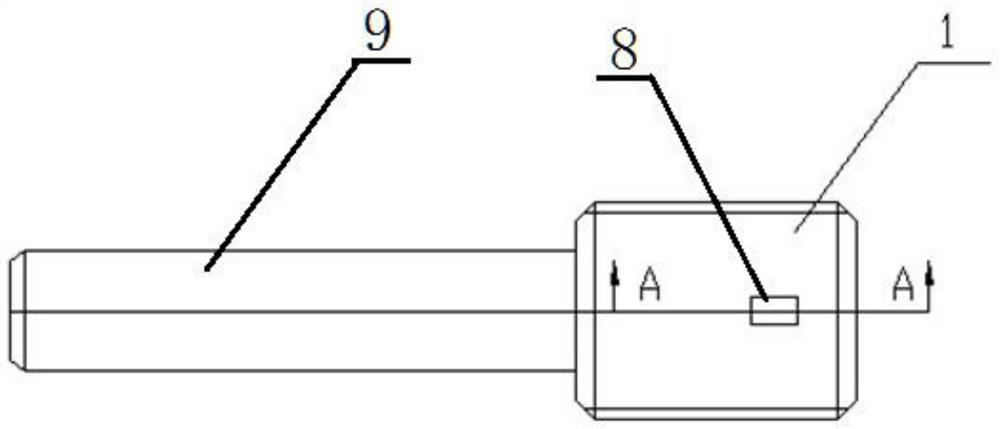

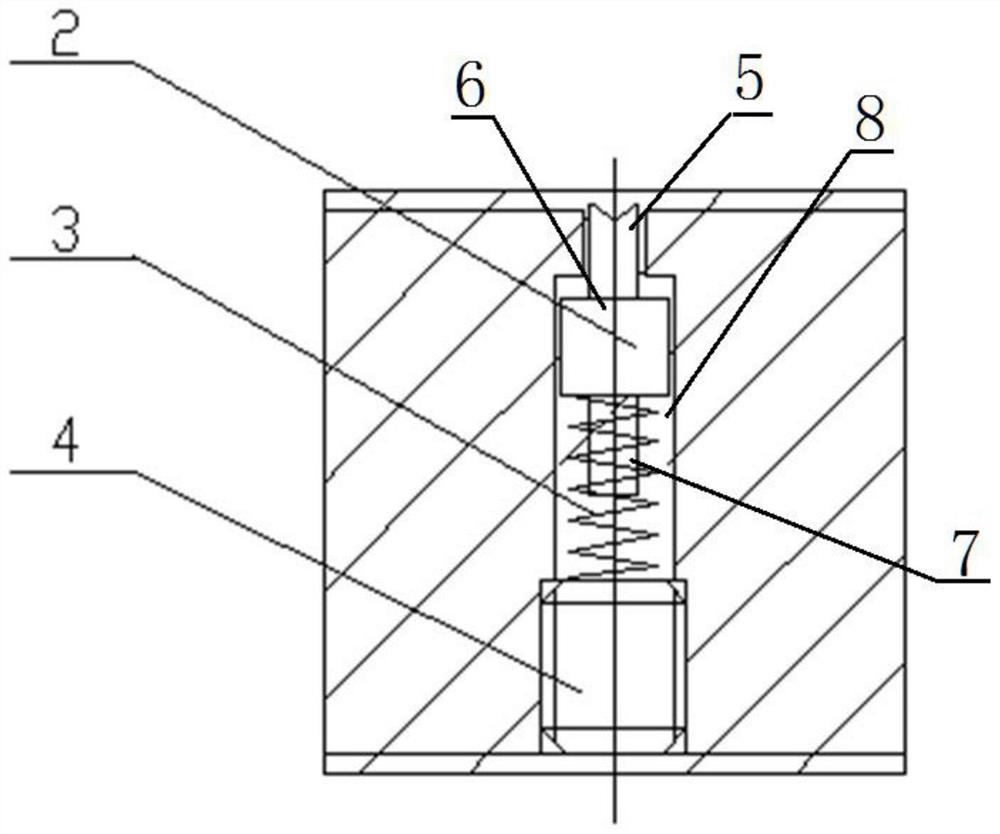

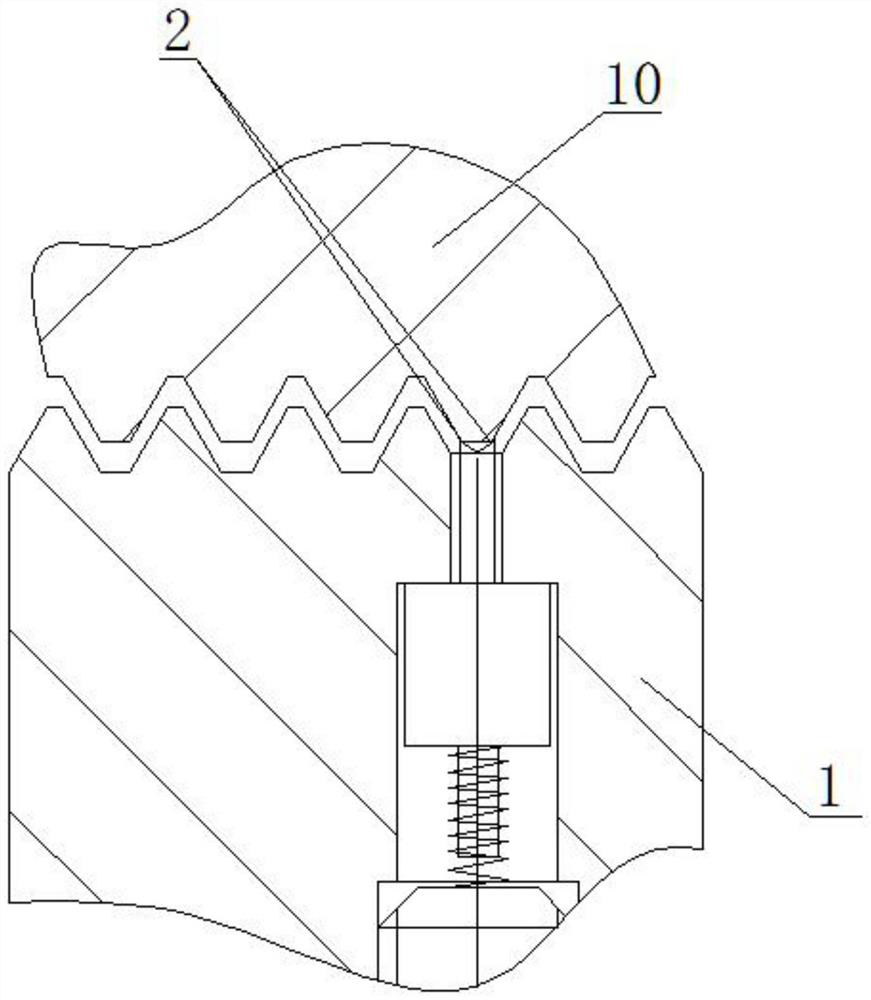

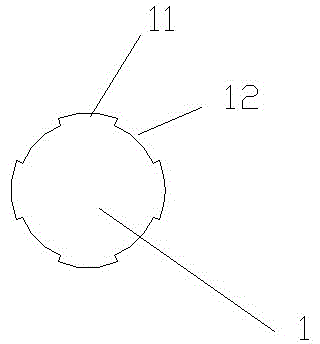

Adjustable internal thread deburring device

PendingCN114083066ANot easy to scratchSolve the problem that the stuck can not be taken outEngineeringCutting force

The invention discloses an adjustable internal thread deburring device which comprises a screw rod (1) and is characterized in that a mounting groove (8) is formed in the bottom of the screw rod (1), a guide blade (2) is arranged in the mounting groove (8), the guide blade (2) is connected with a spring (3), and the other end of the spring (3) is connected with a plug (4). The device has low requirements on machining environments such as the appearance and the thread position of a machined workpiece, and the process operability is high; the use is convenient, the thread is not easy to scratch, and smooth transition between thread forms is realized. The problem that parts such as screws cannot be taken out due to clamping stagnation of burrs after being screwed into internal threads is solved. And when internal threads with the same specification are machined, the influence of the diameter of a bottom hole of the internal threads is avoided, the cutting force of the adjustable plug and the spring on the guide blade is automatically adjusted, and the flexibility is high.

Owner:GUIZHOU HONGLIN MACHINERY

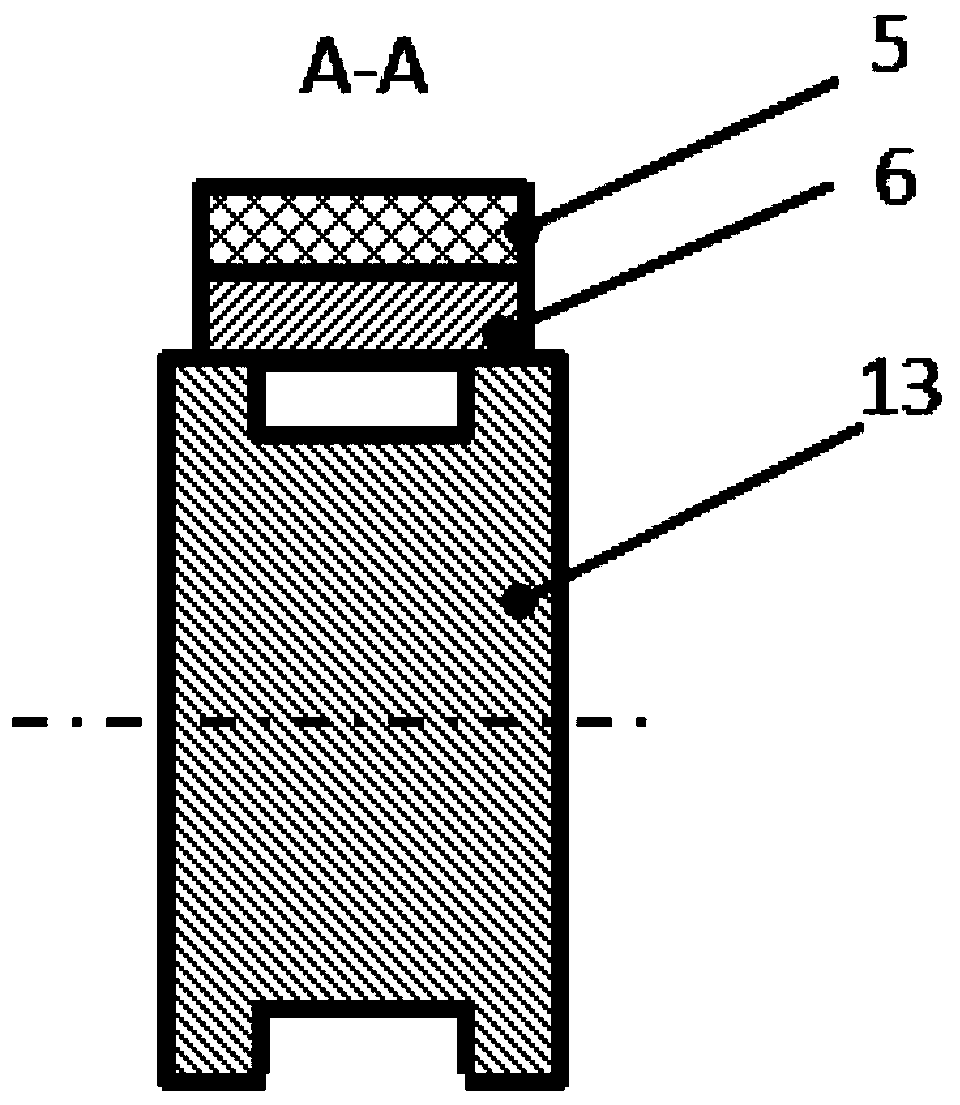

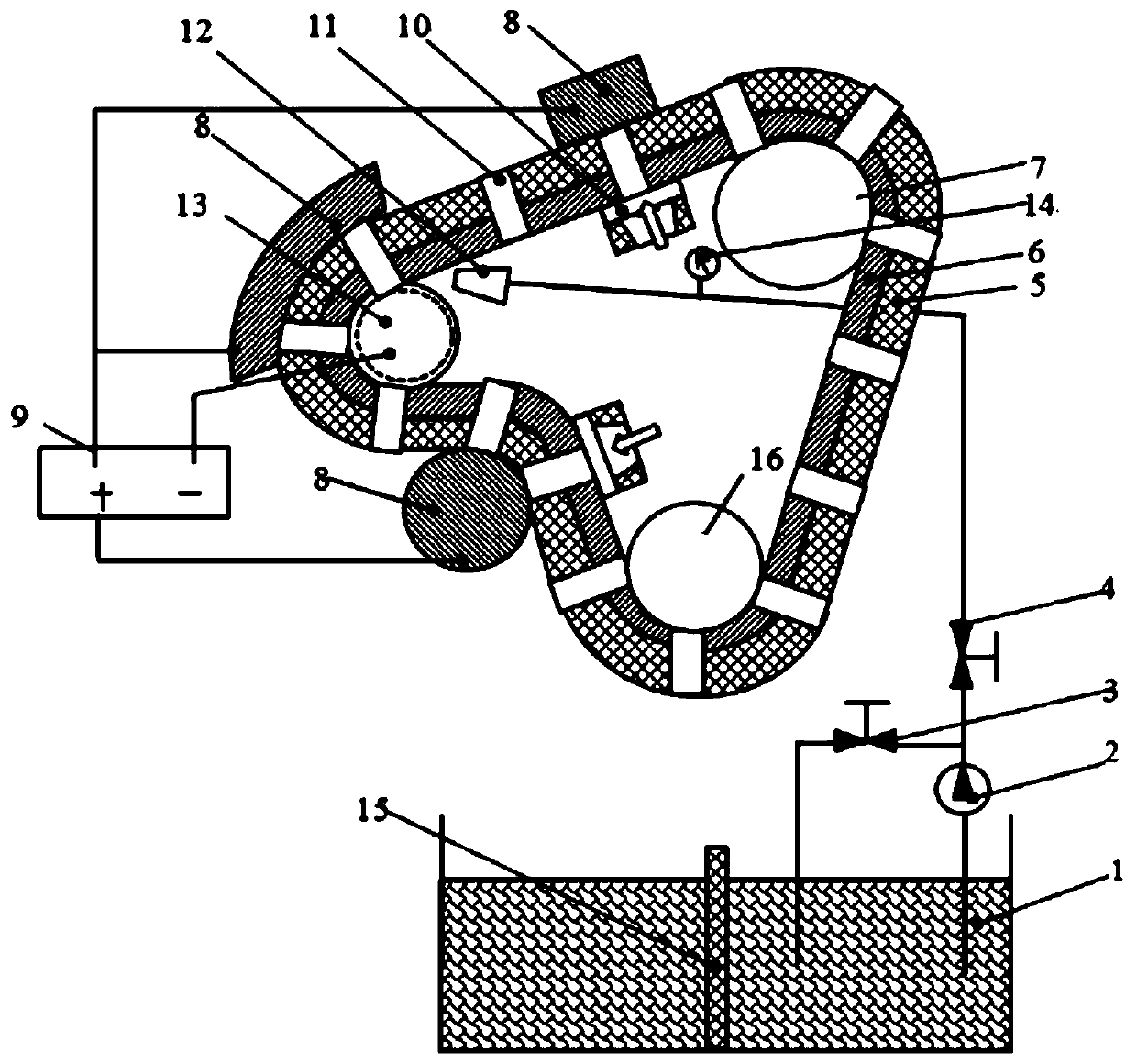

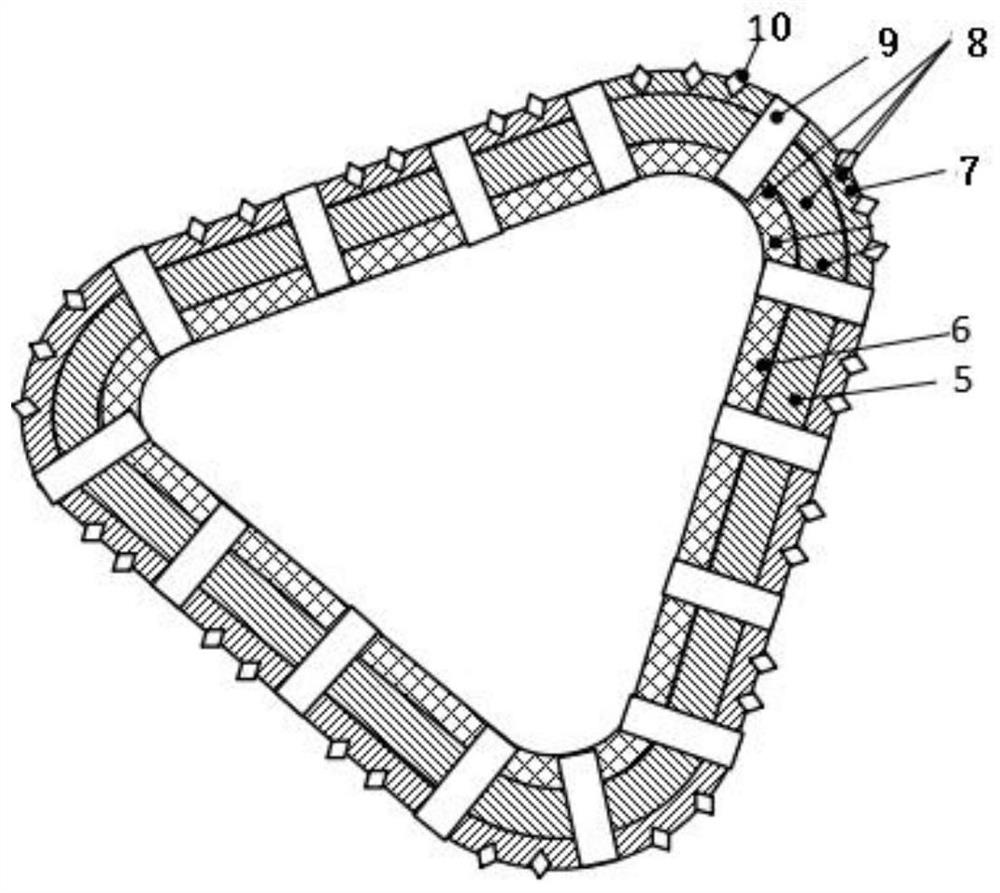

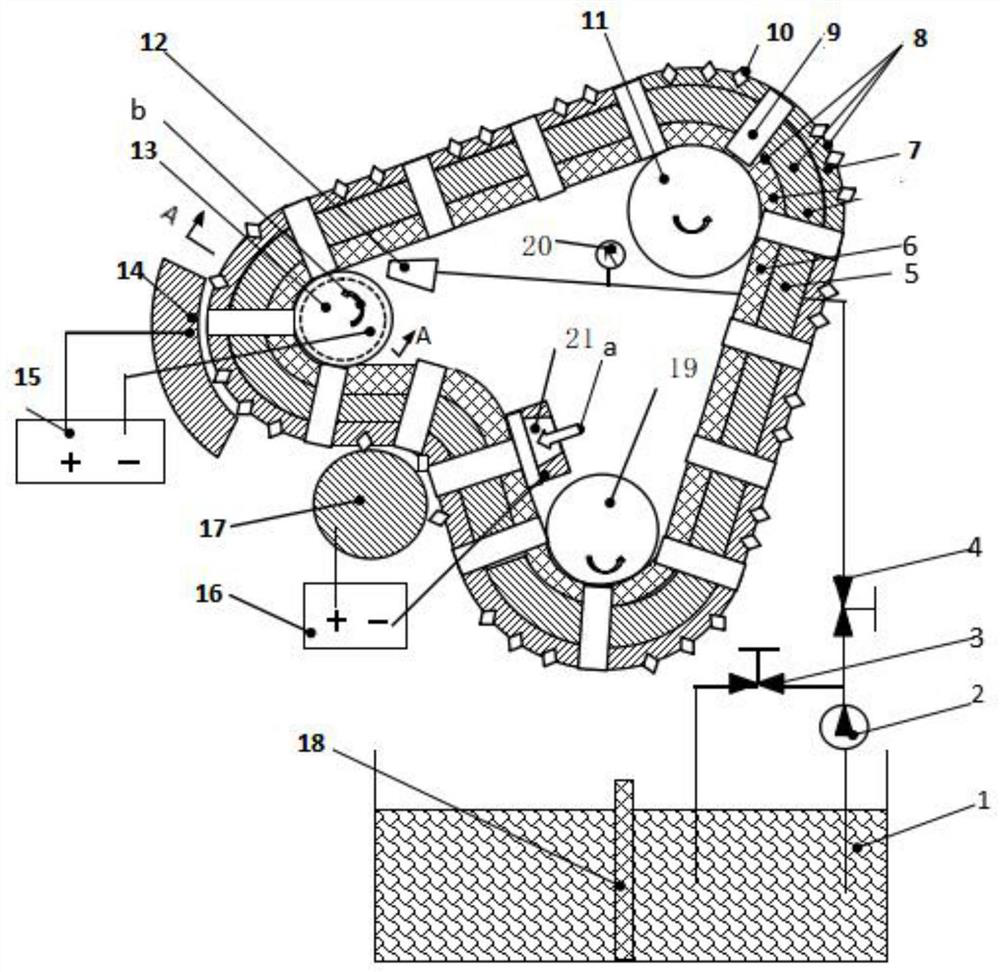

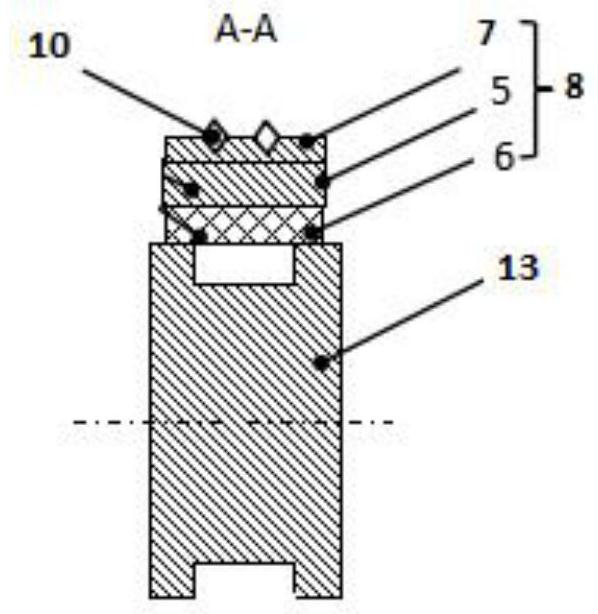

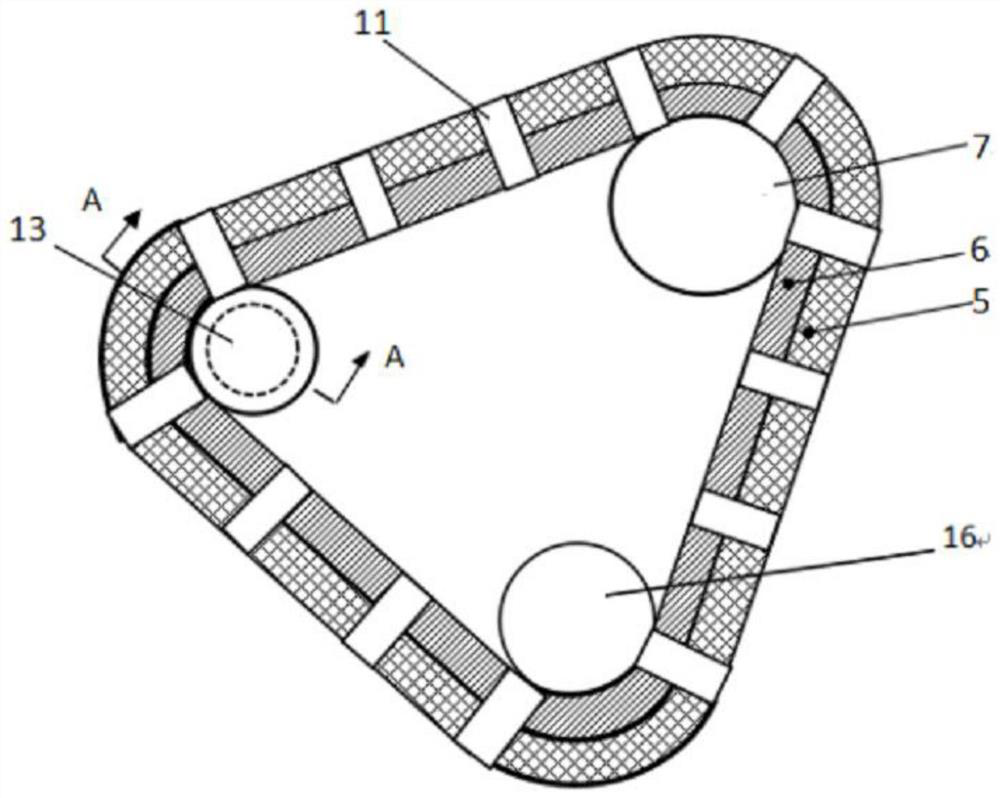

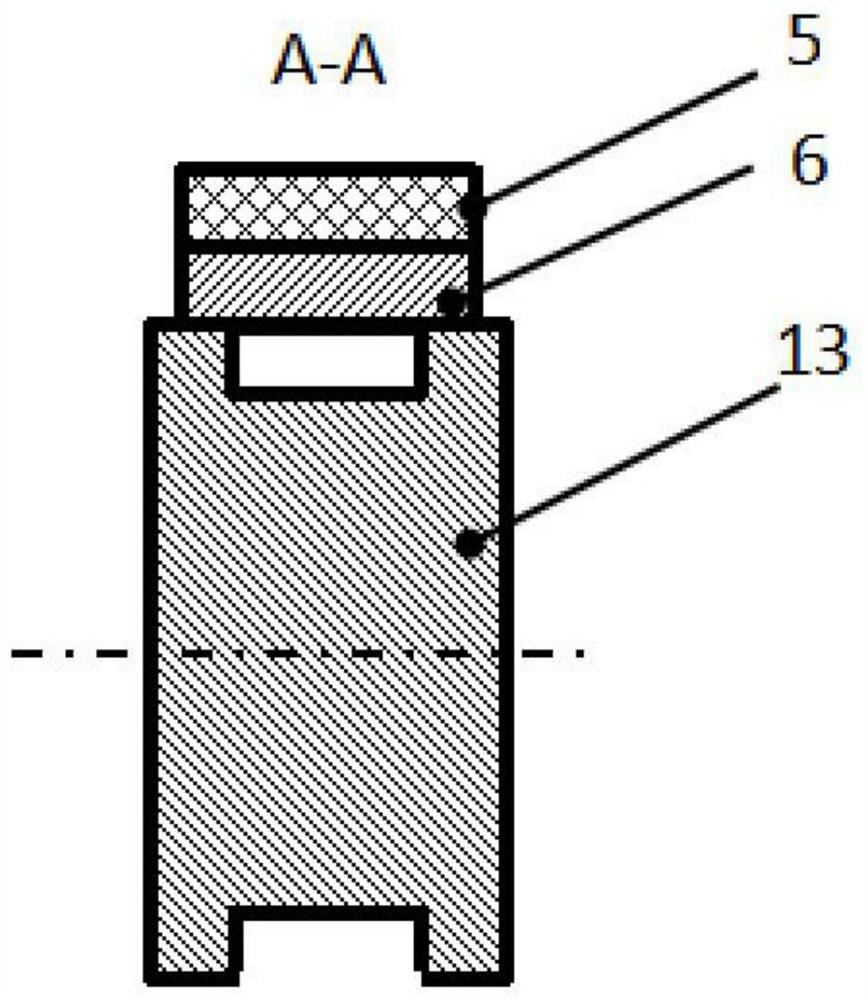

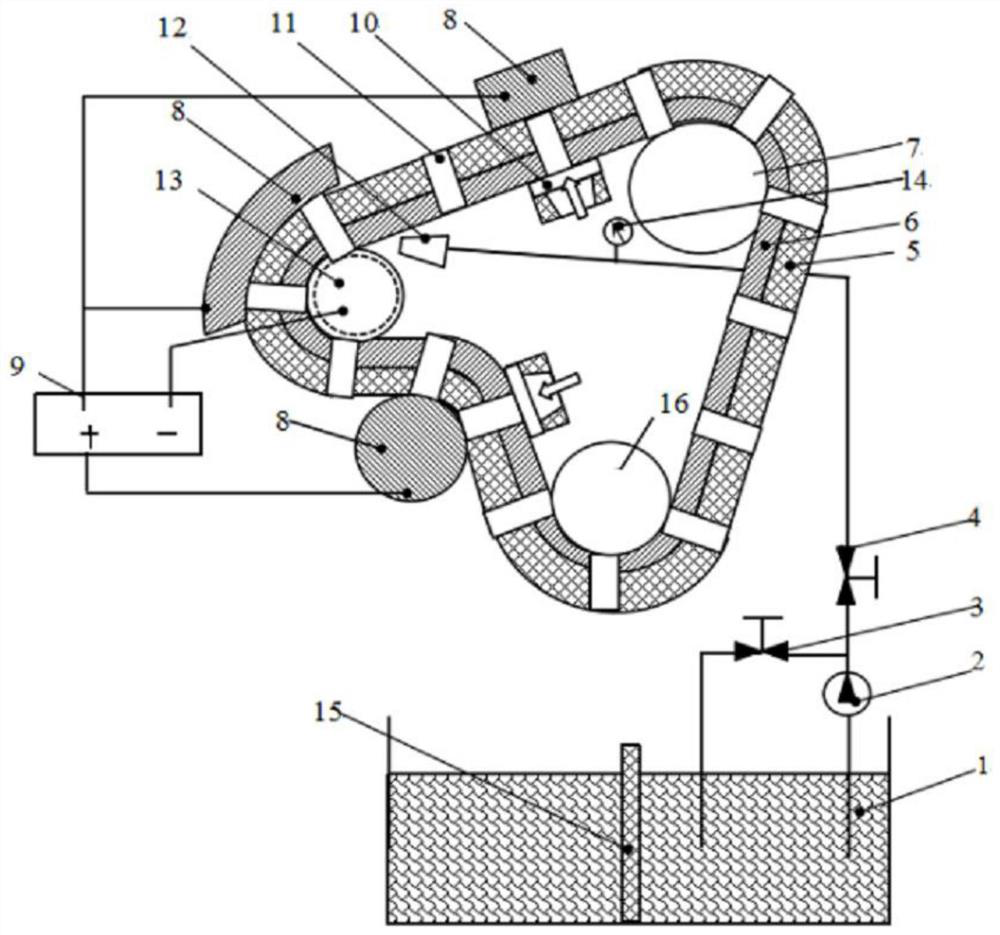

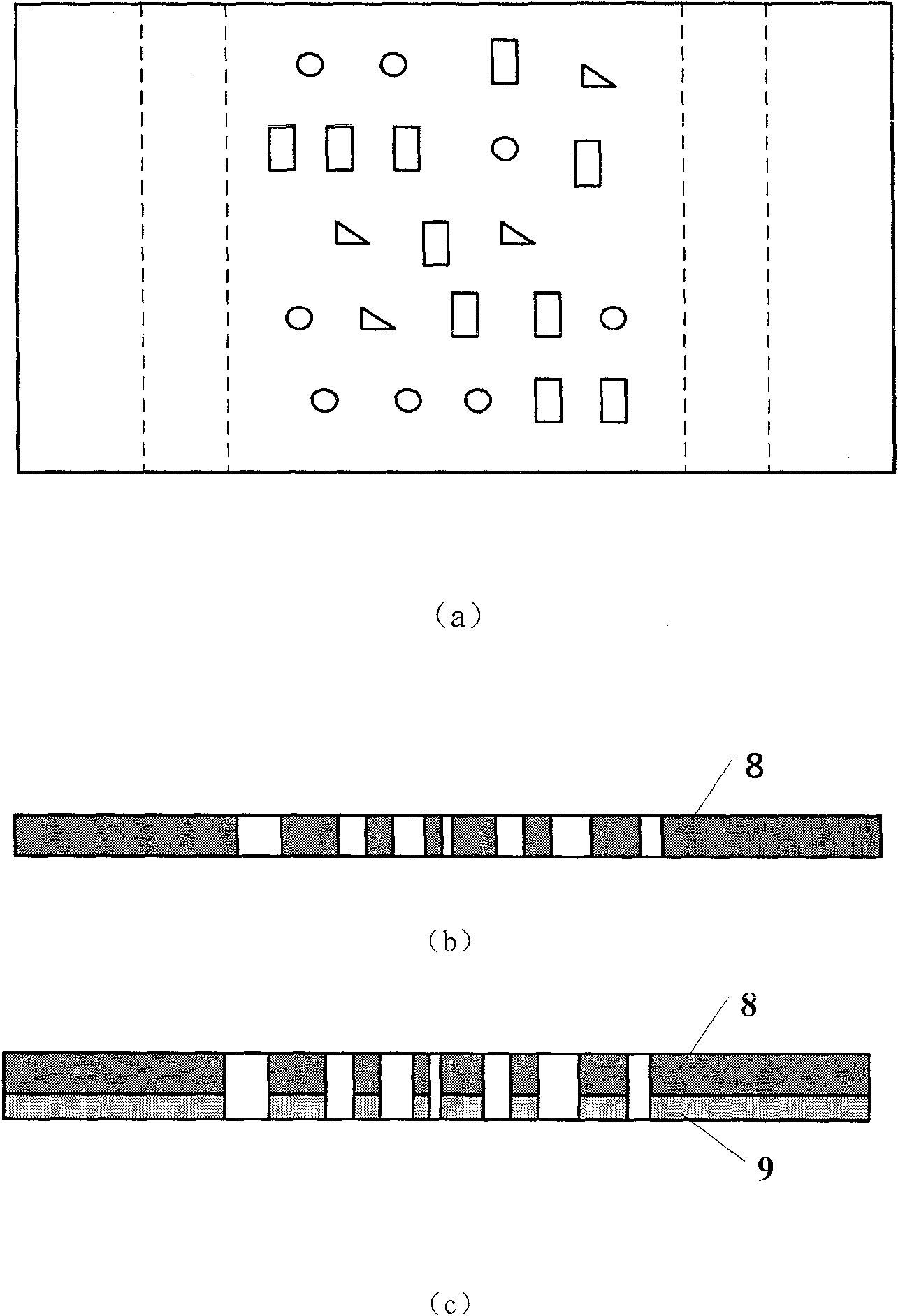

Electrolytic grinding cathode, cathode processing method, electrolytic grinding system comprising cathode and application method

The invention discloses an electrolytic grinding cathode, a cathode processing method, an electrolytic grinding system comprising the cathode and an application method in the technical field of electrolytic grinding combined machining. The electrolytic grinding cathode comprises a conducting layer, a flexible insulation layer, a metal deposition layer, a flexible plate strip, a group hole structure and artificial diamond particles. The surface of the conducting layer is plated with the metal deposition layer. The artificial diamond abrasive particles are arranged on the metal deposition layer.The flexible plate strip is mounted on a contact wheel, a tensioning wheel and a guide wheel in sequence and is tensioned. A workpiece is attached to the artificial diamond abrasive particles of theflexible plate strip, and a certain grinding pressure is maintained. The workpiece is electrically connected with a positive electrode of a power supply. The contact wheel and a forward liquid spraying device are electrically connected with a negative electrode of the power supply, and the forward liquid spraying device sprays electrolyte to a workpiece machining region. The flexible plate strip is driven to do circular motion at a certain speed. Through the electrolytic grinding cathode, the flexible plate strip evenly sweeps across the surface of the workpiece to implement electrolytic grinding. The method is low in cost and easy to operate. The machining efficiency is improved, and the electrolytic grinding cathode is ingenious in manufacturing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

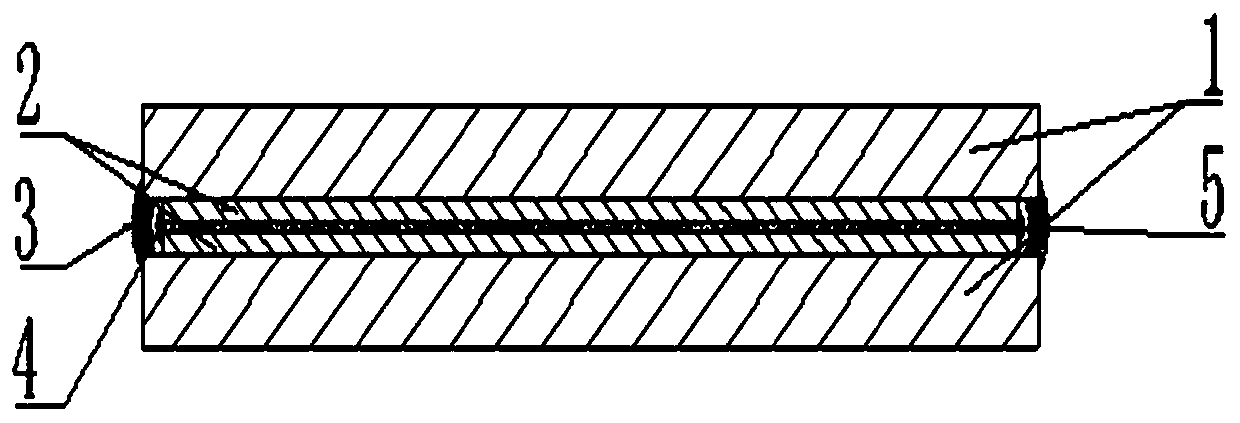

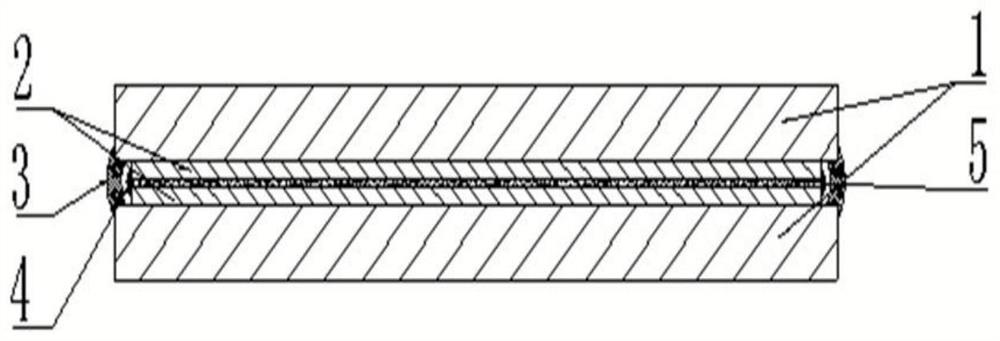

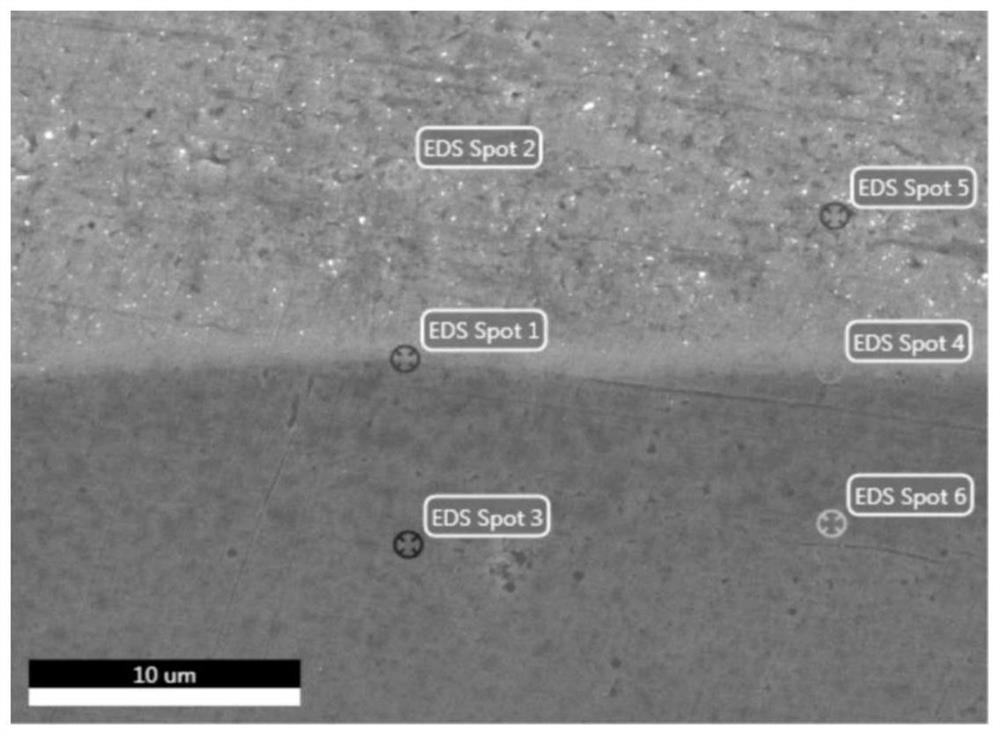

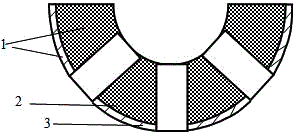

Zirconium steel composite board, and preparation method thereof

ActiveCN109703130ALow processing environment requirementsImprove corrosion resistanceMetal layered productsExplosive claddingWorking environment

The invention discloses a zirconium steel composite board, and a preparation method thereof. The zirconium steel composite board comprises carbon steel layers, a diffusion layer, and zirconium layers;the diffusion layer comprises carbon steel diffusion layers in the zirconium layers, and zirconium diffusion layers in the carbon steel layers. According to the preparation method, calendering combination after soldering and sealing is adopted, production can be carried out at a common working environment, problems of explosive cladding processing such as remote environment is needed, time is long, labor is consumed, and danger degree is high are solved.

Owner:NANJING YOUTIAN METAL TECH

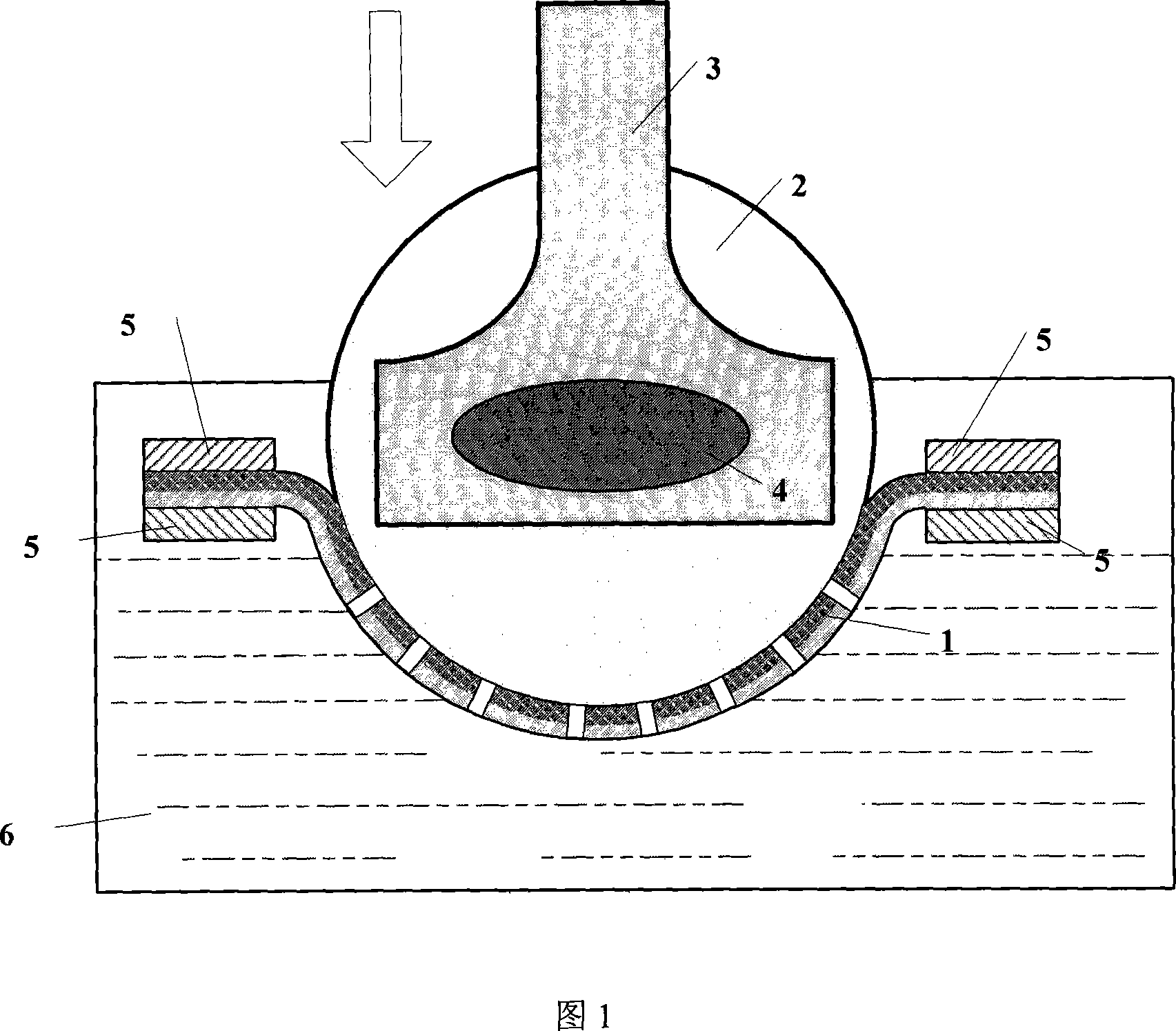

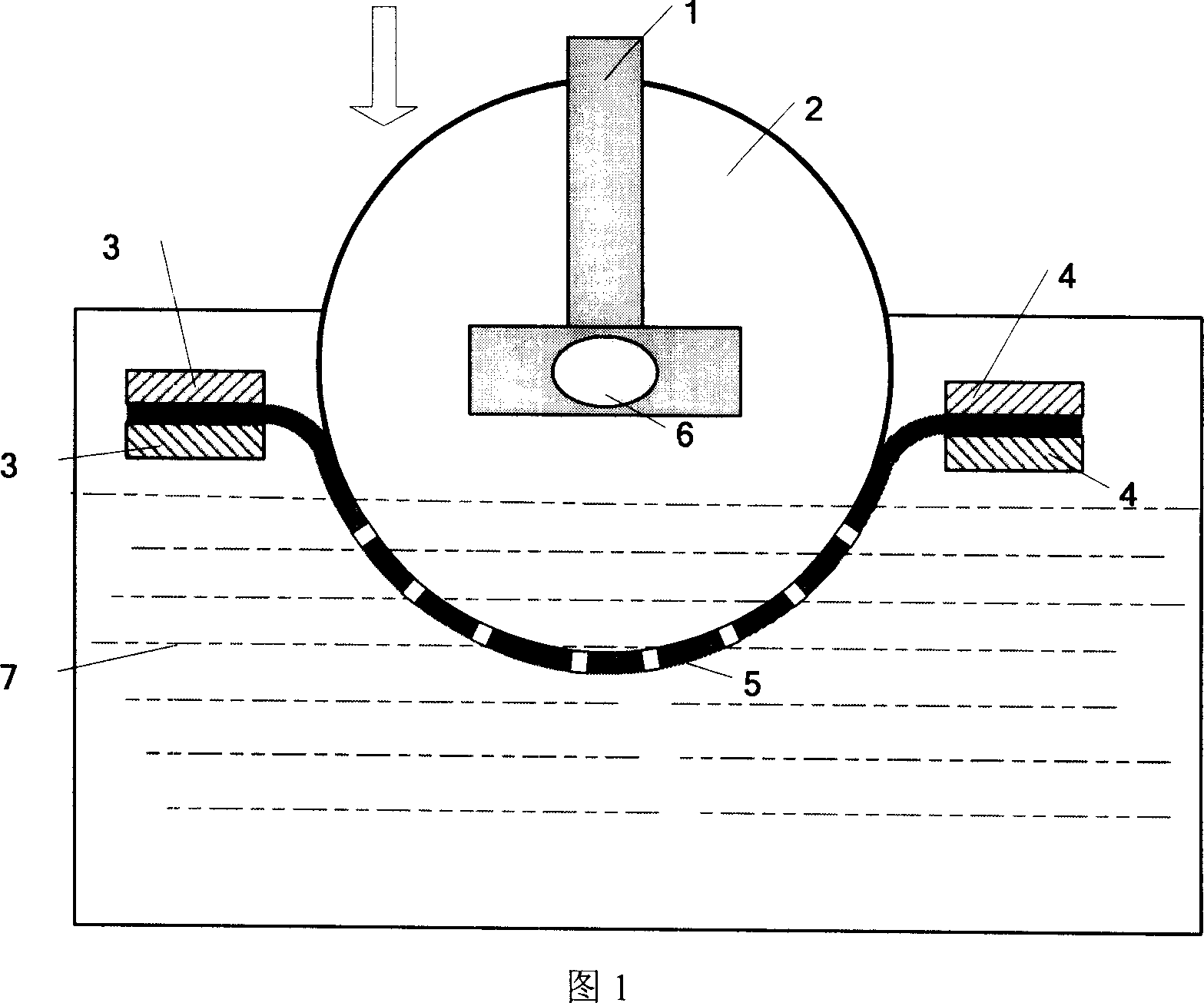

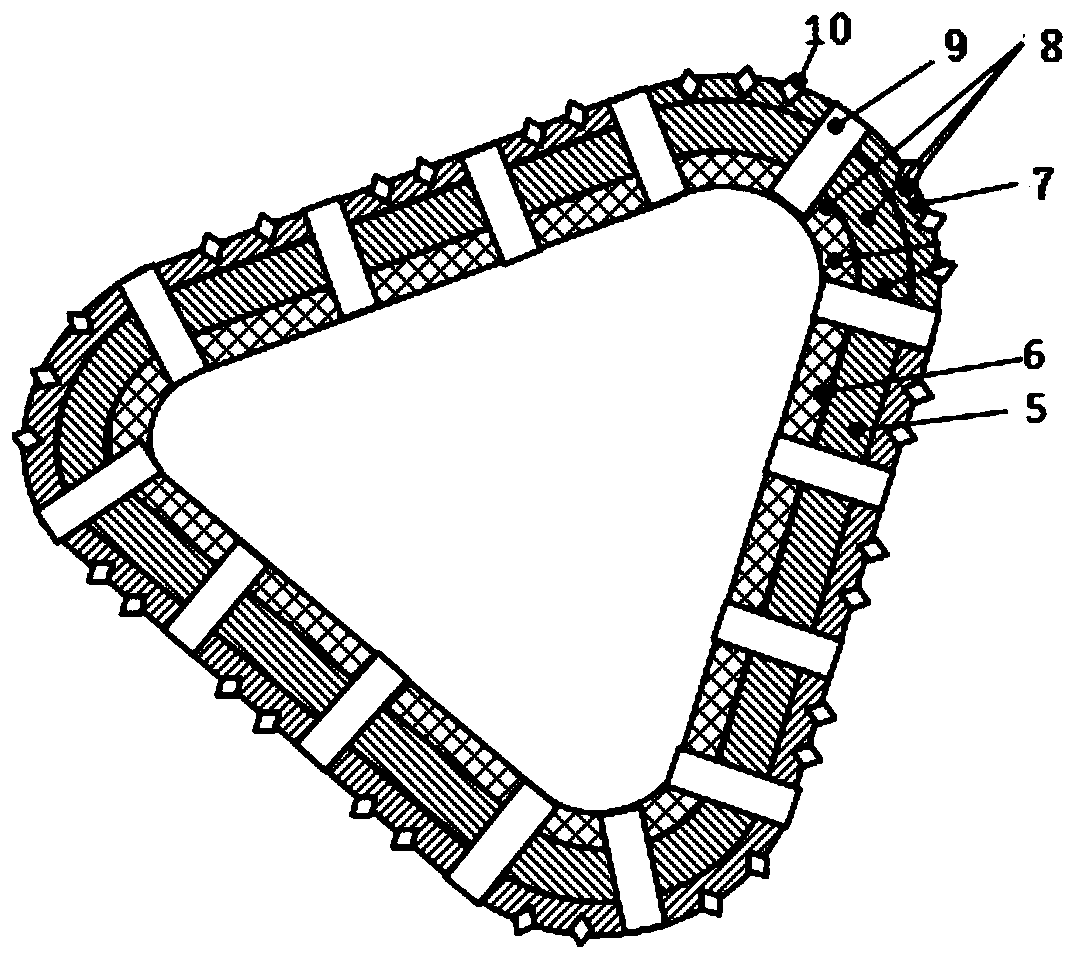

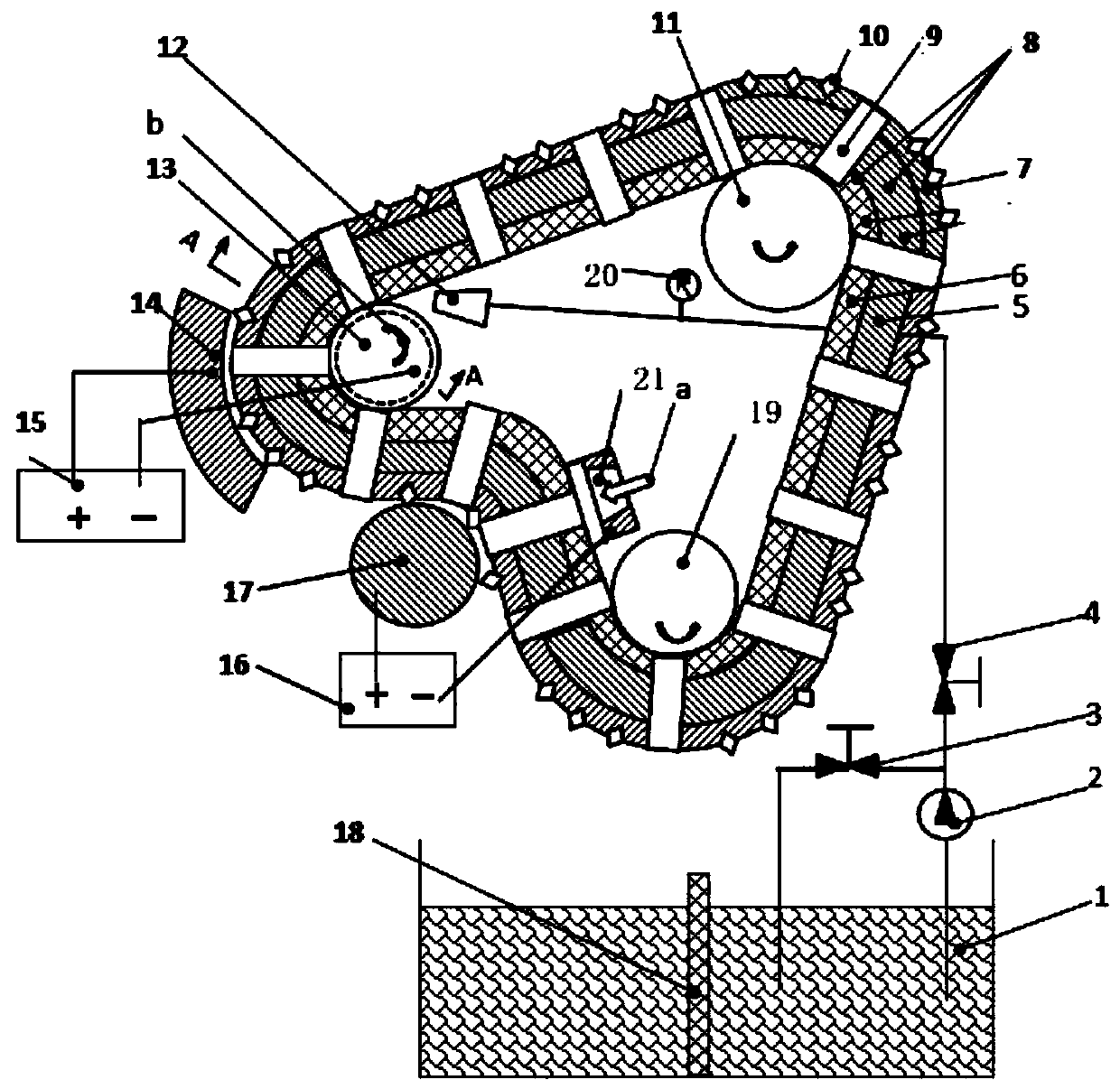

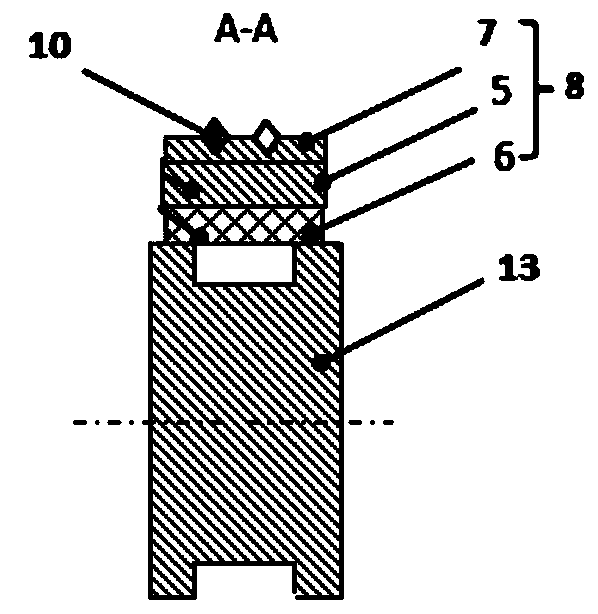

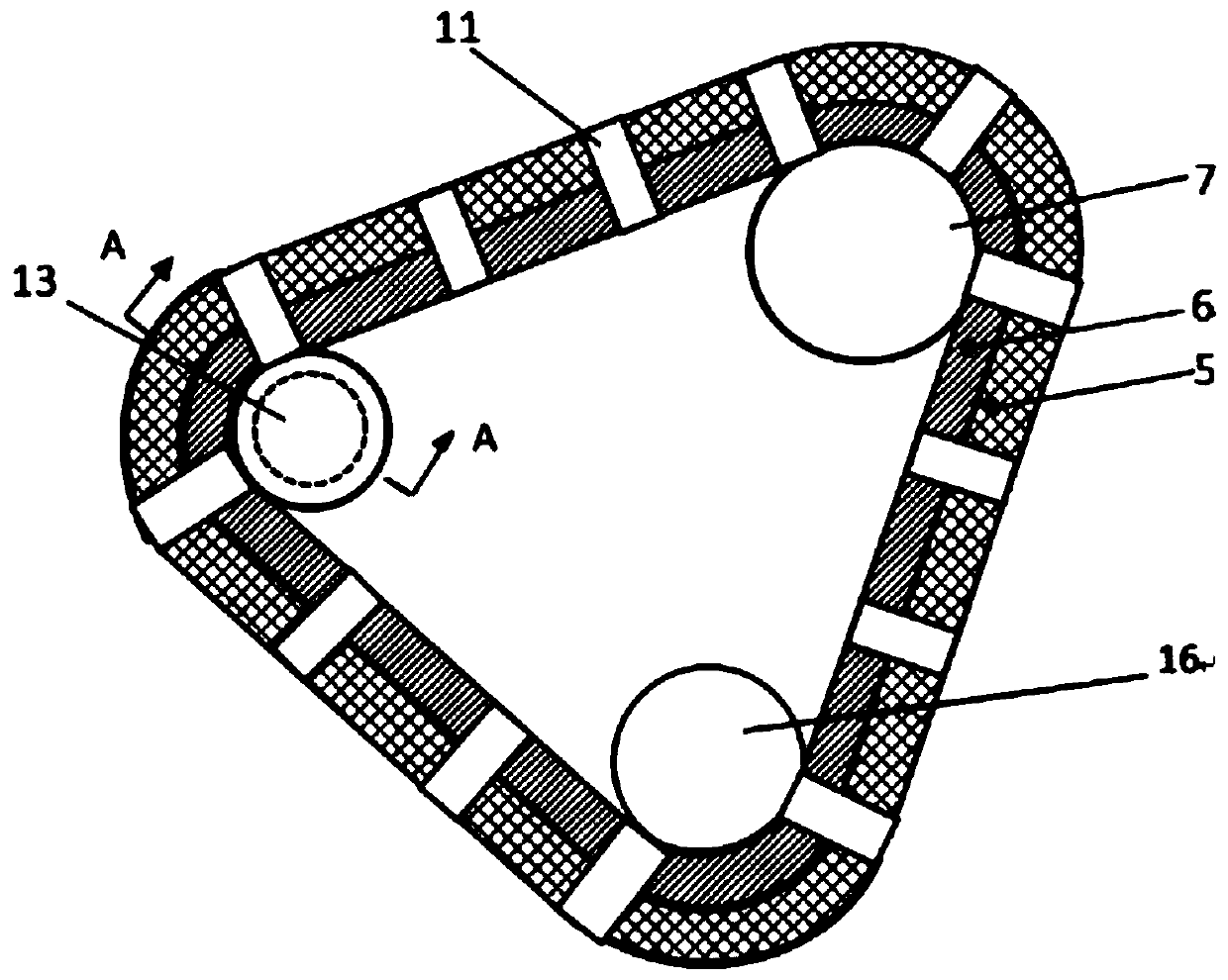

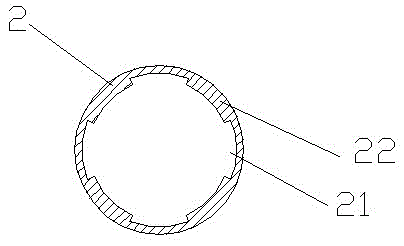

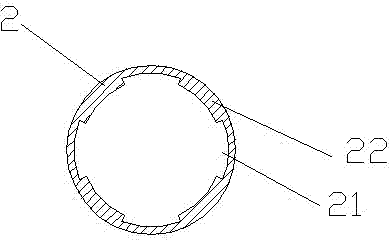

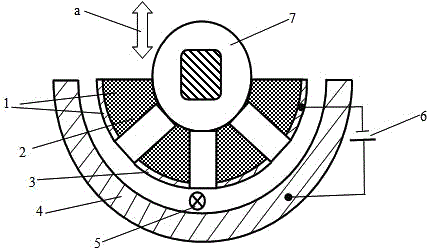

Electrolysis cathode, cathode processing method, electrolysis system containing cathode and system application method

ActiveCN111168169ARealize flexible productionLow costMachining electrodesMachining working media supply/regenerationElectrolytic agentInsulation layer

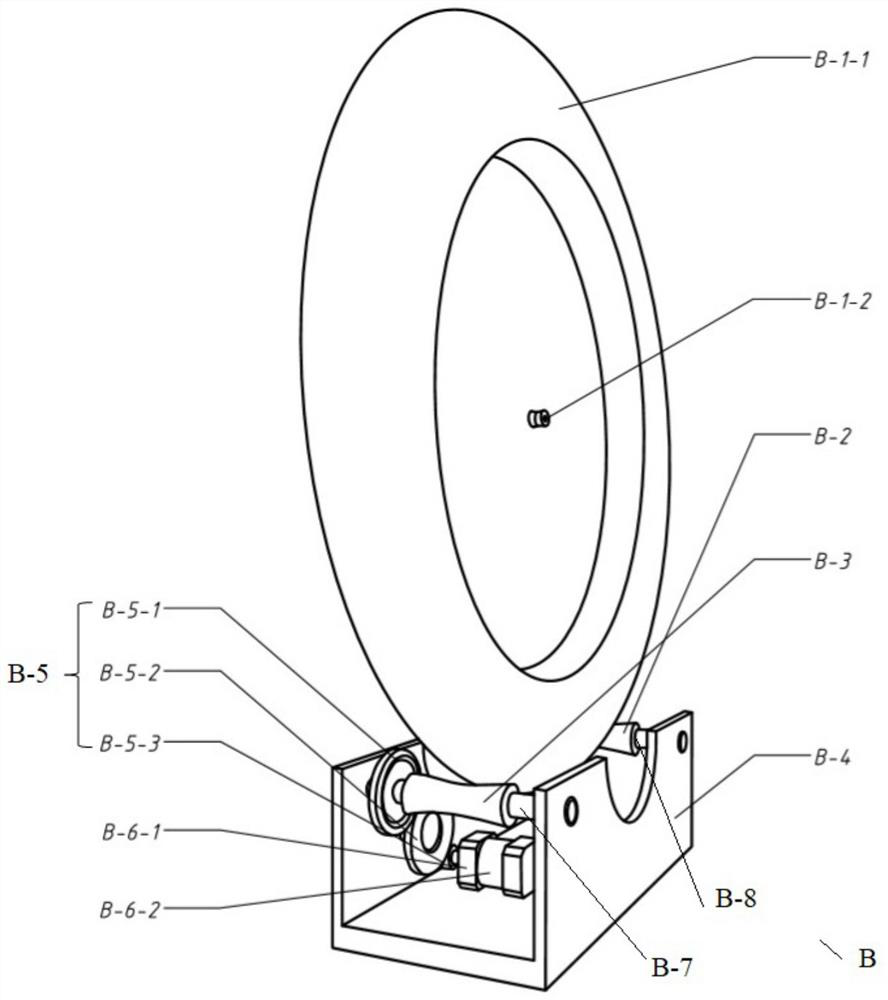

The invention discloses an electrolysis cathode, a cathode processing method, an electrolysis system containing the cathode and a system application method in the technical field of electrolysis processing. A processing cathode of an annular strip-shaped structure is disclosed. The processing cathode comprises an annular strip, the outer strip face of the annular strip is a flexible insulation layer, the inner strip face of the annular strip is a conductive layer, through holes are formed in a strip body of the annular strip at equal intervals, and a group hole structure is jointly formed by all the through holes. A belt wheel set is in winding joint in the annular strip, and the annular strip forms a straight line section and an arc section suitable for workpiece usage through the belt wheel set. The flexible plate strip serving as the tool cathode is sequentially arranged on a contact wheel, a tensioning wheel and a guide wheel and is tensioned, an electrolyte is sprayed into the group hole structure of the flexible plate strip, respective fine structures are machined on the workpiece surfaces at a time, and the characteristics that the machining range is wide, the machining efficiency is high, and the tool cathode is ingenious in design are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

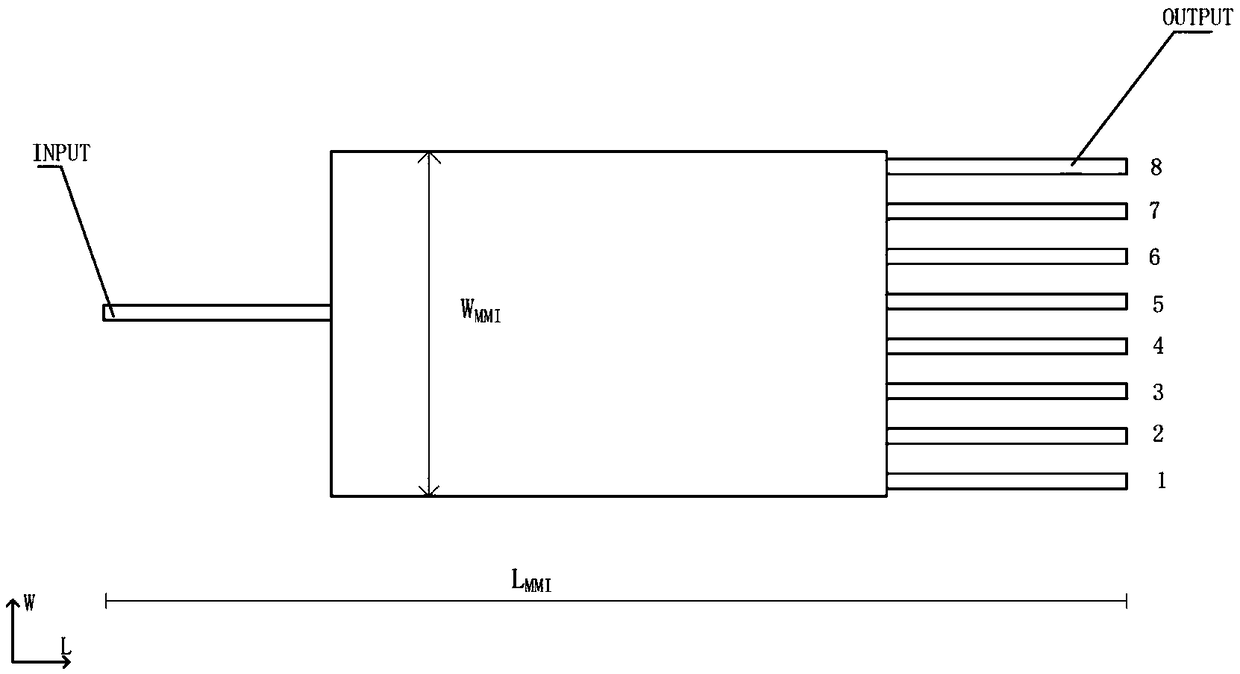

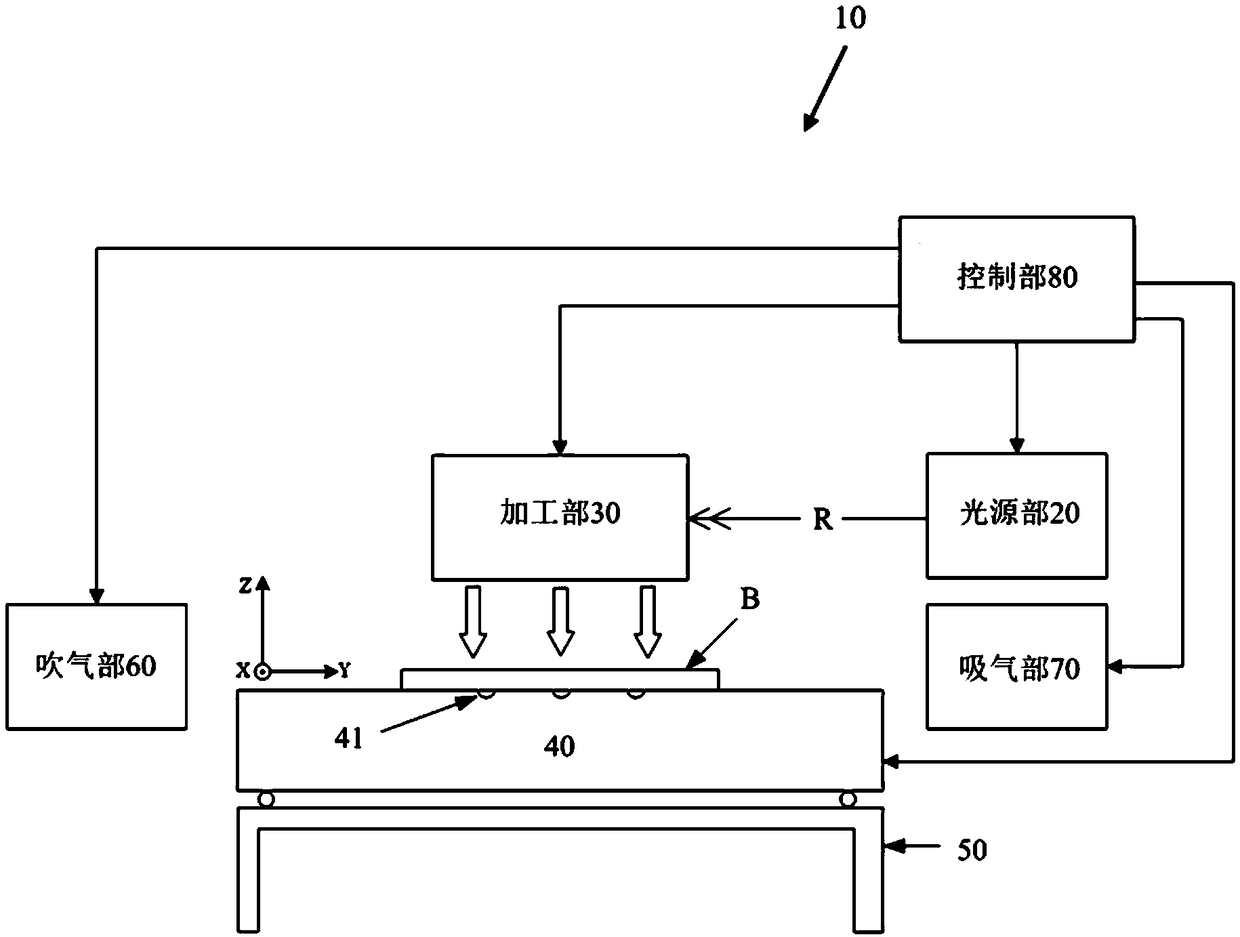

Femtosecond laser processing device and 1x8 ridge type optical splitter processed through device

InactiveCN108941925AReduce manufacturing costImprove adaptabilityWelding/soldering/cutting articlesLaser beam welding apparatusLithography processLaser processing

The invention relates to a femtosecond laser processing device and a 1x8 ridge type optical splitter processed through device. When an optical device is processed through the femtosecond laser processing device, femtosecond pulsed laser beams sequentially pass through a half wave plate, a mirror and a microscope objective and then are focused to a substrate material fixed on a six-degree-of-freedom working platform, the focused femtosecond pulsed laser beams lithograph the substrate material into the optical device in the movement process of the six-degree-of-freedom working platform, and airflow between a blowing part and a sucking part is used for dedusting in the lithography process. The processing device is simple in structure, and the optical device processed by the processing deviceis low in processing cost, high in precision and good in consistency.

Owner:HUBEI UNIV OF TECH

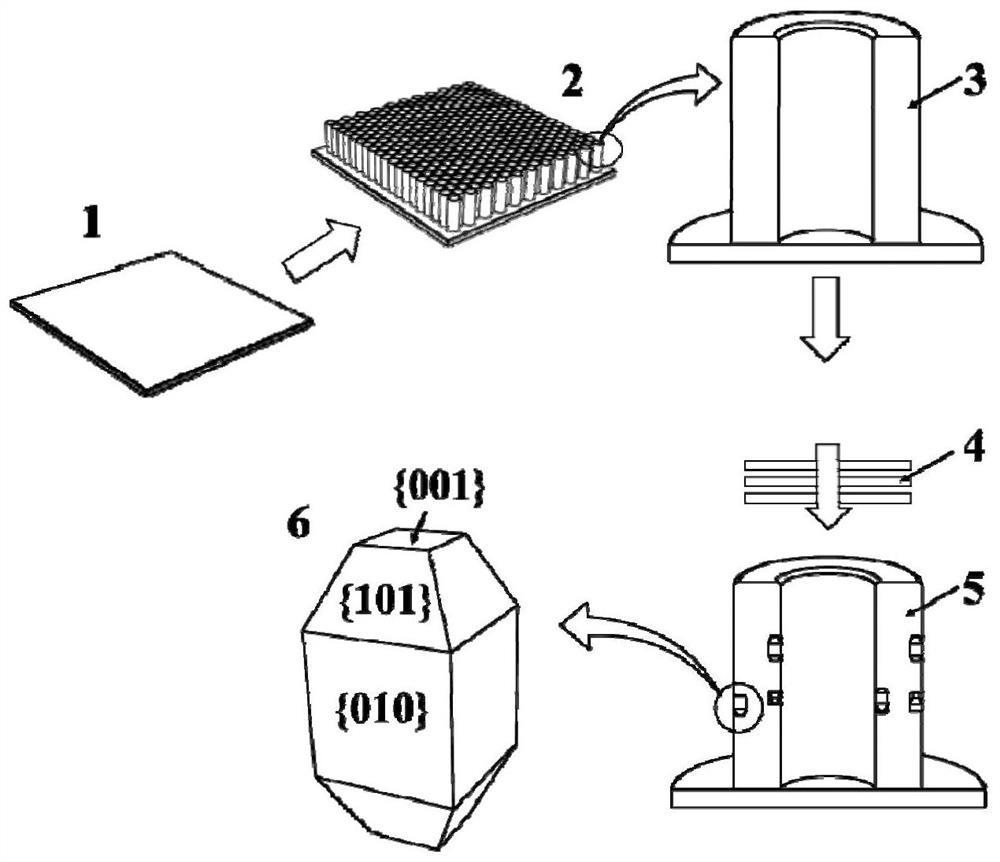

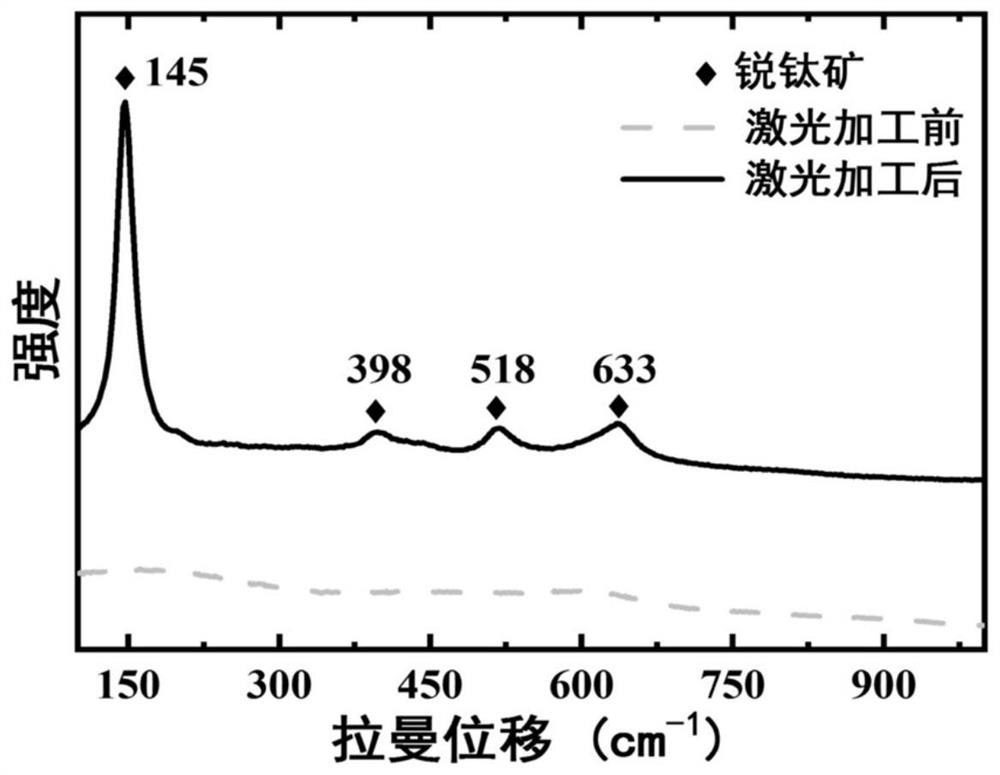

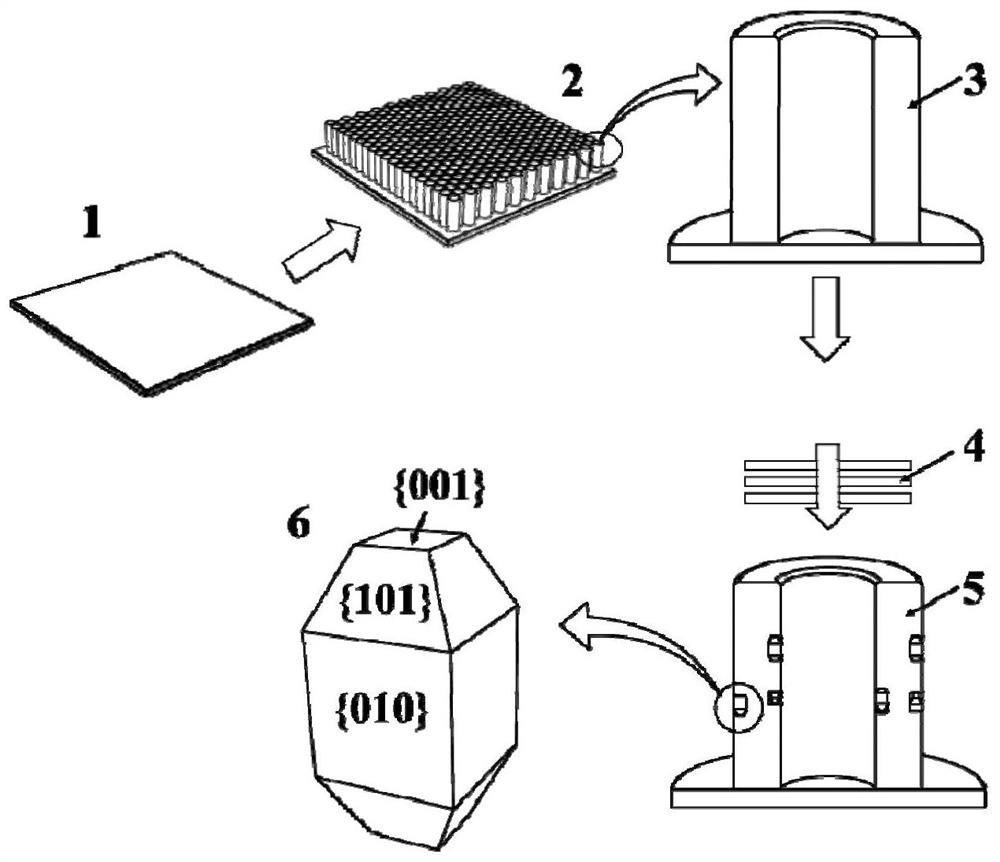

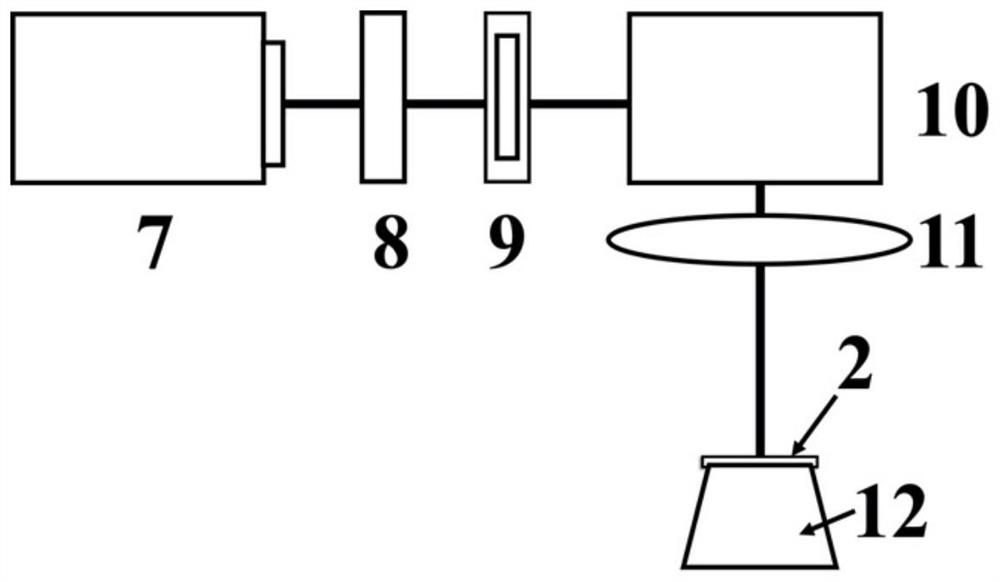

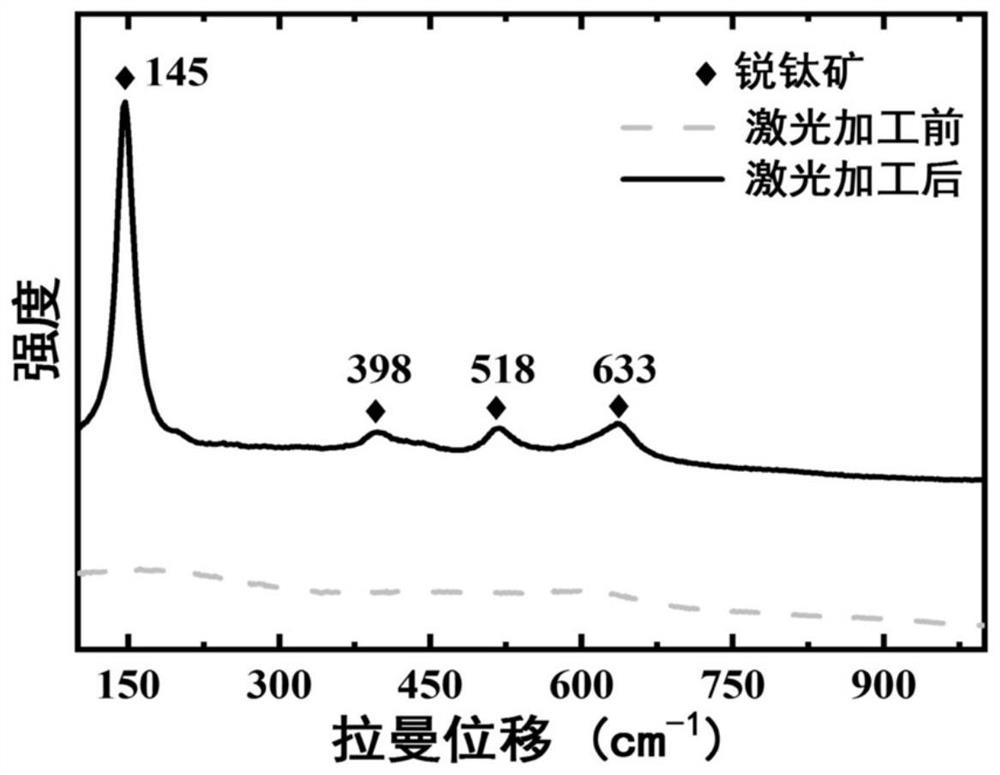

Method and system for preparing titanium dioxide with exposure high-activity surface by utilizing femtosecond laser

ActiveCN111850653AImprove energy utilizationImprove photocatalytic efficiencySurface reaction electrolytic coatingTio2 nanotubeFemto second laser

The invention provides a method and system for preparing titanium dioxide with exposure high-activity surface by utilizing femtosecond laser and belongs to the technical field of femtosecond laser application. According to the method and system for preparing the titanium dioxide with exposure high-activity surface by utilizing the femtosecond laser, an anodic oxidation method is firstly utilized,a solid titanium dioxide nanotube array film is prepared on the surface of a titanium sheet, and then line-by-line scanning is performed by the femtosecond laser to obtain anatase titanium dioxide with exposure {010} crystal surface. Compared with traditional methods, the method has the advantages that solid titanium dioxide can be processed directly, the processing environment requirements are low, the energy utilization rate is high, the speed is fast, and the like. The anatase titanium dioxide with the exposure {010} crystal surface prepared and obtained by utilizing the method and system can be used for photocatalysis and solar cell preparation, and obtaining of the high photocatalytic or photoelectric conversion efficiency is facilitated.

Owner:TSINGHUA UNIV +1

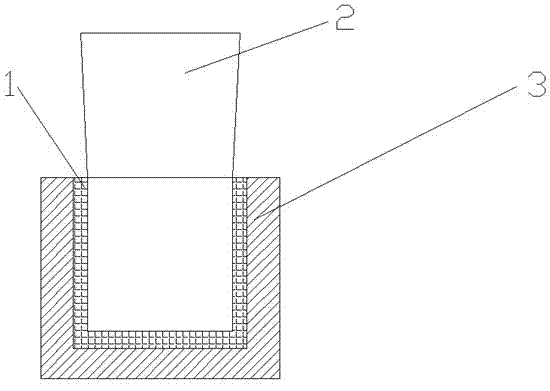

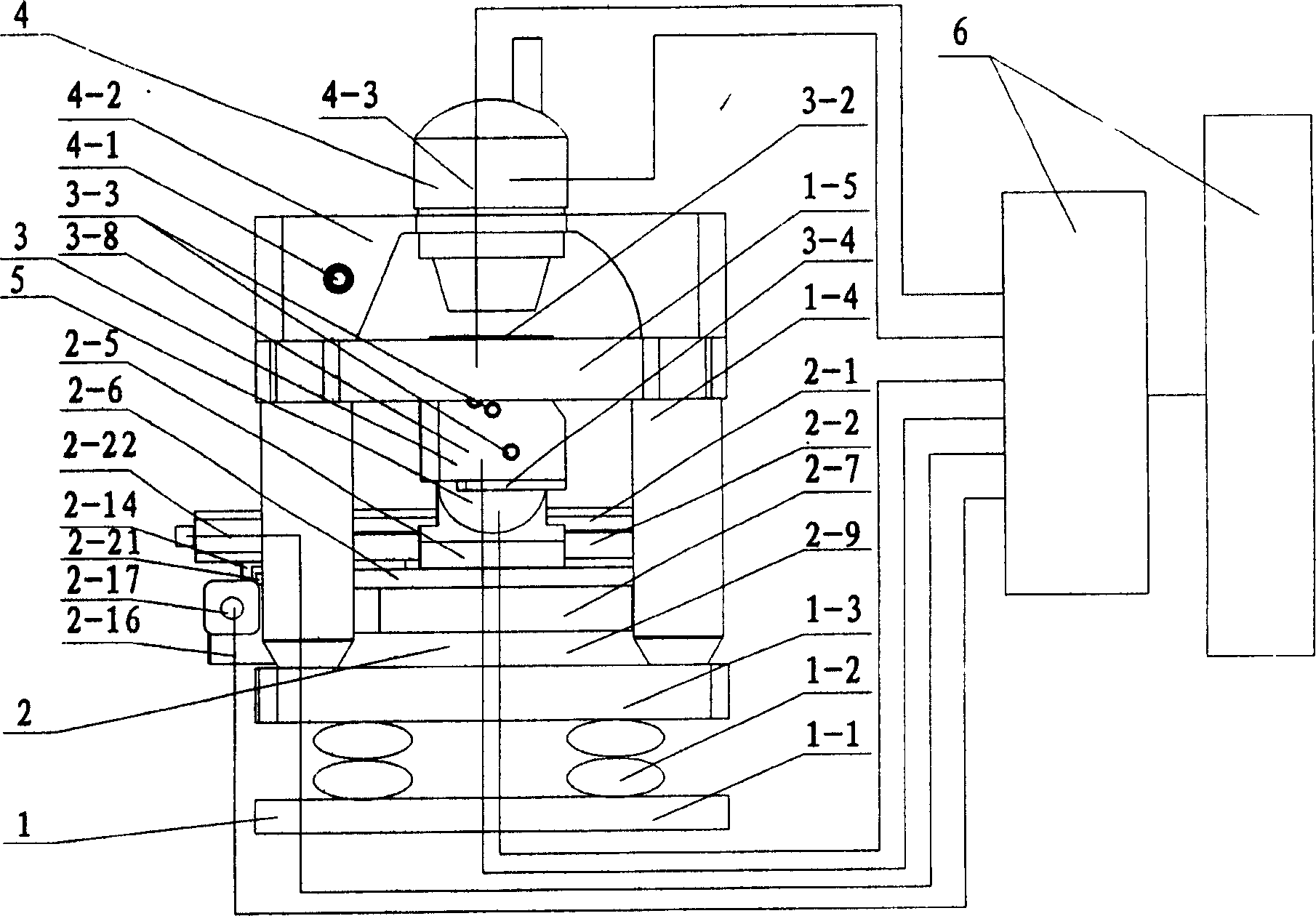

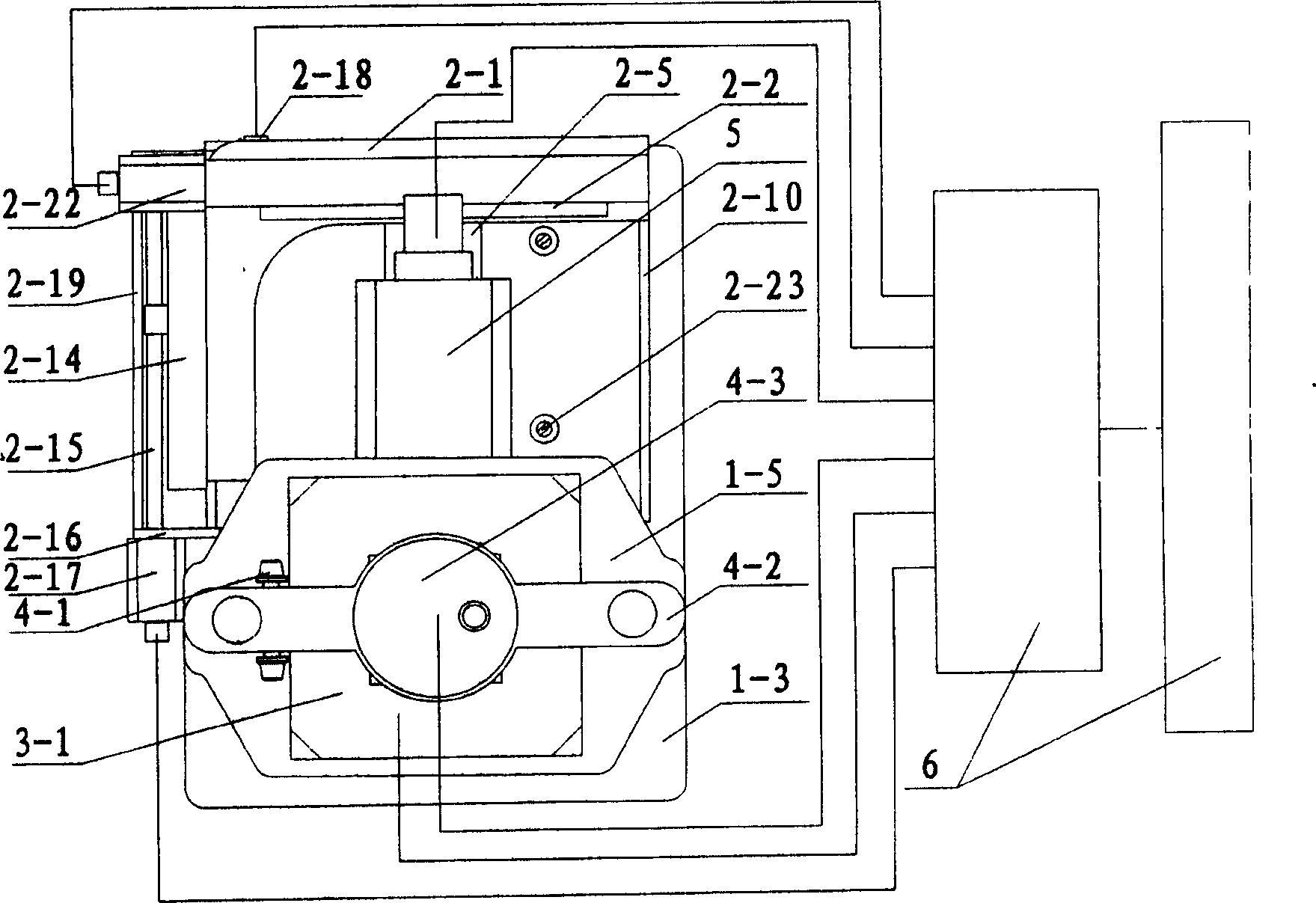

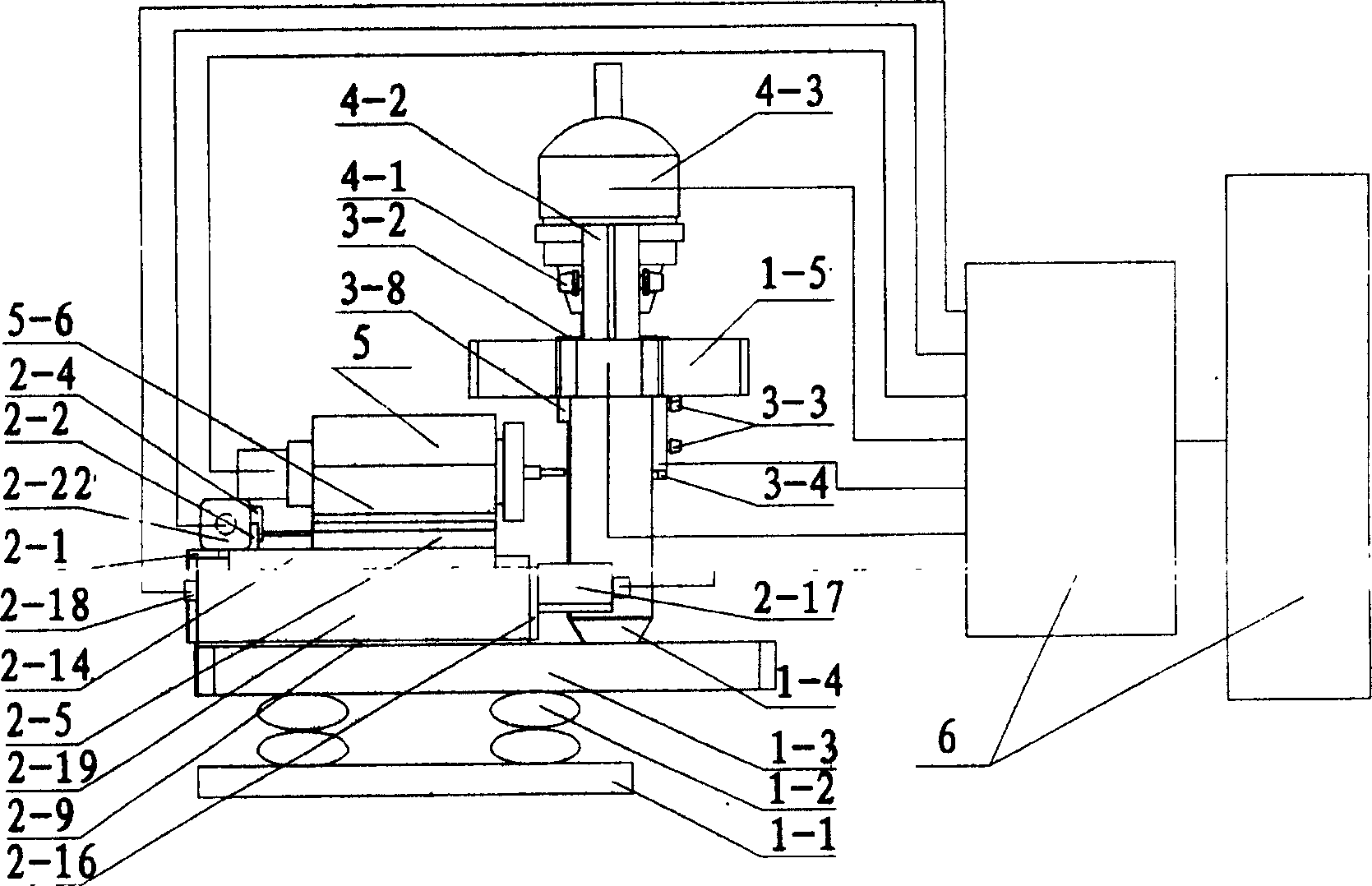

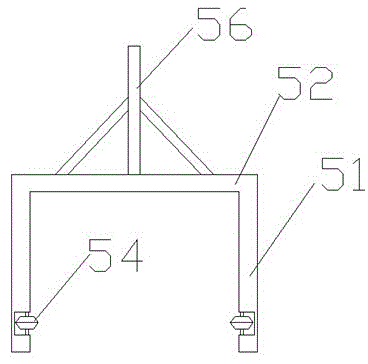

Micromechanical parts three-dimensional processing device

InactiveCN1253285CHigh precisionEasy to operateLarge fixed membersMetal working apparatusDiamond turningControl system

The utility model relates to a three-dimensional processing device for micromechanical parts, which belongs to a nano-processing device. The existing processing based on the scanning probe microscope is limited to the plane two-dimensional micro-pattern, and has not formed a complete set of processing mechanism and related technologies similar to ultra-precision diamond turning. The invention comprises a mechanical table body (1), a three-dimensional coarse motion workbench (2) arranged on the mechanical table body (1), and a processing head part (3) and an optical system ( 4), a spindle system (5) is provided on the three-dimensional coarse motion table (2), the three-dimensional coarse motion table (2), the processing head part (3), the optical system (4), the spindle system (5 ) are all connected with the control system (6). The product of the invention has the advantages of high precision and good effect.

Owner:HARBIN INST OF TECH

Electrolytic grinding cathode, cathode processing method, electrolytic grinding system including the cathode, and use method

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

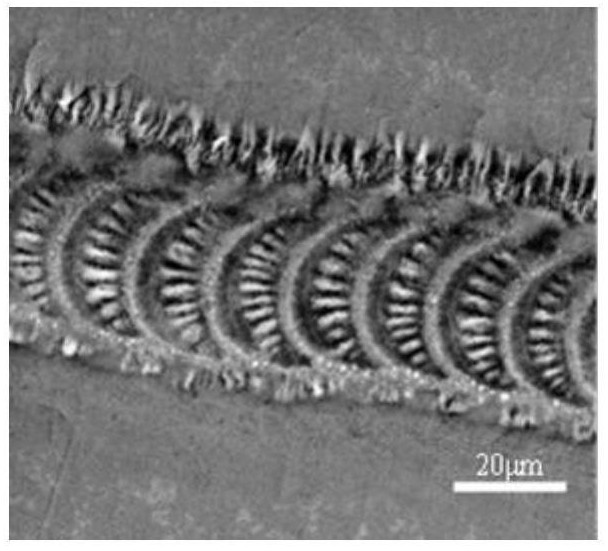

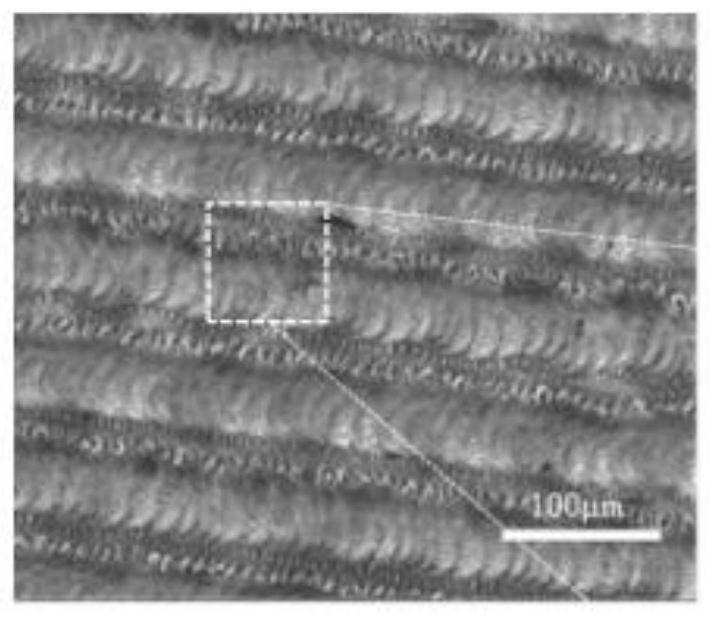

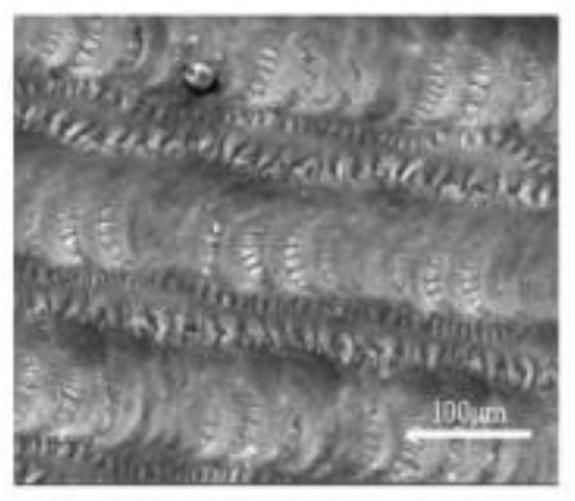

A micro-nano self-organized structure prepared on the surface of stainless steel and its preparation method

ActiveCN109128512BLow costLow processing environment requirementsDecorative surface effectsChemical vapor deposition coatingMicro nanoSS - Stainless steel

A micro-nano self-organized structure prepared on the surface of stainless steel and its preparation method. The surface of a single-sided polished stainless steel 316L sheet is polished to a mirror luster, and then placed in acetone, alcohol, and deionized water for ultrasonic cleaning, and a long-pulse fiber laser is used. The cleaned stainless steel 316L sheet is subjected to continuous pulse laser burst processing to generate micro-nano self-organized structures, and then pulsed laser continuous bursts are performed on the micro-nano self-organized structures to prepare large-area two-dimensional self-organized micro-nano structures on the surface of 316L stainless steel. The structure can prepare periodic self-organized micro-nanostructures. This method is easy to operate and has low requirements on the processing environment. According to the processing parameters, periodic micro-nanostructures can be prepared on the surface of 316L stainless steel quickly, at low cost, and in a large area.

Owner:SHAANXI UNIV OF SCI & TECH

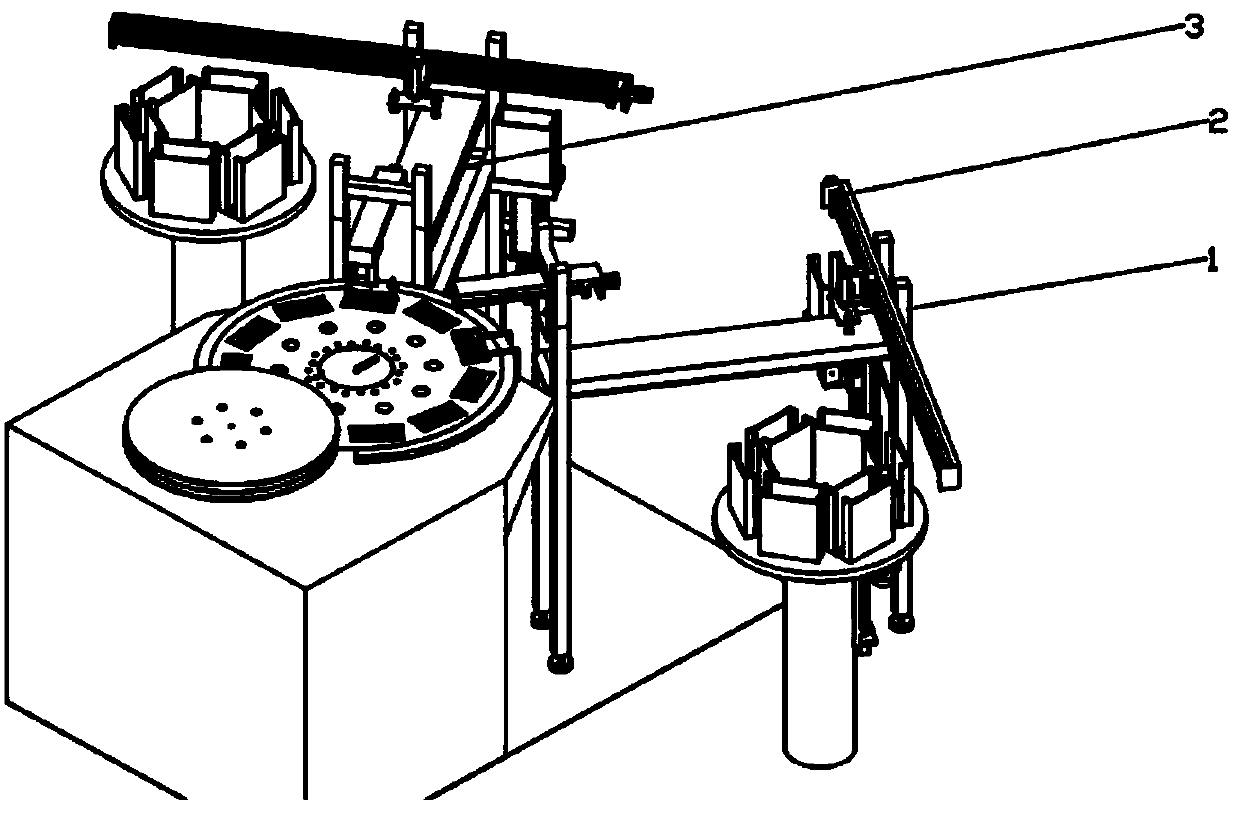

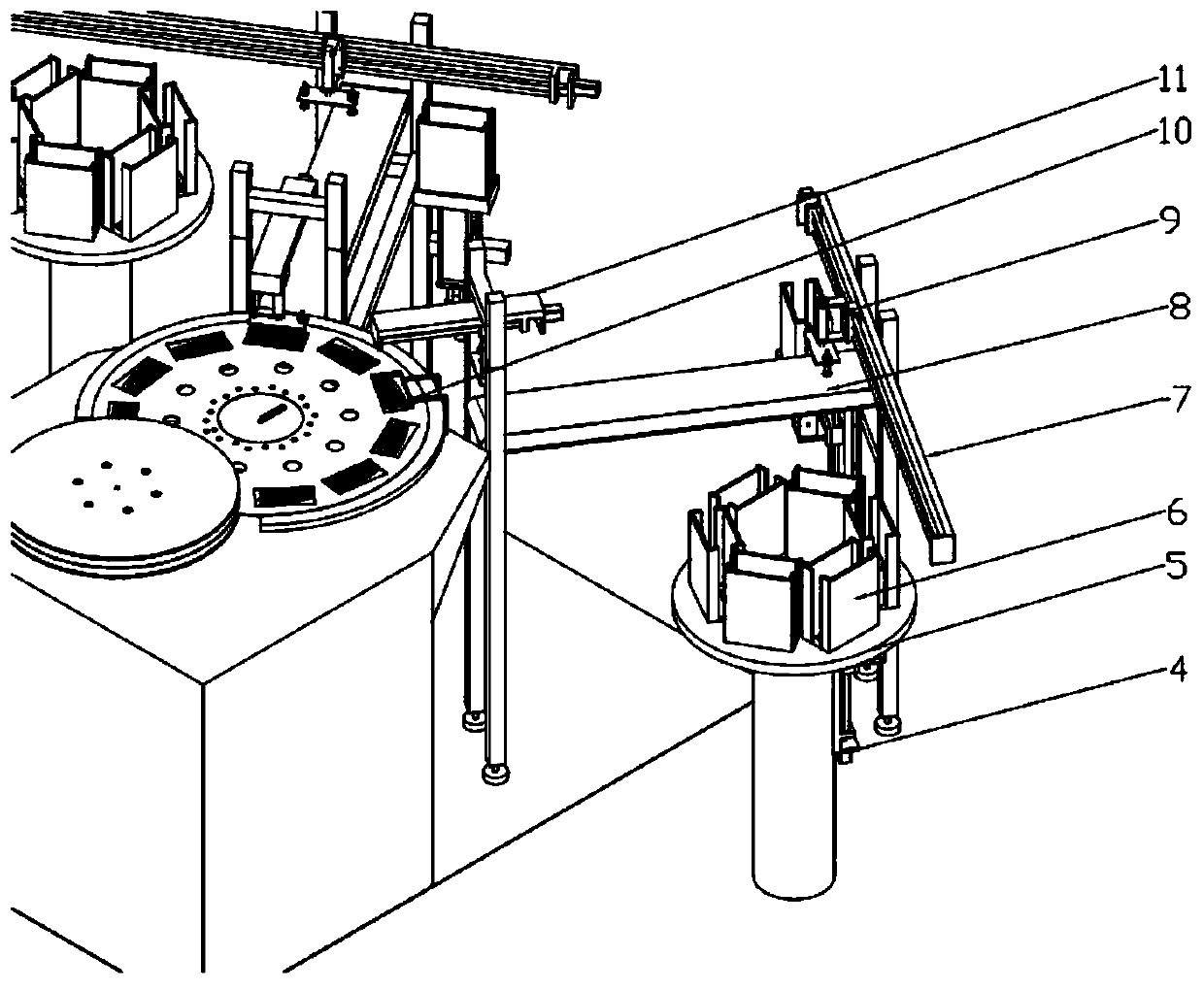

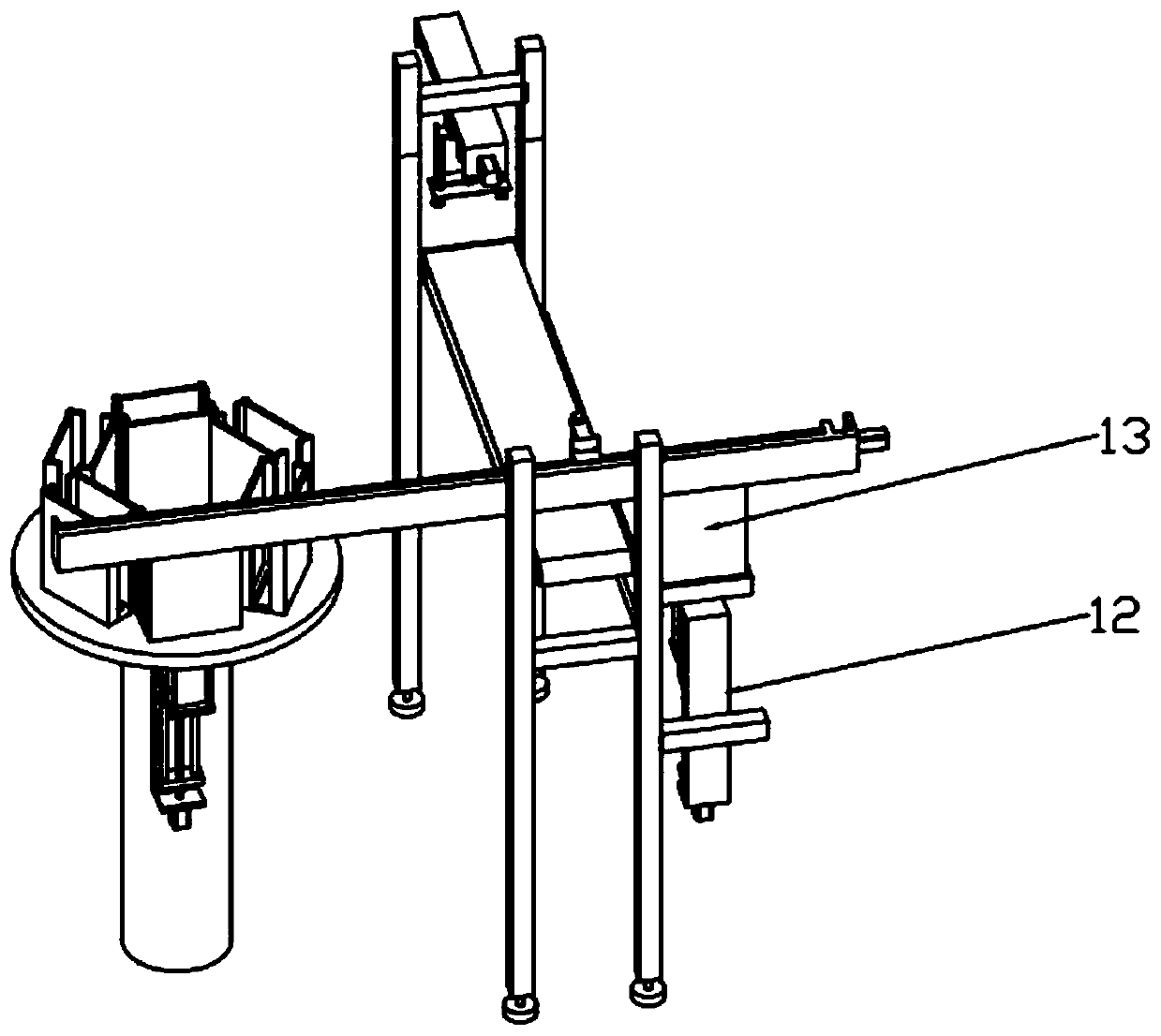

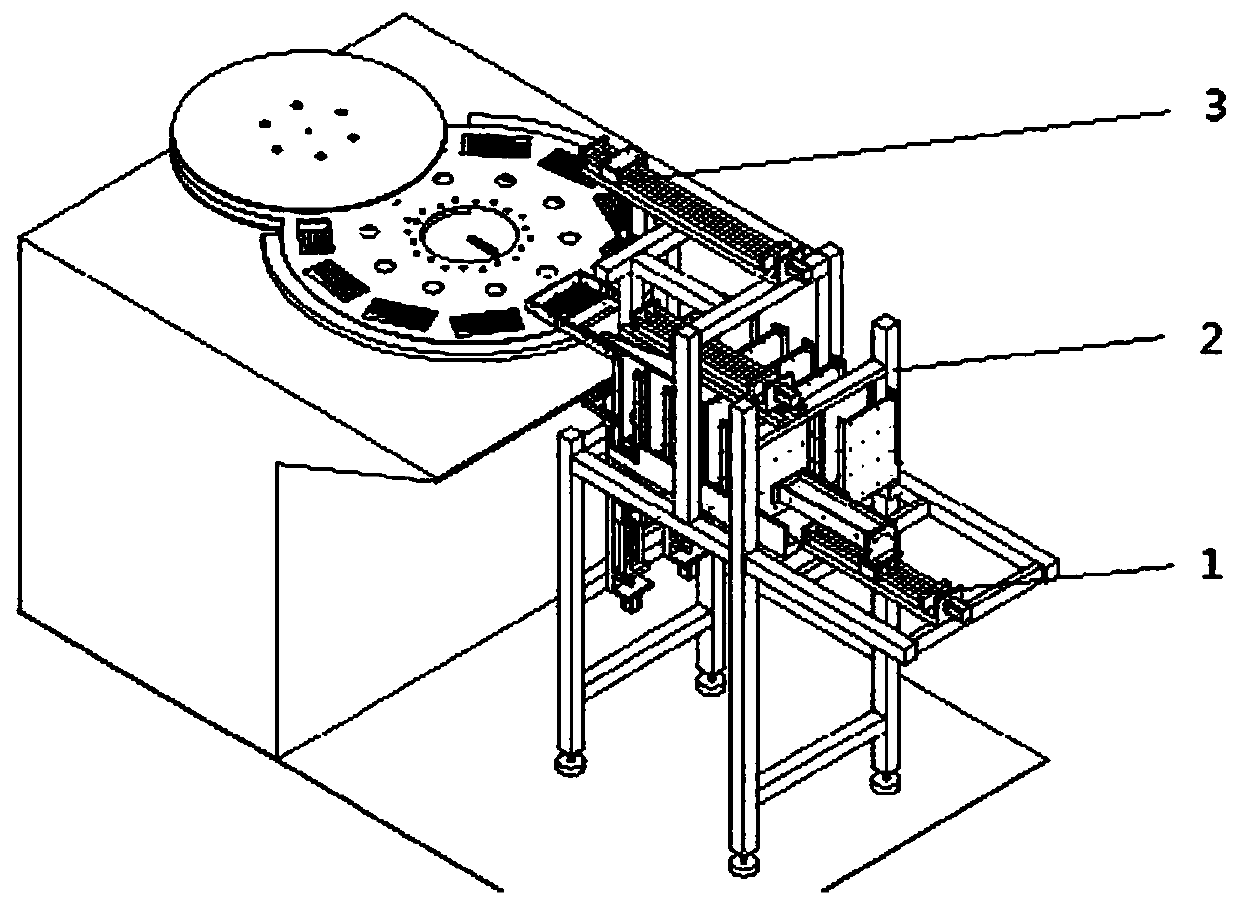

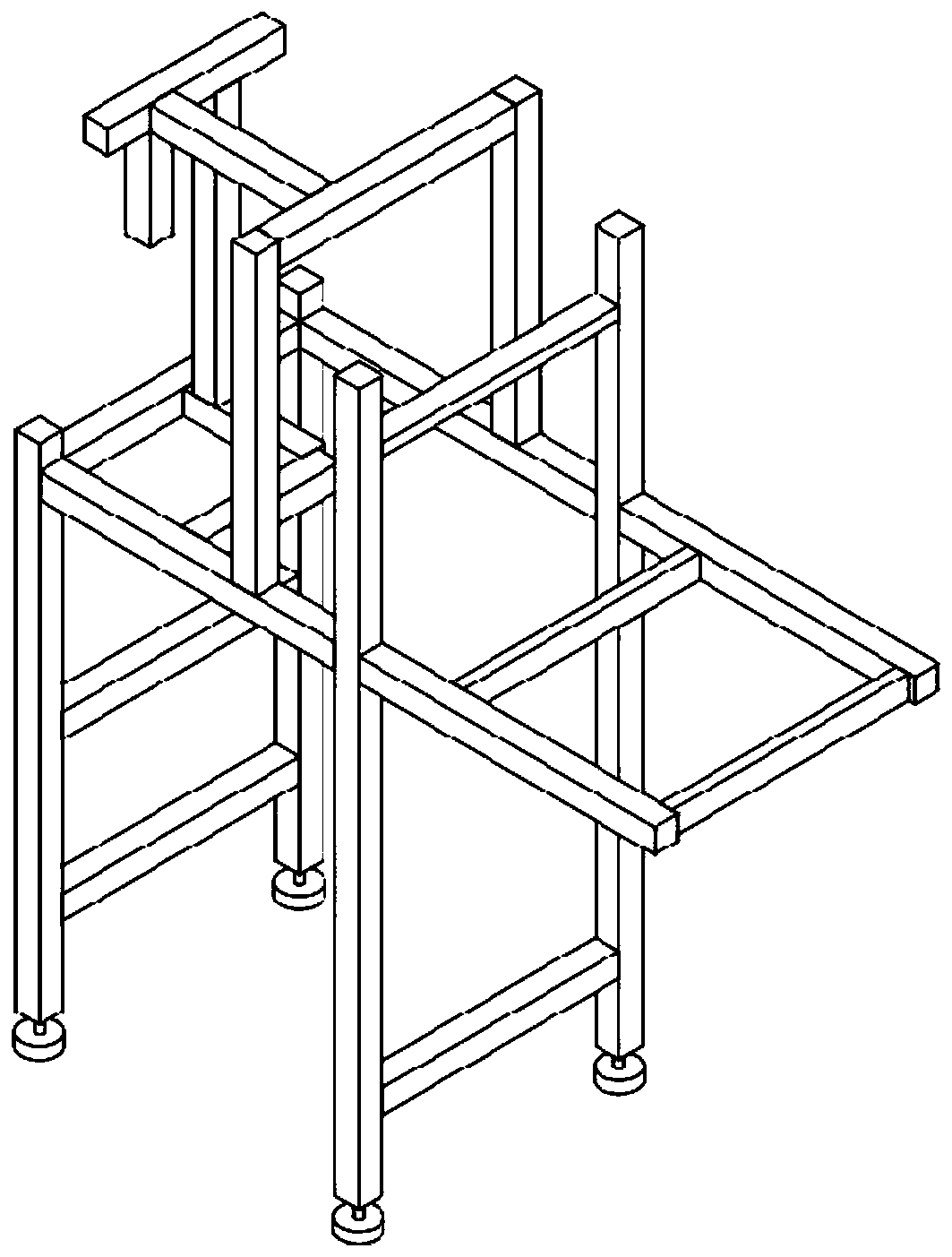

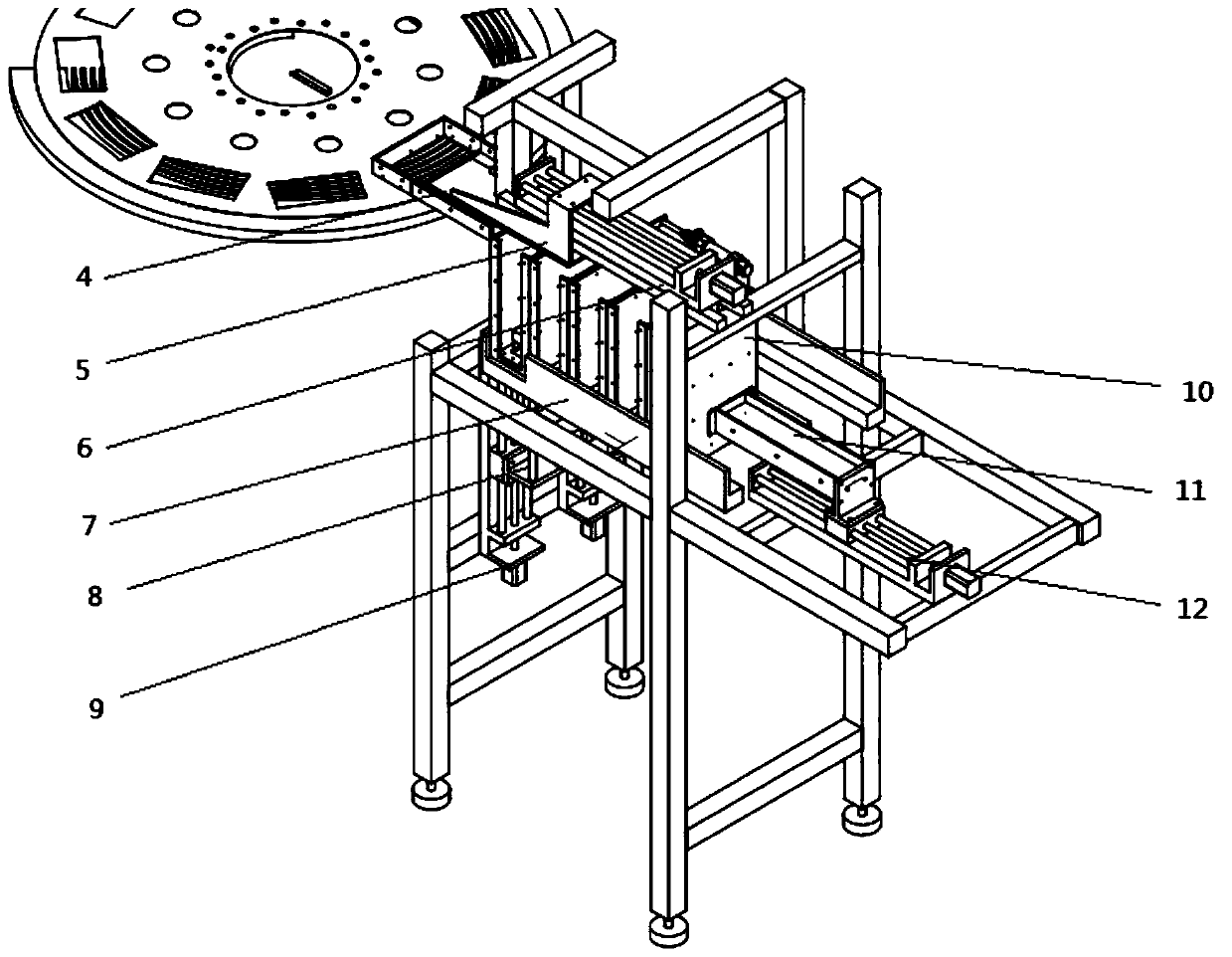

Glass grinder automatic feeding and discharging device with continuous rapid compatibility

ActiveCN110270926AEfficiencySimple structureGrinding machinesGrinding feedersMechanical equipmentAutomation

The invention discloses a glass grinder automatic feeding and discharging device with continuous rapid compatibility, and relates to the technical field of mechanical equipment. The device comprises a workbench, a feeding device and a discharging device. The feeding device and the discharging device are arranged on a rack on one side of the workbench. The feeding device comprises a first horizontal lead screw, a grabbing device is mounted on the first horizontal lead screw, a feeding conveying belt is arranged below the first horizontal lead screw, a first rotary table is arranged on one side of the feeding conveying belt, a material box is arranged on the first rotary box in a surrounding manner, and a first vertical lead screw is arranged at the bottom of the first rotary table. A second horizontal lead screw is arranged above the end, away from the first horizontal lead screw, of the feeding conveying belt. The discharging device and the feeding device have the same structures. Multiple discharging frames are arranged below the end of the second horizontal lead screw in a surrounding manner, and the discharging frames are located on the workbench. The glass grinder automatic feeding and discharging device with continuous rapid compatibility is good in compatibility, high in automation degree and free of spare takts during work.

Owner:SHANGHAI UNIV

A zirconium-steel composite plate and its preparation method

ActiveCN109703130BLow processing environment requirementsImprove corrosion resistanceMetal layered productsExplosive claddingWorking environment

The invention discloses a zirconium steel composite board, and a preparation method thereof. The zirconium steel composite board comprises carbon steel layers, a diffusion layer, and zirconium layers;the diffusion layer comprises carbon steel diffusion layers in the zirconium layers, and zirconium diffusion layers in the carbon steel layers. According to the preparation method, calendering combination after soldering and sealing is adopted, production can be carried out at a common working environment, problems of explosive cladding processing such as remote environment is needed, time is long, labor is consumed, and danger degree is high are solved.

Owner:NANJING YOUTIAN METAL TECH

Electrolytic cathode, cathode processing method, electrolysis system containing the cathode, and method of using the system

ActiveCN111168169BRealize flexible productionLow costMachining electrodesMachining working media supply/regenerationElectrolytic agentInsulation layer

The invention discloses an electrolysis cathode, a cathode processing method, an electrolysis system containing the cathode and a system application method in the technical field of electrolysis processing. A processing cathode of an annular strip-shaped structure is disclosed. The processing cathode comprises an annular strip, the outer strip face of the annular strip is a flexible insulation layer, the inner strip face of the annular strip is a conductive layer, through holes are formed in a strip body of the annular strip at equal intervals, and a group hole structure is jointly formed by all the through holes. A belt wheel set is in winding joint in the annular strip, and the annular strip forms a straight line section and an arc section suitable for workpiece usage through the belt wheel set. The flexible plate strip serving as the tool cathode is sequentially arranged on a contact wheel, a tensioning wheel and a guide wheel and is tensioned, an electrolyte is sprayed into the group hole structure of the flexible plate strip, respective fine structures are machined on the workpiece surfaces at a time, and the characteristics that the machining range is wide, the machining efficiency is high, and the tool cathode is ingenious in design are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of layered ti-ni shape memory composite material and preparation method thereof

ActiveCN105058914BHigh specific strengthImprove toughness and plasticityMetal rolling arrangementsMetal layered productsBiocompatibility TestingTitanium

This invention discloses a layered Ti-Ni shape memory composite material and its preparation method, which belongs to the technical field of preparation of functional composite materials; pure titanium and pure nickel are the initial raw materials, and the titanium plate and nickel plate are subjected to surface pretreatment, accumulated Composite rolling, diffusion annealing, and controlled cooling are used to prepare a heterogeneous multi-layer structure shape memory composite material including a Ti layer as the outermost layer, a Ti-Ni layer wrapped in the Ti layer, and a Ni layer. The shape memory composite material prepared by the method has the characteristics of high specific strength, good plastic toughness, high fatigue strength, strong interfacial bonding, excellent electrical conductivity, non-magnetic, non-toxic, high corrosion resistance, good biocompatibility and the like. The preparation method of the invention has the advantages of simple process and convenient operation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method and system for preparing titanium dioxide exposed high active surface by using femtosecond laser

ActiveCN111850653BImprove energy utilizationImprove photocatalytic efficiencySurface reaction electrolytic coatingTio2 nanotubeHigh energy

The invention provides a method and system for preparing titanium dioxide exposed to a high-activity surface by using a femtosecond laser, and belongs to the technical field of femtosecond laser applications. In the invention, a solid titanium dioxide nanotube array film is prepared on the surface of a titanium sheet by an anodic oxidation method, and then the anatase titanium dioxide with an exposed {010} crystal plane is obtained by scanning a femtosecond laser line by line. Compared with the traditional method, the invention has the advantages of direct processing of solid titanium dioxide, low processing environment requirements, high energy utilization rate, fast speed and the like. The anatase titanium dioxide with exposed {010} crystal face prepared by the method and system of the present invention can be used for photocatalysis and solar cell preparation, which is beneficial to obtain high photocatalysis or photoelectric conversion efficiency.

Owner:TSINGHUA UNIV +1

A kind of processing method of aluminum alloy bottle stopper

InactiveCN103522019BReduce processing burdenGuaranteed connection qualityScrew threadAluminium alloy

Disclosed is a method for processing an aluminum alloy stopper. The method includes a vertical rib processing step and an outer thread processing step. The vertical rib processing step includes using a die sleeve to process a stopper blank, accordingly extruding a concave part and a convex part on the cylindrical outer side wall of the stopper blank, and obtaining the stopper blank with the concave part and the convex part. The outer thread processing step includes utilizing an executing component to contact with the cylindrical outer side wall of the stopper blank with the concave part and the convex part, starting a hydraulic lifting device and a rotary motor, forming a thread on the convex part accordingly, and obtaining the aluminum alloy stopper.

Owner:青岛亚华制盖有限公司

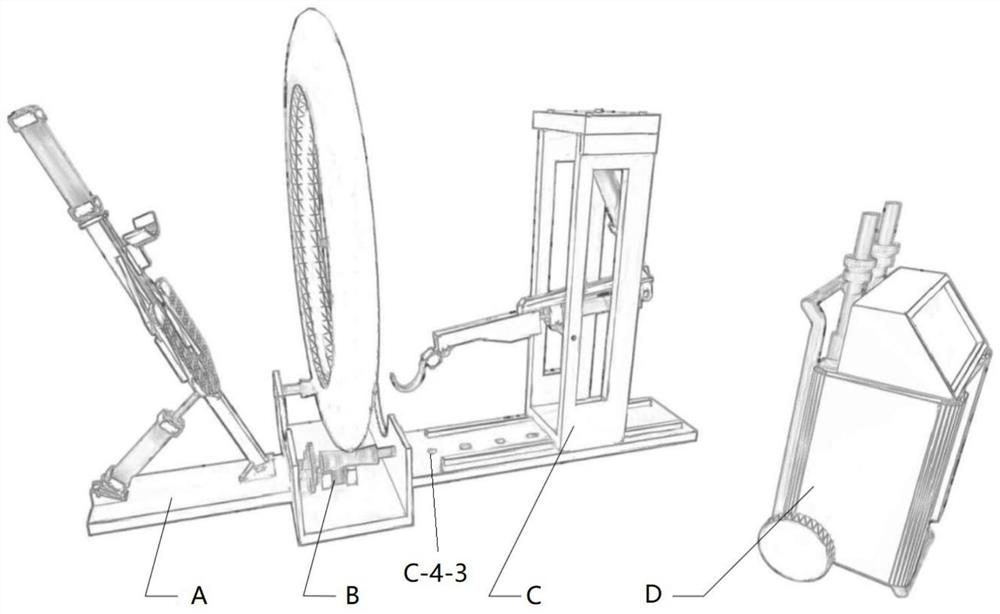

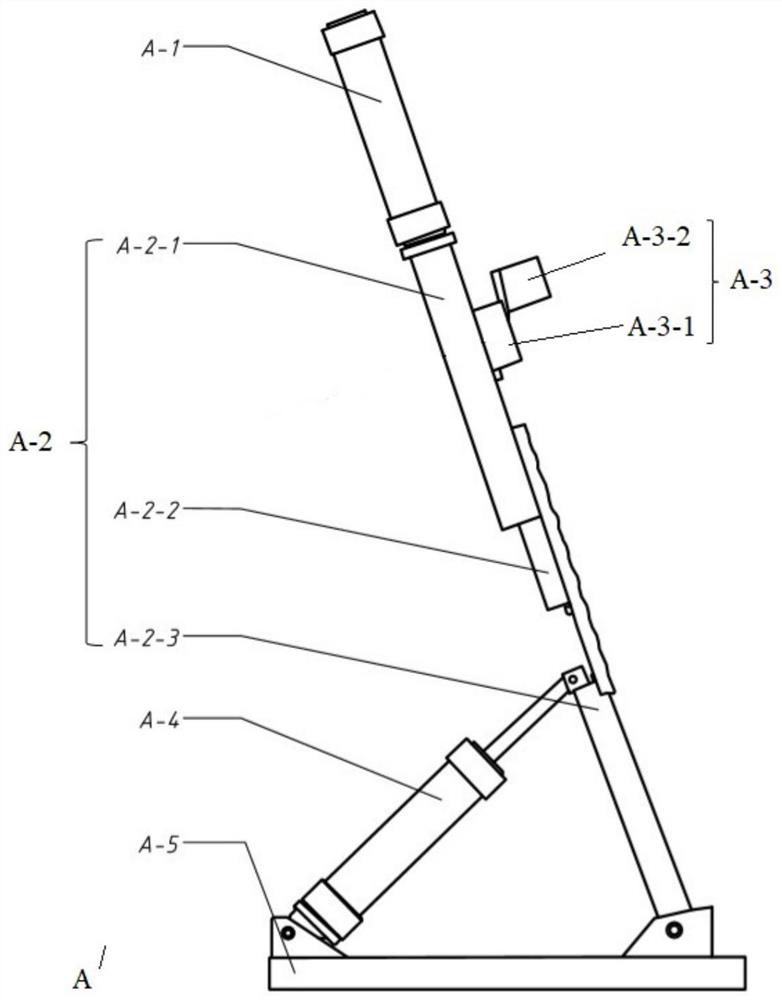

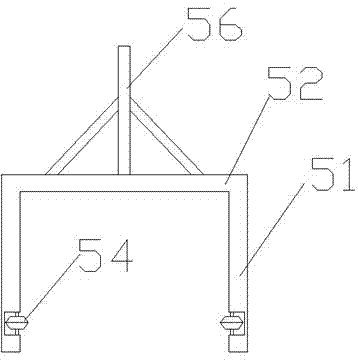

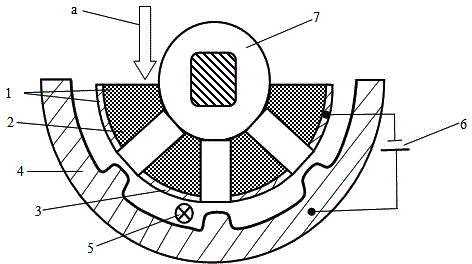

A solid tire filling device

The invention relates to a solid tire filling device, which comprises a tire clamping tool, a tire rotator, a foam filler injecting mechanical arm system, a foam material generating system and a control system integrated in sequence, and the tire clamping tool includes a first base , a swing rod bracket assembly rotatably arranged on the first base, and a wheel shaft fixing claw assembly movably arranged on the swing rod bracket assembly, the tire rotator includes a second base, a The drive assembly and the friction wheel assembly are arranged on the second base. The foam filler injecting mechanical arm system includes a third base and a mechanical arm assembly movably arranged on the third base. Compared with the prior art, the invention realizes the environmental protection reuse of tires with air leakage but in good wear state or that have been used for a long time, which can meet the processing and production needs of families or street stores.

Owner:TONGJI UNIV

Waveguide micro-nano processing system and processing method

ActiveCN107116308BReduce manufacturing costImprove adaptabilityLaser beam welding apparatusProcess systemsMicro nano

Owner:HUBEI UNIV OF TECH

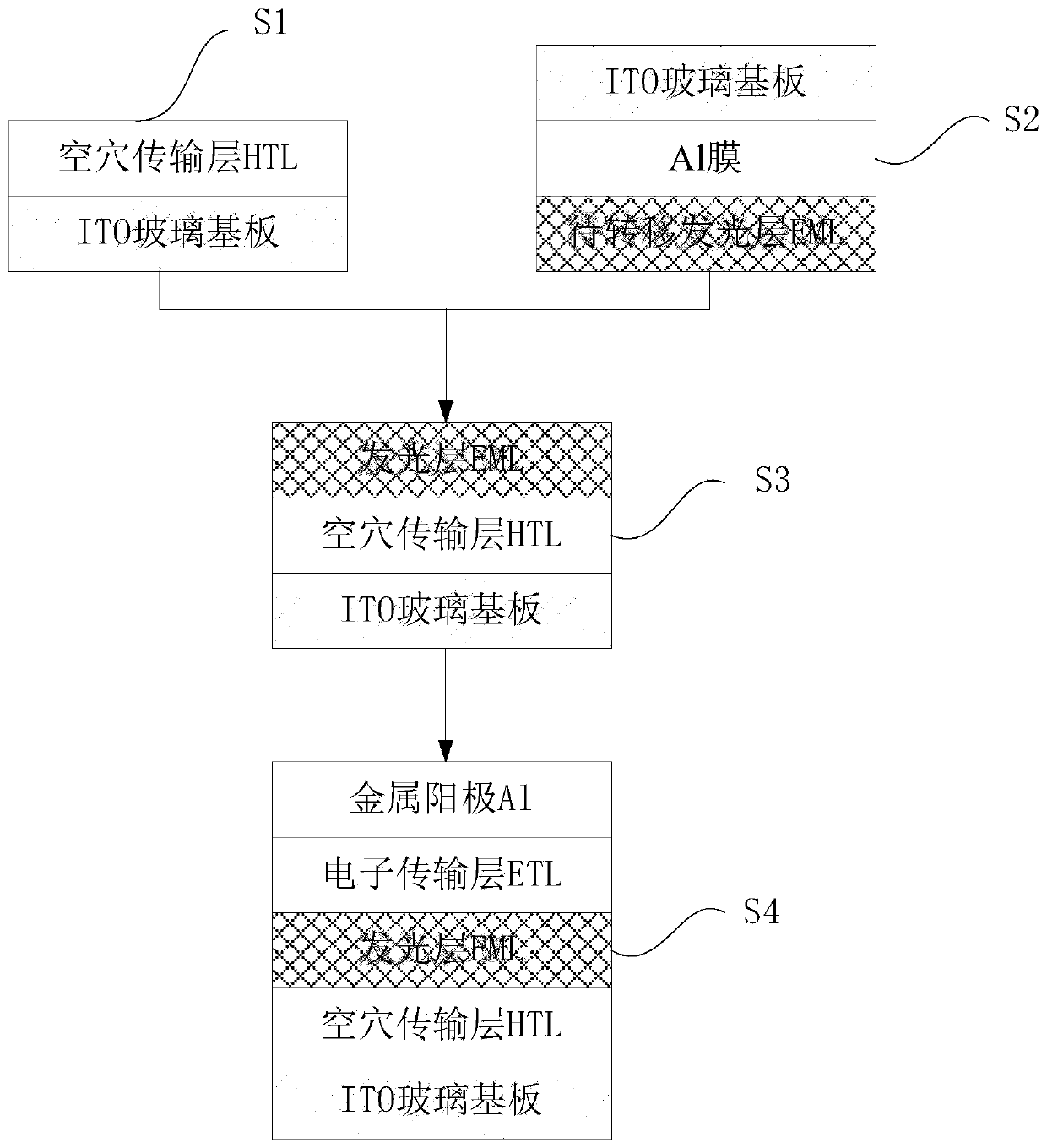

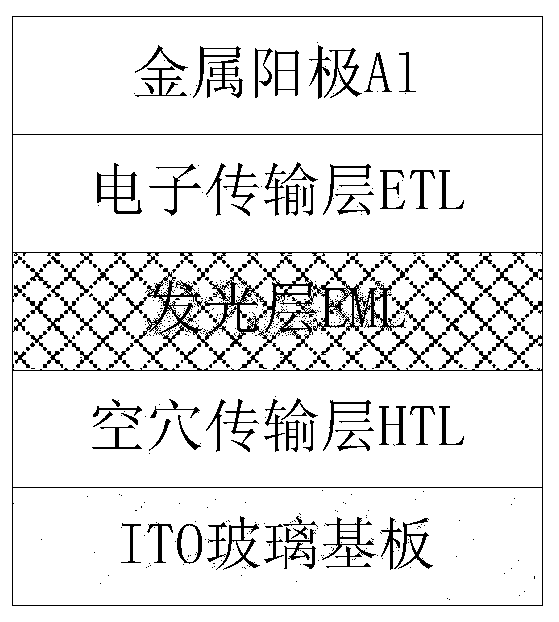

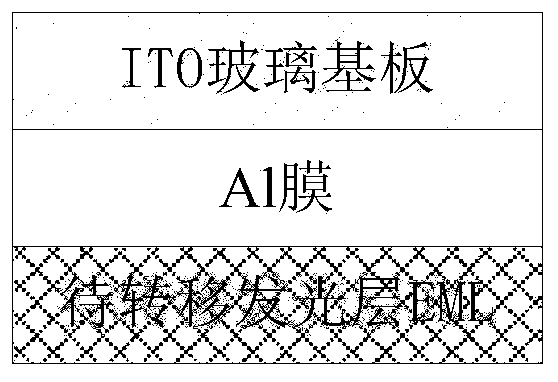

Method for preparing OLED device by femtosecond laser forward transfer technology

InactiveCN111384313ALow processing environment requirementsLow costSolid-state devicesSemiconductor/solid-state device manufacturingAcceptorElectron hole

The invention discloses a method for preparing an OLED device by a femtosecond laser forward transfer technology, and the method comprises the following steps: evaporating a hole transport layer HTL on an ITO glass substrate to form an acceptor ITO glass substrate; then preparing a donor ITO glass substrate of a to-be-transferred light-emitting layer EML with a specific pattern; then transferringa light-emitting layer EML on the donor ITO glass substrate to the hole transport layer HTL in the step S1 by using femtosecond laser pulses; and finally, evaporating an electron transport layer ETL and a metal anode Al on the transferred light-emitting layer EML. According to the method, the organic light-emitting functional layer thin film material can be accurately transferred to the corresponding substrate in a high-resolution and specific shape under the non-vacuum condition, accurate control over the transfer area is achieved, the requirement for the machining environment is low, the cost is reduced, and meanwhile, the production efficiency is improved.

Owner:WUHAN UNIV OF TECH

An automatic loading and unloading device for a glass grinder

ActiveCN110270927BSimple structureEasy to operateGrinding machinesGrinding feedersStructural engineeringMechanical equipment

The invention discloses a small rapid compatible automatic loading and unloading device of a glass grinding machine and belongs to the technical field of mechanical equipment. The automatic loading and unloading device comprises a grinding machine and a frame, wherein a loading device and an unloading device are arranged on the frame; the loading device comprises a loading sliding rail; a material box is arranged on the loading sliding rail; a first screw and a material box pushing plate are mounted at one end of the loading sliding rail; a fourth screw is arranged at the other end of the loading sliding rail; a loading pushing plate is arranged on the fourth screw; a second screw and a glass pushing plate are arranged above the material box; a glass sliding rail is arranged at the front end of the second screw; the unloading device comprises an unloading sliding rail; a longitudinal moving cylinder and a first pushing plate are arranged on the outer side of the unloading sliding rail; transverse channels are formed in the ends of the unloading sliding rail and the loading sliding rail; a transverse moving cylinder is arranged on the outer sides of the transverse channels; one side close to the loading sliding rail of the transverse moving cylinder is connected with a second pushing plate; and a third screw and a gripping device are arranged above the unloading sliding rail. The small rapid compatible automatic loading and unloading device of the glass grinding machine is high in automation degree, simple in structure and excellent in compatibility.

Owner:SHANGHAI UNIV

Gun drill manufacturing method of employing integrated 3D printing

InactiveCN112719823AAvoid decompositionImprove toughnessAdditive manufacturing apparatusArc welding apparatus3d printEngineering

The invention belongs to the technical field of gun drill manufacturing through 3D printing, and particularly relates to a gun drill manufacturing method of employing rapid integrated 3D printing for electric arc 3D printing of a drill handle and a drill stem of a gun drill, and supersonic flame 3D printing of a carbide gun drill bit. The interface properties of the drill handle and the drill stem obtained through electric arc 3D printing are superior to that of the gun drill interface welded and manufactured by a traditional method; and transition layer metal Co powder can avoid the brittleness of the interface between a low alloy layer and a medium carbon steel layer, so that the toughness of the gun drill interface is improved, the average hardness of the medium carbon steel layer is improved by 19.7%, the average hardness of the alloy steel layer is improved by 12.1%, and the tensile strength of the composite material is improved by 11.9%. According to the carbide gun drill bit obtained through supersonic flame 3D printing, the average hardness is greater than or equal to 89 HRC, and the internal organization structure is stable and uniform in distribution; flame 3D printing equipment is adopted, and decomposition of WC in the printing process can be effectively inhibited, so that the bonding strength is high, the compactness is achieved, and the wear resistance is excellent; and the manufacturing method provided by the invention has low requirements on a processing environment, and does not need a vacuum and sealed environment.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for processing aluminum alloy stopper

InactiveCN103522019AReduce processing burdenGuaranteed connection qualityScrew threadAluminium alloy

Disclosed is a method for processing an aluminum alloy stopper. The method includes a vertical rib processing step and an outer thread processing step. The vertical rib processing step includes using a die sleeve to process a stopper blank, accordingly extruding a concave part and a convex part on the cylindrical outer side wall of the stopper blank, and obtaining the stopper blank with the concave part and the convex part. The outer thread processing step includes utilizing an executing component to contact with the cylindrical outer side wall of the stopper blank with the concave part and the convex part, starting a hydraulic lifting device and a rotary motor, forming a thread on the convex part accordingly, and obtaining the aluminum alloy stopper.

Owner:青岛亚华制盖有限公司

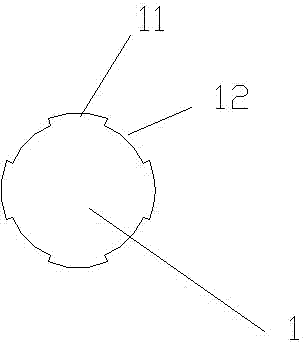

A kind of electrolytic machining method of inner surface micro-bulges of sleeve parts

ActiveCN103433579BElastic property advantageProtection from erosionElectrochemical machining apparatusThin slabEngineering

The invention provides an electrochemical machining method for micro-protrusions on the inner surface of a sleeve part, belonging to the field of electrochemical machining. According to the electrochemical machining method, an elastic insulating sheet with a tiny group pore structure is utilized, one surface of the elastic insulating sheet facing to the part is subjected to conductive treatment, a tool cathode is formed by a conductive layer of the elastic insulating sheet and the elastic insulating sheet, the sleeve part is taken as a tool anode, electrolyte is filled between the cathode and the anode, and the anode and the cathode are respectively connected with a positive electrode and a negative electrode of a power supply for electrochemical machining to produce micro-protrusion structures on the inner surface of the sleeve part. By adopting the electrochemical machining method provided by the invention, the micro-protrusion structures can be formed on the inner surface of the sleeve part, and the electrochemical machining method has the characteristics of high production speed of the micro-protrusions, low cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Electromoulding processing method for micro-structure on external surface of cylindrical revolving body element

InactiveCN100567582CReduce processing costsImprove efficiencyElectroforming processesMetallic materialsTitanium

The invention relates to an electroforming processing method for the microstructure of the outer surface of a cylindrical revolving body part, which belongs to the field of electroforming processing. The feature of this method is to make a flexible electroformed shielding film with a micro-pore structure; use mechanical extrusion to closely fit the cylindrical rotating body part and the flexible shielding film, use the part as the cathode for electroforming, and Micro-protruding structures are formed on the surface of the body; the electroformed shielding film can be made entirely of insulating materials, or it can be made of insulating materials plus a layer of metal materials (such as platinum, titanium, etc.) with electrochemical insoluble properties. By adopting the electroforming processing method of the present invention, the micro-protruding structure can be formed on the outer surface of the cylindrical revolving body part, and has the characteristics of high manufacturing precision, high speed and low cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com