Lithium/air battery

An air battery and metal lithium technology, applied in battery electrodes, battery pack components, circuits, etc., can solve problems such as easy power failure, corrosion of anode metal lithium, and poor cycle performance, and achieve reduced corrosion, wide electrochemical window, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

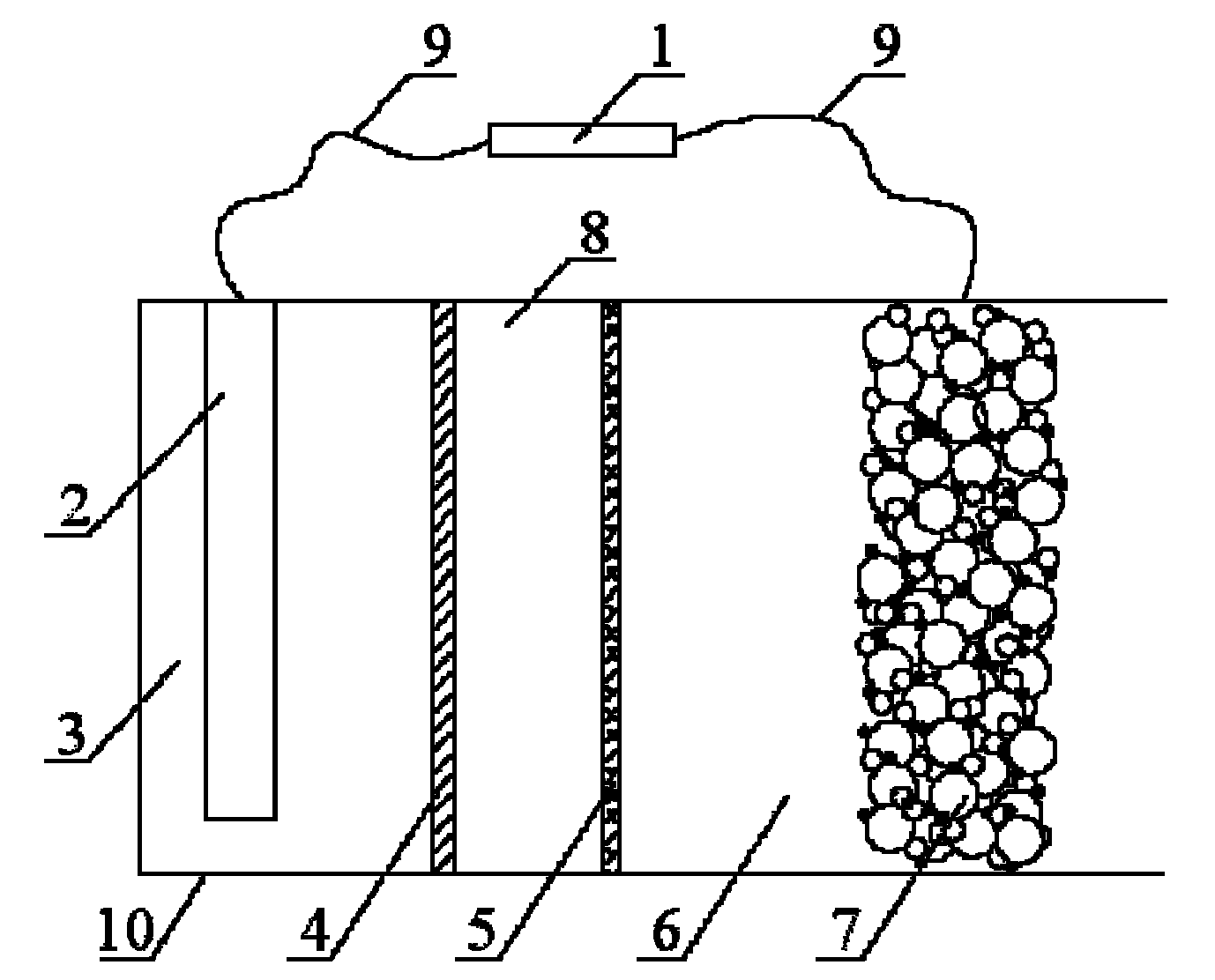

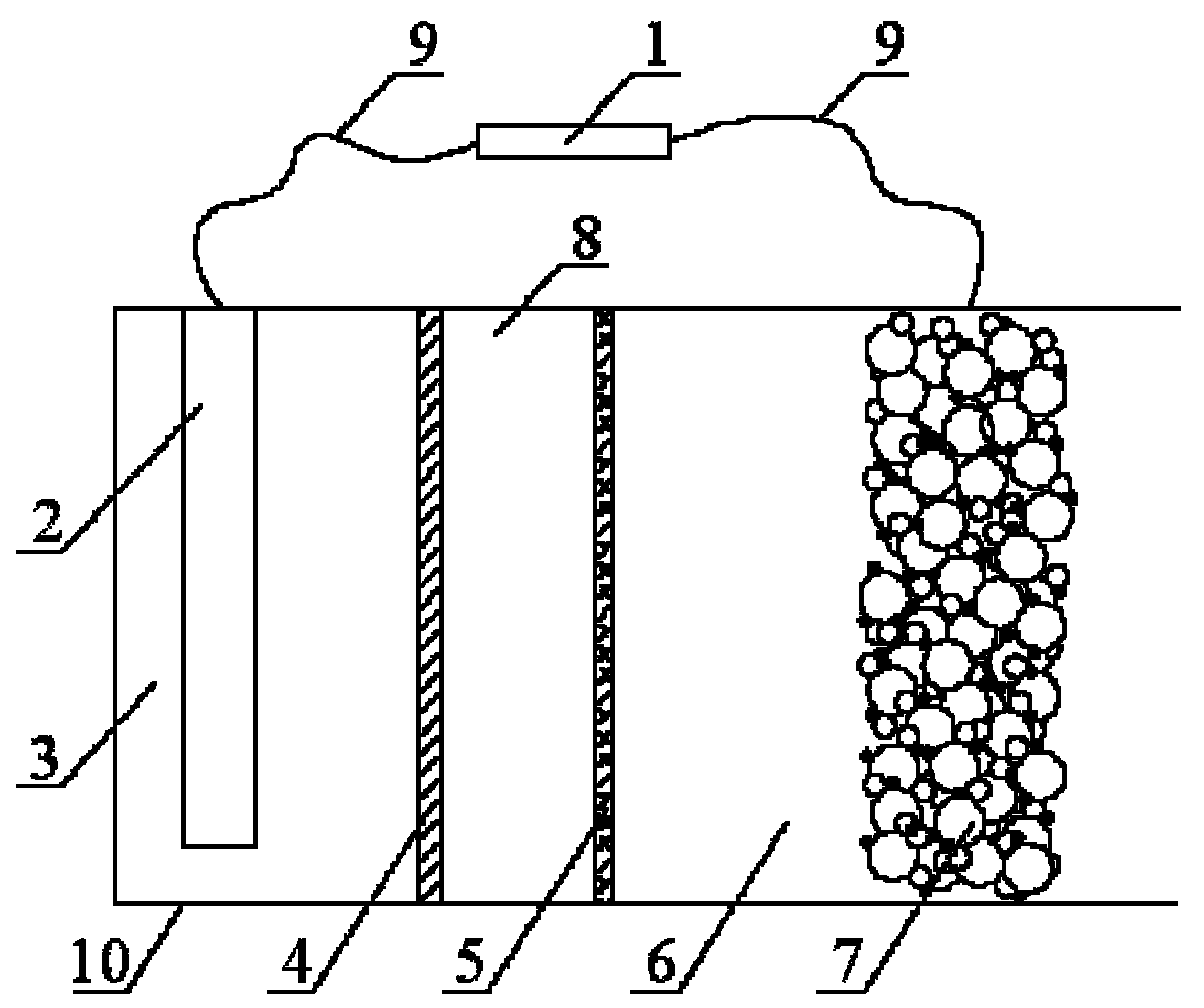

[0014] Specific implementation mode 1: Combination figure 1 To illustrate, the lithium / air battery of this embodiment consists of a lithium metal anode 2, an anode chamber 3, a solid inorganic electrolyte (ie, inorganic fast ion conductor, super ion conductor) membrane 4, a diaphragm 5, a cathode chamber 6, a cathode 7, and a buffer chamber 8. , Wire 9 and casing 10; one end of the casing 10 is closed, the other end is open, the cathode 7 is fixed at the open end, the cathode 7 is composed of a carbon-supported catalyst; the casing 10 is separated by a solid inorganic electrolyte membrane 4 and a diaphragm 5 into an anode compartment 3 , The buffer chamber 8 and the cathode chamber 6, in which the diaphragm 5 is close to the open end of the casing 10, an anode chamber 3 is formed between the casing 10 and the solid inorganic electrolyte membrane 4, the anode chamber 3 is provided with a lithium metal anode 2, and the anode chamber 2 There is a hydrophobic ionic liquid inside. A...

specific Embodiment approach 2

[0018] Specific embodiment two: this embodiment is different from specific embodiment one in that the membrane 5 is a polypropylene nanofiltration membrane or a polyethylene nanofiltration membrane. Others are the same as the first embodiment.

[0019] The diaphragm 5 is used to form a buffer chamber 8 between the anode chamber 3 and the cathode chamber 6 to limit the cathode discharge product OH - The diffusion near the fast ion conductor produces an alkalinity gradient, so that the alkalinity in the buffer chamber 8 is not too high, thereby slowing down the corrosion of the fast ion conductor.

specific Embodiment approach 3

[0020] Specific embodiment three: this embodiment is different from specific embodiment one or two in that the material of the metal lithium anode 2 is lithium or a lithium alloy. Others are the same as the first or second embodiment.

[0021] The anode of this embodiment can use (battery grade) metallic lithium, or (industrial grade) metallic lithium, or lithium aluminum alloy, lithium magnesium alloy, or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com