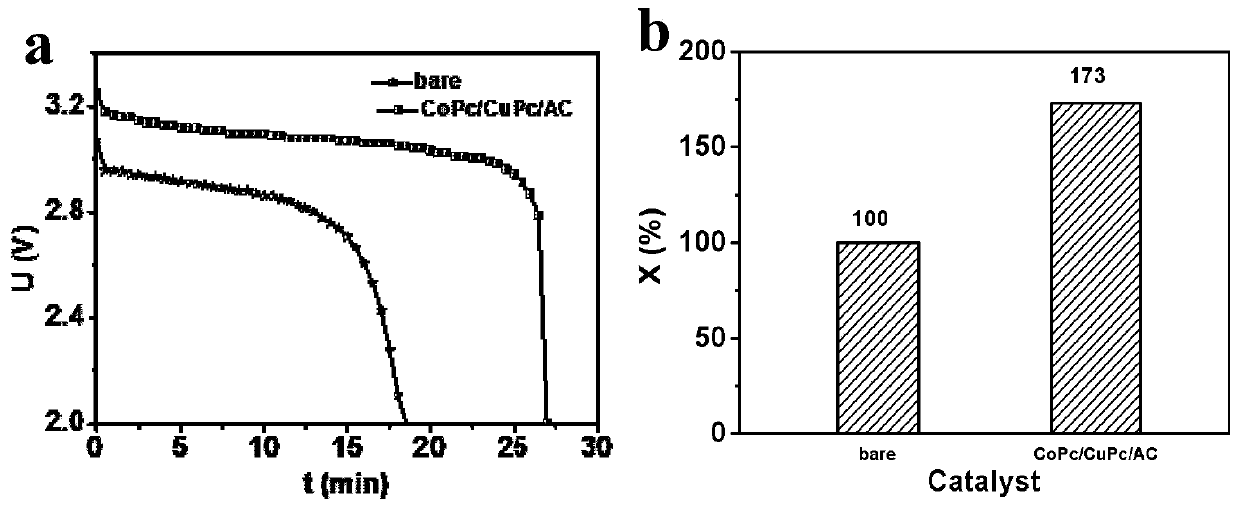

Cobalt phthalocyanine/copper phthalocyanine/pitch coke activated carbon catalytic material and method for preparing lithium thionyl chloride battery positive plate by using catalytic material

A lithium thionyl chloride battery, catalytic material technology, applied in battery electrodes, electrodes of primary batteries, electrode forming and other directions, can solve the problems of poor product repeatability and uniformity, unfavorable large-scale production, difficult process control, etc. The effect of short cycle, high repeatability and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

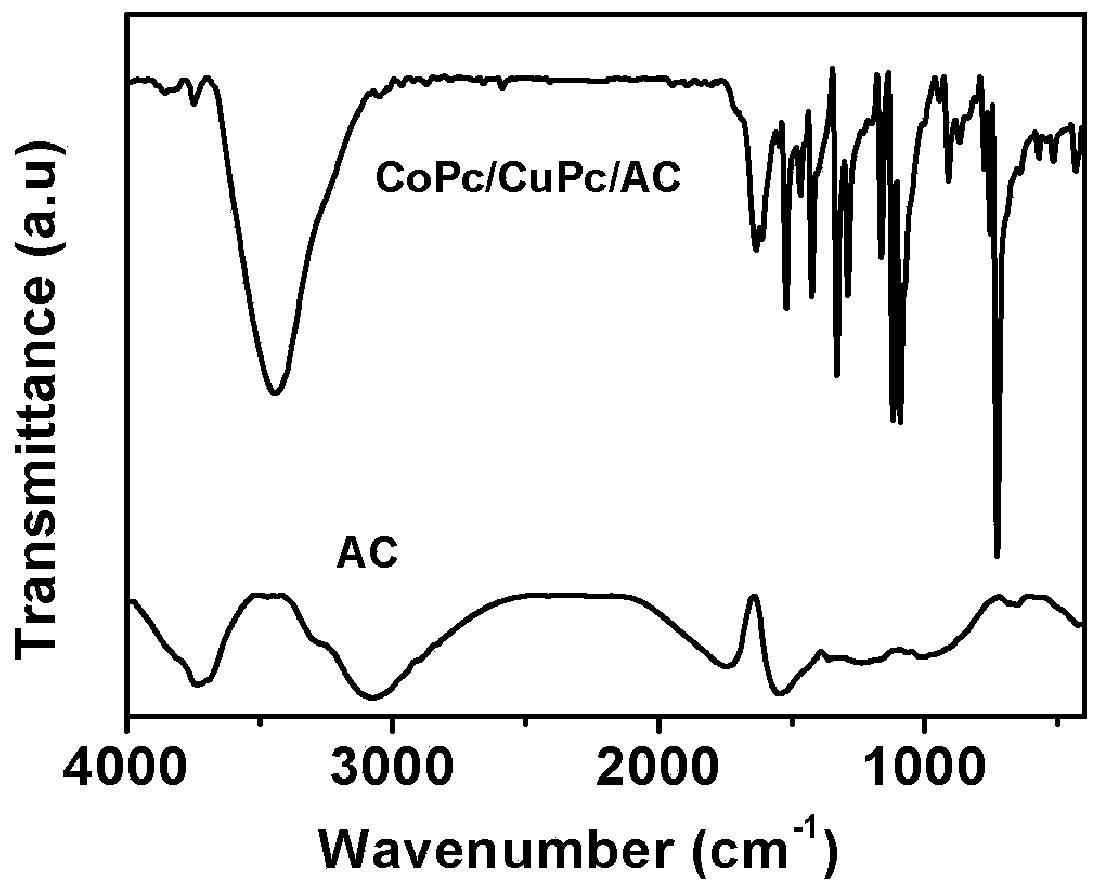

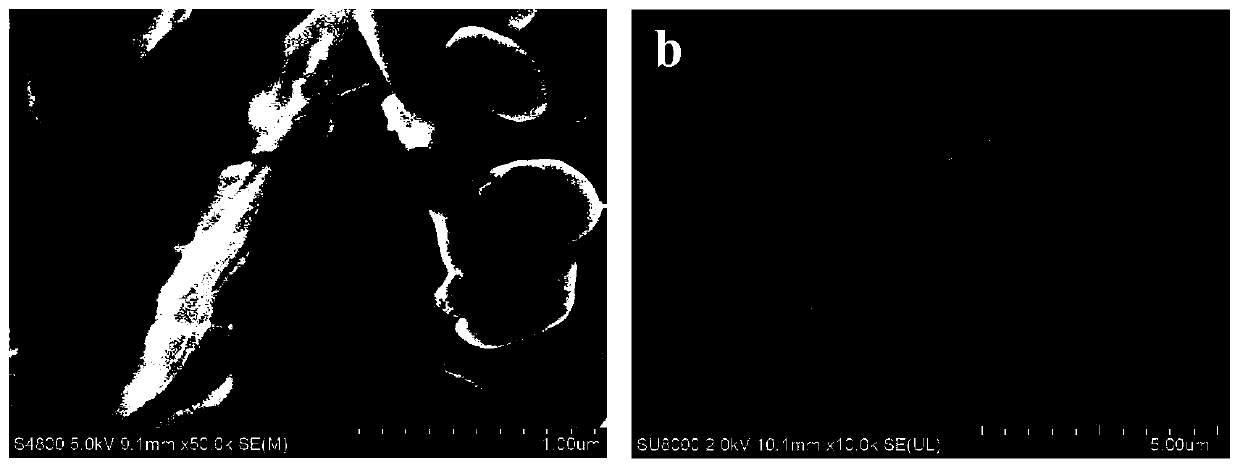

[0035] Preparation of cobalt phthalocyanine / copper phthalocyanine / pitch coke activated carbon catalytic material:

[0036] 1) First set the specific surface area to 800m 2 / g of pitch coke activated carbon is placed in deionized water, the water is changed once a day, soaked repeatedly for 3 times, and then dried in a blast drying oven at 80°C;

[0037] 2) Get 0.1g of phthalic anhydride and 0.02g of pitch coke activated carbon in step 1) and mix them uniformly in a glass mortar;

[0038] 3) Get the urea of 0.1g, the ammonium molybdate of 0.01g, the cobalt chloride hexahydrate of 0.1g, the cupric chloride dihydrate of 0.01g join respectively in the glass mortar of step 2) and put into the crucible after fully grinding In the muffle furnace at 8°C min -1 The heating rate is increased from room temperature to 180°C and kept for 0.1h; then at 10°C min -1 The temperature was raised to 350°C at a certain speed, and the temperature was kept for 1.5h;

[0039] 4) After naturally...

Embodiment 2

[0045] Preparation of cobalt phthalocyanine / copper phthalocyanine / pitch coke activated carbon catalytic material:

[0046] 1) First set the specific surface area to 800m2 / g of pitch coke activated carbon is placed in deionized water, the water is changed once a day, soaked repeatedly for 3 times, and then dried in a blast drying oven at 80°C;

[0047] 2) Get the phthalic anhydride of 0.82g and the pitch coke activated carbon of 0.05g step 1) and mix uniformly in a glass mortar;

[0048] 3) The urea of 1.2g, the ammonium molybdate of 0.12g, the cobalt chloride hexahydrate of 0.545g, the copper chloride dihydrate of 0.0425g join respectively in the glass mortar of step 2) and put into the crucible after fully grinding In the Furnace at 10°C min -1 The heating rate is increased from room temperature to 150°C and kept for 0.5h; then at 5°C min -1 The temperature is raised to 260°C at a high speed, and the temperature is kept for 2 hours;

[0049] 4) After being naturally coo...

Embodiment 3

[0055] Preparation of cobalt phthalocyanine / copper phthalocyanine / pitch coke activated carbon catalytic material:

[0056] 1) First set the specific surface area to 800m 2 / g of pitch coke activated carbon is placed in deionized water, the water is changed once a day, soaked repeatedly for 3 times, and then dried in a blast drying oven at 80°C;

[0057] 2) Get the phthalic anhydride of 0.41g and the pitch coke activated carbon of 0.02g step 1) and mix uniformly in a glass mortar;

[0058] 3) Get the urea of 0.6g, the ammonium molybdate of 0.06g, the cobalt chloride hexahydrate of 0.485g, the cupric chloride dihydrate of 0.085g join respectively in the glass mortar of step 2) and put into the crucible after fully grinding In the muffle furnace at 5°C min -1 The heating rate is increased from room temperature to 135°C and kept for 0.8h; then at 3°C min -1 The temperature is raised to 280°C at a certain speed, and the temperature is kept for 2.5h;

[0059] 4) After being ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com