Method and system for preparing titanium dioxide with exposure high-activity surface by utilizing femtosecond laser

A technology of femtosecond laser and titanium dioxide, applied in the field of femtosecond laser application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

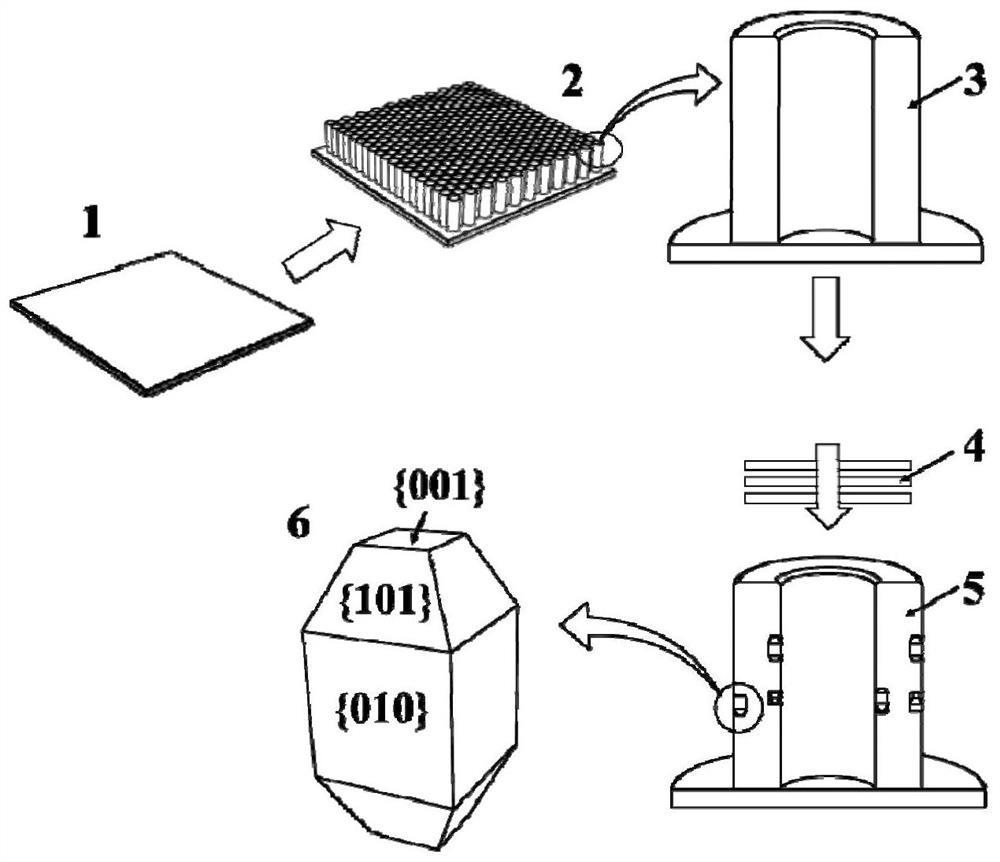

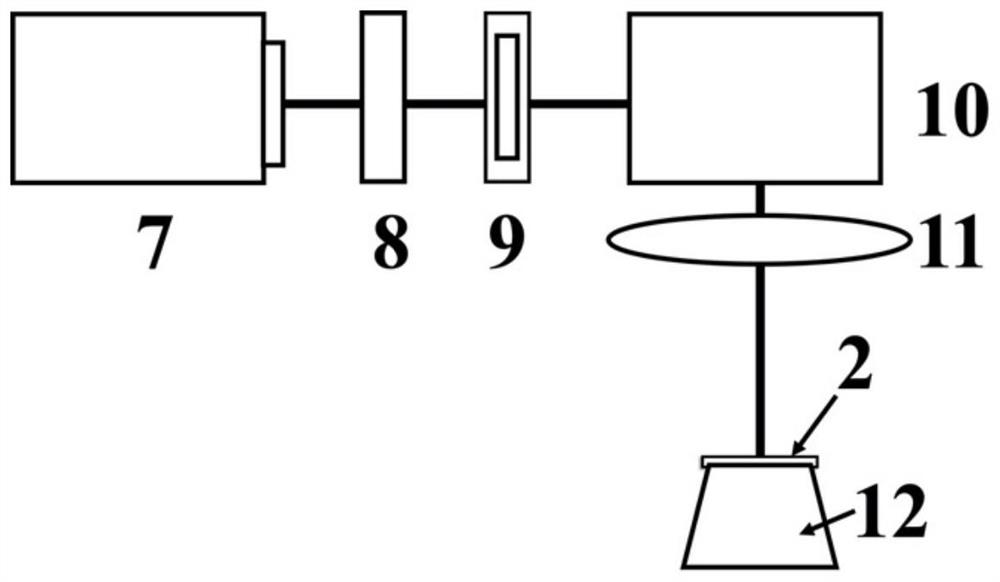

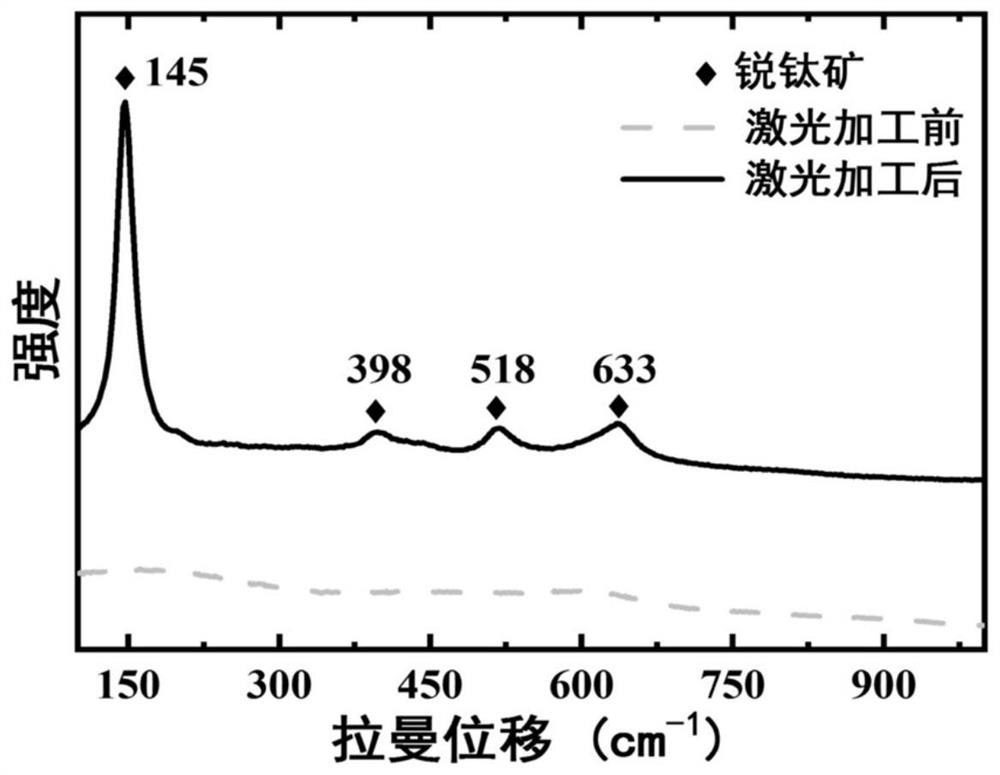

Method used

Image

Examples

Embodiment 1

[0033] (1) Utilize the anodic oxidation method to prepare a solid titanium dioxide nanotube array film on the surface of the titanium sheet 1, the process is as follows:

[0034] (1-1) A titanium piece whose surface is polished and has a purity of 99% or more is cut into a rectangle of 2 cm×4 cm. Put the titanium sheet into ethanol and deionized water and ultrasonically clean it three times, each time for 10 minutes, and dry it in a blast drying oven for later use;

[0035] (1-2) Measure water and ethylene glycol according to the volume ratio of 1:49, and prepare solution A;

[0036] (1-3) Slowly add ammonium fluoride with a mass fraction of 0.5% to solution A, and stir until the ammonium fluoride is completely dissolved to obtain solution B;

[0037] (1-4) Using the solution B in step (1-3), the titanium sheet 1 in step (1-1) is used as the anode, and the platinum mesh is used as the cathode, and the platinum mesh and the titanium sheet 1 are placed opposite each other at a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com