A kind of processing method of aluminum alloy bottle stopper

A technology of aluminum alloy and bottle stopper, applied in the field of bottle stopper processing, can solve the problem of not providing low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

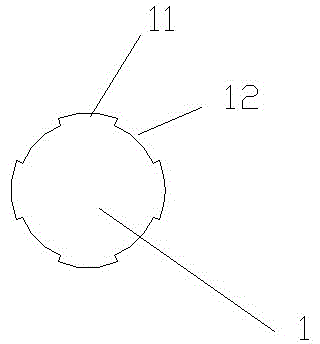

[0030] A processing method for an aluminum alloy bottle stopper 1, comprising:

[0031] I longitudinal rib processing steps

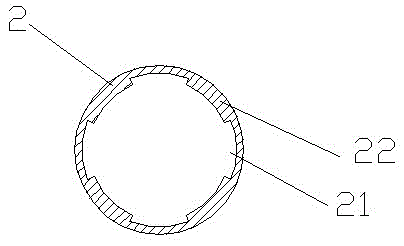

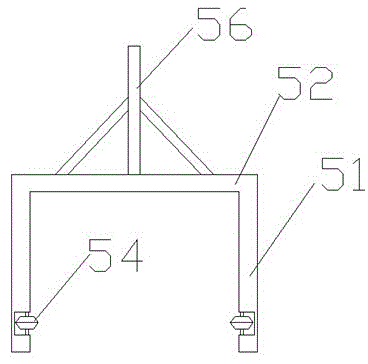

[0032] Wherein, the longitudinal rib part processing step uses a longitudinal rib part processing device, and the longitudinal rib part processing device includes: an extrusion sleeve drawing die 2, and the extrusion sleeve drawing die 2 is roughly cylindrical, and the cylindrical There are longitudinal protruding strips 22 and longitudinal grooves 21 on the inner side, the number of the longitudinal protruding strips 22 and the longitudinal grooves 21 are four, and they are arranged at intervals. In any section in the longitudinal direction, the longitudinal protruding strips 22 and the longitudinal grooves 21 have arc cross-sections, and the arc cross-sections of the longitudinal protruding strips 22 and the longitudinal grooves 21 have the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com