Silicon-based chip with mid-infrared spectrum signal enhancement function, and preparation method thereof

An infrared spectrum and signal technology, applied in the final product manufacturing, sustainable manufacturing/processing, antennas, etc., can solve the problems of compatibility of III-V semiconductors, unfavorable light modulation of nano-antenna sensors, and absorption of mid-infrared radiation. , to achieve the effect of improving stability and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

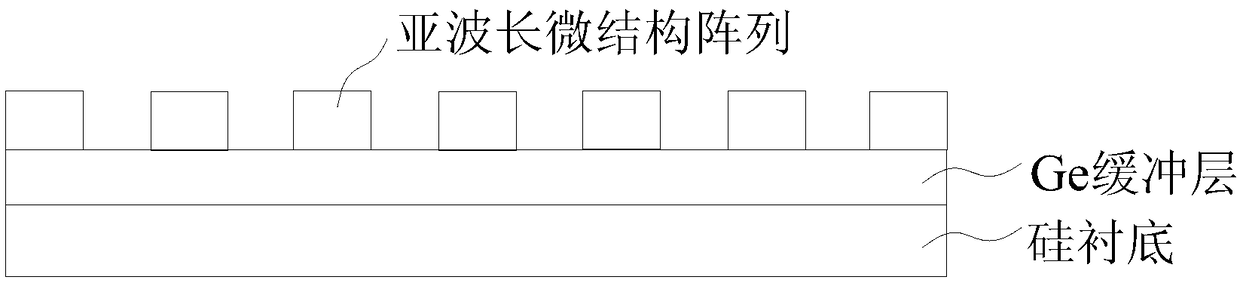

[0062] A silicon-based chip with enhanced FTIR signal is fabricated as follows:

[0063] (1) Clean the silicon wafer with the standard RCA cleaning method. The specific steps of the RCA cleaning method are as follows:

[0064] (1-1) Ultrasonic cleaning with acetone solution for 5 to 20 minutes, and then repeated washing with deionized water to remove organic residues on the surface of the silicon wafer;

[0065] (1-2) Put the silicon wafer into an isopropanol solution and ultrasonically clean it for 5 to 20 minutes, and then rinse it repeatedly with deionized water to remove the acetone residue on the surface of the silicon wafer;

[0066] (1-3) Put the silicon chip into a mixed solution of ammonia, hydrogen peroxide and water (1:1:5 by volume) and boil for 10 to 20 minutes, then rinse it repeatedly with deionized water, and the particles attached to the surface of the silicon chip will is cleared in the mixed solution;

[0067] (1-4) Soak the silicon chip in 4% HF solution ...

Embodiment 2

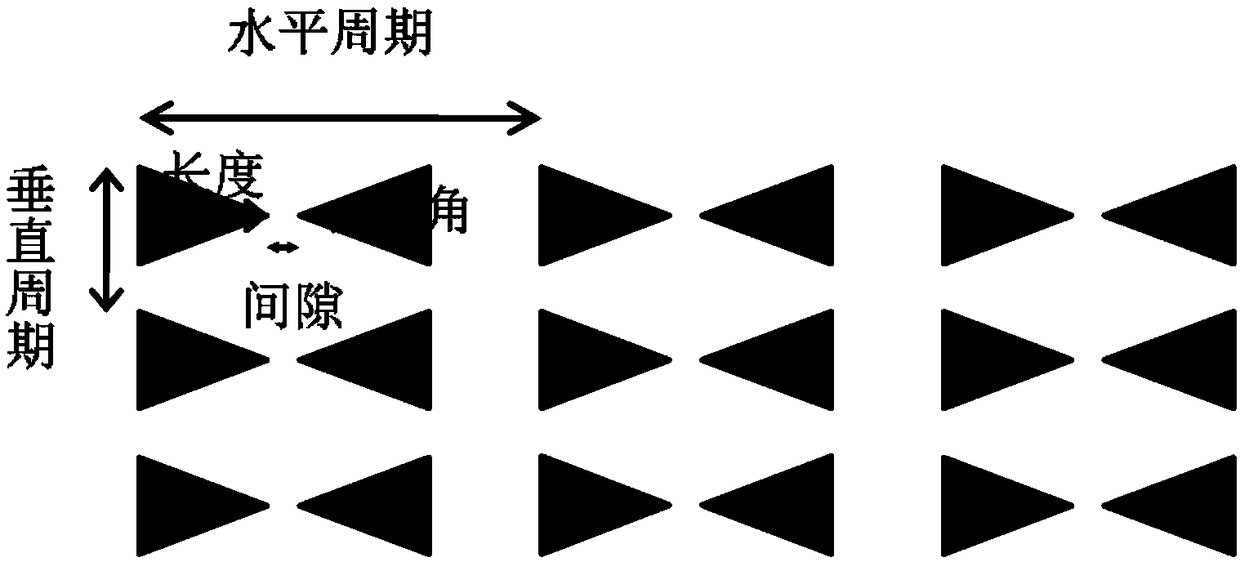

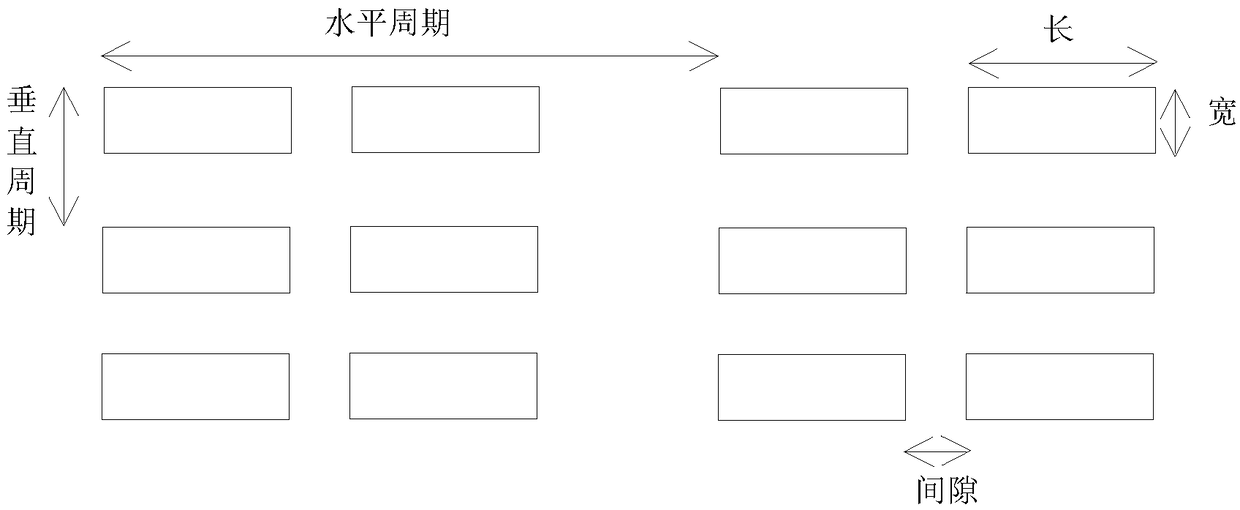

[0080] A silicon-based chip with enhanced FTIR signal function, the specific preparation process is the same as the process in Example 1, the difference is that the sub-wavelength microstructure array to be etched consists of a bow-tie antenna structure array (such as figure 2 shown) is transformed into a cuboid dipole antenna structure array (such as image 3 shown). A single dipole antenna structure consists of two cuboid structures facing each other in the long side direction. The cuboid has a length of 3 μm, a width of 0.8 μm, and a height of 1.5 μm. The period is 2 μm and the gap between the cuboids is 0.3 μm.

[0081] For the silicon-based chip with enhanced FTIR signal enhancement prepared in Example 2, the local plasmon resonance wavelength of the dipole antenna structure array is 9.4 μm, and the electric field strength near the hot spot of the electromagnetic field energy density is 31 times the initial incident electric field strength.

Embodiment 3

[0083] A silicon-based chip with enhanced FTIR signal function, the specific preparation process is the same as the process in Example 1, the difference is that the sub-wavelength microstructure array to be etched consists of a bow-tie antenna structure array (such as figure 2 shown) is transformed into a cylindrical structure array (such as Figure 4 shown). Each cylinder has a height of 1 μm, a diameter of 2 μm, and a period of 2.2 μm.

[0084] The silicon-based chip with enhanced FTIR signal enhancement prepared in embodiment 3, its electromagnetic field is respectively as follows Figure 5 As shown, the localized plasmon resonance wavelength of the cylindrical structure array is 8.0 μm, and the electric field strength near the hotspot of the electromagnetic field energy density is 13 times of the initial incident electric field strength.

[0085] As can be seen from Examples 1 to 3, the water chestnut and the tip in the subwavelength microstructure array (bow-tie antenn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth temperature | aaaaa | aaaaa |

| Growth temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com