Ocean epoxy zinc-rich anti-corrosion powder coating and preparation method thereof

An epoxy zinc-rich powder coating technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of affecting service life and safety, lower coating anti-corrosion performance, high zinc powder content, etc., to achieve Effects of reducing zinc oxide mist, improving anti-corrosion performance, and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

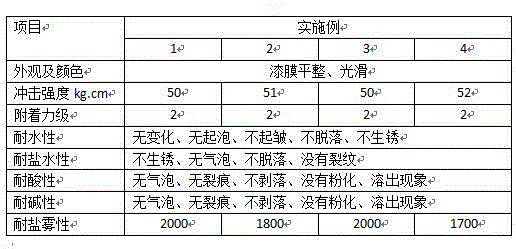

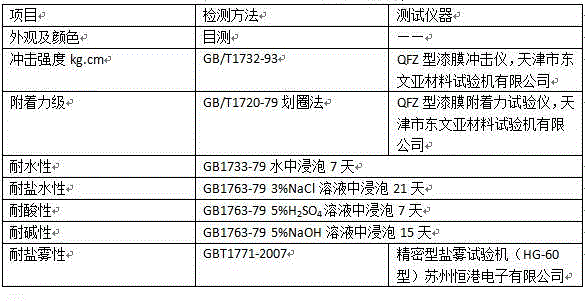

Examples

Embodiment 1

[0025] A kind of marine epoxy zinc-rich anticorrosion powder coating, is made up of the following raw materials of weight part:

[0026] 40 parts of E-12 epoxy resin, 16 parts of novolac epoxy resin, 10 parts of trimethylhexamethylenediamine, 2 parts of polyvinyl butyral, 0.2 parts of dimethylimidazole, aminopropyl triethoxy 3 parts of base silane, 20 parts of zinc powder with a particle size of 5-20 μm, 10 parts of aluminum powder with a particle size of 100 nm, 1 part of graphene, 0.6 part of ethylene bisstearamide, 0.8 part of polyethylene wax powder, antioxidant Agent DNP 2 parts, composite filler 10 parts;

[0027] Above-mentioned composite filler is made up of the raw material of following weight part:

[0028] 50 parts of clay, 50 parts of iron slag powder, 5 parts of nano jade powder, 2 parts of aluminum nitride powder, 2 parts of aluminum hydroxide powder, 2 parts of rare earth powder, 2 parts of vanadium diboride, 2,6-di-tert-butyl 1 part of p-cresol, 0.1 part of i...

Embodiment 2

[0033] A kind of marine epoxy zinc-rich anticorrosion powder coating, is made up of the following raw materials of weight part:

[0034] 50 parts of E-12 epoxy resin, 12 parts of novolac epoxy resin, 7 parts of trimethylhexamethylenediamine, 1 part of polyvinyl butyral, 0.1 part of dimethylimidazole, aminopropyl triethoxy 2 parts of silane, 16 parts of zinc powder with a particle size of 5-20 μm, 13 parts of aluminum powder with a particle size of 100 nm, 3 parts of graphene, 1 part of ethylene bisstearamide, 0.1 part of polyethylene wax powder, antioxidant 1 part of DNP, 15 parts of composite filler.

[0035] Above-mentioned composite filler is made up of the raw material of following weight part:

[0036] 40 parts of clay, 45 parts of iron slag powder, 7 parts of nano jade powder, 1 part of aluminum nitride powder, 1 part of aluminum hydroxide powder, 1 part of rare earth powder, 1 part of vanadium diboride, 2,6-di-tert-butyl 2 parts of p-cresol, 0.2 part of di-n-octyl tin...

Embodiment 3

[0040] A kind of marine epoxy zinc-rich anticorrosion powder coating, is made up of the following raw materials of weight part:

[0041] 45 parts of E-12 epoxy resin, 9 parts of novolak epoxy resin, 4 parts of trimethylhexamethylenediamine, 2 parts of polyvinyl butyral, 0.1 part of dimethylimidazole, aminopropyl triethoxy 1 part of base silane, 15 parts of zinc powder with a particle size of 5-20 μm, 15 parts of aluminum powder with a particle size of 100 nm, 2 parts of graphene, 1 part of ethylene bisstearamide, 0.1 part of polyethylene wax powder, antioxidant Agent DNP1 part, composite filler 20 parts.

[0042] Above-mentioned composite filler is made up of the raw material of following weight part:

[0043]45 parts of clay, 40 parts of iron slag powder, 6 parts of nano jade powder, 2 parts of aluminum nitride powder, 1 part of aluminum hydroxide powder, 2 parts of rare earth powder, 1 part of vanadium diboride, 2,6-di-tert-butyl 2 parts of p-cresol, 0.3 parts of di-n-octy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com