Lithium air or oxygen battery

A lithium-air battery, oxygen battery technology, applied in battery electrodes, circuits, electrical components, etc., to achieve high specific capacity, good industrial practical value, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

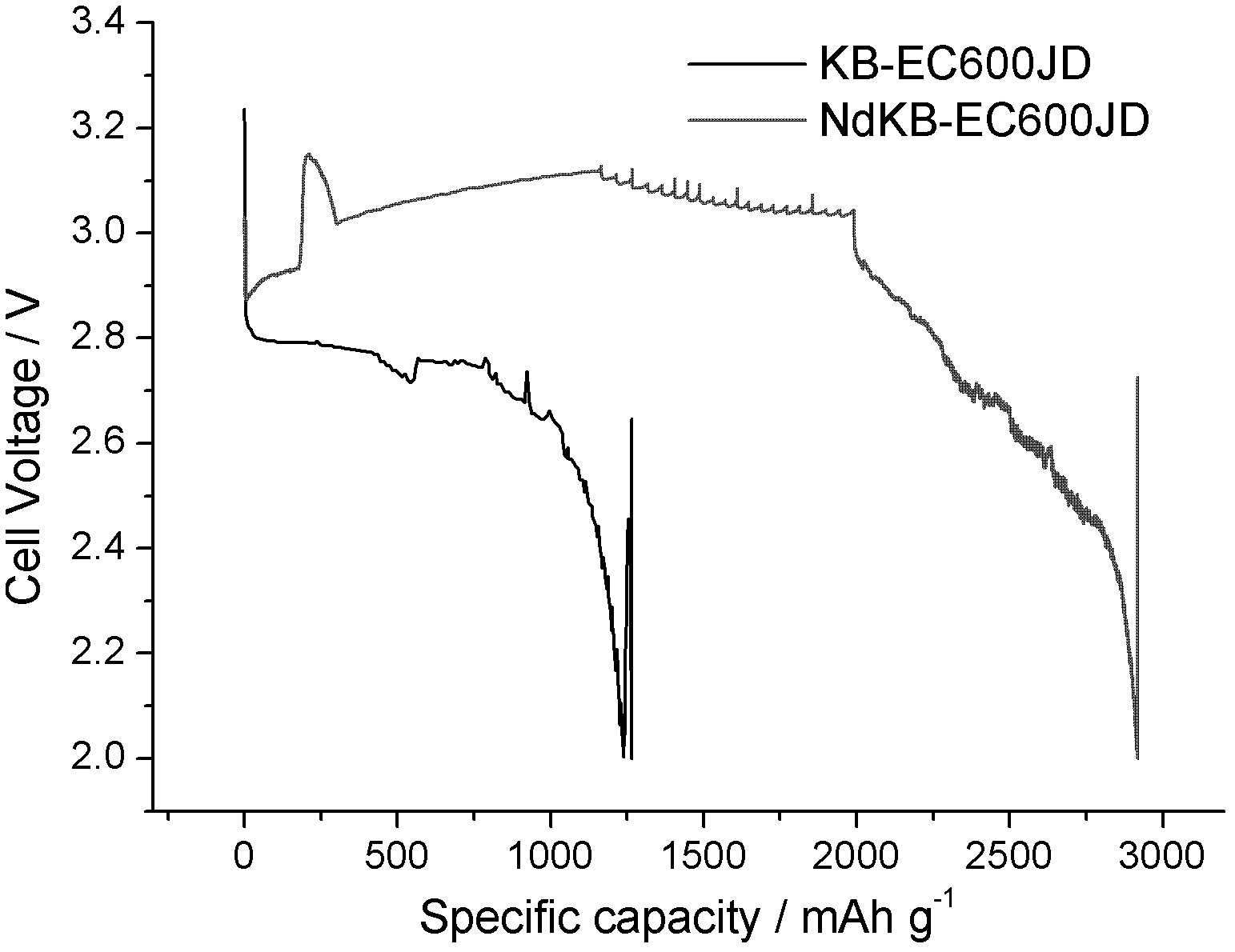

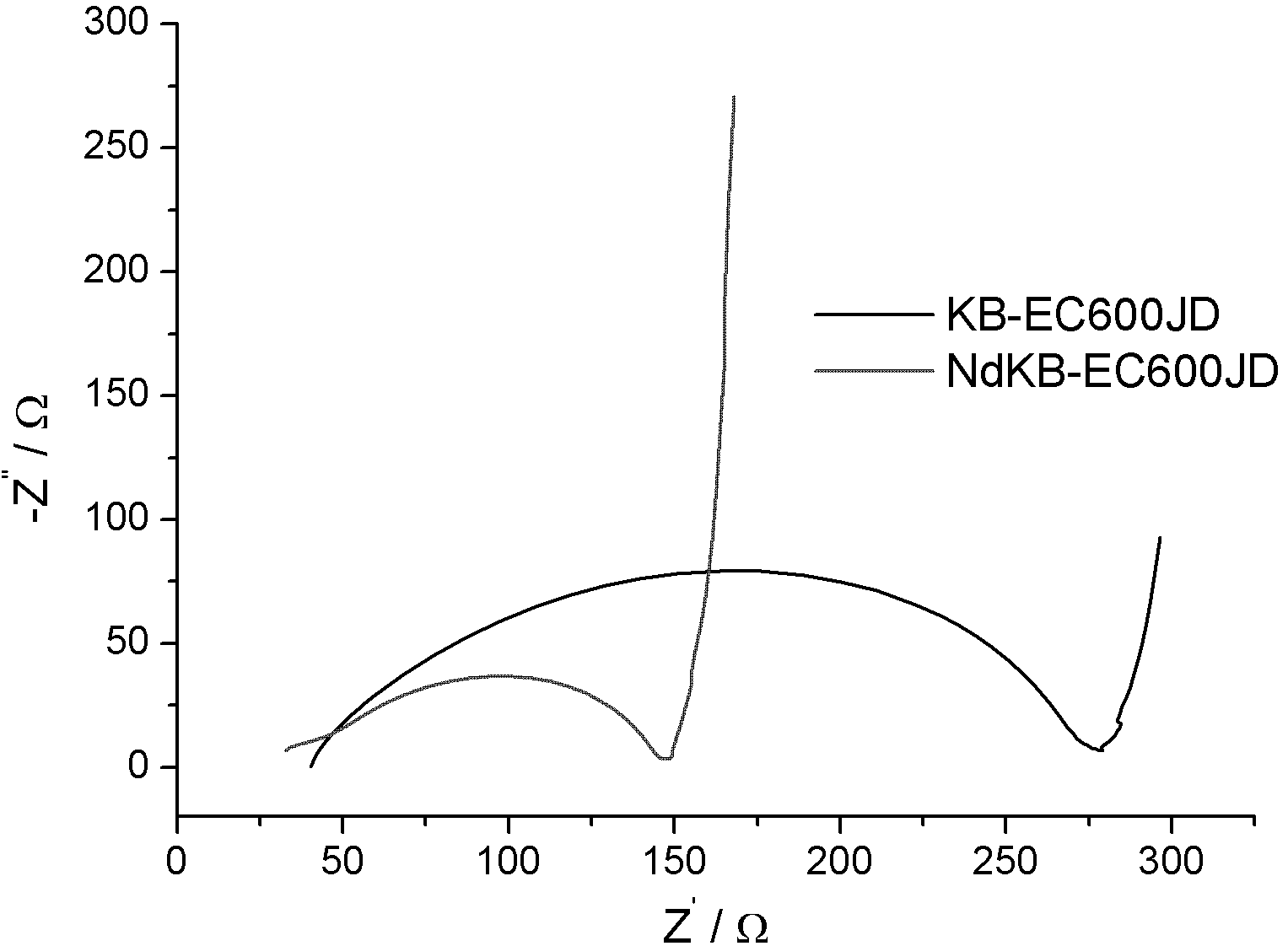

Embodiment 1

[0043] 1. Air or oxygen electrode preparation

[0044] Nitrogenous carbon (NdKB-EC600JD) material is prepared by existing preparation methods, reference: "Highly dispersed and high-load core-shell structure carbon material-supported platinum catalyst for methanol electrocatalytic oxidation" (Gang Wu, Deyu Li, Changsong Dai, Dianlong Wang, and Ning Li, Well-Dispersed High-Loading Pt Nanoparticles Supported by Shell-Core Nanostructured Carbon for Methanol Electrooxidation, Langmuir, 2008, 24, 3566-3575).

[0045] Niza Ketjen Black (NdKB-EC600JD) preparation method: stirring-ultrasonic dispersion of Ketjen Black (KB-EC600JD) methanol solution to obtain a uniform Ketjen Black methanol suspension, put the beaker containing the suspension In the ice-water bath, the sulfuric acid solution (mol ratio is 1: 1) of aniline (aniline feed intake is 2.7% excessive 15% is calculated by the mass percentage composition of nitrogen element in the target product azaketjen black) and ammonium per...

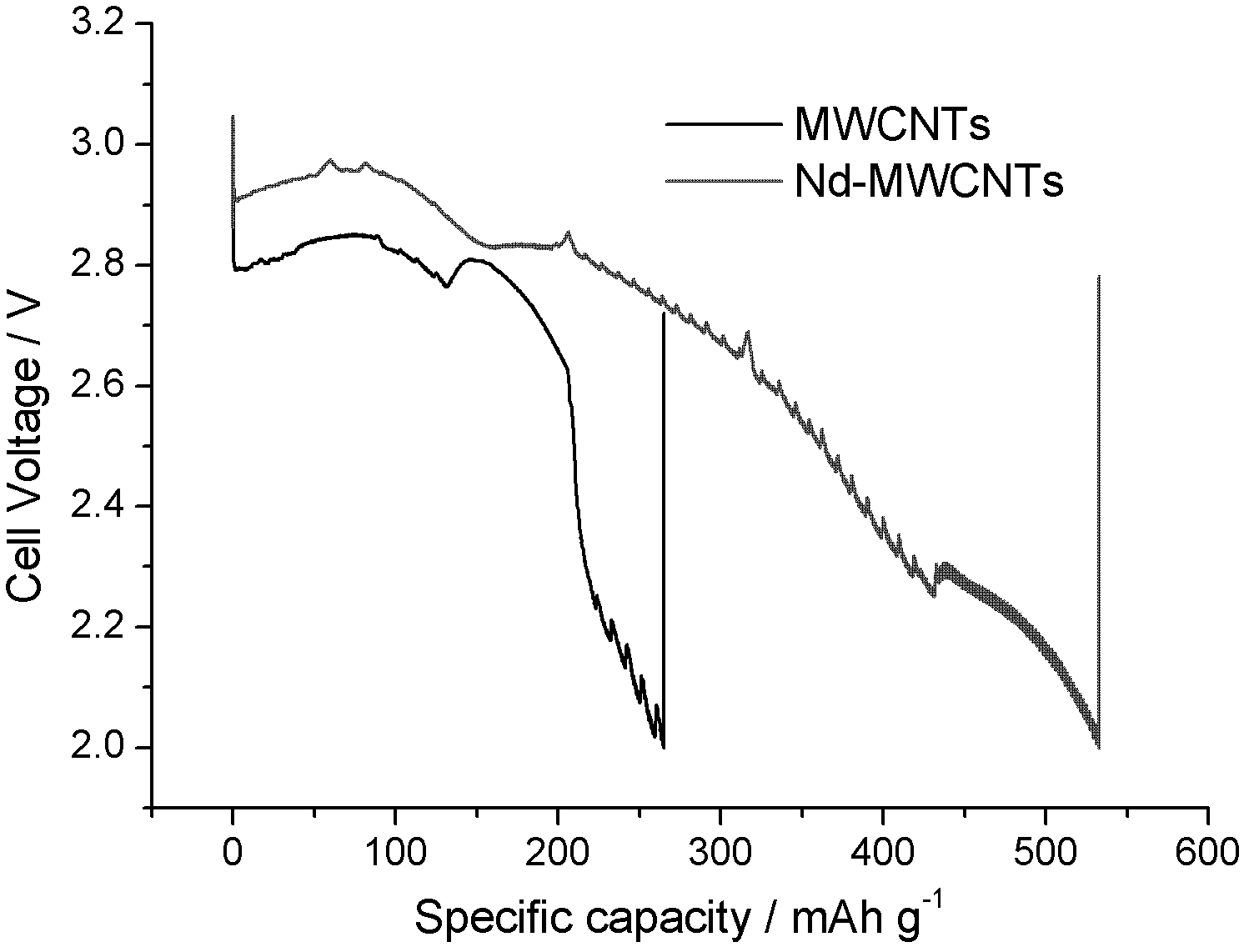

Embodiment 2

[0064] 1. Air or oxygen electrode preparation

[0065] Nitrogenous carbon (Nd-MWCNTs) materials are prepared by existing preparation methods, reference: "Highly dispersed and high-loaded core-shell structure carbon material-supported platinum catalyst for methanol electrocatalytic oxidation" (Gang Wu, Deyu Li, Changsong Dai, Dianlong Wang, and Ning Li, Well-Dispersed High-Loading Pt Nanoparticles Supported by Shell-Core Nanostructured Carbon for Methanol Electrooxidation, Langmuir, 2008, 24, 3566-3575).

[0066]Preparation method of aza multi-walled carbon nanotubes (Nd-MWCNTs): Stir-ultrasonic dispersion of methanol solution of multi-walled carbon nanotubes (MWCNTs) to obtain a uniform suspension of multi-walled carbon nanotubes in methanol, which will contain the suspension The beaker of liquid is put into ice-water bath, the sulfuric acid solution (molar ratio 1:1) were added dropwise to the multi-walled carbon nanotube methanol suspension, along with the dropwise addition...

Embodiment 3

[0074] 1. Air or oxygen electrode preparation

[0075] The preparation of azaketjen black (NdKB-EC600JD) is the same as that of azaketjen black in Example 1.

[0076] Mix and grind nitrogen-doped carbon (NdKB-EC600JD) material and TiN at a mass ratio of 99:1 (the homogeneous mixture is marked as NdKB-EC600JD+1wt%TiN), and then add the mixed PTFE+D.I.W+PO emulsion (in the emulsion The weight percentage of PTFE is 60%, the weight percentage of D.I.W is 30%, and the weight percentage of PO is 10%), wherein the mass percentage of nitrogen element in the aza carbon material is 2.7%, aza The mass ratio of the total mass of carbon (NdKB-EC600JD) material and TiN material to PTFE is 85:15, stir it into a viscous state, and apply it on the collector foam nickel with a thickness of about 0.1 mm. After drying, put it in a vacuum oven at 120°C for 10 hours and punch it into a disk-shaped (φ=14mm) nitrogen-doped carbon electrode mixed with 1wt% TiN, and move it into a glove box filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com