Femtosecond laser processing device and 1x8 ridge type optical splitter processed through device

A femtosecond laser processing and femtosecond laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome processing steps, high processing costs, and high processing environment requirements, and achieve low processing environment requirements. , The processing method has fewer steps, and the effect of improving the processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

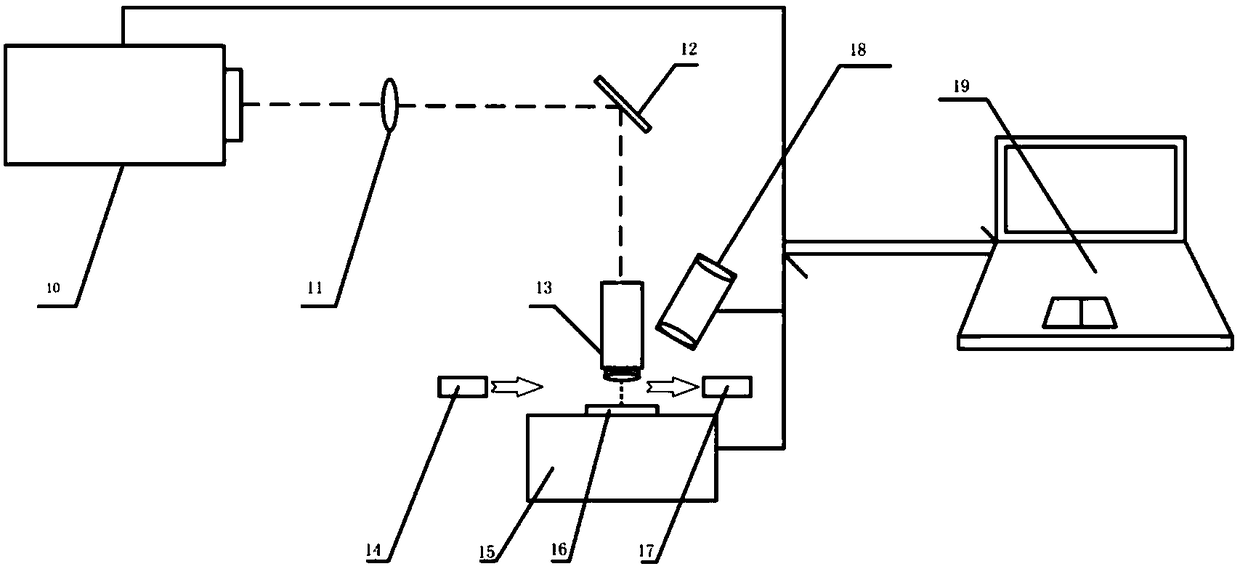

[0014] Such as figure 1 , a femtosecond laser processing device, comprising a femtosecond laser 10, a half-wave plate 11, a mirror 12, a microscope objective lens 13, an air blowing part 14, a six-degree-of-freedom working platform 15, a base material 16, an air suction part 17, CCD camera 18, computer 19.

[0015] Along the path of the femtosecond pulsed laser beam emitted by the femtosecond laser 10, a half-wave plate 11, a mirror 12, a microscopic objective lens 13 and a six-degree-of-freedom working platform 15 are sequentially arranged. Femtosecond laser 10 , six-degree-of-freedom work platform 15 and CCD camera 18 are all connected to computer 19 .

[0016] The processing wavelength of the femtosecond laser 10 is 800nm, the repetition frequency is 10kHZ, the laser pulse is 100fs, and the average power is 300mW.

[0017] The reflector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com