Preparation method of carbon fiber interface atomic-oxygen-resistant phosphorous coating

A technology resistant to atomic oxygen and carbon fiber, applied in the direction of carbon fiber, fiber treatment, chemical instruments and methods, etc., can solve problems such as thermal expansion coefficient mismatch, surface shape change, etc., and achieve the effect of simple production conditions and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

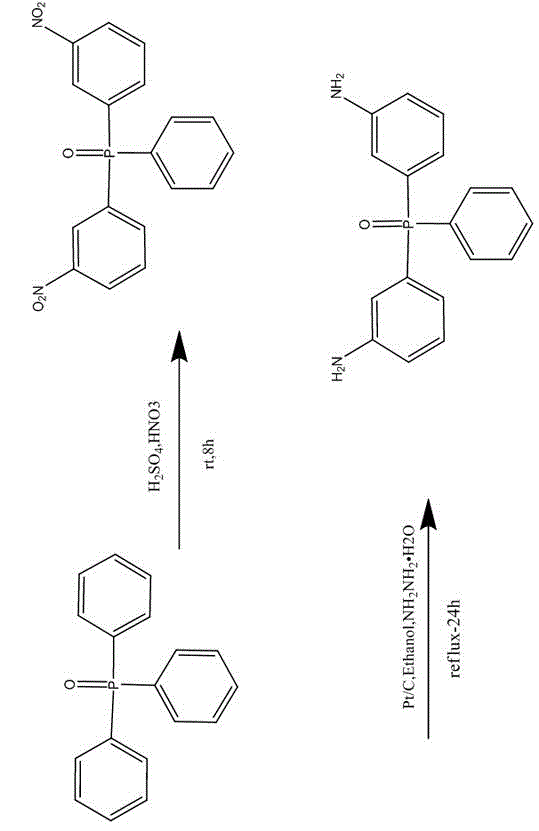

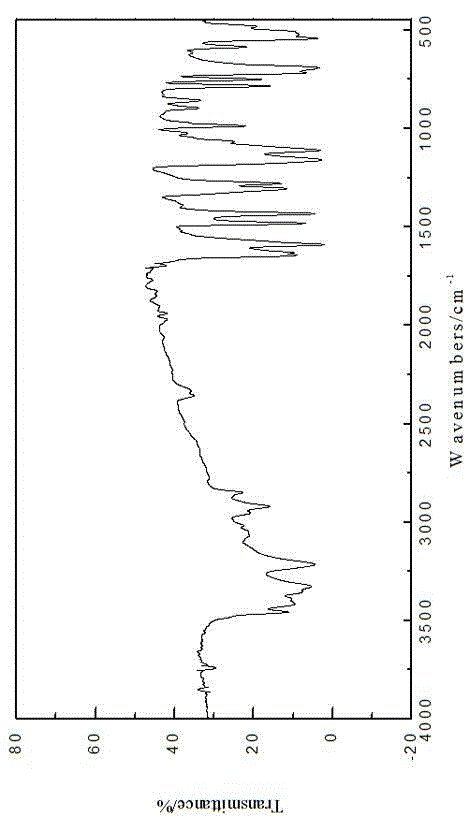

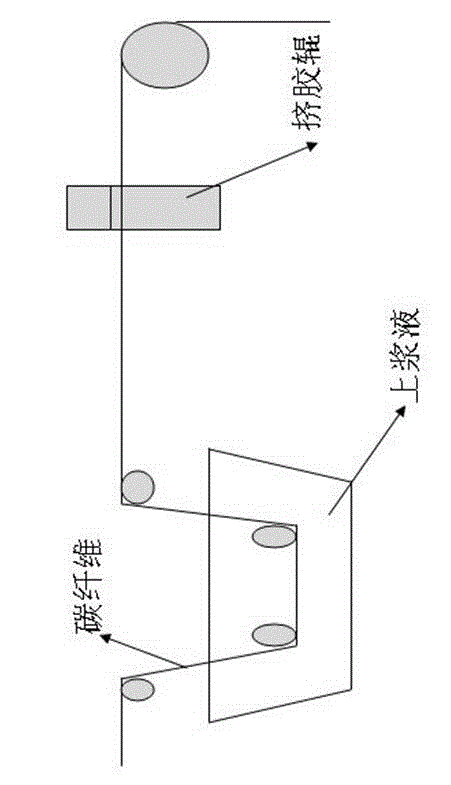

[0025] 1. Synthesis of bis(3-aminophenyl)phenylphosphine oxide ( figure 1 ):

[0026] (1) Nitration of triphenylphosphine oxide: Add 13.9 g of triphenylphosphine oxide and 100 ml of concentrated sulfuric acid in sequence into a container equipped with an electric stirrer, a constant pressure dropping funnel and a thermometer. The mixture of smoked nitric acid 7.4g and concentrated sulfuric acid 50ml is carried out under the condition of ice-salt bath. The temperature was controlled at -5°C, the time for dropping the mixed acid was controlled at 2 hours, and the reaction time was 8 hours. After the reaction is over, pour the reaction solution into a 1L container with ice-water mixture. When the temperature drops to room temperature, use chloroform to extract, use sodium bicarbonate or sodium carbonate aqueous solution to adjust the pH value to neutral, and wash it twice with water Finally, the chloroform solvent was removed to obtain a crude product, which was dried i...

Embodiment 2

[0030] 1. Synthesis of bis(3-aminophenyl)phenylphosphine oxide:

[0031] (1) For nitration of triphenylphosphine oxide, add 14 g of triphenylphosphine oxide and 100 ml of concentrated sulfuric acid in sequence into a container equipped with an electric stirrer, a constant pressure dropping funnel and a thermometer, and put fuming gas into the constant pressure dropping funnel. Nitric acid 7.4g and the mixture of concentrated sulfuric acid 50ml, react under the condition of ice-salt bath. The temperature is controlled at -10°C, the dropwise addition of mixed acid is controlled at 3 hours, and the reaction time is 10 hours. After the reaction is over, pour the reaction solution into a 1L container with ice-water mixture. When the temperature drops to room temperature, use chloroform to extract, use sodium bicarbonate or sodium carbonate aqueous solution to adjust the pH value to neutral, and wash it twice with water Finally, use a rotary evaporator for 4 hours to remove the chl...

Embodiment 3

[0035] 1. Synthesis of bis(3-aminophenyl)phenylphosphine oxide:

[0036](1) For nitration of triphenylphosphine oxide, add 13.8 g of triphenylphosphine oxide and 100 ml of concentrated sulfuric acid in sequence into a container equipped with an electric stirrer, a constant pressure dropping funnel and a thermometer, and put the hair into the constant pressure dropping funnel. The mixture of smoked nitric acid 7.5g and concentrated sulfuric acid 50ml is carried out under the condition of ice-salt bath. The temperature is controlled at -10°C, the dropwise addition of mixed acid is controlled at 3 hours, and the reaction time is 10 hours. After the reaction is over, pour the reaction solution into a 1L container with a mixture of ice and water. When the temperature drops to room temperature, use chloroform to extract, use sodium bicarbonate or sodium carbonate aqueous solution to adjust the pH value to neutral, and wash with water for 2~ After 5 times, finally use a rotary evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com