Start-stop battery electrolyte and lithium ion battery

A technology for starting and stopping batteries and electrolytes, which is applied in the field of lithium-ion batteries to achieve the effects of good power and high temperature cycle performance, low impedance and low impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

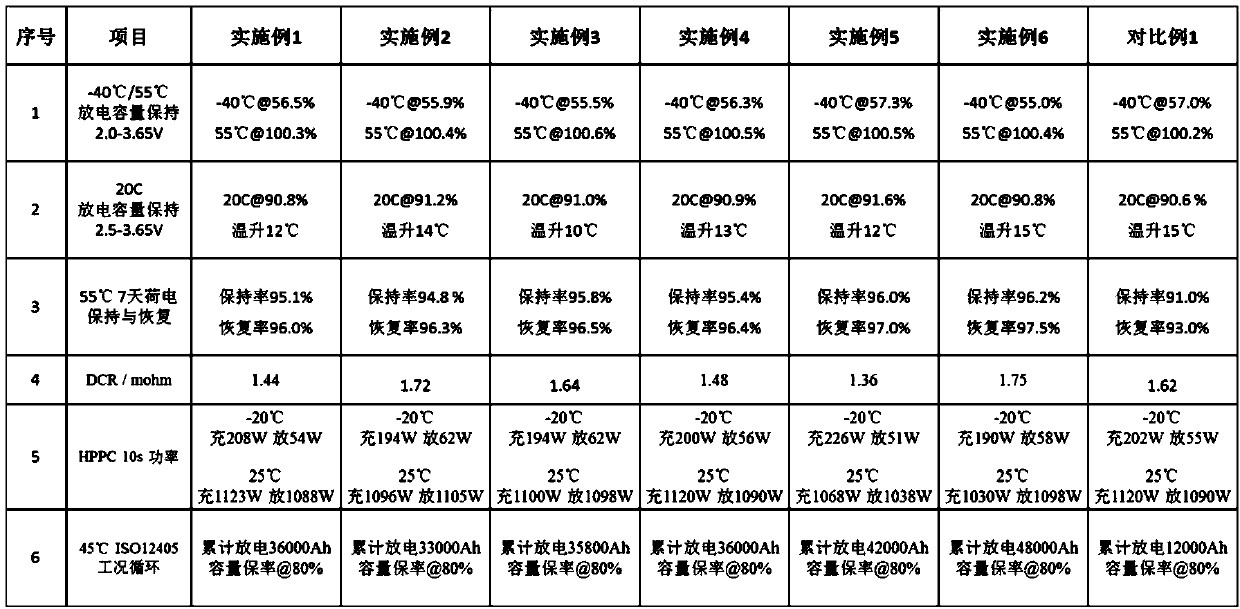

Examples

Embodiment 1

[0024] An electrolyte solution for start-stop batteries, the components of which include lithium salts, carbonate organic solvents, and functional additives. The mass fractions of each component in the lithium salt in the electrolyte of the start-stop battery are: lithium hexafluorophosphate LiPF 6 7.5%, lithium bisfluorosulfonimide LiFSI 9.0%. The carbonate organic solvent includes three components, and the mass fractions of the three components in the start-stop battery electrolyte are: 20% ethylene carbonate EC, 30.5% ethyl methyl carbonate EMC and 32% dimethyl carbonate DMC. The functional additive includes two components, and the mass fractions of the two components in the electrolyte solution of the start-stop battery are: lithium difluorophosphate LiPO 2 f 2 0.7% and lithium difluorobisoxalate phosphate LiPF 2 (C 2 o 4 ) 2 0.3%.

[0025] The preparation method of the start-stop battery electrolyte of this embodiment is: uniformly mixing lithium salt, carbonate...

Embodiment 2

[0028] An electrolyte solution for start-stop batteries, the components of which include lithium salts, carbonate organic solvents, and functional additives. The mass fractions of each component in the lithium salt in the electrolyte of the start-stop battery are: lithium hexafluorophosphate LiPF 6 12.5% and LiFSI 3.0%. The carbonate organic solvent includes two components, and the mass fractions of the two components in the electrolyte solution of the start-stop battery are 25% of ethylene carbonate EC and 58% of ethyl methyl carbonate EMC. Functional additives include three components, and the mass fractions of the three components in the start-stop battery electrolyte are: vinylene carbonate VC 0.3%, vinyl sulfate DTD 0.7% and lithium difluorophosphate LiPO 2 f 2 0.5%.

[0029] The preparation method of the start-stop battery electrolyte of this embodiment is: uniformly mixing lithium salt, carbonate organic solvent, and functional additives.

[0030] Lithium-ion ba...

Embodiment 3

[0032] An electrolyte solution for start-stop batteries, the components of which include lithium salts, carbonate organic solvents, and functional additives. The mass fractions of each component in the lithium salt in the electrolyte of the start-stop battery are: lithium hexafluorophosphate LiPF6 12.5% and LiFSI 3.0%. The carbonate organic solvent includes three components, and the mass fractions of the three components in the start-stop battery electrolyte are: ethylene carbonate EC 25%, ethyl methyl carbonate EMC 42% and dimethyl carbonate DMC 15%. Functional additives include three components, and the mass fractions of the three components in the start-stop battery electrolyte are: vinylene carbonate VC 0.5%, vinyl sulfate DTD 0.8% and lithium difluorophosphate LiPO 2 f 2 0.5%.

[0033] The preparation method of the start-stop battery electrolyte of this embodiment is: uniformly mixing lithium salt, carbonate organic solvent, and functional additives.

[0034] Lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com