Layered Ti-Ni shape memory composite material and preparation method thereof

A composite material, ti-ni technology, applied in metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of poor mechanical properties, weak interface bonding of shape memory alloy wire filled shape memory composite materials, etc. Achieve high fatigue strength, good biocompatibility and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides a layered Ti-Ni shape memory composite material with a TiNi phase volume content of 15%, which is obtained through the following steps:

[0032] (1) Take two industrial pure titanium plates and one pure nickel plate with a size of 100mm×75mm×0.7mm, soak the titanium and nickel plates in acetone for 30 minutes, polish the contact surface with a water grinder and clean them with alcohol, and use Ti / Ni / Ti structures stacked together;

[0033] (2) Preheat the above-mentioned stacked materials in a vacuum resistance furnace at 400-500°C for 8-10 minutes, and then immediately perform single-pass rolling compounding at a reduction of 50%-60%, and then roll The obtained composite plate is cut into two halves from the middle along the width direction, and the cut composite plate is subjected to repeated surface treatment, preheating, rolling, and three passes of cumulative composite rolling;

[0034] (3) The clad plate obtained by cumulative clad rolling ...

Embodiment 2

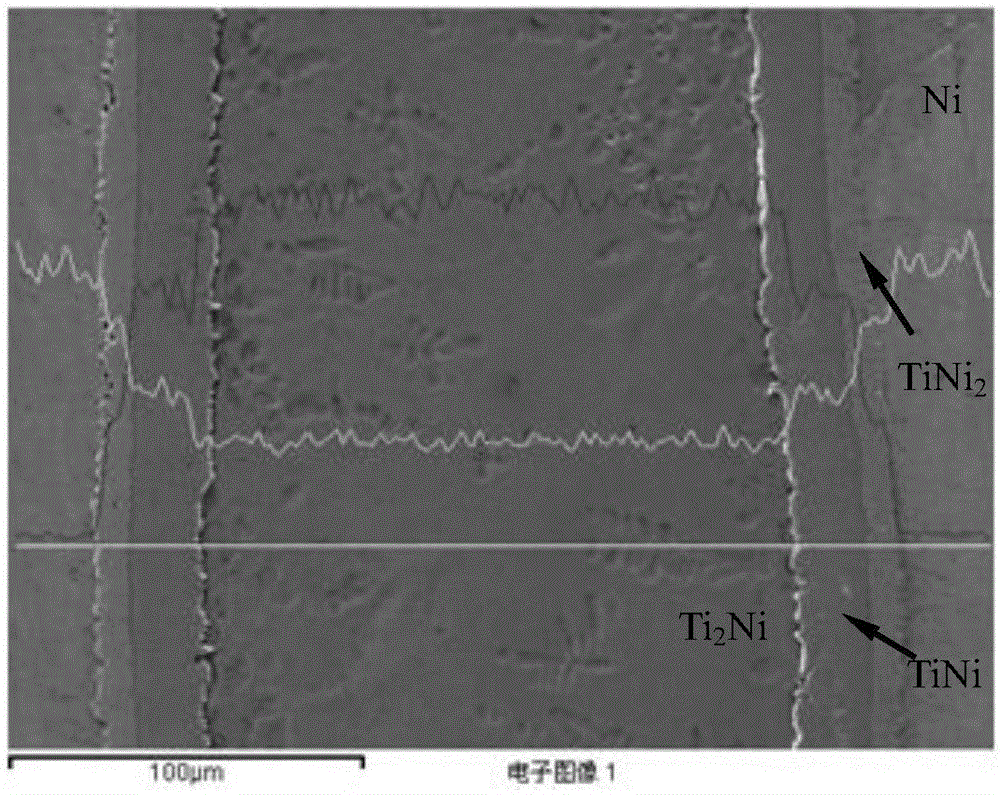

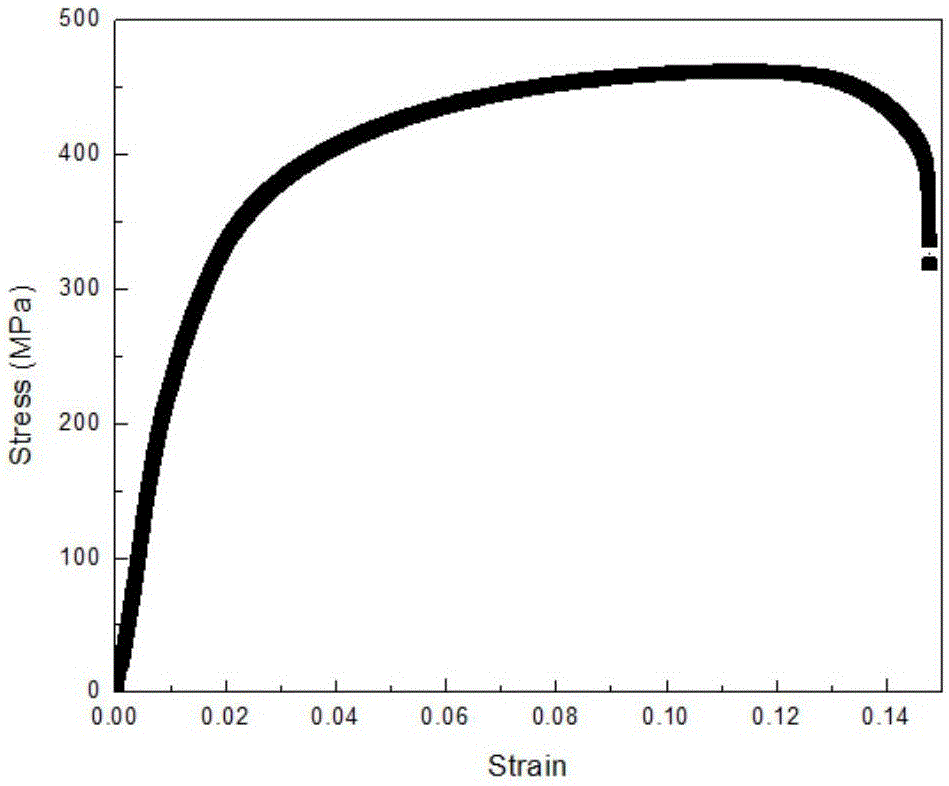

[0039] This example provides a layered Ti-Ni shape memory composite material with a TiNi phase volume content of 30%. The specific implementation method is: change the diffusion annealing process in Example 1 to annealing at 900°C for 3 hours, and keep other processes unchanged. The interface microstructure of the obtained composite is as follows: Figure 5 As shown, it can be seen that the thickness of the TiNi phase layer is obviously wider, and the thickness of the TiNi phase layer is about 50 μm, and the total thickness of the eight layers is 400 μm, accounting for about 30% of the composite material; at this time, the stress-strain curve of the composite material is as follows Figure 6 As shown, the yield strength is 202.4MPa, the tensile strength is 376.4MPa, and the elongation at break is about 14%.

Embodiment 3

[0041] This example provides a layered Ti-Ni shape memory composite material with a TiNi phase volume content of 50%. The specific implementation method is: change the diffusion annealing process in Example 1 to annealing at 900°C for 12 hours, and keep other processes unchanged. Change the diffusion annealing process in Example 1 to annealing at 900 °C for 12 h, and keep other processes unchanged, the interface microstructure of the obtained composite material is as follows Figure 7 As shown, the measured thickness of the TiNi phase layer is about 80 μm, and the total thickness of the eight layers is 640 μm, accounting for about 50% of the composite material; at this time, the stress-strain curve of the composite material is as follows Figure 8As shown, the yield strength is 244MPa, the tensile strength is 435.8MPa, and the elongation at break is about 14%. It can be seen that with the increase of the diffusion annealing temperature (compared with Example 1) and the increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com