Long-life thermal insulation material and efficient submerged arc furnace

A technology with thermal insulation and long service life, applied in the field of smelting furnaces, which can solve the problems of thermal energy leakage in the furnace, falling off of refractory materials, and difficult installation of refractory bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

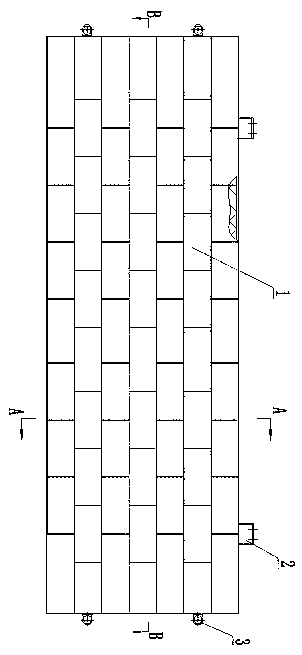

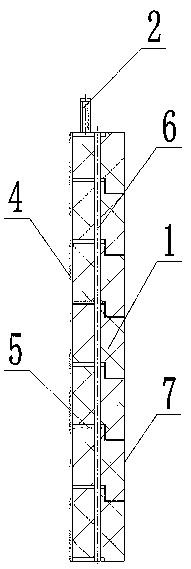

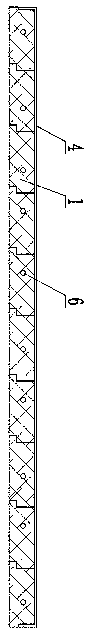

[0023] like figure 1 , figure 2 and image 3 In the shown long-life thermal insulation material and high-efficiency submerged arc furnace, the furnace door includes a furnace door bottom plate 4 and a refractory brick 1 installed on the furnace door bottom plate 4 . The furnace door bottom plate 4 is a steel rectangular plate, and peripheral cabinet plates are fixedly welded around the steel rectangular plate; two lifting ring seats 2 are welded on the upper side of the furnace door bottom plate 4, so as to lift or lower the furnace door. Both sides of the door bottom plate 4 are respectively provided with two sliding guide wheels 3 . like Figure 4 As shown, a number of reinforcing ribs 5 parallel to each other are fixedly welded on the bottom plate 4 of the furnace door, and each reinforcing rib 5 is provided with pin holes corresponding to the number of refractory bricks 1 . The rib height of the reinforcing rib 5 is lower than the thickness of the refractory brick 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com