Nitrogen-rich eggshell type lithium sulfur battery anode material and preparation method and application thereof

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as fragmentation, density difference, volume expansion of sulfur cathode, and achieve regular shape, effective adsorption, and control simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

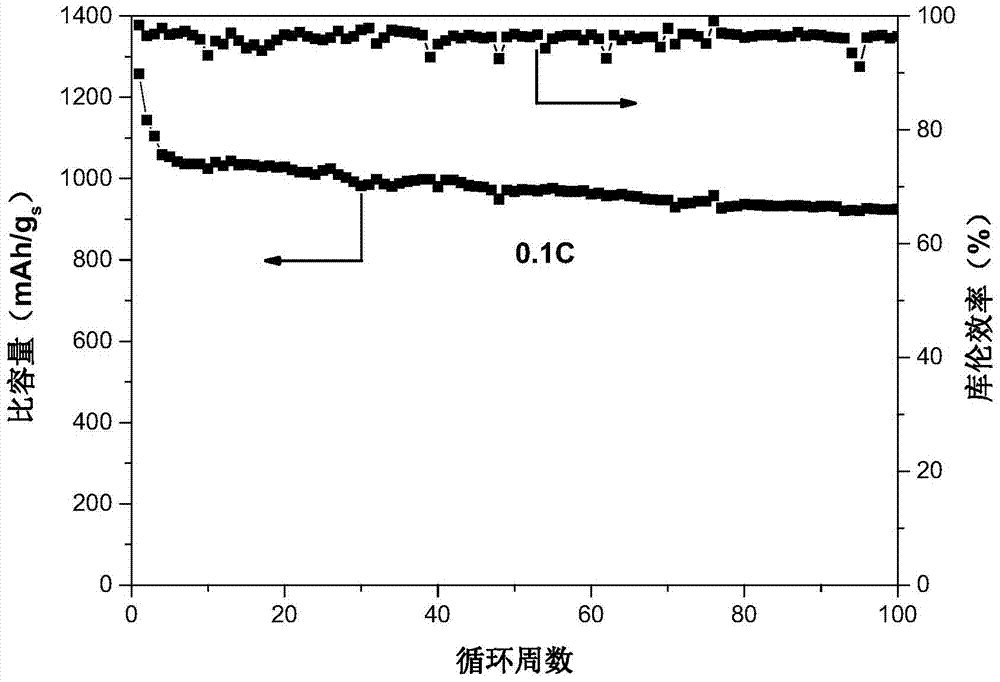

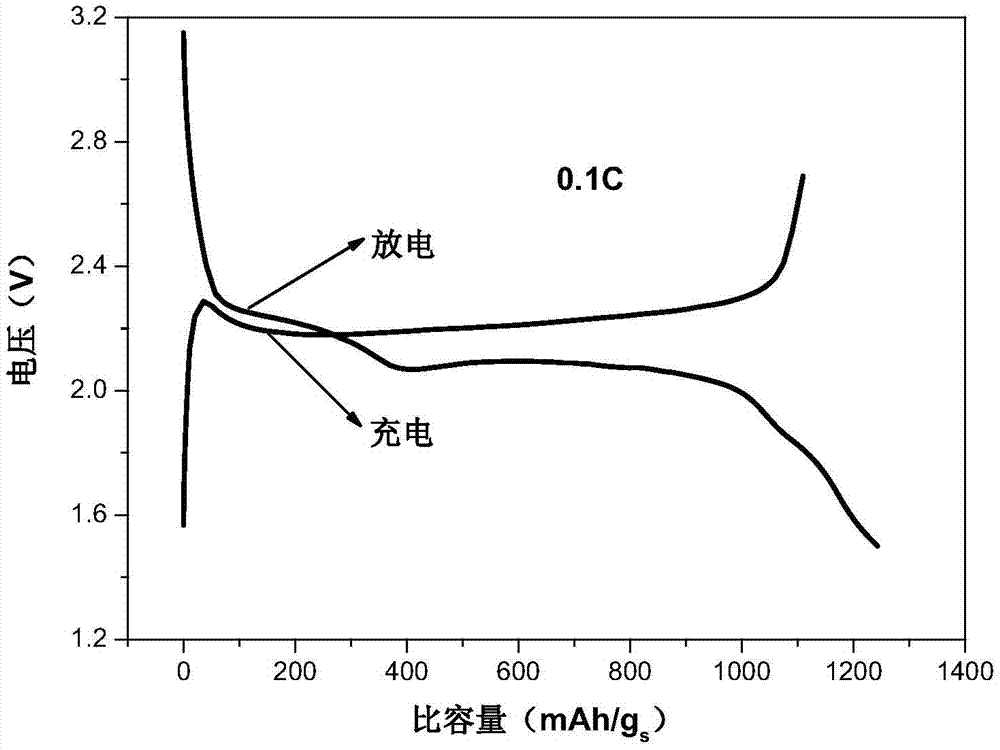

Embodiment example 1

[0044] Put 2.0g of melamine, 3.6mL of formaldehyde and 20mL of deionized water in a 100mL three-neck flask, stir and mix evenly, then add triethanolamine, control the pH value to 8, heat the water bath to 75°C and continue stirring for 20min to obtain the reaction product A; Add 32mL of silica sol and 100mL of deionized water into a 250mL three-neck flask, stir well, and ultrasonically treat for 1 hour, then add the reaction product A, adjust the pH to 6 with acetic acid, heat in a water bath, slowly raise the temperature to 60°C, and keep stirring 2h, cooling. Filter, wash, and dry to obtain the core-shell structure B of melamine-formaldehyde resin-coated silica. Set B at 3°C min -1 Carbonization was carried out at 800°C for 3h in a high-purity nitrogen atmosphere at the heating rate. Then the carbonized product was etched with 5M NaOH solution at 100°C for 8h, washed with deionized water until the pH value remained unchanged, filtered, and dried at 80°C for 24h to obtain...

Embodiment example 2

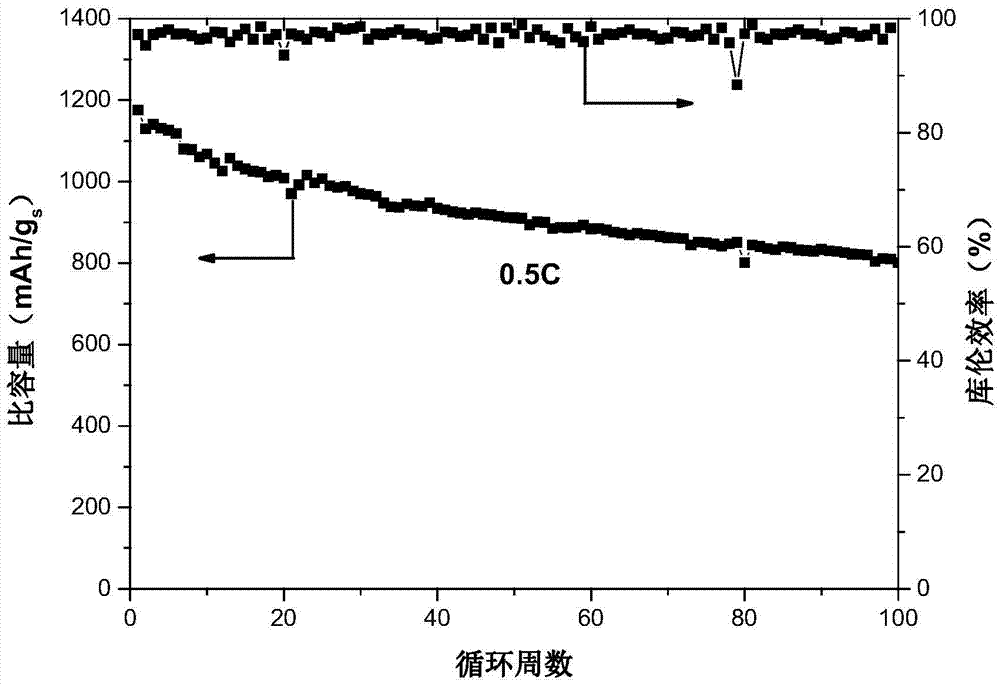

[0053] Put 2.0g of melamine, 4.8mL of formaldehyde and 20mL of deionized water in a 100mL three-neck flask, stir and mix evenly, then add triethanolamine, control the pH value to 9, heat the water bath to 75°C and continue stirring for 20min to obtain the reaction product A; Add 40mL of silica sol and 100mL of deionized water into a 250mL three-necked flask, stir well, and ultrasonically treat for 1 hour, then add the reaction product A, adjust the pH to 6 with acetic acid, heat in a water bath, slowly raise the temperature to 60°C, and keep stirring 2h, cooling. Filter, wash, and dry to obtain the core-shell structure B of melamine-formaldehyde resin-coated silica. The dried melamine-formaldehyde resin-coated silica core-shell structure B was carbonized at 800°C under a high-purity nitrogen atmosphere for 3 hours at a heating rate of 3°C min-1. Then the carbonized product was etched with 5M NaOH solution at 100°C for 8h, washed with deionized water until the pH value remaine...

Embodiment example 3

[0062]Put 2.0g of melamine, 6mL of formaldehyde and 20mL of deionized water in a 100mL three-necked flask, stir and mix evenly, add triethanolamine, control the pH value to 9, heat the water bath to 75°C and continue stirring for 20min to obtain the reaction product A; Add 40mL of silica sol and 100mL of deionized water into a 250mL three-neck flask, stir well, and ultrasonically treat for 1 hour, then add the reaction product A, adjust the pH to 6 with chromic acid, heat in a water bath, slowly raise the temperature to 60°C, and keep it warm Stir for 2h and cool. Filter, wash, and dry to obtain the core-shell structure B of melamine-formaldehyde resin-coated silica. Dry the core-shell structure B of melamine-formaldehyde resin-coated silica at 3°C min -1 Carbonization was carried out at 800°C for 3h in a high-purity nitrogen atmosphere at the heating rate. Then the carbonized product was etched with 5M NaOH solution at 100°C for 8h, washed with deionized water until the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com