Electromoulding processing method for micro-structure on external surface of cylindrical revolving body element

A technology of microstructure and processing method, applied in electroforming, electrolysis process, etc., to achieve the effect of saving processing time, reducing processing cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

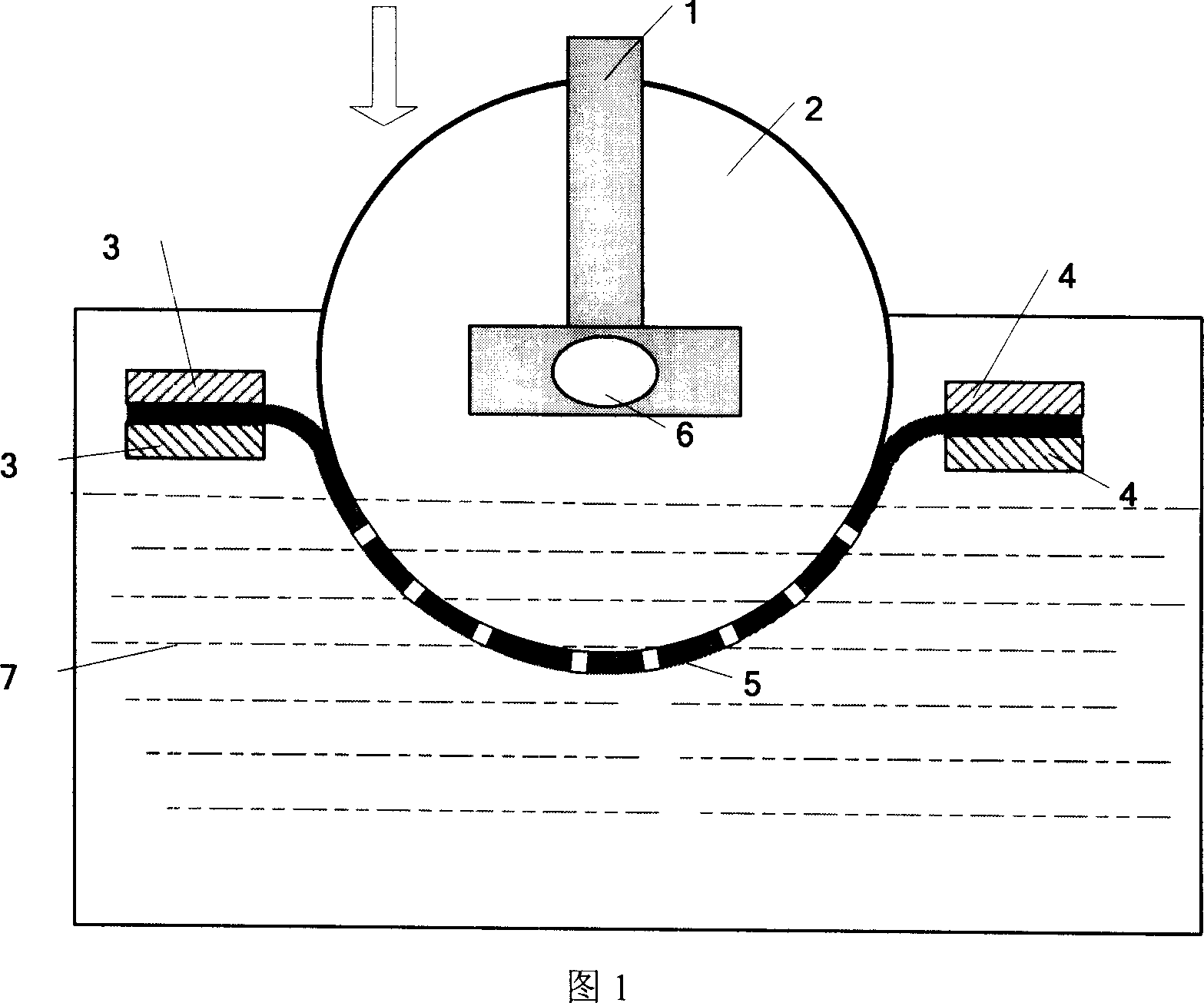

[0020] The operation process of implementing the present invention-"electroforming method for micro-protrusion structure on the outer surface of cylindrical revolving body parts" will be described below in conjunction with specific examples.

[0021] The metal radiator of cylindrical electronic components used in the electronics industry has the best shape as a thin-walled cylinder with a large number of small protrusions with high aspect ratio on the surface. These tiny protrusions can increase the heat dissipation area, and when used, the thin-walled cylinder Covered on the outer surface of cylindrical electronic components, it can quickly reduce the temperature.

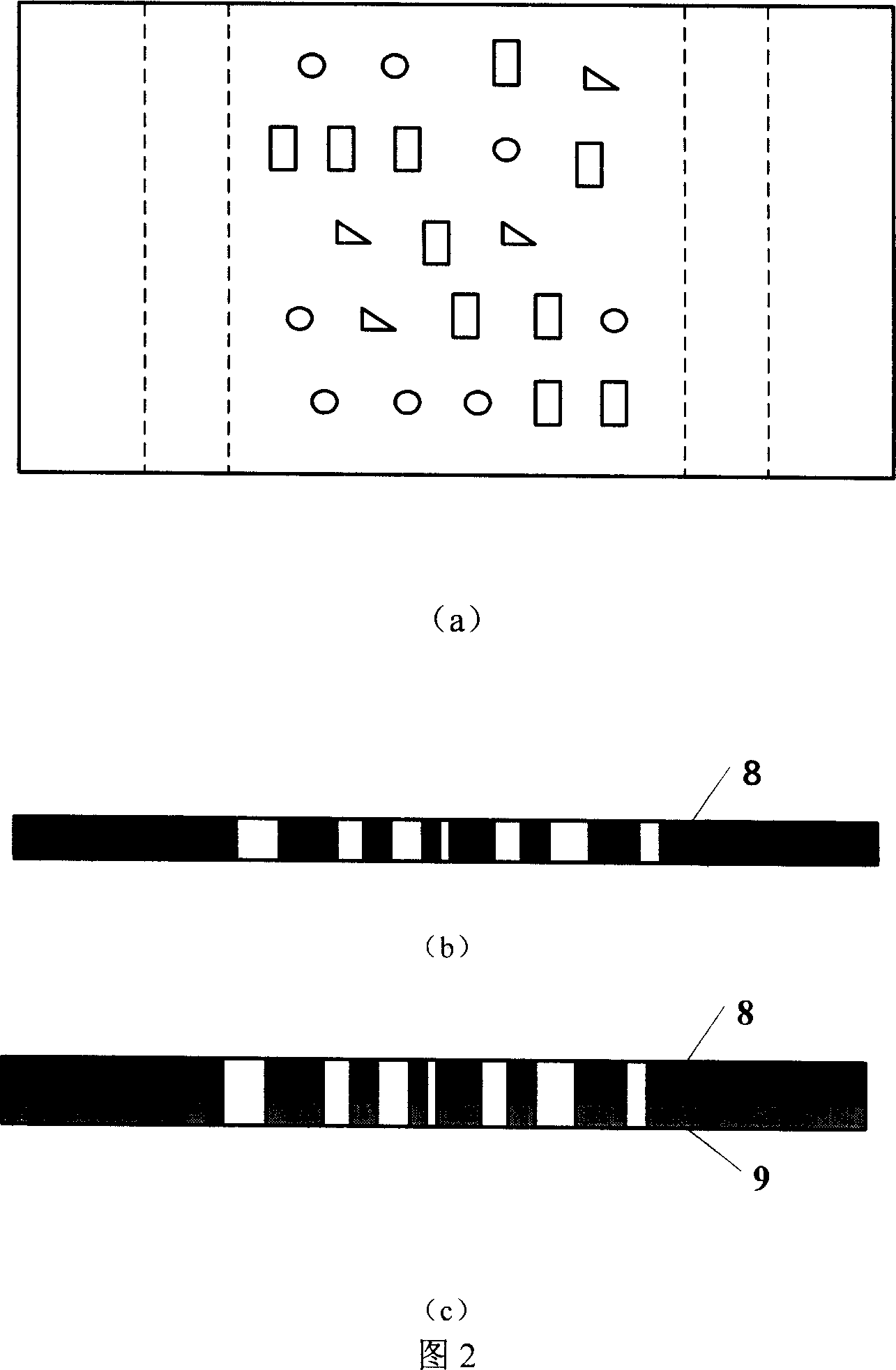

[0022] In the process of electroforming, it is planned to use 3 times of electroforming, that is, 1 / 3 of the thin-walled cylinder is processed by electroforming each time. Referring to Figure 1, the specific processing implementation process goes through the following steps in sequence:

[0023] (1), using drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com