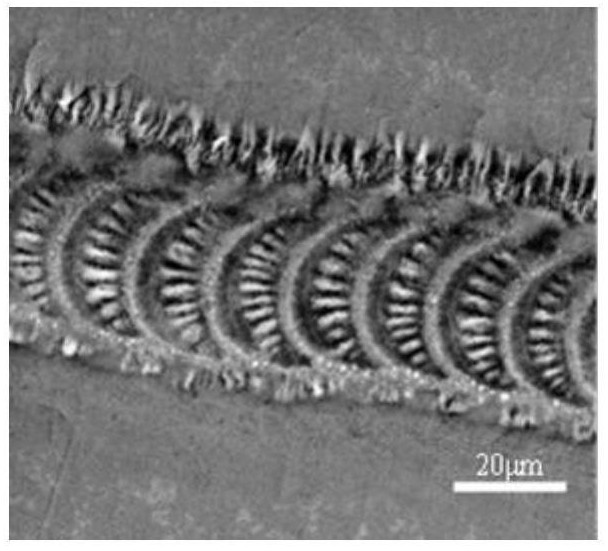

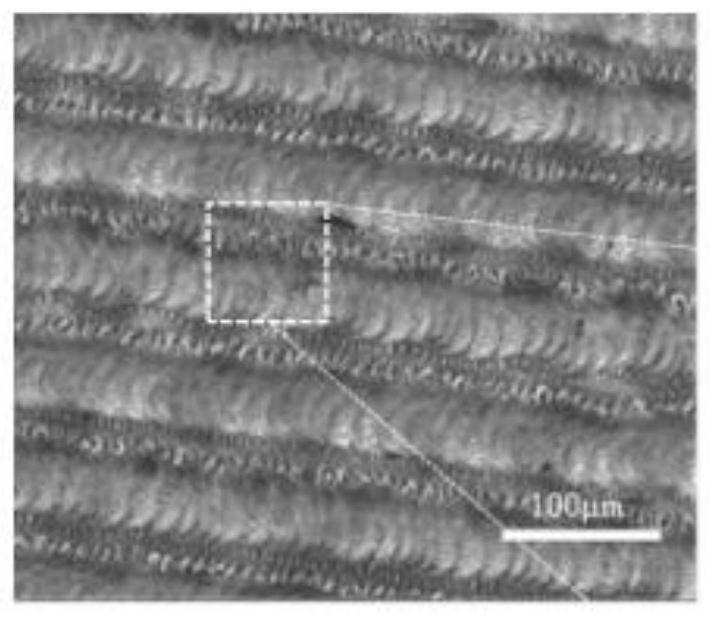

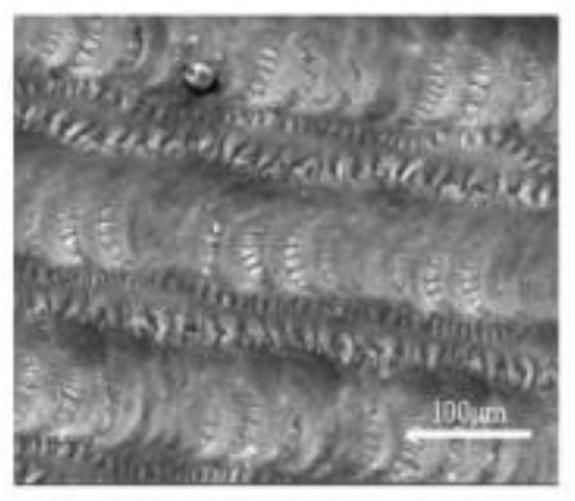

A micro-nano self-organized structure prepared on the surface of stainless steel and its preparation method

A micro-nano, self-organizing technology, applied in the direction of manufacturing micro-structure devices, micro-structure technology, micro-structure devices, etc., can solve the problems of structure manufacturing that cannot achieve nano-level precision, achieve low processing environment requirements, increase contact angle, Effect of increasing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The optical fiber laser processing system adopted in the method includes three parts: a laser, an optical path transmission system, and a mobile platform for fixing workpieces. The pulsed fiber laser system includes three main parts: SP-100C-0020 fiber laser, digital signal generator and laser control software from British SPI Company. The laser control software is used to control the output laser power, pulse frequency, pulse duty cycle, etc.; The optical fiber laser optical transmission system mainly includes: laser collimator, aperture, reflector 1, focusing convex lens 2 and other optical components; the workbench 6 for fixing the sample 5 is a two-dimensional mobile platform of Shenzhen Good Technology Co., Ltd., using motion Control software and write G code programs to realize precise positioning and movement of workpieces.

[0025] A method for preparing a micro-nano self-organized structure on the surface of stainless steel by using a pulsed fiber laser, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com