Method for machining butterfly-shaped nanometer gap through coordinative shaping of femtosecond laser phase position amplitude

A nano-slit and femtosecond laser technology, applied in the field of laser applications, can solve problems such as low efficiency, low precision, and unfriendly environment, and achieve the effects of improving processing efficiency, avoiding system errors, and requiring low processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

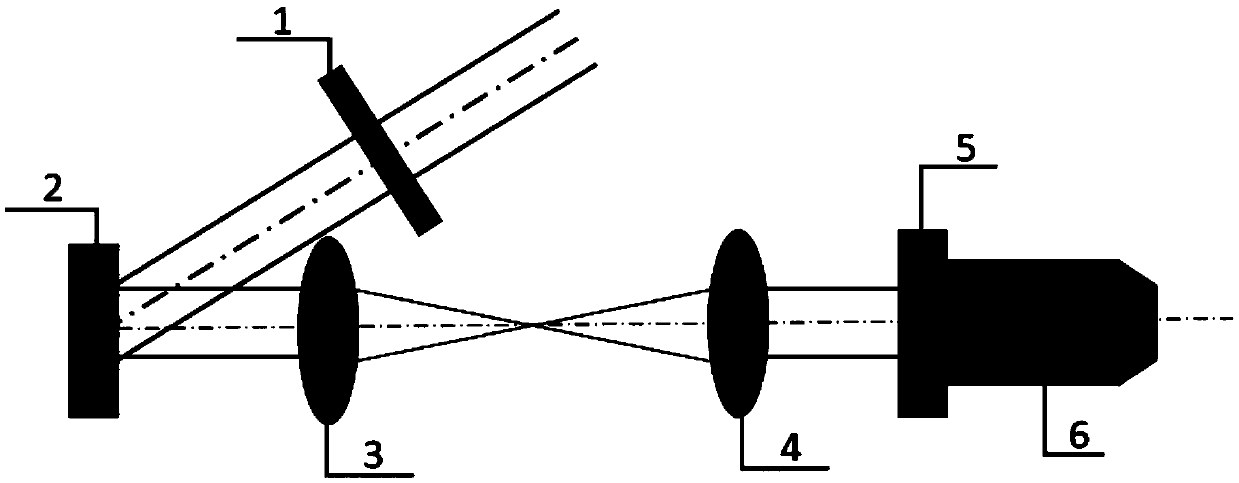

[0029] A device for implementing a femtosecond laser phase-amplitude cooperative shaping method for processing butterfly-shaped nano-slits, such as figure 1 As shown, it is mainly composed of an energy adjustment device 1 , a reflective phase liquid crystal spatial light modulator 2 , a first plano-convex lens 3 , a second plano-convex lens 4 , a slit device 5 and a focusing objective lens 6 .

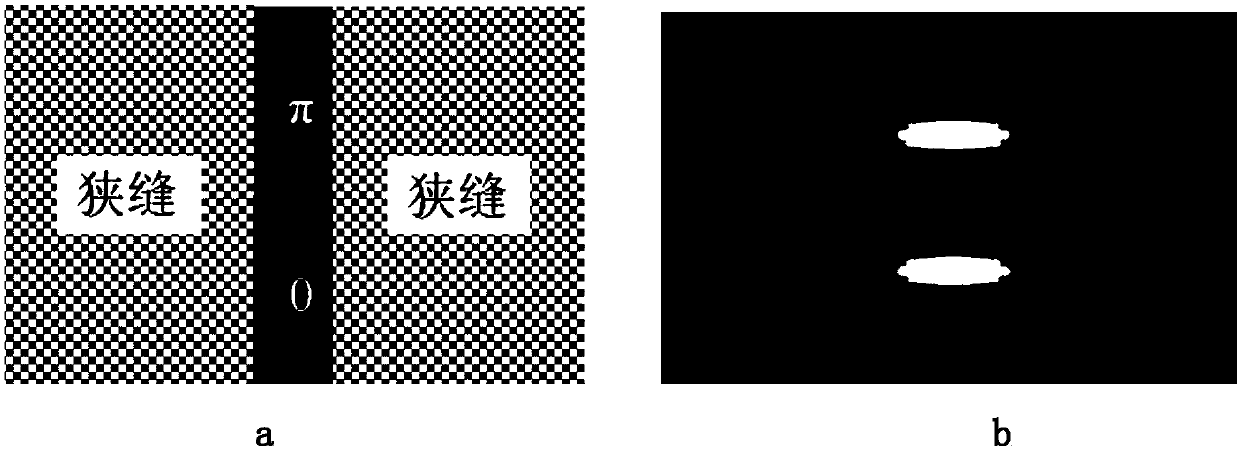

[0030] The femtosecond laser amplification stage generates a Gaussian beam, and the beam energy 1 is adjusted by the energy adjustment device, and the energy is 1.1mw. The adjusted light beam is incident on the liquid crystal surface of the reflective phase-type liquid crystal spatial light modulator 2 at a small angle, and the phase loaded by the reflective phase-type liquid crystal spatial light modulator is:

[0031]

[0032] In this embodiment, k=0, n=2.

[0033] The incident beam passes through the spatial light modulator to complete phase shaping, and the shaped beam passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com