Method for effectively screening self-discharging batteries

A self-discharge and charging method technology, applied in the field of battery manufacturing, can solve the problems of unscientific self-discharge screening methods, easy misjudgment of non-self-discharge batteries, and difficulty in detecting self-discharge batteries, so as to reduce the irreversible capacity loss of batteries and achieve excellent battery performance. Chemical performance and safety performance, the usual effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

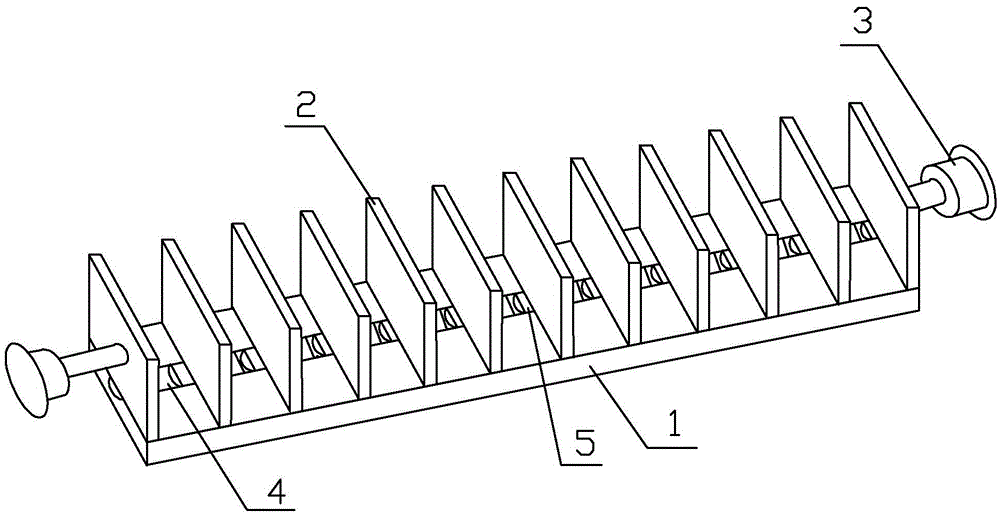

Image

Examples

Embodiment

[0024] Embodiment: A kind of method of effectively screening self-discharge battery of the present embodiment, carries out self-discharge screening to nickel-cobalt lithium manganate (523) / artificial graphite system flexible packaging 20Ah lithium-ion battery, comprises the following steps:

[0025] ①Use the low-current charging method to determine the inflection point of the low-voltage state voltage of the battery:

[0026] a. At room temperature T1, use charging and discharging equipment to discharge multiple batteries that are normally produced to empty with a current of 100mA (high current can be selected for early discharge), and obtain the total rated capacity of the battery;

[0027] b. At room temperature T1, use a charging and discharging device to charge each battery with a current of 100mA for 1 hour, stand still for 0.5 hours, measure the battery voltage OCV, then charge with a current of 100mA for 1 hour, stand still for 0.5 hours, measure the battery voltage OCV,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com