Surface in-situ coated lithium-enriched material and preparation method thereof

A lithium-rich material and in-situ coating technology, applied in the field of lithium-ion batteries, can solve the problems of insufficient bonding of the coating layer and lithium-rich materials, uneven coating layer, and difficulty in scaling up. Popularization, good reproducibility of results, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

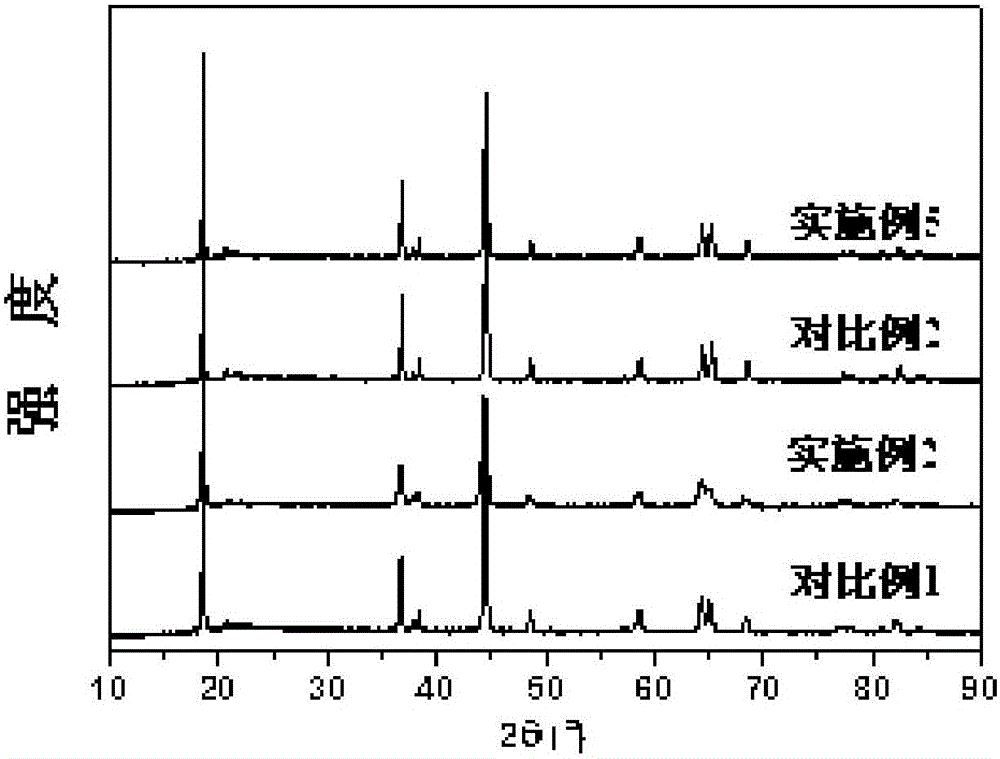

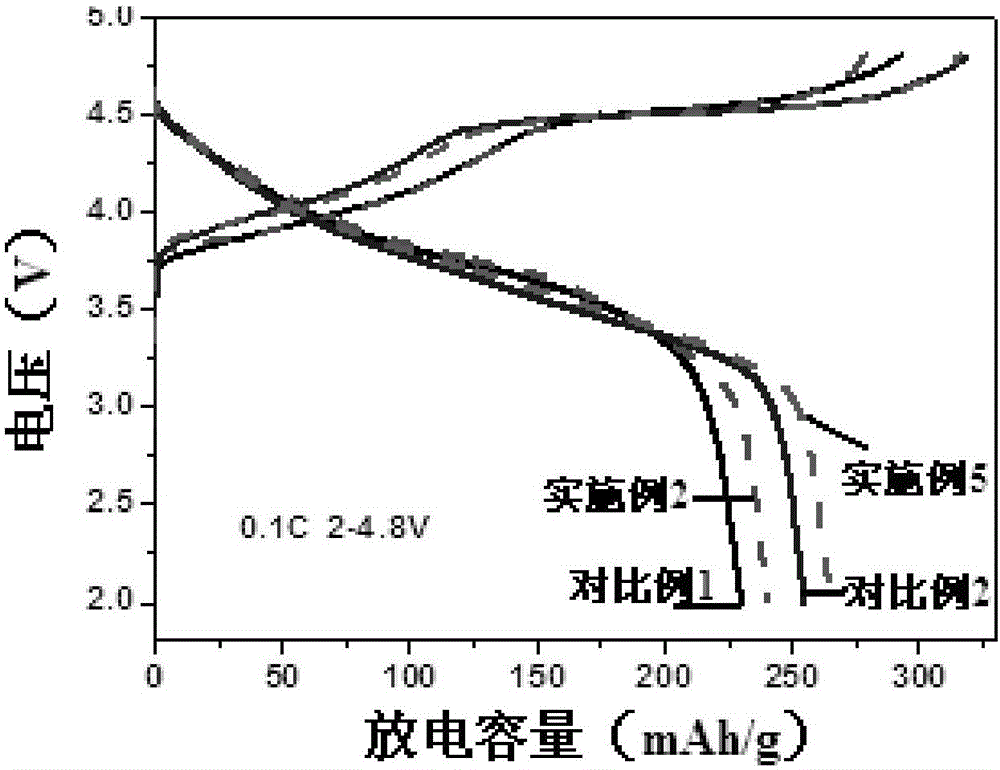

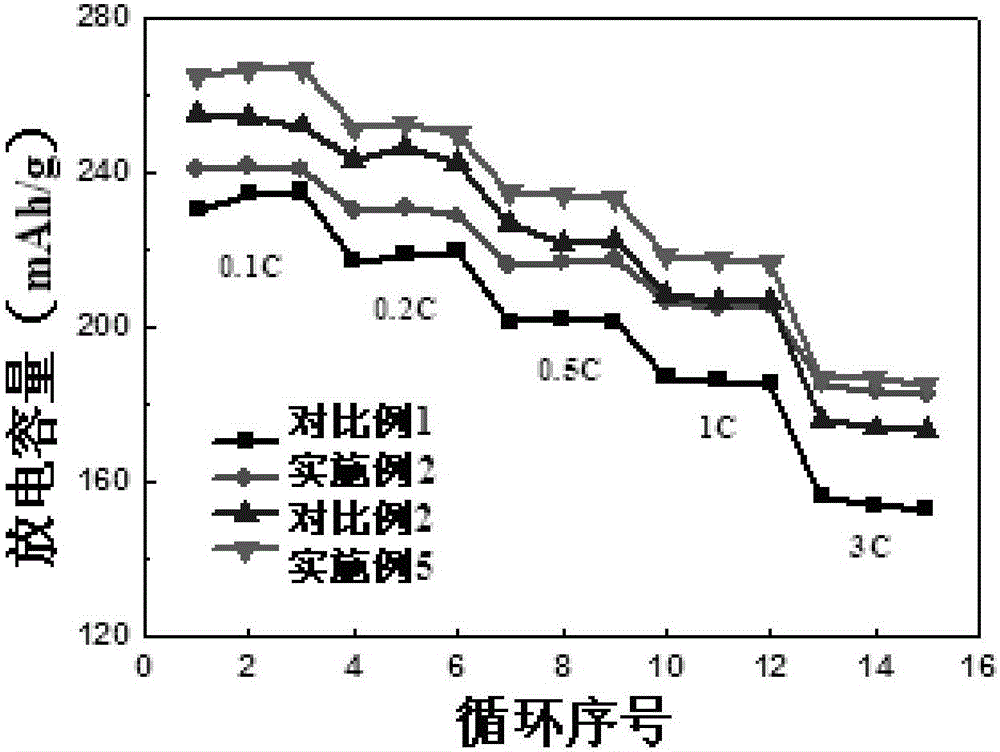

[0034] Embodiment 1: The present invention discloses a lithium-rich material coated in situ on the surface. The raw material includes a coating layer and a lithium-rich material precursor. The raw material of the coating layer is manganese oxide, and the lithium-rich material precursor is mn 0.52 Ni 0.3 co 0.06 o 2 A mixture with lithium hydroxide, using any method in the prior art to prepare a lithium-rich material Li[Li 0.12 Ni 0.3 co 0.06 mn 0.5 】O 2 , the cladding layer is MnO 2 -Li[Mn 2 ]O 4 .

Embodiment 2

[0035] Embodiment 2: The present invention discloses a lithium-rich material with in-situ coating on the surface. The raw material includes a coating layer and a lithium-rich material precursor. The mass percentage of the coating layer accounts for 20% of the mass percentage of the raw material, and the rest is lithium-rich A material precursor, the cladding layer raw material is manganese hydroxide, and the lithium-rich material precursor is Mn 0.6 Al 0.1 S 0.2 A mixture of hydroxide and lithium carbonate, Li and Mn 0.6 Al 0.1 S 0.2 The molar ratio is 1:1.

[0036] In the method for preparing the above-mentioned lithium-rich material, the precursor particles of the lithium-rich material are coated with a metal compound, and then sintered at a high temperature to form a lithium-rich material whose surface is coated with spinel oxide.

[0037] The chemical formula of the finally obtained lithium-rich material is Li [Al 0.1 S 0.2 mn 0.6 】O 1.8 , the cladding layer is Mn...

Embodiment 3

[0039] Embodiment 3: The present invention discloses a lithium-rich material coated in situ on the surface. The raw material includes a coating layer and a lithium-rich material precursor. The mass percentage of the coating layer accounts for 10% of the mass percentage of the raw material, and the rest is lithium-rich Material precursor, the cladding layer raw material is nickel acetate, and the lithium-rich material precursor is Mn 0.52 Mg 0.3 Cr 0.3 P 0.2 A mixture of carbonate and lithium carbonate, Li and Mn 0.52 Mg 0.3 Cr 0.3 P 0.2 The molar ratio is 1.5:1.

[0040] The method for preparing the above-mentioned lithium-rich material includes coating metal acetate on the precursor particles of the lithium-rich material, and then sintering at a high temperature to form a lithium-rich material whose surface is coated with spinel oxide.

[0041] Specifically, the preparation method includes the following steps: (1) adding nickel acetate solution to the lithium-rich mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com