Numerical control five-axle linkage super-high pressure water jet cutting machine

A water cutting machine, five-axis linkage technology, applied in shearing devices, shearing machine equipment, metal processing and other directions, can solve the problems of affecting the dimensional accuracy of water cutting, unsatisfactory and clean incisions, and increased processing costs. Reduce cutting cost, high cutting efficiency, and overcome the effect of beveled edge of incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

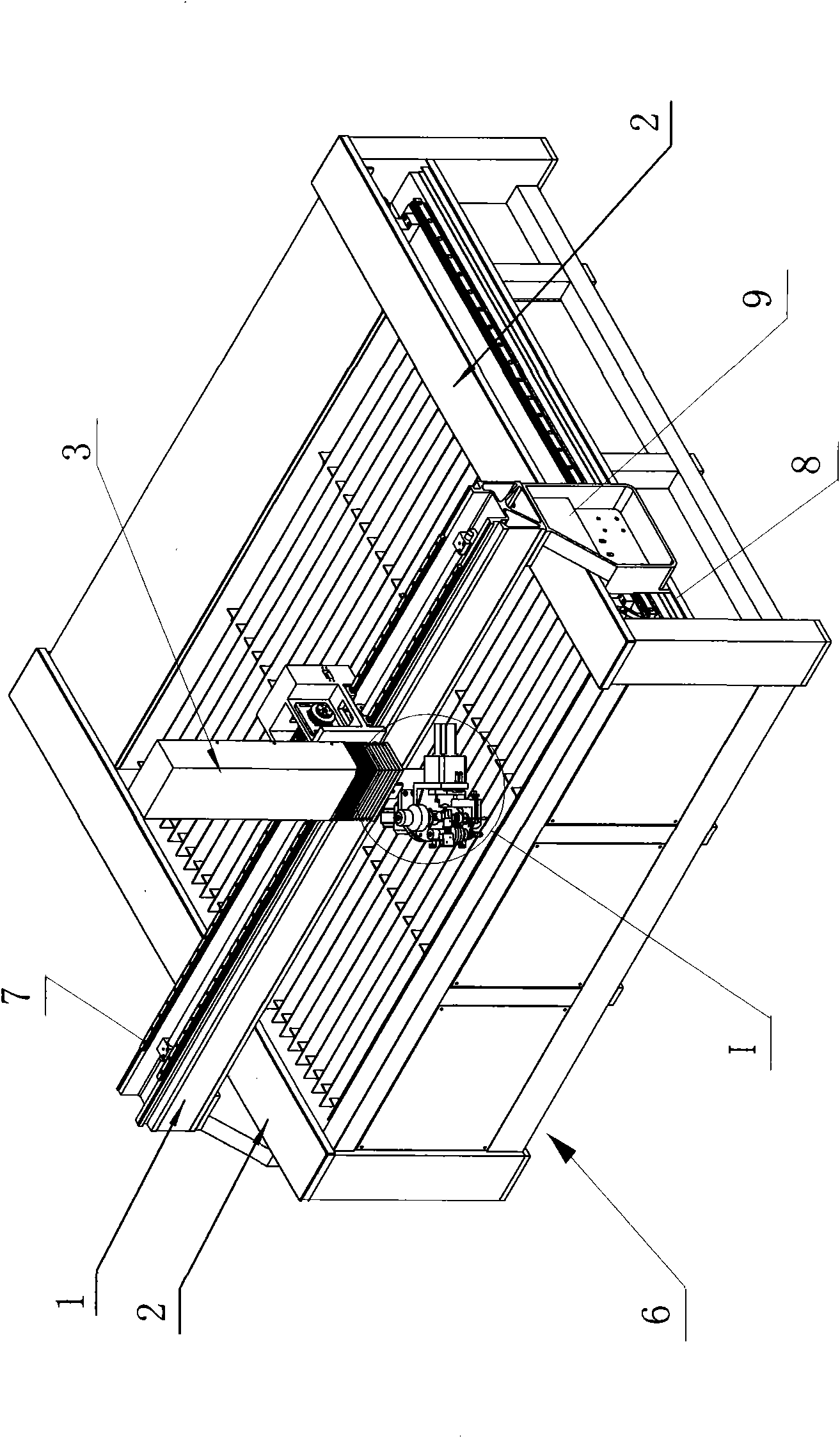

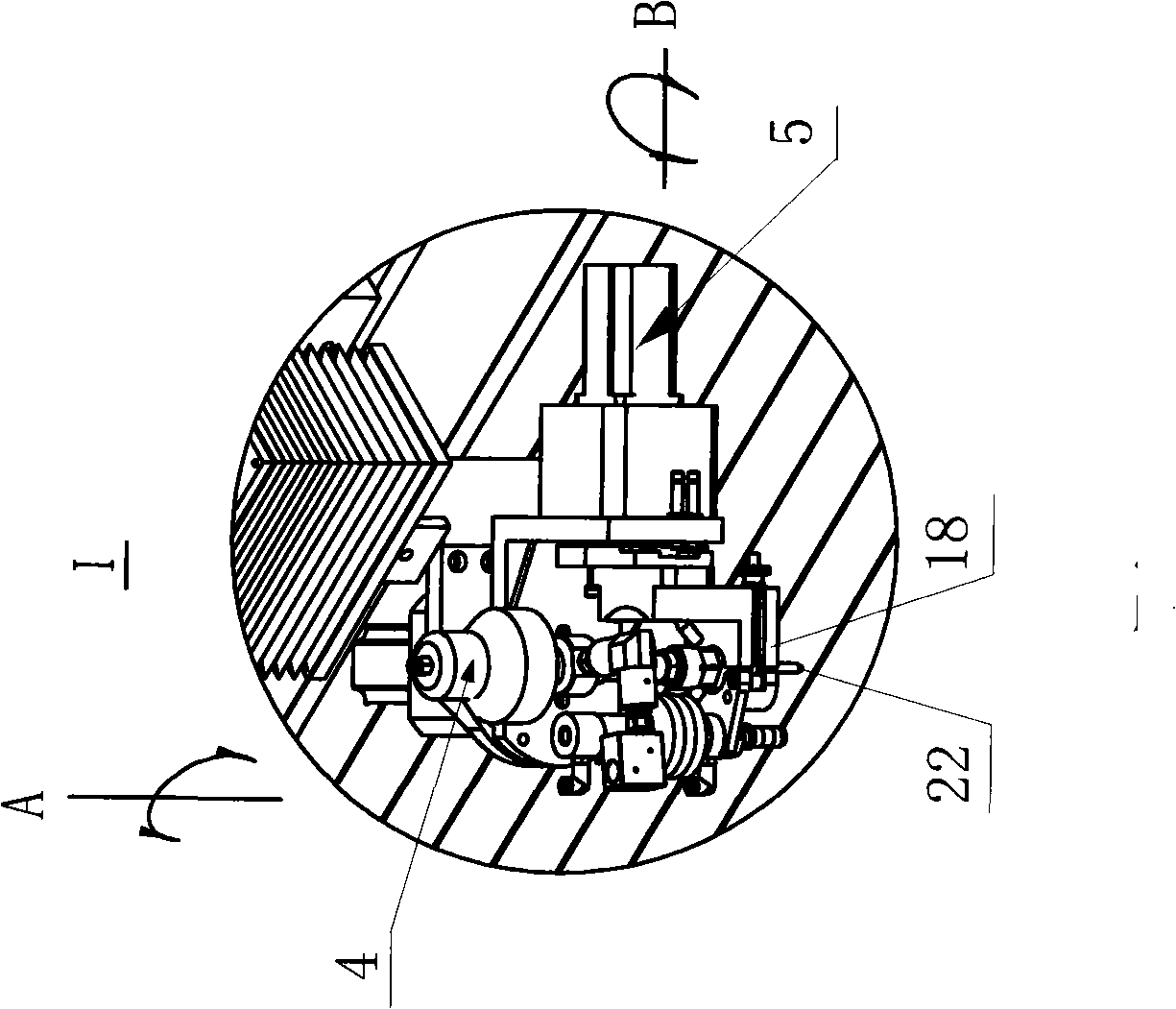

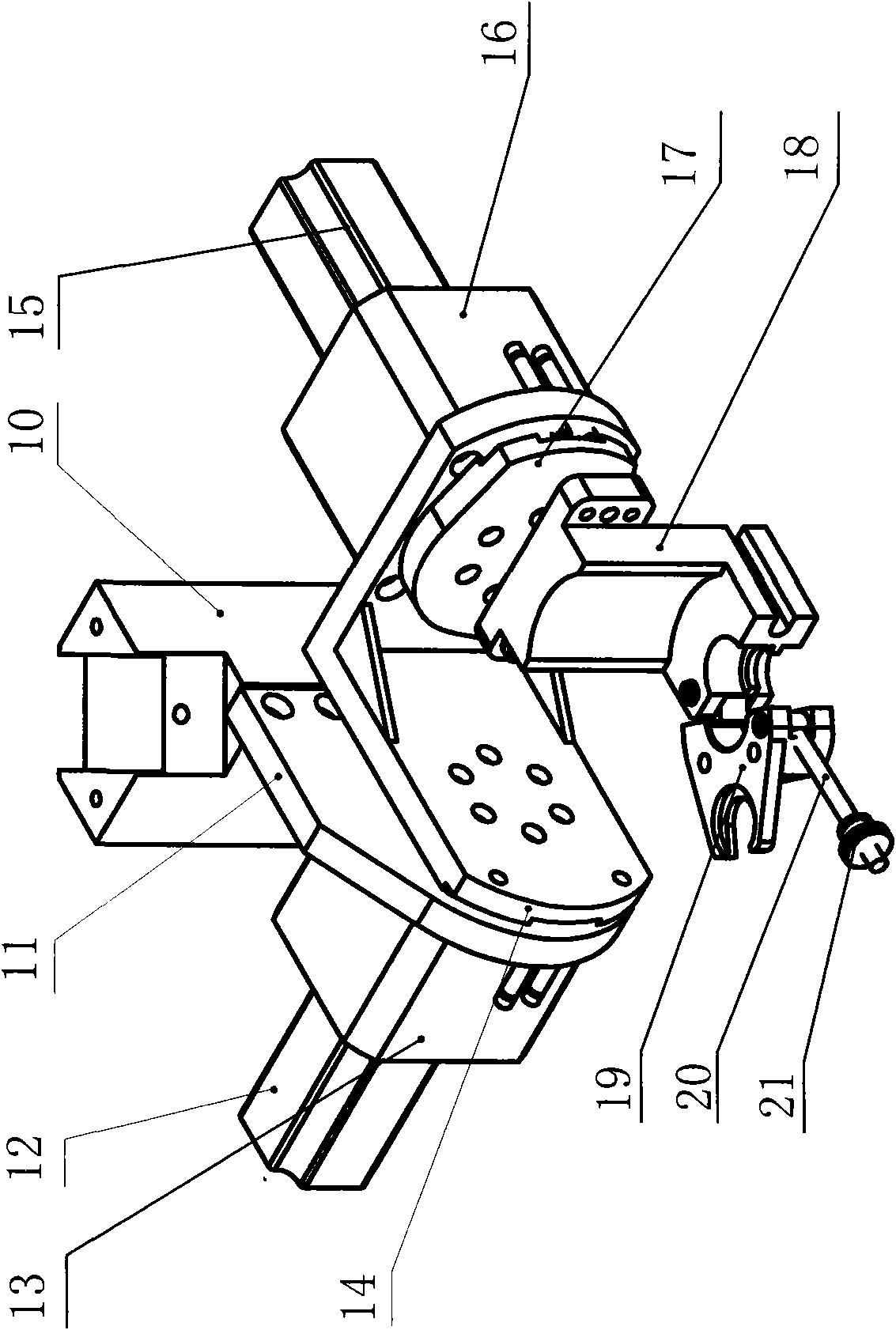

[0010] A CNC five-axis linkage ultra-high pressure water cutting machine, including an ultra-high pressure water jet generator, a water jet cutting platform 6 composed of a column 9, a beam 7, and a guide rail 8, an X-axis transmission mechanism 1 mounted on the water jet cutting platform 6, Y-axis transmission mechanism 2, Z-axis transmission mechanism 3, the digital control circuit of the X-axis, Y-axis and Z-axis feed motors of the water jet cutting platform 6 are contained in the cutting head 22 connected with the Z-axis transmission mechanism. The cutting head 22 is a cutting head provided with A-axis transmission 4 and B-axis transmission 5 composite rotation, A-axis, B-axis transmission compound rotary cutting head, including A-axis motor 12, A-axis reducer 13, B-axis motor 15. B-axis reducer 16, A, B-axis connecting plate 14, joint seat 18. The A-axis reducer 13 is fixed on the A-axis connection plate 11, and the A-axis connection plate 11 is fixedly connected on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com