Nozzle coating for continuous casting of rare earth steel and preparation method of nozzle coating

A coating and rare earth technology, which is applied in the field of rare earth steel continuous casting nozzle coating and its preparation, can solve the problems of nozzle nodulation and blockage, achieve the effect of improving utilization efficiency and reducing foreign inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

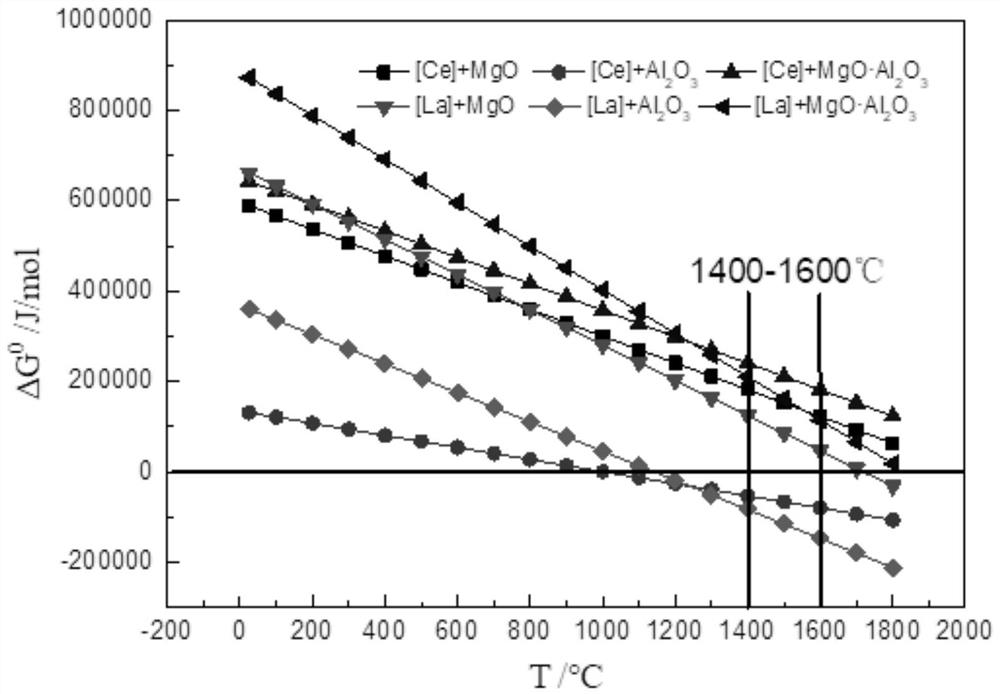

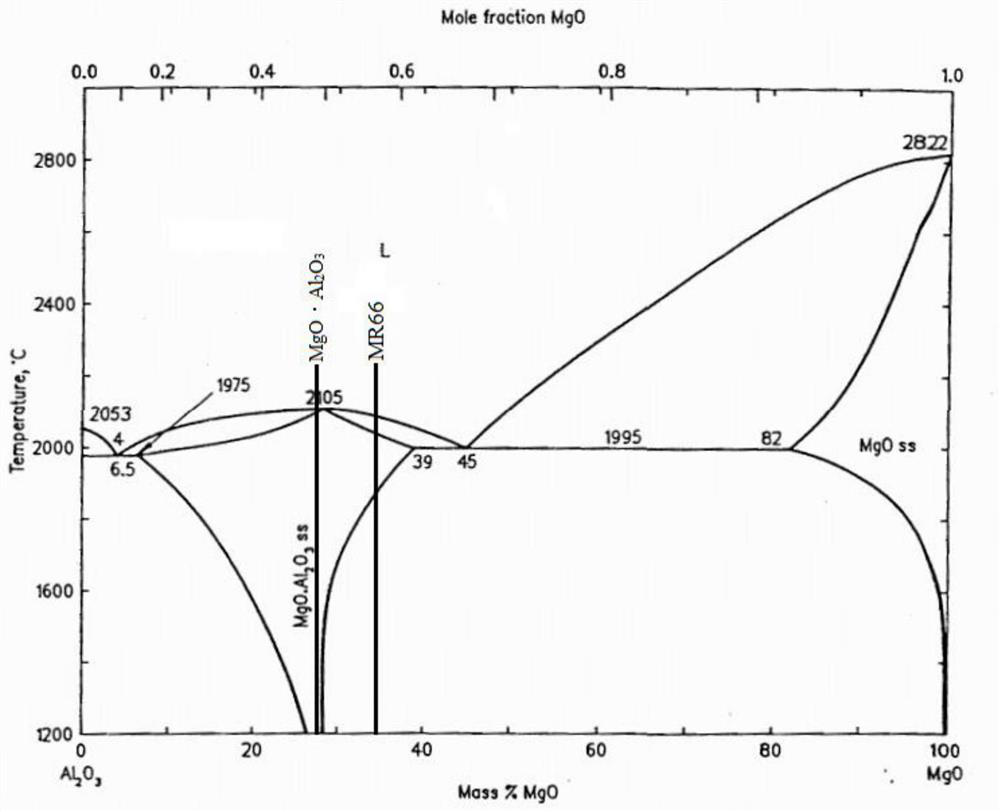

Problems solved by technology

Method used

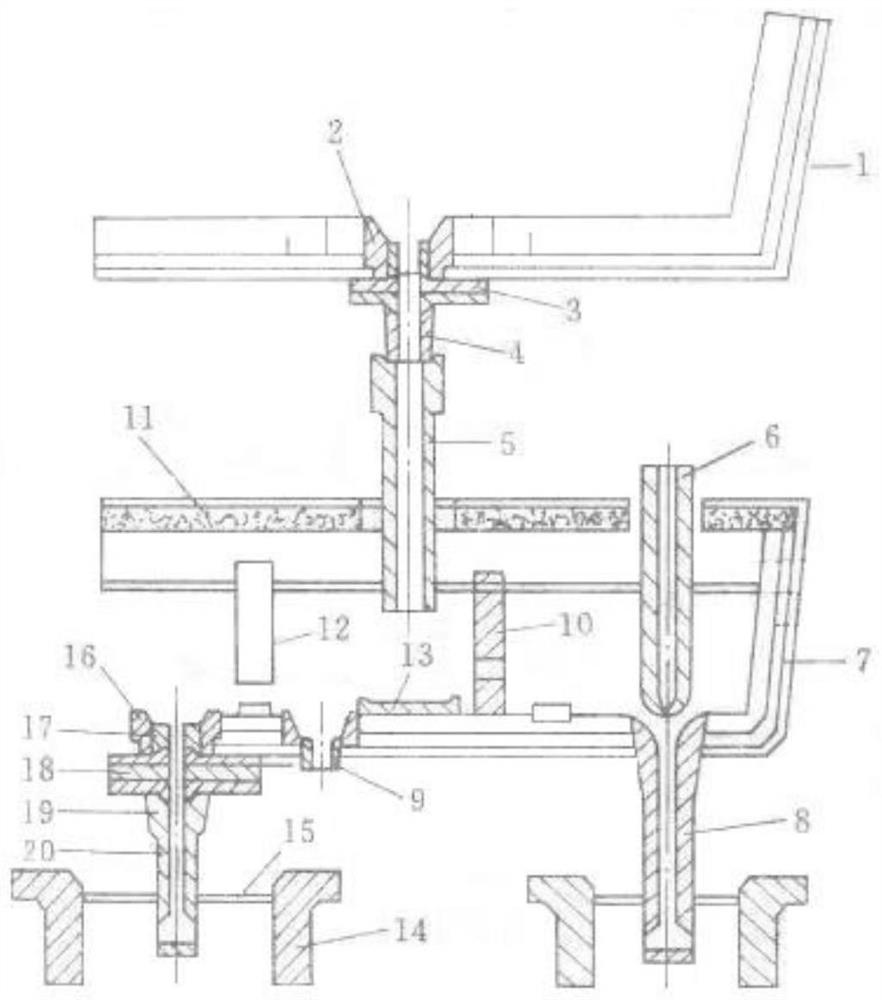

Image

Examples

preparation example Construction

[0060] On the other hand, the present invention provides the preparation method of the above coating, the preparation method comprises the steps:

[0061] Step 1. Grind the alumina material, the magnesia material, the cerium oxide material and / or the lanthanum oxide material, and the binder into powders of less than 200 mesh (<0.075mm) respectively;

[0062] Step 2. Mix the above materials evenly in proportion;

[0063] Step 3, drying the above-mentioned mixed materials for later use.

[0064] Specifically, in step 1, according to the mass percentage content, Al in the alumina material 2 O 3 ≥98%, such as industrial alumina; MgO ≥98% in magnesia materials, such as magnesia; CeO in cerium oxide materials 2 ≥99%; La in lanthanum oxide material 2 O 3 ≥99%; the binder is the binder used for refractory gunning materials, and the binder is powdered organic matter, such as natural organic matter: dextrin, starch, etc.; synthetic organic matter: phenolic resin, epoxy resin, etc. ...

Embodiment 1

[0088] The steel produced is wear-resistant steel NM400, and the production process is converter → LF furnace → RH furnace → continuous casting. The target composition is: C0.19-0.21%; Si 0.55-0.65%; Mn 1.45-1.60%; P≤0.015%; S≤0.005%; Cr 0.35-0.45%; Ti 0.01-0.02%; Ce 0.005%; La 0.005%.

[0089] The raw materials used are industrial alumina, magnesia, cerium oxide, lanthanum oxide and dextrin. The chemical composition of industrial alumina is Al 2 O 3 It accounts for 98.5%; the chemical composition of magnesia is MgO, accounting for 99%; cerium oxide and lanthanum oxide are pure reagents, and the content of rare earth oxides is 99%. Starch acts as a binder. The specific composition is: industrial alumina 59%, magnesia 26%, cerium oxide 5%, lanthanum oxide 5%, dextrin 5%.

[0090] Preparation method of powder:

[0091] Step 1. Grind industrial alumina, magnesia, cerium oxide, lanthanum oxide and dextrin into powders below 200 meshes respectively;

[0092] Step 2, mix the ...

Embodiment 2

[0101] The steel produced is wear-resistant steel NM400, and the production process is converter → LF furnace → RH furnace → continuous casting. The target composition is: C0.19-0.21%; Si 0.55-0.65%; Mn 1.45-1.60%; P≤0.015%; S≤0.005%; Cr 0.35-0.45%; Ti 0.01-0.02%; Ce 0.005%; La 0.005%.

[0102] The raw materials used are industrial alumina, magnesia, cerium oxide, lanthanum oxide and starch. The chemical composition of industrial alumina is Al 2 O 3 It accounts for 99%; the chemical composition of magnesia is MgO, accounting for 98.5%; cerium oxide and lanthanum oxide are pure reagents, and the content of rare earth oxides is 99%. Starch acts as a binder. The specific composition is: industrial alumina 65%, magnesia 29%, cerium oxide 1.5%, lanthanum oxide 1.5%, starch 3%.

[0103] Preparation method of powder:

[0104] Step 1. Grind industrial alumina, magnesia, cerium oxide, lanthanum oxide and starch into powders below 200 meshes respectively;

[0105] Step 2, mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com