Positive pole piece, negative pole piece and high-energy density lithium ion battery

A technology for lithium-ion batteries and negative pole pieces, which is applied to battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve the problems of low energy density and achieve the effect of improving energy density, simple method, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

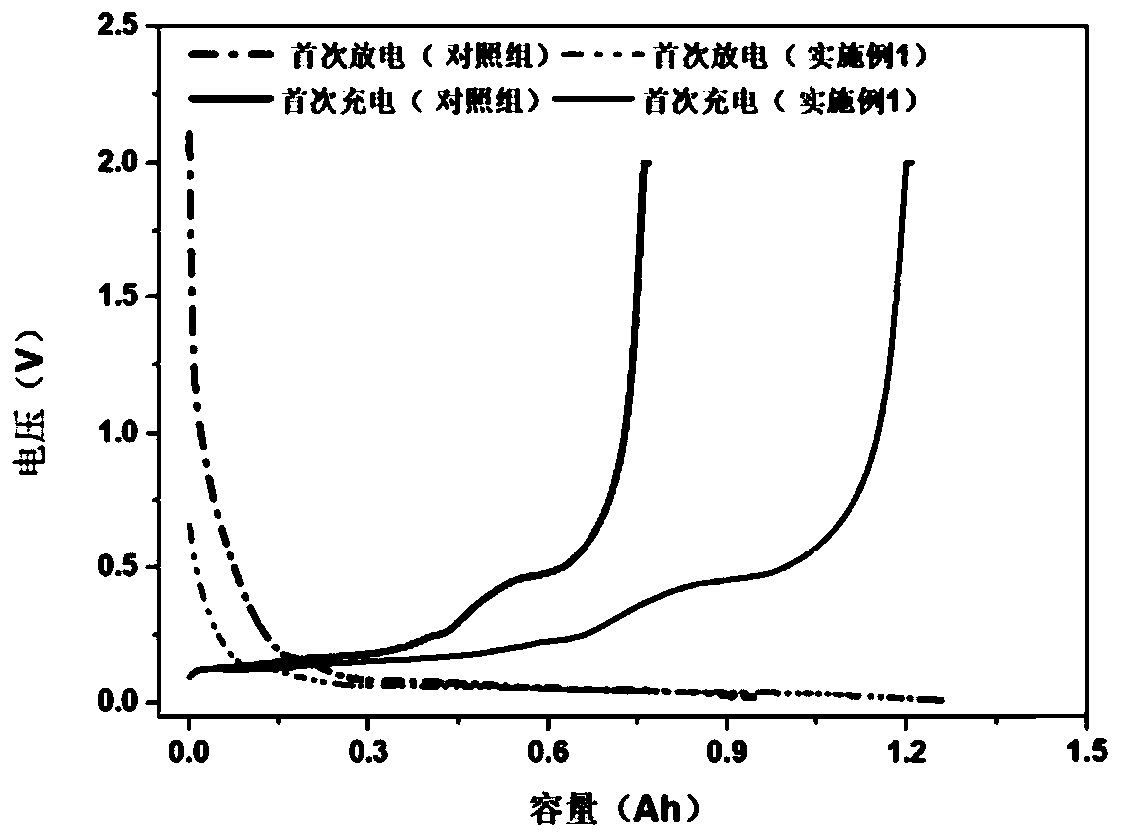

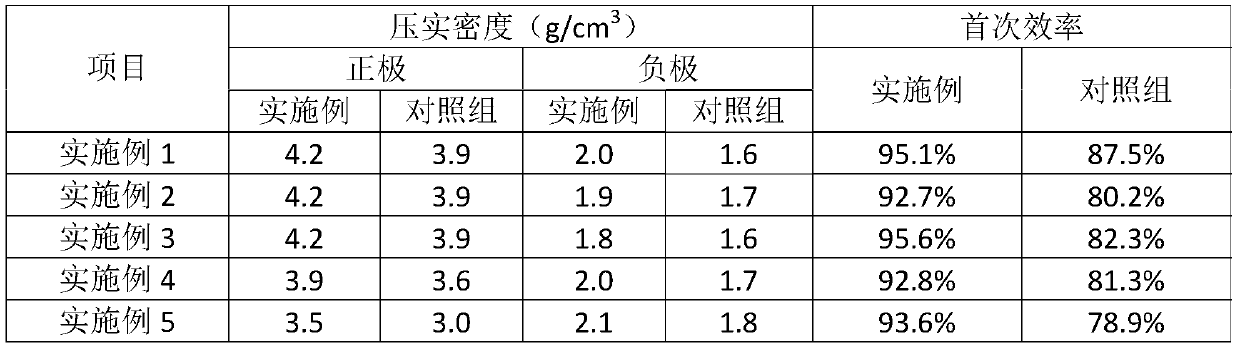

Embodiment 1

[0029] The present embodiment provides a method for improving the energy density of a lithium-ion battery, which comprises the steps of:

[0030] Step 1: Use a lithium-containing copper foil with a thickness of 30 microns and a lithium content of 6% as the current collector of the negative electrode, and apply a conductive coating with SP as the conductive agent and sodium carboxymethyl cellulose as the binder. Obtain a lithium-containing copper foil with a conductive coating; use aluminum foil as a current collector for the positive electrode, and coat a conductive coating with SP as a conductive agent and sodium carboxymethyl cellulose as a binder to obtain a conductive coating with a aluminum foil;

[0031] Step 2: Prepare the negative pole piece, fully mix the silicon carbon material, SP and polytetrafluoroethylene, then roll it into a thin film, and then hot press it on the lithium-containing copper foil with a conductive coating to obtain the negative pole piece;

[003...

Embodiment 2

[0036] The present embodiment provides a method for improving the energy density of a lithium-ion battery, which comprises the steps of:

[0037] Step 1: Use a lithium-containing copper foil with a thickness of 12 microns and a lithium content of 12% as the current collector of the negative electrode, and coat a conductive coating with carbon nanotubes as the conductive agent and polyacrylic acid as the binder to obtain a There is a lithium-containing copper foil with a conductive coating; aluminum foil is used as a current collector for the positive electrode, and a conductive coating with carbon nanotubes as a conductive agent and polyacrylic acid as a binder is coated to obtain an aluminum foil with a conductive coating;

[0038] Step 2: Prepare the negative electrode sheet, fully mix silicon oxide, acetylene black and polytetrafluoroethylene, then roll it into a film, and then hot press it on the lithium-containing copper foil with a conductive coating to obtain the negativ...

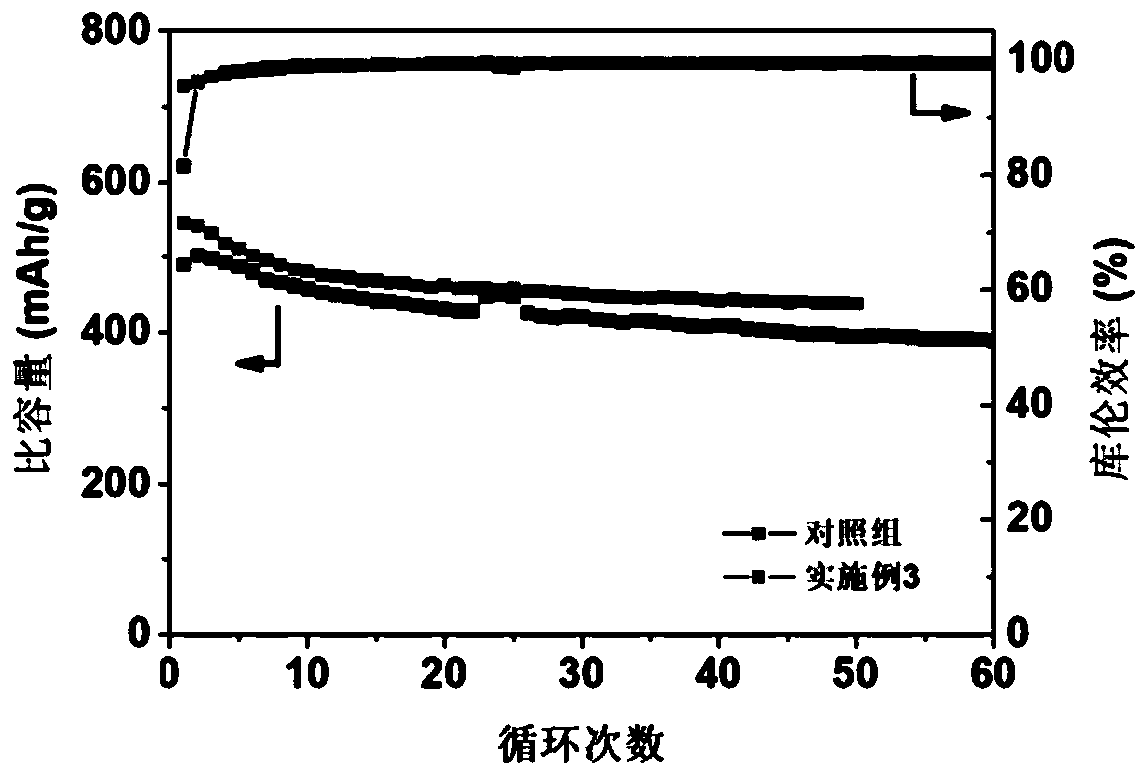

Embodiment 3

[0043] The present embodiment provides a method for improving the energy density of a lithium-ion battery, which comprises the steps of:

[0044] Step 1: Use a lithium-containing copper foil with a thickness of 7 microns and a lithium content of 2% as the current collector of the negative electrode, and apply a conductive coating with graphene as the conductive agent and polyacrylic acid as the binder to obtain Lithium-containing copper foil with conductive coating; aluminum foil is used as the current collector of the positive electrode, and a conductive coating with graphene as the conductive agent and polyacrylic acid as the binder is coated to obtain an aluminum foil with a conductive coating;

[0045]Step 2: Prepare the negative pole piece, fully mix the nano-silicon material, carbon nanotubes and polyvinylidene fluoride, then spray it on the lithium-containing copper foil with a conductive coating, and obtain the negative pole piece through heating and rolling;

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com