Adjustable internal thread deburring device

An internal thread and deburring technology, which is applied in the field of adjustable internal thread deburring devices, can solve the problems of difficult removal of internal thread tooth burrs, easy-to-bruise thread removal, poor deburring effect, etc., to achieve processing The effect of low environmental requirements, strong process operability, and convenient tool replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

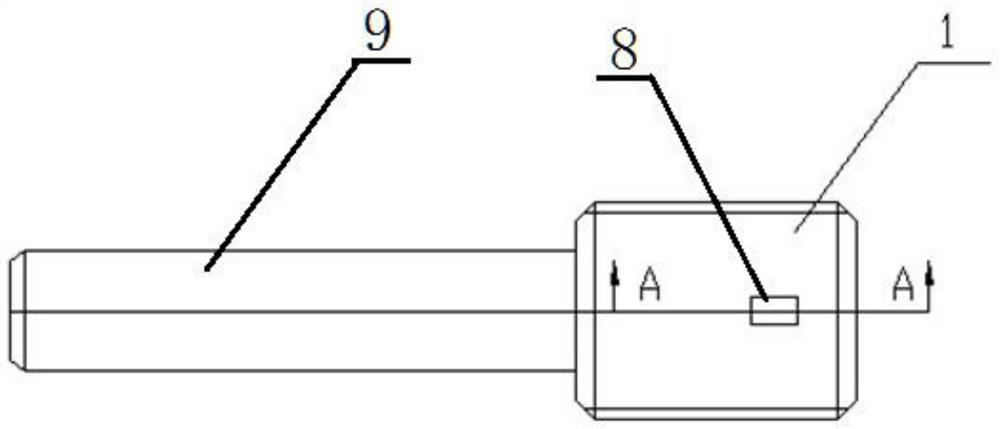

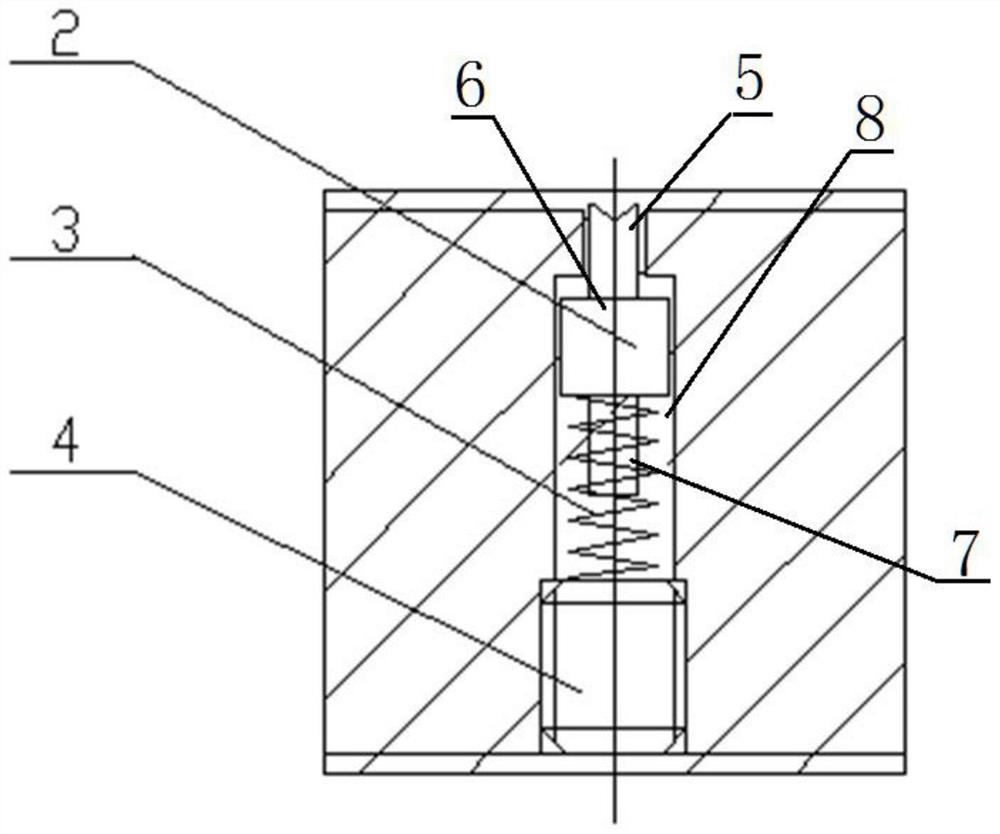

[0018] Embodiment 1 of the present invention: an adjustable internal thread deburring device, including a screw rod 1, the bottom of the screw rod 1 is provided with a mounting groove 8, and a guide blade 2 is arranged in the mounting groove 8, and the guide blade 2 is connected to a spring 3, and the spring 3 The other end is connected to the plug 4.

[0019] The head of the guide blade 2 is a cutting head 5, the middle is a blade body 6, and the bottom is a spring connecting column 7.

[0020] The plug 4 is threadedly connected to the mounting groove 8, the mounting groove 8 is square at one end of the cutting bit 5, and other parts can be circular.

[0021] The screw rod 1 is connected with a clamping rod 9 .

[0022] The thread part of the screw 1 is processed according to the actual internal thread size, the clamping rod 9 is a polished rod, which can be clamped, and the installation groove 8 is opened at the bottom of the screw 1 tooth profile, and the guide blade 2 is ...

Embodiment 2

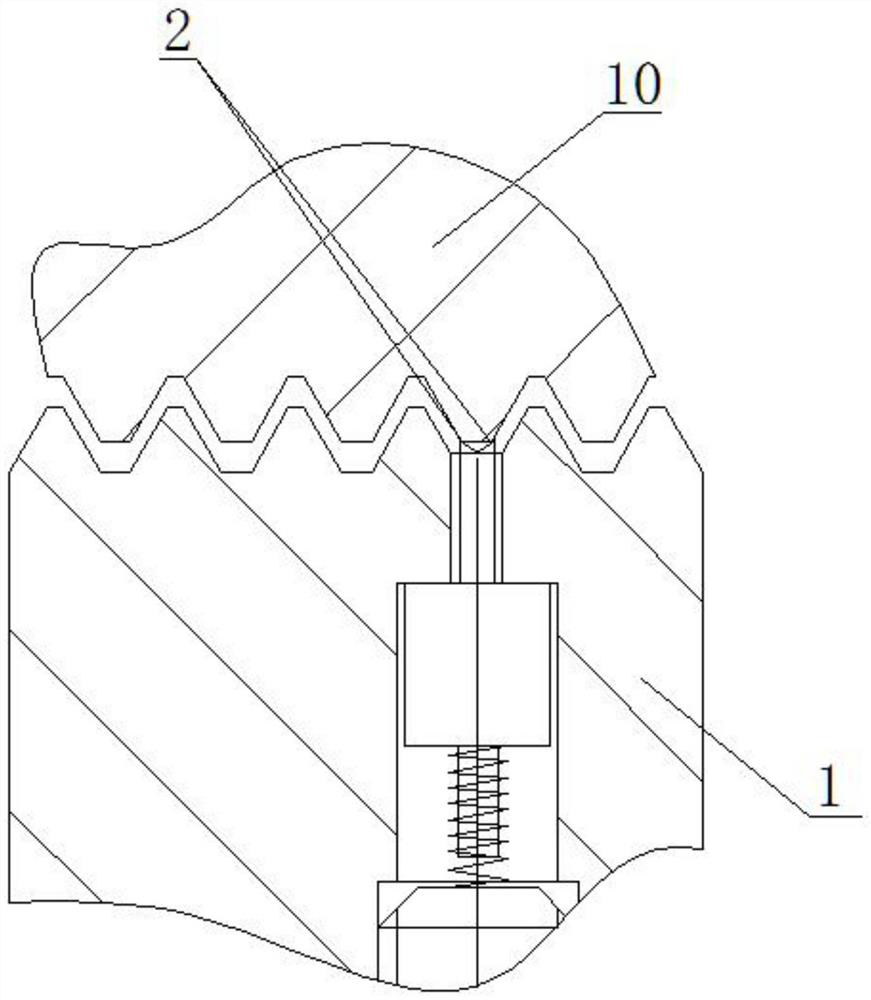

[0023] Embodiment 2 of the present invention: an adjustable internal thread deburring device, including a screw rod 1, an installation groove 8 is opened at the bottom of the screw rod 1, a guide blade 2 is arranged in the installation groove 8, the guide blade 2 is connected to a spring 3, and the spring 3 The other end is connected to the plug 4.

[0024] The installation groove 8 is square, which can limit the position of the guide blade 2.

[0025] The screw rod 1 is connected with a clamping rod 9 .

[0026] The threaded part of the screw 1 is processed according to the actual internal thread size, the clamping rod 9 is a polished rod, which can be clamped, and the installation groove 8 is opened at the bottom of the screw rod 1, and the spring connecting column 7 of the guide blade 2 is loaded into the spring 3, and then installed Enter plug 4. According to the screw thread matching clearance, when the screw rod 1 is screwed into the internal thread of the workpiece 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com