A kind of electrolytic machining method of inner surface micro-bulges of sleeve parts

A processing method and technology of sleeves, which are applied in the field of electrolytic machining of micro-protrusions on the inner surface of sleeve parts, to achieve the effects of low processing environment requirements, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

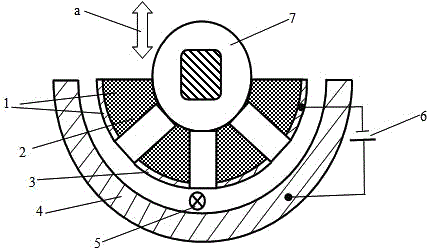

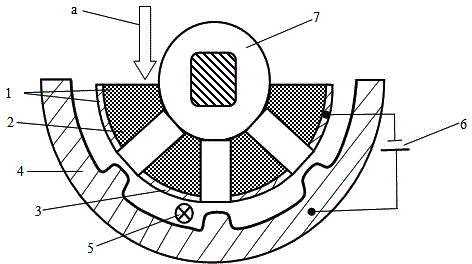

[0023] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

[0024] The micro-protrusion structure can effectively reduce wear, which has been verified in bionic mechanical tests. In the process of electrolytic machining, it is proposed to use 3 times of electrolytic forming, that is, 1 / 3 of the inner surface of each electrolytic machining. (Of course, other times of electroforming can also be used). Combined with the accompanying drawings, the specific processing implementation process goes through the following steps in sequence:

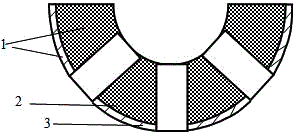

[0025] (1) Reference figure 1 As shown, using the drilling technology, drill a tiny cluster hole structure on the elastic insulating sheet 2 and the conductive layer 3 (generally using inert metals, such as platinum, etc.), to obtain the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com